E3d titan extruder

Posted by msaeger

|

E3d titan extruder April 14, 2016 10:18PM |

Registered: 8 years ago Posts: 430 |

Has anyone tried the e3d titan extruder? I have an ok wades type one but am thinking about getting the titan while filastruder has it on sale.

I like how small the titan is it looks about like a direct drive one but it's a 3 to 1 gear ratio. Is 3 to 1 geared down enough? I believe the wades is 5 to 1.

Newbie with Folgertech 2020 i3.

I like how small the titan is it looks about like a direct drive one but it's a 3 to 1 gear ratio. Is 3 to 1 geared down enough? I believe the wades is 5 to 1.

Newbie with Folgertech 2020 i3.

|

Re: E3d titan extruder April 15, 2016 02:08AM |

Registered: 10 years ago Posts: 14,672 |

I find a 3:1 gear ratio about right and that is what I use on both my printers. 5:1 is OK with short motors but not with long ones in my experience.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3d titan extruder April 15, 2016 09:31AM |

Registered: 9 years ago Posts: 517 |

I ordered one from E3D before Filastruder had them available. One thing I noticed with Filastruder is they don't have the motor listed as available. The extruder calls for a motor with a D shaft but all the listings I have found are the smooth shaft. I sent a message to Filastruder asking about the motor. Waiting to hear back from them.

UPDATE: Filastruder is not carrying the motors at this time.

Edited 1 time(s). Last edit at 04/15/2016 11:28AM by ElmoC.

UPDATE: Filastruder is not carrying the motors at this time.

Edited 1 time(s). Last edit at 04/15/2016 11:28AM by ElmoC.

|

Re: E3d titan extruder April 15, 2016 02:32PM |

Registered: 8 years ago Posts: 3,525 |

Just take a dremel to the motor shaft.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: E3d titan extruder April 15, 2016 07:12PM |

Registered: 8 years ago Posts: 601 |

Anyone had any experience with this extruder yet? I'm seriously tempted to get one of these.

I've only had experience with direct drive printed extruders off thingiverse (non-geared), so the idea of an affordable high precision extruder sounds great. The only thing putting me off is that they don't have a mirrored version so that you can have a dual extruder set up with a nice minimal carriage size

I've only had experience with direct drive printed extruders off thingiverse (non-geared), so the idea of an affordable high precision extruder sounds great. The only thing putting me off is that they don't have a mirrored version so that you can have a dual extruder set up with a nice minimal carriage size

|

Re: E3d titan extruder April 16, 2016 01:56AM |

Registered: 9 years ago Posts: 40 |

Tom Sandladerer already has one that he's going to review, according to his latest video: Tom Sandladerer's Extruder/Hotend Video

Hopefully we won't have to wait too long for his review.

Hopefully we won't have to wait too long for his review.

|

Re: E3d titan extruder April 16, 2016 09:45AM |

Registered: 8 years ago Posts: 430 |

Quote

ElmoC

I ordered one from E3D before Filastruder had them available. One thing I noticed with Filastruder is they don't have the motor listed as available. The extruder calls for a motor with a D shaft but all the listings I have found are the smooth shaft. I sent a message to Filastruder asking about the motor. Waiting to hear back from them.

UPDATE: Filastruder is not carrying the motors at this time.

Do you really need the D shaft or are they saying that because it would give a better grip on the grub screw? The hole in the gear looks round in their instructions.

Newbie with Folgertech 2020 i3.

|

Re: E3d titan extruder April 16, 2016 10:00AM |

Registered: 8 years ago Posts: 430 |

Quote

JonS

Tom Sandladerer already has one that he's going to review, according to his latest video: Tom Sandladerer's Extruder/Hotend Video

Hopefully we won't have to wait too long for his review.

Can't wait for that the sale ends Sunday :-)

Newbie with Folgertech 2020 i3.

|

Re: E3d titan extruder April 16, 2016 11:26AM |

Registered: 9 years ago Posts: 517 |

Quote

msaeger

Quote

ElmoC

I ordered one from E3D before Filastruder had them available. One thing I noticed with Filastruder is they don't have the motor listed as available. The extruder calls for a motor with a D shaft but all the listings I have found are the smooth shaft. I sent a message to Filastruder asking about the motor. Waiting to hear back from them.

UPDATE: Filastruder is not carrying the motors at this time.

Do you really need the D shaft or are they saying that because it would give a better grip on the grub screw? The hole in the gear looks round in their instructions.

I believe it is just for the better grip. I was planning on just filing a flat spot down on the shaft. But in looking around for the motor, they were all coming from China so would be a couple weeks. I ended up just buying the correct one from E3D. Paid a bit more, but will get it a lot faster.

|

Re: E3d titan extruder April 16, 2016 11:27AM |

Registered: 8 years ago Posts: 3,525 |

Quote

dc42

I find a 3:1 gear ratio about right and that is what I use on both my printers. 5:1 is OK with short motors but not with long ones in my experience.

What's the issue with long motors, too much inertia on retraction?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: E3d titan extruder April 16, 2016 03:59PM |

Registered: 8 years ago Posts: 430 |

|

Re: E3d titan extruder April 16, 2016 04:18PM |

Registered: 10 years ago Posts: 14,672 |

Quote

DjDemonD

Quote

dc42

I find a 3:1 gear ratio about right and that is what I use on both my printers. 5:1 is OK with short motors but not with long ones in my experience.

What's the issue with long motors, too much inertia on retraction?

It's a matter of balancing torque vs. acceleration. It's quite common for the extruder nozzle to be temporarily obstructed, e.g. due to over-extrusion or curl-up of the previous layer. In this case, you want to limit the torque so that the motor will skip steps, and extrusion will continue when the obstruction is removed. If instead the torque is too great, the hobbed insert will grind an indentation into the filament, so extrusion will not restart when the obstruction is removed.

Using a 48mm long Nema 17 motor in a 5:1 geared extruder, I found that I had to set the motor current to about 400mA (compared to a rated current of 1.66A) in order to get reliable extrusion but not grind the filament when the nozzle is obstructed. However, that meant there was not enough torque to accelerate the motor as fast as I wanted during retraction. What I needed was a much shorter motor, run closer to its rated current to get the same torque, but with lower rotor inertia to get better acceleration at that torque.

Edited 2 time(s). Last edit at 04/16/2016 04:19PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3d titan extruder April 16, 2016 04:52PM |

Registered: 9 years ago Posts: 425 |

Quote

dc42

It's a matter of balancing torque vs. acceleration. It's quite common for the extruder nozzle to be temporarily obstructed, e.g. due to over-extrusion or curl-up of the previous layer

Is this a theory or a fact backed up with evidence of the the recurring blockage?

How can molten plastic on the tip of a hotend heated to melting temperature cause a blockage? I would like to understand this more.

|

Re: E3d titan extruder April 16, 2016 05:14PM |

Registered: 11 years ago Posts: 5,780 |

My experience has been that if the motor chews a divot into the filament, the pressure roller isn't pressing the filament onto the drive gear hard enough. I've never had the filament strip in my BullDog XL with it set so the roller almost crushes the filament.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3d titan extruder April 16, 2016 05:50PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Mutley3D

Quote

dc42

It's a matter of balancing torque vs. acceleration. It's quite common for the extruder nozzle to be temporarily obstructed, e.g. due to over-extrusion or curl-up of the previous layer

Is this a theory or a fact backed up with evidence of the the recurring blockage?

How can molten plastic on the tip of a hotend heated to melting temperature cause a blockage? I would like to understand this more.

This is from experience, when my delta printer was printing less well than it is now and I had regular problems with over extrusion and curl up. When the nozzle is moving at a typical printing speed over the previous layer, but is too close to it, the plastic under the nozzle does not have time to melt.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3d titan extruder April 16, 2016 06:14PM |

Registered: 8 years ago Posts: 3,525 |

I thought it was primarily to do with the idler tension rather than the motor torque. My flex3drive is running 40:1 gearing and never chews the filament. I am using a 40mm 1.68A motor. I could use a little less current but I need to do quite rapid retractions requiring a fairly large number of steps due to the gearing.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: E3d titan extruder April 16, 2016 06:22PM |

Registered: 10 years ago Posts: 14,672 |

What happens on your machine if you try to extrude when the nozzle is touching the bed?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3d titan extruder April 16, 2016 06:28PM |

Registered: 8 years ago Posts: 3,525 |

Good question. I'll try it at some point soon and see. I've got a print running right now.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: E3d titan extruder April 16, 2016 06:36PM |

Registered: 10 years ago Posts: 14,672 |

Just don't damage the bed on my account, put something between it and the nozzle when you do the test.

Edited 1 time(s). Last edit at 04/17/2016 04:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/17/2016 04:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3d titan extruder April 16, 2016 06:50PM |

Registered: 8 years ago Posts: 3,525 |

Good point, but it okay it's a cheap glass plate at the moment on that printer and I'm about to embark on a re-sizing from a 20x20cm to a 20x30cm build plate, so I have a new bed to fit (once I've cut my 4 new 2020 extrusions to exactly the same length - wedo3dprinting supplied 4x50cm extrusions and offered to cut them to length if I wanted, so had I asked for 499mm they would have all been the same size, but they are all a little different in length as they stock imprecisely cut 50cm lengths. I was planning to use a mitre saw and metal cutting disc but there is a precision engineering company near to me so I am tempted to have them cut a little more precisely, I also need the centre holes tapped to m6).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: E3d titan extruder April 16, 2016 07:25PM |

Registered: 8 years ago Posts: 177 |

Unless it's a specialist disk for aluminium it will be worse by a lot than using a fine tooth tungsten carbide wood blade. It's easy to get them exact, just make a jig from some timber firstQuote

DjDemonD

I was planning to use a mitre saw and metal cutting disc but there is a precision engineering company near to me so I am tempted to have them cut a little more precisely, I also need the centre holes tapped to m6).

|

Re: E3d titan extruder April 16, 2016 07:25PM |

Registered: 9 years ago Posts: 1,873 |

One thing I have discovered after going on a bit of a filament binge (it seems to be my new obsession) is that there is huge variation between how much force can be applied to different filaments before they start to shred, and also how they respond to idler tension. It makes it pretty hard to make generalisations without getting into a lot of caveats about what filament type/brand/diameter and details of the drive gear being used, and I suspect this contributes to some of the problems we sometimes seem to have reaching a consensus.

|

Re: E3d titan extruder April 16, 2016 07:33PM |

Registered: 8 years ago Posts: 3,525 |

Aussiephil - yeah I am leaning towards letting the pro's do the job for me.

JamesK - I'd second that even within filaments from one company. I am using Excelvan at the moment and its surprisingly good for a budget filament, but I've got white and black pla which are two totally different materials, the white is softer and smoother. The black feels a little harder on the surface and is seems slightly textured which makes for much better grip in the extruder.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

JamesK - I'd second that even within filaments from one company. I am using Excelvan at the moment and its surprisingly good for a budget filament, but I've got white and black pla which are two totally different materials, the white is softer and smoother. The black feels a little harder on the surface and is seems slightly textured which makes for much better grip in the extruder.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: E3d titan extruder April 17, 2016 12:25AM |

Registered: 9 years ago Posts: 40 |

Quote

msaeger

Quote

JonS

Tom Sandladerer already has one that he's going to review, according to his latest video: Tom Sandladerer's Extruder/Hotend Video

Hopefully we won't have to wait too long for his review.

Can't wait for that the sale ends Sunday :-)

What sale?

Just buy one then and review it for everyone.

|

Re: E3d titan extruder April 17, 2016 01:06AM |

Registered: 8 years ago Posts: 430 |

Quote

JonS

Quote

msaeger

Quote

JonS

Tom Sandladerer already has one that he's going to review, according to his latest video: Tom Sandladerer's Extruder/Hotend Video

Hopefully we won't have to wait too long for his review.

Can't wait for that the sale ends Sunday :-)

What sale?

Just buy one then and review it for everyone.

I bought it. They have slow shipping so it probably won't be here for a week.

Coupon code Kickstarter gets 10% off the Titan. Not that much off but it was enough to push me over the edge.

Newbie with Folgertech 2020 i3.

|

Re: E3d titan extruder April 18, 2016 05:44PM |

Registered: 8 years ago Posts: 77 |

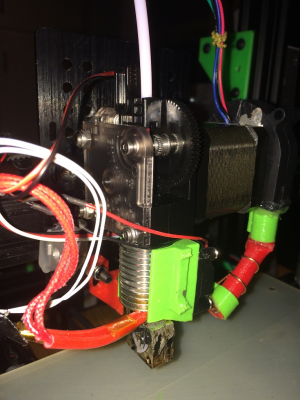

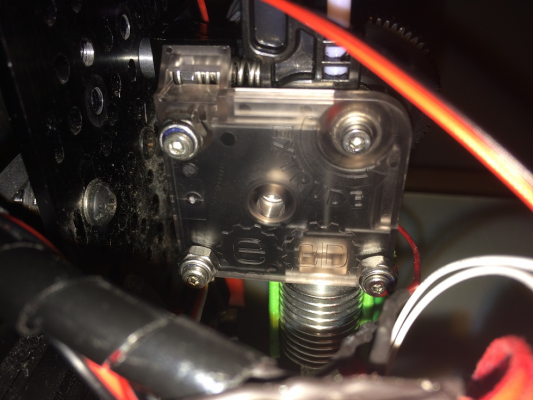

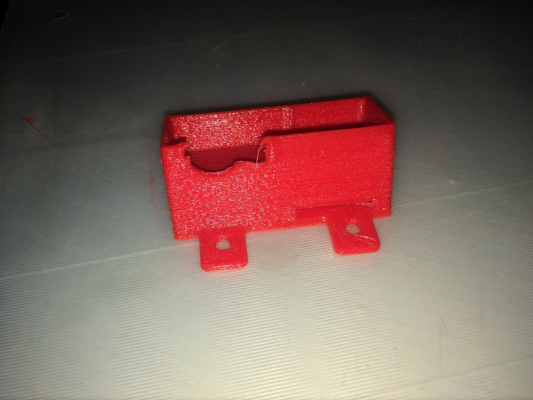

]I bought a Titan, fitted and working. Just went for the plain version, and bolted to my printer using a standard metal right angle for stepper motors (about 2mm thick).

Boxed item

Inside the box

Fitted

Quick print @ 100mm/s red flex

Goes together fairly well, but, the screw length is a bit off. The "short" bolts need a couple extra mm to bite onto my stepper motor, so Ive had to use the longer bolts and some nuts to take up the slack.

Will now tidy it up and tune the settings from stock.

Boxed item

Inside the box

Fitted

Quick print @ 100mm/s red flex

Goes together fairly well, but, the screw length is a bit off. The "short" bolts need a couple extra mm to bite onto my stepper motor, so Ive had to use the longer bolts and some nuts to take up the slack.

Will now tidy it up and tune the settings from stock.

|

Re: E3d titan extruder April 18, 2016 06:37PM |

Registered: 9 years ago Posts: 1,699 |

Quote

dc42

Using a 48mm long Nema 17 motor in a 5:1 geared extruder, I found that I had to set the motor current to about 400mA (compared to a rated current of 1.66A) in order to get reliable extrusion but not grind the filament when the nozzle is obstructed. However, that meant there was not enough torque to accelerate the motor as fast as I wanted during retraction. What I needed was a much shorter motor, run closer to its rated current to get the same torque, but with lower rotor inertia to get better acceleration at that torque.

That sounds interesting. Does that mean that I have to use different motors for my Extruders? I will use 48mm motors with 400 steps for my own design for the axes. So I should better use standard 40mm long motors for the Extruders with a probaly 3:1 geared setup?

@Phytone Do you have any differences between your old Extruder and the Titan? This is much money, but is it worth?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: E3d titan extruder April 18, 2016 07:28PM |

Registered: 9 years ago Posts: 425 |

DC42 - I wonder if the issues you were having were down to the E axis jerk/start speed being too high coupled with high E axis accel?

In my experience I found that high jerk and accel values, coupled with a vref that was too high would lead to motor stall during high speed retracts amongst other issues. It woud also lead to hot motors. Reducing the jerk value to absolute minimum, and using a realistic acceleration value resolved this if the vref was reduced.

If one takes a look at the relative motion values between axis movement and extruder speeds, there is a major difference, yet motion control settings often do not reflect this.

In my experience I found that high jerk and accel values, coupled with a vref that was too high would lead to motor stall during high speed retracts amongst other issues. It woud also lead to hot motors. Reducing the jerk value to absolute minimum, and using a realistic acceleration value resolved this if the vref was reduced.

If one takes a look at the relative motion values between axis movement and extruder speeds, there is a major difference, yet motion control settings often do not reflect this.

|

Re: E3d titan extruder April 18, 2016 11:21PM |

Registered: 8 years ago Posts: 430 |

Quote

Phytone

]I bought a Titan, fitted and working. Just went for the plain version, and bolted to my printer using a standard metal right angle for stepper motors (about 2mm thick).

Boxed item

[attachment 76668 IMG_2604.JPG]

Inside the box

[attachment 76669 IMG_2605.JPG]

[attachment 76670 IMG_2606_1.jpg]

Fitted

[attachment 76671 IMG_2609_1.jpg]

[attachment 76672 IMG_2610_1.jpg]

Quick print @ 100mm/s red flex

[attachment 76673 IMG_2611_1.jpg]

Goes together fairly well, but, the screw length is a bit off. The "short" bolts need a couple extra mm to bite onto my stepper motor, so Ive had to use the longer bolts and some nuts to take up the slack.

Will now tidy it up and tune the settings from stock.

Is there more than one version? I am only finding one.

Newbie with Folgertech 2020 i3.

|

Re: E3d titan extruder April 19, 2016 12:32AM |

Registered: 9 years ago Posts: 1,699 |

You have some options at the homepage of the manufacturer [e3d-online.com]

Edited 1 time(s). Last edit at 04/19/2016 12:33AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Edited 1 time(s). Last edit at 04/19/2016 12:33AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.