Pololu geared DC motor 30g prototype extruder

Posted by ipcalit

|

Re: Pololu geared DC motor 30g prototype extruder May 19, 2016 06:14PM |

Registered: 8 years ago Posts: 181 |

Well, I had another night of fun

I have got the motor working with L298N and tried to paint a bit of a black line on the gear I wanted. I found that it has a gear ratio ~1:31 with the final shaft. So that would have worked.

However, for the love of God I was not able to glue anything to the gear. It's so smooth that no glue stick to it. I tried superglue, rubber-like glue, even hot glue (extremely thin layer due to the space constraints) and, as expected, none of them works.

So I gave up and I'll try to contact China sellers for some price quotes. I'm not buying the one from pololu - I have 5 of these with no encoder for $15. I'm not willing to pay $15 for one with encoder.

If I can't get anything reasonable from china, I still can go to i2c ASM sensor - I'll glue the magnet to the end of the 5mm shaft (as soon as I'm able to get my hands on one) and I'll measure the magnet rotation as Misan did with his servo-driven extruder.

I have got the motor working with L298N and tried to paint a bit of a black line on the gear I wanted. I found that it has a gear ratio ~1:31 with the final shaft. So that would have worked.

However, for the love of God I was not able to glue anything to the gear. It's so smooth that no glue stick to it. I tried superglue, rubber-like glue, even hot glue (extremely thin layer due to the space constraints) and, as expected, none of them works.

So I gave up and I'll try to contact China sellers for some price quotes. I'm not buying the one from pololu - I have 5 of these with no encoder for $15. I'm not willing to pay $15 for one with encoder.

If I can't get anything reasonable from china, I still can go to i2c ASM sensor - I'll glue the magnet to the end of the 5mm shaft (as soon as I'm able to get my hands on one) and I'll measure the magnet rotation as Misan did with his servo-driven extruder.

|

Re: Pololu geared DC motor 30g prototype extruder May 19, 2016 11:57PM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

Well, I had another night of fun

I have got the motor working with L298N and tried to paint a bit of a black line on the gear I wanted. I found that it has a gear ratio ~1:31 with the final shaft. So that would have worked.

However, for the love of God I was not able to glue anything to the gear. It's so smooth that no glue stick to it. I tried superglue, rubber-like glue, even hot glue (extremely thin layer due to the space constraints) and, as expected, none of them works.

So I gave up and I'll try to contact China sellers for some price quotes. I'm not buying the one from pololu - I have 5 of these with no encoder for $15. I'm not willing to pay $15 for one with encoder.

If I can't get anything reasonable from china, I still can go to i2c ASM sensor - I'll glue the magnet to the end of the 5mm shaft (as soon as I'm able to get my hands on one) and I'll measure the magnet rotation as Misan did with his servo-driven extruder.

I had the same issues with those gears. That's why I suggested bouncing some light either off the gears or some transparent disk half darkened like this:

L | D

_V_

where L is the IR LED, D is the photodiode sensor, V is the path of the IR beam, | is some shielding to direct the light, and ___ is the surface of the gear.

On my motors the exposed gear is similar with this one and Sharpies seem to paint it rather well. Need to grab some IR LEDs to try as the common optoendstops seem well encapsulated and they would need to be placed diagonally across the gearbox.

[g03.a.alicdn.com]

Alternatively, do you think you can magnetize that gear? A couple of strikes in the same direction with a strong magnet should do it. No idea how sensitive the hall sensor has to be to detect the weak field from it.

|

Re: Pololu geared DC motor 30g prototype extruder May 20, 2016 12:39AM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder May 20, 2016 11:10AM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

Honestly, the problem with the ir led is the size - try it and you'll see

Magnetizing seems more plausible, but the gearbox i have is pressed together - I was unable to take it apart.

I got an old mouse that has a smaller IR sensor. Not sure if I can just cut it in two to get the parts aligned to make that V beam. Will try over the weekend.

Magnetizing the gear can be done from the outside with the magnet from a 3.5" HDD, but it is weak. Did you have any luck with the sensor on the outside of the motor casing?

|

Re: Pololu geared DC motor 30g prototype extruder May 20, 2016 04:10PM |

Registered: 8 years ago Posts: 181 |

Not yet - to read it, I'd need oscilloscope. And I ordered it already, but it will travel from China, so I expect it in like 4 weeks or so.Quote

ipcalit

Did you have any luck with the sensor on the outside of the motor casing?

I went shopping again and had another no-luck situation with the 5-to-3mm shaft.

Out of desperation I bought aluminium rivets. They are not exactly 5mm wide (something like 4.8-4.7mm) and the internal diameter is also not exactly ideal (had to drill it a bit), but it works.

The small deviation in rotation can be fixed with spring pushing on idler ball bearing, so I'll check the design of yours and try to adjust it.

However, I cannot do anything tomorrow as I have work-related activities, but I'll try to find some time on Sunday (if the family situation allows it).

For now, here is the video of PWM controlled motor with MK7 gear. The long screw is a replacement of the original - it's temporary only, due to the fact that the original is not long enough and they seem to not bother to sell M3-sized screws around here

Video of the motor with MK7 gear.

I'd say we are onto something here.

|

Re: Pololu geared DC motor 30g prototype extruder May 21, 2016 02:44AM |

Registered: 7 years ago Posts: 78 |

Found our motor GM12-N20VA-EN with encoder on Amazon for $15, or a slighter larger GM14-050SH-EN. Perhaps they have discounts if you buy directly from them:

[www.ttmotor.com]

Seems there's also this drop-in replacement of our steppers (no idea about price):

GMP10-10BY - [www.ttmotor.com]

There are a couple other suppliers for "N20" or "12G" or "12mm gear motor" with encoder on Alibaba that accept samples.

[www.alibaba.com]

If anybody knows some reputable seller it would be great to know as Alibaba is the wild west.

Edited 1 time(s). Last edit at 05/21/2016 02:59AM by ipcalit.

[www.ttmotor.com]

Seems there's also this drop-in replacement of our steppers (no idea about price):

GMP10-10BY - [www.ttmotor.com]

There are a couple other suppliers for "N20" or "12G" or "12mm gear motor" with encoder on Alibaba that accept samples.

[www.alibaba.com]

If anybody knows some reputable seller it would be great to know as Alibaba is the wild west.

Edited 1 time(s). Last edit at 05/21/2016 02:59AM by ipcalit.

|

Re: Pololu geared DC motor 30g prototype extruder May 21, 2016 01:59PM |

Registered: 12 years ago Posts: 972 |

Quote

rklauco

...

I have no idea what mistake I did, but I burned 2 TB6612 drivers - their capacitors blew directly upon connecting 12V.

Other people had the same experience.

I guess it is due to defective/under-rated capacitors on some boards.

Edited 1 time(s). Last edit at 05/21/2016 02:04PM by misan.

|

Re: Pololu geared DC motor 30g prototype extruder May 21, 2016 02:28PM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder May 21, 2016 07:14PM |

Registered: 8 years ago Posts: 181 |

Well, a little more progress.

First of all, I remembered that I have 1 more gear - something like this, although I paid $4 for 5 of them.

So I did another attempt with the motor and after 30 minutes of filing and press-fitting I was able to put the gear onto the motor.

And it works pretty OK.

Now, I printer the original STL, but due to my printer's "qualities" it was quite tight - I had really press the motor into the housing and I was not able to push it all the way in.

So I am now designing a housing with a bit more plastic over the motor (ventilation) and a bit different part for the feed - I'll use some ball bearing mechanism to press against the wheel.

But for today I'm too tired, so I'll work on it tomorrow.

First of all, I remembered that I have 1 more gear - something like this, although I paid $4 for 5 of them.

So I did another attempt with the motor and after 30 minutes of filing and press-fitting I was able to put the gear onto the motor.

And it works pretty OK.

Now, I printer the original STL, but due to my printer's "qualities" it was quite tight - I had really press the motor into the housing and I was not able to push it all the way in.

So I am now designing a housing with a bit more plastic over the motor (ventilation) and a bit different part for the feed - I'll use some ball bearing mechanism to press against the wheel.

But for today I'm too tired, so I'll work on it tomorrow.

|

Re: Pololu geared DC motor 30g prototype extruder May 21, 2016 11:39PM |

Registered: 7 years ago Posts: 78 |

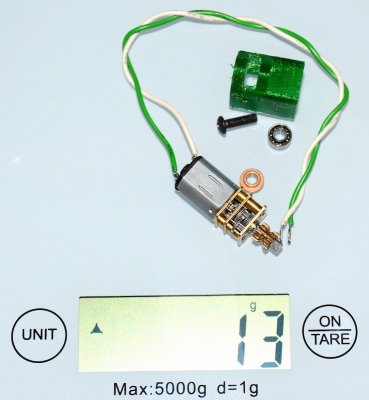

Funny as I was looking today into doing a similar thing. Found a tiny 683 bearing and old Meccano brass gear 10T that I drilled to ~3mm and then made a groove with triangular file. Heated the gear up on the stove then quickly press-fit it on the shaft - solid like a rock now. I adjusted the size of the extruder to fit the new parts and guess what.... 15g total and it works like a champ. The evolution of the design is rather nice (v1-v2-v3) with strong torque and minimal parts count.

New parts:

1x 683 bearing (3x7x3)

1x brass bushing (3mm inner, 5mm outer, 7mm outer flange, 2.5mm thick)

1x 10T brass gear

1x N20 gear motor 1:100 (30rpm)

1x M3 screw 10mm

Attached are two STL files for the extruder, one including a guide for the filament and the other without it if your printer cannot handle fine details.

Edited 1 time(s). Last edit at 05/23/2016 01:20PM by ipcalit.

New parts:

1x 683 bearing (3x7x3)

1x brass bushing (3mm inner, 5mm outer, 7mm outer flange, 2.5mm thick)

1x 10T brass gear

1x N20 gear motor 1:100 (30rpm)

1x M3 screw 10mm

Attached are two STL files for the extruder, one including a guide for the filament and the other without it if your printer cannot handle fine details.

Edited 1 time(s). Last edit at 05/23/2016 01:20PM by ipcalit.

|

Re: Pololu geared DC motor 30g prototype extruder May 22, 2016 03:25PM |

Registered: 8 years ago Posts: 9 |

Quote

ipcalit

Funny as I was looking today into doing a similar thing. Found a tiny 683 bearing and old Meccano brass gear 10T that I drilled to ~3mm and then made a groove with triangular file. Heated the gear up on the stove then quickly press-fit it on the shaft - solid like a rock now. I adjusted the size of the extruder to fit the new parts and guess what.... 15g total and it works like a champ. The evolution of the design is rather nice (v1-v2-v3) with strong torque and minimal parts count.

New parts:

1x 683 bearing (3x7x3)

1x brass bushing (3mm inner, 5mm outer, 7mm outer flange, 2.5mm thick)

1x 10T brass gear

1x N20 gear motor 1:100 (30rpm)

1x M3 screw 10mm

Attached are two STL files for the extruder, one including a guide for the filament and the other without it if your printer cannot handle fine details.

That looks awesome! How much force can it apply to the filament?

|

Re: Pololu geared DC motor 30g prototype extruder May 22, 2016 05:32PM |

Registered: 8 years ago Posts: 181 |

Well, this starts to look like something useful.

So - I started to re-design the thing based on the original shape.

I was thinking about using 4-screw bearing hold with springs to provide sufficient grip for the gear.

So I printed the file attached.

And then I found I do hot have screws long enough to hold the bearing holder AND the spring.

Just out of curiosity I tested it without spring - and IT WORKS!!!

Fantastically.

Thanks to the very small space between the motor and the housing the motor is able to bent out of it's position just enough to grip the 1.75mm filament like hell.

So, as it turns out, I do not really need the bearing to be held by 5 screws - I can come up with a design with just 1 screw I think - I'm about to start to redesign it

The 5 screws used now have some impact - the weight of the full device is now 44 grams, instead of 30. But that's also due to the fact that I over-engineered the extruder and used unnecessary thick walls.

I think I'm gonna invest and pay the ~$16 for the version with encoder - I'd love to see this working.

So - I started to re-design the thing based on the original shape.

I was thinking about using 4-screw bearing hold with springs to provide sufficient grip for the gear.

So I printed the file attached.

And then I found I do hot have screws long enough to hold the bearing holder AND the spring.

Just out of curiosity I tested it without spring - and IT WORKS!!!

Fantastically.

Thanks to the very small space between the motor and the housing the motor is able to bent out of it's position just enough to grip the 1.75mm filament like hell.

So, as it turns out, I do not really need the bearing to be held by 5 screws - I can come up with a design with just 1 screw I think - I'm about to start to redesign it

The 5 screws used now have some impact - the weight of the full device is now 44 grams, instead of 30. But that's also due to the fact that I over-engineered the extruder and used unnecessary thick walls.

I think I'm gonna invest and pay the ~$16 for the version with encoder - I'd love to see this working.

|

Re: Pololu geared DC motor 30g prototype extruder May 22, 2016 10:14PM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

So - I started to re-design the thing based on the original shape.

I was thinking about using 4-screw bearing hold with springs to provide sufficient grip for the gear.

So I printed the file attached.

And then I found I do hot have screws long enough to hold the bearing holder AND the spring.

Just out of curiosity I tested it without spring - and IT WORKS!!!

Told you it works, just let the housing material be the spring and you're all set. My latest design is just a cap over the gearbox to hold the rest in place. Using a single 683 bearing also cuts 6-7g off from the dual 624 for the shaft + 623 idler. You may need to support the free end of the shaft with something to avoid stressing the gearbox too much. A brass ring/spacer as bushing (or another 683) does wonders.

Quote

rklauco

The 5 screws used now have some impact - the weight of the full device is now 44 grams, instead of 30. But that's also due to the fact that I over-engineered the extruder and used unnecessary thick walls.

I think I'm gonna invest and pay the ~$16 for the version with encoder - I'd love to see this working.

I'm using 1.2mm walls (3 perimeters) and they are plenty strong. Next I'm trying the large wheel design.

|

Re: Pololu geared DC motor 30g prototype extruder May 22, 2016 10:30PM |

Registered: 7 years ago Posts: 78 |

Quote

nallar

Quote

ipcalit

Funny as I was looking today into doing a similar thing. Found a tiny 683 bearing and old Meccano brass gear 10T that I drilled to ~3mm and then made a groove with triangular file. Heated the gear up on the stove then quickly press-fit it on the shaft - solid like a rock now. I adjusted the size of the extruder to fit the new parts and guess what.... 15g total and it works like a champ. The evolution of the design is rather nice (v1-v2-v3) with strong torque and minimal parts count.

New parts:

1x 683 bearing (3x7x3)

1x brass bushing (3mm inner, 5mm outer, 7mm outer flange, 2.5mm thick)

1x 10T brass gear

1x N20 gear motor 1:100 (30rpm)

1x M3 screw 10mm

Attached are two STL files for the extruder, one including a guide for the filament and the other without it if your printer cannot handle fine details.

That looks awesome! How much force can it apply to the filament?

I didn't get a chance to test it in comparison with v1. Just by feel I would say it is better as the gear grips a bit around the filament. However, looking closely at the tooth profile with a 10x magnifier I noticed an issue with the cross-section of the teeth. Filing by hand got some of them slightly rounded off, which produces variations in the amount of torque it can apply and may slip if the filament has imperfections. Next I'll try to see if I can use an off-the-shelf gear like rklauco or find a reliable way to make the gear with simple tools.

|

Re: Pololu geared DC motor 30g prototype extruder May 24, 2016 02:16PM |

Registered: 8 years ago Posts: 181 |

This is AMAZING.

Not only it has a great grip on filament, it is also unexpectedly fast.

It works great and on 12V it runs through the filament like a knife through a butter.

Tomorrow I'll test direct connection to my fake e3d-v5 to see how it performs in real life situation.

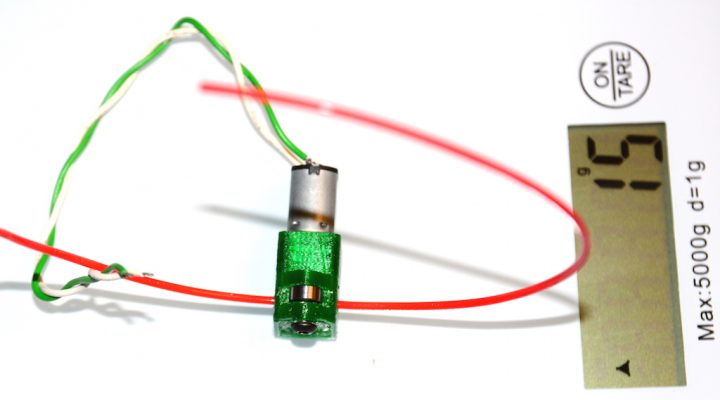

The current version is 25grams only.

I decided I won't install the encoder for the motor - it's too expansive. Instead, I'll glue magnet on top of the actual wheel and set the AS5600 and use misan's code for i2c communication. The resolution is 12bit, so theoretically I should be able to read 4096 positions, therefore the resolution should be somewhere around 0.08 degree.

I do not plan to go to this detail - even 1024 bit resolution is an overkill according my opinion.

The reason of not using the onshaft encoder is twofold - first of all the size - I would not be able to fit in the encoder as it extends for more than 1mm and therefore the snug fit of the motor body would not be so snug. And the second reason is the price - I can get 5 pieces of the AS5600 including the magnet for ~$18 including shipping - making it less then $4 for single extruder.

Funny thing is that not only will this be significantly smaller and lighter then extruder with stepper - it will be also much cheaper.

Current price list:

- motor N20-12V-100 (1:100 gear reduction, 12V) for $3

- encoder with magnet for less then $4

- gear for $1.5

- bearing mr126zz for $0.14

- M3 bolt 20mm for $0.01

- M3 nut 20mm for $0.01

- ATtiny85 for $1

Total price of the whole setup is therefore less then $10 (not including the 3 printed parts).

See attached photos and the OpenSCAD design.

I have to modify the design a bit - the nut is difficult to insert without heating it up and the nut and bolt "cover" is too thin (printing it on my crappy printer is quite bad), but the functionality is OK.

I printed mine in ABS with 50% infill, 3 top and 3 bottom layers and 3 perimeters.

Now I have to make 3 of them and buy the diamond hotend

Not only it has a great grip on filament, it is also unexpectedly fast.

It works great and on 12V it runs through the filament like a knife through a butter.

Tomorrow I'll test direct connection to my fake e3d-v5 to see how it performs in real life situation.

The current version is 25grams only.

I decided I won't install the encoder for the motor - it's too expansive. Instead, I'll glue magnet on top of the actual wheel and set the AS5600 and use misan's code for i2c communication. The resolution is 12bit, so theoretically I should be able to read 4096 positions, therefore the resolution should be somewhere around 0.08 degree.

I do not plan to go to this detail - even 1024 bit resolution is an overkill according my opinion.

The reason of not using the onshaft encoder is twofold - first of all the size - I would not be able to fit in the encoder as it extends for more than 1mm and therefore the snug fit of the motor body would not be so snug. And the second reason is the price - I can get 5 pieces of the AS5600 including the magnet for ~$18 including shipping - making it less then $4 for single extruder.

Funny thing is that not only will this be significantly smaller and lighter then extruder with stepper - it will be also much cheaper.

Current price list:

- motor N20-12V-100 (1:100 gear reduction, 12V) for $3

- encoder with magnet for less then $4

- gear for $1.5

- bearing mr126zz for $0.14

- M3 bolt 20mm for $0.01

- M3 nut 20mm for $0.01

- ATtiny85 for $1

Total price of the whole setup is therefore less then $10 (not including the 3 printed parts).

See attached photos and the OpenSCAD design.

I have to modify the design a bit - the nut is difficult to insert without heating it up and the nut and bolt "cover" is too thin (printing it on my crappy printer is quite bad), but the functionality is OK.

I printed mine in ABS with 50% infill, 3 top and 3 bottom layers and 3 perimeters.

Now I have to make 3 of them and buy the diamond hotend

|

Re: Pololu geared DC motor 30g prototype extruder May 24, 2016 05:11PM |

Registered: 8 years ago Posts: 181 |

So. My findings from this night:

Also, another negative finding - my gear is mounted a bit wrong - it has a tiny bit more grip on one part a a tiny bit less grip on the other side - therefore one can hear the sound of the motor being uneven - when the gear has smaller distance to the ball bearing, it has to work significantly more as the resistance from the actual gear is much higher. Then, when it's over the "peak", it starts to go very fast - until another revolution and therefore another bump.

Seems like the coupling of 5mm gear to 3mm shaft will be the most critical part here.

- It does work.

- The motor is quite strong.

- Actually too strong - when trying to push filament through 0.2mm nozzle the whole extruder assembly torn appart the ABS bond.

Also, another negative finding - my gear is mounted a bit wrong - it has a tiny bit more grip on one part a a tiny bit less grip on the other side - therefore one can hear the sound of the motor being uneven - when the gear has smaller distance to the ball bearing, it has to work significantly more as the resistance from the actual gear is much higher. Then, when it's over the "peak", it starts to go very fast - until another revolution and therefore another bump.

Seems like the coupling of 5mm gear to 3mm shaft will be the most critical part here.

|

Re: Pololu geared DC motor 30g prototype extruder May 24, 2016 06:01PM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

This is AMAZING.

Not only it has a great grip on filament, it is also unexpectedly fast.

It works great and on 12V it runs through the filament like a knife through a butter.

Indeed. I was surprised the first time too. You don't have to run it at 12V, even 5V is enough as I played with AA batteries.

Quote

rklauco

Tomorrow I'll test direct connection to my fake e3d-v5 to see how it performs in real life situation.

The current version is 25grams only.

Get rid of the nut as you don't need it. Also your walls are too thick. I'm printing in PETG and you have to be careful with the orientation of the layers. If you print the housing vertically -- the layers are perpendicular to the axis of the motor, then you don't have to worry about layers splitting up.

Quote

rklauco

I decided I won't install the encoder for the motor - it's too expansive. Instead, I'll glue magnet on top of the actual wheel and set the AS5600 and use misan's code for i2c communication. The resolution is 12bit, so theoretically I should be able to read 4096 positions, therefore the resolution should be somewhere around 0.08 degree.

I do not plan to go to this detail - even 1024 bit resolution is an overkill according my opinion.

That's interesting. I have to try that. Do you have a picture of the intended setup?

Quote

rklauco

The reason of not using the onshaft encoder is twofold - first of all the size - I would not be able to fit in the encoder as it extends for more than 1mm and therefore the snug fit of the motor body would not be so snug. And the second reason is the price - I can get 5 pieces of the AS5600 including the magnet for ~$18 including shipping - making it less then $4 for single extruder.

Funny thing is that not only will this be significantly smaller and lighter then extruder with stepper - it will be also much cheaper.

Current price list:

- motor N20-12V-100 (1:100 gear reduction, 12V) for $3

- encoder with magnet for less then $4

- gear for $1.5

- bearing mr126zz for $0.14

- M3 bolt 20mm for $0.01

- M3 nut 20mm for $0.01

- ATtiny85 for $1

Total price of the whole setup is therefore less then $10 (not including the 3 printed parts).

See attached photos and the OpenSCAD design.

I have to modify the design a bit - the nut is difficult to insert without heating it up and the nut and bolt "cover" is too thin (printing it on my crappy printer is quite bad), but the functionality is OK.

I printed mine in ABS with 50% infill, 3 top and 3 bottom layers and 3 perimeters.

Now I have to make 3 of them and buy the diamond hotend

Haha... color printing is next

Price wise we are close to a cheap NEMA17 + Mk8 + driver, but at 1/10 of weight.

Price wise we are close to a cheap NEMA17 + Mk8 + driver, but at 1/10 of weight.

|

Re: Pololu geared DC motor 30g prototype extruder May 24, 2016 06:52PM |

Registered: 9 years ago Posts: 483 |

|

Re: Pololu geared DC motor 30g prototype extruder May 24, 2016 07:03PM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

So. My findings from this night:

- It does work.

- The motor is quite strong.

- Actually too strong - when trying to push filament through 0.2mm nozzle the whole extruder assembly torn appart the ABS bond.

I only tried with 0.4mm nozzle on E3Dv6 and it was going very smoothly at 4.8V. Didn't try 12V as my motor is supposedly 6V and I wanted to keep it cool.

Quote

rklauco

Next step - print the extruder including the e3d-v5 holder together to avoid splitting under heavy loads.

Also, another negative finding - my gear is mounted a bit wrong - it has a tiny bit more grip on one part a a tiny bit less grip on the other side - therefore one can hear the sound of the motor being uneven - when the gear has smaller distance to the ball bearing, it has to work significantly more as the resistance from the actual gear is much higher. Then, when it's over the "peak", it starts to go very fast - until another revolution and therefore another bump.

Seems like the coupling of 5mm gear to 3mm shaft will be the most critical part here.

That's exactly my experience with the modified gear. Some teeth are slightly round and have less grip than the others. Thus you hear some uneven tone, which I don't like. A 5mm pipe or stock would be the best to use off the shelf extruder gears. I got some spare Mk8 gears so that I'll try to adapt a brass M3 standoff to fit onto the motor shaft and then stick the Mk8 onto it.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 01:06AM |

Registered: 7 years ago Posts: 78 |

Quote

etfrench

The AS5600 is only 0-360 degrees. Don't you need an incremental encoder like AS5247?

Not sure what rklauco intended, but AS5600 could be used as a cheap encoder while relying on the host controller to do the counting. If I'm guessing correctly, when the magnet is on the gearbox output shaft, then the rate is not an issue as we have less than 100rpm, which even a busy Arduino board could handle. Similar with the extruder steps per mm you would have a factor for the rotation angle vs mm of filament extruded.

The AS5247 would be great if used directly on the motor shaft or the exposed wheel (e.g. put a ring magnet there or cut a slit into a magnetized steel disk and insert there). However, this is 2-3x the price of the AS5600 and when placed on the gearbox output shaft it doesn't really bring any benefits. Did you have something else in mind/

Now, one clever idea would be to put the magnet on the idler bearing instead of the output shaft. A ring magnet from an broken earphone would do the trick.

- Benefits: detection of filament slip, out of filament, clogged nozzle.

- Drawback: it probably needs PID closed loop to control the motor accurately, but we might get away with an easier setup for such slow speeds.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 02:48AM |

Registered: 12 years ago Posts: 972 |

I would favor the idea of doing the counting with the idler (or with an additional wheel just for that purpose). This way you measure actual filament feed. If the gear is eating the filament or the filament somehow slips then it is not counted though motor output shaft is moving. If measured, a too-high error signal can alert you of extruder trouble. That combined with current measurement can give you an idea of hotend backpressure.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 03:55AM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 04:06AM |

Registered: 12 years ago Posts: 972 |

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 08:20AM |

Registered: 14 years ago Posts: 351 |

Quote

ipcalit

Awaiting for encoder and perhaps insights into using QEI with Smoothieboard.

You can wire the encoder to the Smoothieboard and the hardware peripheral exists, but the Smoothie firmware has no code to use it at this point.

So you'd need to add support for that yourself.

Also, there is only one QEI peripheral, so this'd work only for one axis.

If you need help with anything, you can email me at wolf.arthur@gmail.com, always love to see folks trying unusual things.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 11:02AM |

Registered: 7 years ago Posts: 78 |

Quote

misan

I like to have at least 400 counts per revolution, but resolution depends of the wheel's radius. I would aim at a filament length resolution of at least 0.1mm.

I've seen many filament detectors running with 24 count encoders, so we don't have to go too high. AS5600 would do just fine.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 11:04AM |

Registered: 7 years ago Posts: 78 |

Quote

arthurwolf

Quote

ipcalit

Awaiting for encoder and perhaps insights into using QEI with Smoothieboard.

You can wire the encoder to the Smoothieboard and the hardware peripheral exists, but the Smoothie firmware has no code to use it at this point.

So you'd need to add support for that yourself.

Also, there is only one QEI peripheral, so this'd work only for one axis.

If you need help with anything, you can email me at wolf.arthur@gmail.com, always love to see folks trying unusual things.

If we use AS5600 as rklauco suggested, perhaps we don't even have to worry about QEI as we'll track the filament directly (precision has to be determined). Then we can use existing I2C or SPI (which is used by the display anyway) libraries. What do you think?

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 11:06AM |

Registered: 14 years ago Posts: 351 |

Quote

ipcalit

Quote

arthurwolf

Quote

ipcalit

Awaiting for encoder and perhaps insights into using QEI with Smoothieboard.

You can wire the encoder to the Smoothieboard and the hardware peripheral exists, but the Smoothie firmware has no code to use it at this point.

So you'd need to add support for that yourself.

Also, there is only one QEI peripheral, so this'd work only for one axis.

If you need help with anything, you can email me at wolf.arthur@gmail.com, always love to see folks trying unusual things.

If we use AS5600 as rklauco suggested, perhaps we don't even have to worry about QEI as we'll track the filament directly (precision has to be determined). Then we can use existing I2C or SPI (which is used by the display anyway) libraries. What do you think?

I think using the QEI is the best way of going about this, by far. You are essentially implementing a PID servo controller for the extruder right ? If so you want as much of the work going on withing the firmware, or you'll meet problems very easily with synchronizatio, precision etc.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 11:59AM |

Registered: 8 years ago Posts: 5,232 |

Quote

If so you want as much of the work going on withing the firmware, or you'll meet problems very easily with synchronizatio, precision etc.

What synchronization?

The ATtiny gets the step/dir signal from the Atmega ( or other main controller ) and takes care of one motor in a closed loop. But AFAIK there is no feedback to the planner of the maincontroller that allows to sync the other axes with a skipping extruder. For the main controller it is still an open loop, right?

Would it work to use a multiplexer for the single QEI of the smoothieboard?

@rklauko

I'd make an e3d holder with integrated clamping holder for the motor/gear. That way you can easily change the motor when brushes or gears are worn out.

Edited 1 time(s). Last edit at 05/25/2016 12:02PM by o_lampe.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 12:02PM |

Registered: 14 years ago Posts: 351 |

Quote

o_lampe

Quote

If so you want as much of the work going on withing the firmware, or you'll meet problems very easily with synchronizatio, precision etc.

What synchronization?

The ATtiny gets the step/dir signal from the Atmega ( or other main controller ) and takes care of one motor in a closed loop. But AFAIK there is no feedback to the planner of the maincontroller that allows to sync the other axes with a skipping extruder. For the main controller it is still an open loop, right?

@rklauko

I'd make an e3d holder with integrated clamping holder for the motor/gear. That way you can easily change the motor when brushes or gears are worn out.

Sorry I thought you were going to use the QEI peripheral on the lpc1768.

Yeah if you use step/dir, the lpc1768 doesn't care a bit what's going on

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 12:03PM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.