Pololu geared DC motor 30g prototype extruder

Posted by ipcalit

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 12:04PM |

Registered: 14 years ago Posts: 351 |

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 12:35PM |

Registered: 12 years ago Posts: 972 |

But even in that case (only one axis moving) you'd need to store the current count of one axis before the next one starts to move, and do not forget restoring the original count for that other axis, and do all that on time ...

I do not think multiplexing a single QEI would be very convenient, plus most of the 3D printing moves involve multiple axis.

I do not think multiplexing a single QEI would be very convenient, plus most of the 3D printing moves involve multiple axis.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 12:44PM |

Registered: 7 years ago Posts: 78 |

Quote

arthurwolf

Quote

o_lampe

Quote

If so you want as much of the work going on withing the firmware, or you'll meet problems very easily with synchronizatio, precision etc.

What synchronization?

The ATtiny gets the step/dir signal from the Atmega ( or other main controller ) and takes care of one motor in a closed loop. But AFAIK there is no feedback to the planner of the maincontroller that allows to sync the other axes with a skipping extruder. For the main controller it is still an open loop, right?

@rklauko

I'd make an e3d holder with integrated clamping holder for the motor/gear. That way you can easily change the motor when brushes or gears are worn out.

Sorry I thought you were going to use the QEI peripheral on the lpc1768.

Yeah if you use step/dir, the lpc1768 doesn't care a bit what's going on

I think there are multiple ways of interfacing the "encoder":

1) rklauco's way with the ATtiny doing the closed loop control over the motor and accepting dir/step commands as any other stepper driver. This way you don't need QEI or firmware changes and the controller could be Smothieboard, Arduino or anything.

2) etfrench's way with AS5247 or other "smart" encoder to get directly the amount of movement (e.g. pulse count/angular change) and interface with the controller via I2C or SPI. This needs some firmware changes but there's support for both methods already available in most firmware (see the display interfaces). The cost is slightly higher than (1).

3) my initial plan and what arthur suggested via a regular encoder (optical or magnetic) to generate pulses and use QEI to keep track of the counting -- here we need firmware changes. About the same price as (1) and cheaper than (2).

4) my plan B based on the AS5600 specs - it has analog and I2C output that could be interfaced directly with the controller without any extra hardware (ATtiny). In this case you would need to poll regularly to get the position of the filament. This is already done for filament detection purposes in most firmware. The only question is whether this gives enough control precision to get reliable extrusion. If this works is cheaper than all the above.

Thus, it would be great to refer to the above list when we discuss the options to avoid confusions. If there's another way that I missed, please add to the list.

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 05:00PM |

Registered: 8 years ago Posts: 93 |

|

Re: Pololu geared DC motor 30g prototype extruder May 25, 2016 05:01PM |

Registered: 14 years ago Posts: 351 |

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 03:29AM |

Registered: 8 years ago Posts: 181 |

My idea was a bit of a modification of your nr. 4 - I wanted to use analog input on ATtiny for very fast detection of position - it's much faster to read analog input then to read i2c value - time wise.Quote

ipcalit

4) my plan B based on the AS5600 specs - it has analog and I2C output that could be interfaced directly with the controller without any extra hardware (ATtiny). In this case you would need to poll regularly to get the position of the filament. This is already done for filament detection purposes in most firmware. The only question is whether this gives enough control precision to get reliable extrusion. If this works is cheaper than all the above.

That's why I asked about the resolution - the analog input of ATtiny85 has a resolution of 10bits, however I think reasonable resolution (considering the analog precision of AS5600 and ATtiny85) I expect to get more like 8-bit, therefore 256 values per revolution.

This is 1/2 of what misan suggests as reasonable. So if this is not enough, I'll switch to i2c.

I have to get the magnet first - the AS5600 has to have a different polarization than the regular neodynium magnets I have

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 05:11AM |

Registered: 10 years ago Posts: 18 |

Been following with great interest - and thought I'd try to contribute.

There seems to be very similar motors (6V rather than 12V) available with dual shaft and encoder available from Polulu, with very differing gearings: https://www.pololu.com/blog/549/hpcb-micro-metal-gearmotors-with-extended-motor-shafts

Could this be not used to drive with for example a Arduino Nano, making for a small package?

I realize this can be done very cheaply with custom electronics - but as a proof of concept this might be easier...

There seems to be very similar motors (6V rather than 12V) available with dual shaft and encoder available from Polulu, with very differing gearings: https://www.pololu.com/blog/549/hpcb-micro-metal-gearmotors-with-extended-motor-shafts

Could this be not used to drive with for example a Arduino Nano, making for a small package?

I realize this can be done very cheaply with custom electronics - but as a proof of concept this might be easier...

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 10:40AM |

Registered: 7 years ago Posts: 78 |

Quote

Risingphoenix

Been following with great interest - and thought I'd try to contribute.

There seems to be very similar motors (6V rather than 12V) available with dual shaft and encoder available from Polulu, with very differing gearings: https://www.pololu.com/blog/549/hpcb-micro-metal-gearmotors-with-extended-motor-shafts

Could this be not used to drive with for example a Arduino Nano, making for a small package?

I realize this can be done very cheaply with custom electronics - but as a proof of concept this might be easier...

That's exactly how we initially planned to go. The price is a big higher ($20/setup) and you get option #3 or #1 if count the steps with a different controller. For #3 you need to make changes to the firmware as Arthur confirmed there's no existing support for QEI in Smoothieware and existing 8 bit controllers (RAMPS and alike) can't be used as they lack CPU resources. If you want to bypass these, then you need to do the counting elsewhere and we already have support here for doing that with ATtiny.

[github.com]

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 10:50AM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

My idea was a bit of a modification of your nr. 4 - I wanted to use analog input on ATtiny for very fast detection of position - it's much faster to read analog input then to read i2c value - time wise.Quote

ipcalit

4) my plan B based on the AS5600 specs - it has analog and I2C output that could be interfaced directly with the controller without any extra hardware (ATtiny). In this case you would need to poll regularly to get the position of the filament. This is already done for filament detection purposes in most firmware. The only question is whether this gives enough control precision to get reliable extrusion. If this works is cheaper than all the above.

That's why I asked about the resolution - the analog input of ATtiny85 has a resolution of 10bits, however I think reasonable resolution (considering the analog precision of AS5600 and ATtiny85) I expect to get more like 8-bit, therefore 256 values per revolution.

This is 1/2 of what misan suggests as reasonable. So if this is not enough, I'll switch to i2c.

We could hook-up the analog output directly to the controller (most have one analog input). Alternatively, what do you think about SPI using AS5047P for $2 more (cheaper than AS5247)?

Ah... you're right about the polarization issue. The typical rings we have have the poles on opposite faces of the magnet. Time to google for other magnets. Digikey may have some.Quote

rklauco

I have to get the magnet first - the AS5600 has to have a different polarization than the regular neodynium magnets I have

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 03:29PM |

Registered: 8 years ago Posts: 181 |

Well, I tried to design a holder for the extruder, but I came to a problem.

The whole extruder is so small, that in order to reliably hold it in place, I'd have to have more material for the holder then for the actual extruder.

Therefore I made a modification. I made the whole e3d holder WITH the extruder integrated - therefore it prints as one piece and is as stiff as possible. And still, the installation of the internals is pretty simple.

Unfortunately, I made a little mistake within the source code and instead of 3mm hole printed 4mm one, rendering the ball bearing too loose and with insufficient grip.

Right now I am re-printing it and I'll update the github, too.

These are the relevant files:

Extruder only

Whole X gantry with extruder

The whole extruder is so small, that in order to reliably hold it in place, I'd have to have more material for the holder then for the actual extruder.

Therefore I made a modification. I made the whole e3d holder WITH the extruder integrated - therefore it prints as one piece and is as stiff as possible. And still, the installation of the internals is pretty simple.

Unfortunately, I made a little mistake within the source code and instead of 3mm hole printed 4mm one, rendering the ball bearing too loose and with insufficient grip.

Right now I am re-printing it and I'll update the github, too.

These are the relevant files:

Extruder only

Whole X gantry with extruder

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 03:49PM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 04:04PM |

Registered: 8 years ago Posts: 93 |

This is rather exciting! Assuming it's possible, I think you should aim for being able to use these with pre-existing hardware, I'd love to run these but I wouldn't want to replace my Duet boards.

Could you save more weight by rounding those edges?Quote

rklauco

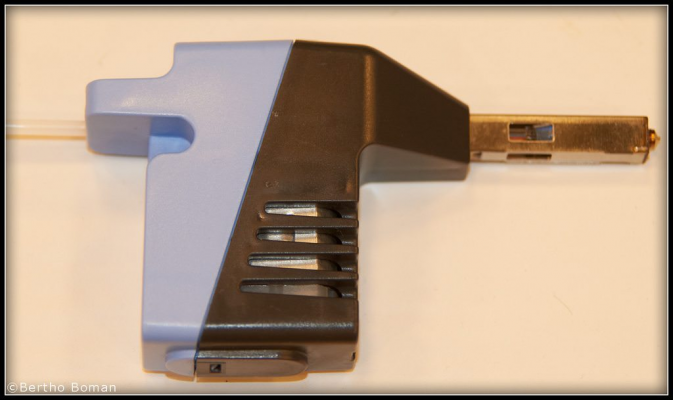

And this is how it looks like with Chinese cheap e3d v6.

|

Re: Pololu geared DC motor 30g prototype extruder May 26, 2016 05:05PM |

Registered: 8 years ago Posts: 181 |

My goal is to make it technically possible NOT to replace anything - you will just pull out your stepper, or redirect the step/direction outputs to free pin and that's it.Quote

asbo

This is rather exciting! Assuming it's possible, I think you should aim for being able to use these with pre-existing hardware, I'd love to run these but I wouldn't want to replace my Duet boards.

The driving of the DC motor and position sensing will be done by external HW - in this case ATtiny85, AS5600 and some DC motor driver (on its way from China for a week already).

Probably. But I am too lazy to do soQuote

asbo

Could you save more weight by rounding those edges?

But the OpenSCAD files are linked in my previous post, feel free to edit them and provide a pull request if you'd like. I think the rounded edges would saved me just miligrams. But I can remove the whole top structure - originally designed as the top holder of the extruder. Now, when I think of it, it's useless...

But the OpenSCAD files are linked in my previous post, feel free to edit them and provide a pull request if you'd like. I think the rounded edges would saved me just miligrams. But I can remove the whole top structure - originally designed as the top holder of the extruder. Now, when I think of it, it's useless...

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 01:52AM |

Registered: 7 years ago Posts: 78 |

The ATtiny85 would have to be collocated on a board with the AS5600 to get the analog input to work properly. Any plans to make such board and add the DC driver there too?Quote

rklauco

My goal is to make it technically possible NOT to replace anything - you will just pull out your stepper, or redirect the step/direction outputs to free pin and that's it. The driving of the DC motor and position sensing will be done by external HW - in this case ATtiny85, AS5600 and some DC motor driver (on its way from China for a week already).

Alternatively, what do you think about Allegro A1334 with SPI for the same price of AS5600 (Digikey)? The motor could be driven by the PWM output of most controllers using existing cheap L298 drivers and you don't need another board for testing, just some wires.

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 02:11AM |

Registered: 8 years ago Posts: 181 |

Wow, the chip is impressive and the $0.40 price from China even more, it has some problems:

- SPI - while a lot faster then i2c, it requires all the pins of ATtiny, so no step input or pwm output. I'd have to switch to different tiny version with more pins - that adds space requirements

- SPI is slower then analog read and more CPU intensive

- I see no PWM output, but even if we had some, we still need some logic to translate step+direction info to PWM

- SPI - while a lot faster then i2c, it requires all the pins of ATtiny, so no step input or pwm output. I'd have to switch to different tiny version with more pins - that adds space requirements

- SPI is slower then analog read and more CPU intensive

- I see no PWM output, but even if we had some, we still need some logic to translate step+direction info to PWM

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 05:32AM |

Registered: 8 years ago Posts: 93 |

That sounds excellentQuote

rklauco

My goal is to make it technically possible NOT to replace anything - you will just pull out your stepper, or redirect the step/direction outputs to free pin and that's it.Quote

asbo

This is rather exciting! Assuming it's possible, I think you should aim for being able to use these with pre-existing hardware, I'd love to run these but I wouldn't want to replace my Duet boards.

The driving of the DC motor and position sensing will be done by external HW - in this case ATtiny85, AS5600 and some DC motor driver (on its way from China for a week already).

Unfortunately I could never wrap my head around OpenSCAD, I am quite good with SolidWorks though.Quote

rklauco

Probably. But I am too lazy to do soQuote

asbo

Could you save more weight by rounding those edges?But the OpenSCAD files are linked in my previous post, feel free to edit them and provide a pull request if you'd like. I think the rounded edges would saved me just miligrams. But I can remove the whole top structure - originally designed as the top holder of the extruder. Now, when I think of it, it's useless...

Out of curiosity I typed motor encoder into aliexpress and there are some cheap motors with encoders already attached. I've no idea if they're any good for this purpose, and you've probably already stumbled across them, but I thought I'd mention it just in case.

[www.aliexpress.com]

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 05:49AM |

Registered: 8 years ago Posts: 181 |

Could the STL export help you? I can make one no problem - even using OpenJSCAD.org I can do it online...Quote

asbo

Unfortunately I could never wrap my head around OpenSCAD, I am quite good with SolidWorks though.

I bought most of them already.Quote

asbo

Out of curiosity I typed motor encoder into aliexpress and there are some cheap motors with encoders already attached. I've no idea if they're any good for this purpose, and you've probably already stumbled across them, but I thought I'd mention it just in case.

[www.aliexpress.com]

The fake Mabuchi 130 are cheap, but have insufficient torque.

The 24V motors like this have enough torque, but the encoder is there only to measure speed, not direction. So it would be quite a big problem for PID implementation (overshoot compensation is a no-go then).

I am testing now the fake mabuchi with some plastic gears for a different purpose, but by using the gears I am adding backlash, so for anything precise this is a no-go.

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 07:21AM |

Registered: 10 years ago Posts: 18 |

Did you also found that you can have the exact model we seem to have narrowed down with the encoder attached?

Just bought a few 100rpm with encoder (be sure to specify when buying, they have all the speeds). Only difference I can see is that with Pololu you can have a higher spec motor, good for double the stalling A.

AliExpress micro Motor 6V w/ encoder

Edited 1 time(s). Last edit at 05/27/2016 09:52AM by Risingphoenix.

Just bought a few 100rpm with encoder (be sure to specify when buying, they have all the speeds). Only difference I can see is that with Pololu you can have a higher spec motor, good for double the stalling A.

AliExpress micro Motor 6V w/ encoder

Edited 1 time(s). Last edit at 05/27/2016 09:52AM by Risingphoenix.

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 07:22AM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 07:58AM |

Registered: 11 years ago Posts: 31 |

They also have the N20 motor with encoder for 10USD on aliexpress

N20 motor with encoder

N20 motor with encoder

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 08:59AM |

Registered: 8 years ago Posts: 93 |

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 12:37PM |

Registered: 8 years ago Posts: 93 |

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 01:01PM |

Registered: 7 years ago Posts: 78 |

All these ready-made N20s with encoder are great, but we have two issues:

1) if the motors burn (at some point) you have to replace it along with the encoder as the long shaft motor is more expensive from Pololu than the bundle from Aliexpress. If we could get the encoder off the motor, then you can get plenty of N20 geared down to 30rpm for $3 each.

2) Unless somebody can point out some reputable sellers, Aliexpress and Alibaba host many scams and buying a couple of N20s (just to have some spares) adds-up quickly.

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 01:15PM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 01:22PM |

Registered: 8 years ago Posts: 181 |

The problem here is that the $3 motors do not have the extended shaft. So you have no place to put the encoder to.Quote

ipcalit

1) if the motors burn (at some point) you have to replace it along with the encoder as the long shaft motor is more expensive from Pololu than the bundle from Aliexpress. If we could get the encoder off the motor, then you can get plenty of N20 geared down to 30rpm for $3 each.

Anyhow, for now the AS5600 seems most viable. I'll try to test it as soon as I got the magnets from china...

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 01:26PM |

Registered: 12 years ago Posts: 972 |

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 02:01PM |

Registered: 7 years ago Posts: 78 |

Quote

rklauco

The problem here is that the $3 motors do not have the extended shaft. So you have no place to put the encoder to.Quote

ipcalit

1) if the motors burn (at some point) you have to replace it along with the encoder as the long shaft motor is more expensive from Pololu than the bundle from Aliexpress. If we could get the encoder off the motor, then you can get plenty of N20 geared down to 30rpm for $3 each.

Anyhow, for now the AS5600 seems most viable. I'll try to test it as soon as I got the magnets from china...

My point exactly - you either buy them with the encoder or just use an external encoder.

The AS5600 is probably the most cost effective option based on the discussion above. I found that my board Azteeg X5 mini (Smoothieboard clone) has P0[25], P0[26], P1[30] as A/D converter 0, input 2, 3 and 4 available on EXP1 header, so I could connect up to three AS5600 directly to the board for testing. What board are you testing with?

Also, I could not find, yet, a ring magnet with the proper pole configuration, so I'm thinking of placing a couple of 3mm dia magnets on an M5 flat washer to attach to the idler and drive the AS5600. Btw. where did you order your AS5600? AMS has both US and EU offices and offers samples.

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 02:08PM |

Registered: 8 years ago Posts: 181 |

My the suggestion of Misan I tried the EU offices - the package came from Austria.

The problem with the magnet of yours is the orientation - check the desired orientation on the documentation from ASM.

Even putting the magnets on the washer will not modify the magnetic field orientation

My idea was to put 3-4 together and glue them using some hot glue or acrylic side-ways.

First I have to test if the strength is sufficient for the AS5600.

Today (maybe) I'll finally have some time.

The problem with the magnet of yours is the orientation - check the desired orientation on the documentation from ASM.

Even putting the magnets on the washer will not modify the magnetic field orientation

My idea was to put 3-4 together and glue them using some hot glue or acrylic side-ways.

First I have to test if the strength is sufficient for the AS5600.

Today (maybe) I'll finally have some time.

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 02:14PM |

Registered: 12 years ago Posts: 972 |

|

Re: Pololu geared DC motor 30g prototype extruder May 27, 2016 02:17PM |

Registered: 7 years ago Posts: 78 |

Quote

misan

Take a look at the AS5601 too, as it provides regular AB encoder outputs too.

If we connect the ASxxxx to the output shaft or the idler, we don't need anything fancy, the cheaper the better as the overall package has to compete with the NEMA17 existing solutions and suppliers will offer ready-made boards or complete extruders. Reliability is a factor to consider as the motors will die sooner than the NEMAs. We don't have to go so far as the big guys with the disposable heads, but if you could keep the controller, encoder, driver and pretty much everything except the $3 motor then having spares around is an option.

See here the Mojo heads: [forums.reprap.org]

and the relevant image, which seem to contain some Mabuchi 130 with worm gear.

Sorry, only registered users may post in this forum.