Pololu geared DC motor 30g prototype extruder

Posted by ipcalit

|

Re: Pololu geared DC motor 30g prototype extruder November 30, 2016 01:08PM |

Registered: 8 years ago Posts: 11 |

Most hobby brushless controllers work that way, yeah. It works best when running at high speeds - there's not enough back EMF at lower RPM, so for low RPM operation and startup from idle the controller essentially has to "guess", which severely degrades low end torque. Hence it tends to work quite well for things like quadcopters where you just need to get it started once then it runs pretty much continuously, but I'm not confident it would perform well for this application. That said, I've not actually tried it - it may work, I just haven't had enough confidence in it to want to make the investment in parts to try.

|

Re: Pololu geared DC motor 30g prototype extruder November 30, 2016 01:08PM |

Registered: 12 years ago Posts: 972 |

|

Re: Pololu geared DC motor 30g prototype extruder December 02, 2016 03:26AM |

Registered: 8 years ago Posts: 5,232 |

Sorry , my memory fooled me... it is of course the gate signal of all 6 FETs that can be used as encoder.

I repeat myself by telling you ( community in general ) to look at brushless gimbal controllers. They actually use BLDC motors as steppers with simple arduino code ( 32bit too ) and 5A 3phase H-bridges.

Edited 1 time(s). Last edit at 12/02/2016 03:30AM by o_lampe.

I repeat myself by telling you ( community in general ) to look at brushless gimbal controllers. They actually use BLDC motors as steppers with simple arduino code ( 32bit too ) and 5A 3phase H-bridges.

Edited 1 time(s). Last edit at 12/02/2016 03:30AM by o_lampe.

|

Re: Pololu geared DC motor 30g prototype extruder December 05, 2016 08:02PM |

Registered: 8 years ago Posts: 916 |

Quote

o_lampe

Sorry , my memory fooled me... it is of course the gate signal of all 6 FETs that can be used as encoder.

I repeat myself by telling you ( community in general ) to look at brushless gimbal controllers. They actually use BLDC motors as steppers with simple arduino code ( 32bit too ) and 5A 3phase H-bridges.

They have way too low a torque for this application. Have you actually held one? If the wires connecting the camera to the quad are slightly too stiff, then the gimbal shakes and misses steps. They are also quite slow.

|

Re: Pololu geared DC motor 30g prototype extruder December 06, 2016 10:03AM |

Registered: 8 years ago Posts: 5,232 |

Yes I've played with a "Martinez-BruGi" gimbal controller and they are quite nervous, because of the 6DOF-sensor and the PID settings. Without this sensor, the current can be much higher and the motors are stronger.

Meet my Olli-Bot, a selfbalancing robot

Meet my Olli-Bot, a selfbalancing robot

|

Re: Pololu geared DC motor 30g prototype extruder December 22, 2016 11:49AM |

Registered: 8 years ago Posts: 11 |

Progress report:

75:1 Pololu motor experiment has thus far failed. Not enough torque - it can run the filament in an aggressive extrude/retract cycle without the hot end for ages without the heat problem with the fan mounted on there, but once you add the hot end, it stalls.

Part of it may be the geometry. When I shifted the motors to the inside of the filament paths, I think it made things a bit too tight - it bites the filament too much, cuts notches, and these are catching on the hot end side of the PTFE path. That's not really a fixable problem with the 30mm design, so I'm going to need to revert to the older 40mm design so that I have more flexibility with the hob positioning relative to the filament path. I'll see if this is enough for the 75:1 to work. If not, there is also a 100:1 I can try as a midpoint between the known working 150:1 and the so far not working 75:1.

Another possible path of exploration is finding a way to retrofit the encoder onto the Pololu 20D motors, which are still compact but significantly more powerful than the tiny ones. They use 130 sized motors, so I may be able to scrounge up a dual-shaft 12v 130 motor to replace the stock one and be able to use an encoder more easily. This also might ease the pain of replacing it when brushes wear out, since 130 motors are only a couple of dollars each if you don't also need to replace the gearbox.

I've also been doing some more research into the idea of using a brushless motor. Attempts to find a small sensored brushless have thus far not worked out. Smallest one I've been able to find is 380 sized, which would be a lot larger than the Pololu motors, but small enough to be worth trying... except it isn't produced any more. Smallest active production one I can find is 540 size, which would be heavier than just using a NEMA17 pancake stepper.

However, I did find a part I'd like to play with - the DFRobot FIT0441. It's a pre-canned brushless gearmotor/controller combination with feedback which comes in at 69gm. Unfortunately the feedback isn't quadrature, but it may be close enough to be worth a try.

Edited 1 time(s). Last edit at 12/22/2016 11:55AM by matthock.

75:1 Pololu motor experiment has thus far failed. Not enough torque - it can run the filament in an aggressive extrude/retract cycle without the hot end for ages without the heat problem with the fan mounted on there, but once you add the hot end, it stalls.

Part of it may be the geometry. When I shifted the motors to the inside of the filament paths, I think it made things a bit too tight - it bites the filament too much, cuts notches, and these are catching on the hot end side of the PTFE path. That's not really a fixable problem with the 30mm design, so I'm going to need to revert to the older 40mm design so that I have more flexibility with the hob positioning relative to the filament path. I'll see if this is enough for the 75:1 to work. If not, there is also a 100:1 I can try as a midpoint between the known working 150:1 and the so far not working 75:1.

Another possible path of exploration is finding a way to retrofit the encoder onto the Pololu 20D motors, which are still compact but significantly more powerful than the tiny ones. They use 130 sized motors, so I may be able to scrounge up a dual-shaft 12v 130 motor to replace the stock one and be able to use an encoder more easily. This also might ease the pain of replacing it when brushes wear out, since 130 motors are only a couple of dollars each if you don't also need to replace the gearbox.

I've also been doing some more research into the idea of using a brushless motor. Attempts to find a small sensored brushless have thus far not worked out. Smallest one I've been able to find is 380 sized, which would be a lot larger than the Pololu motors, but small enough to be worth trying... except it isn't produced any more. Smallest active production one I can find is 540 size, which would be heavier than just using a NEMA17 pancake stepper.

However, I did find a part I'd like to play with - the DFRobot FIT0441. It's a pre-canned brushless gearmotor/controller combination with feedback which comes in at 69gm. Unfortunately the feedback isn't quadrature, but it may be close enough to be worth a try.

Edited 1 time(s). Last edit at 12/22/2016 11:55AM by matthock.

|

Re: Pololu geared DC motor 30g prototype extruder December 22, 2016 01:26PM |

Registered: 8 years ago Posts: 181 |

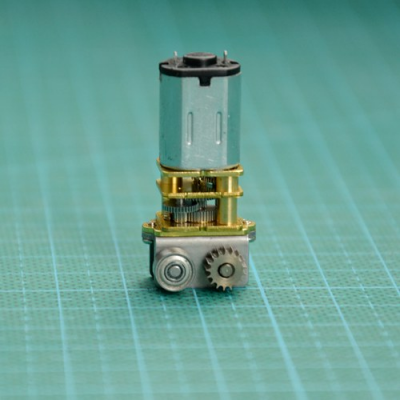

Not 100% sure, but the 20D looks a lot like this one

[www.aliexpress.com]

I got them, but with no gearbox they are weak.

[www.aliexpress.com]

I got them, but with no gearbox they are weak.

|

Re: Pololu geared DC motor 30g prototype extruder December 22, 2016 01:29PM |

Registered: 8 years ago Posts: 181 |

|

Re: Pololu geared DC motor 30g prototype extruder February 09, 2017 06:42AM |

Registered: 8 years ago Posts: 93 |

Does anyone tried to use stepper motors of the same size as pololu's dc motors?

Seems like that motors are underpowered too.

Prices starting from $3.73 without delivery:

[www.aliexpress.com]

[www.aliexpress.com]

[www.aliexpress.com]

[www.aliexpress.com]

And so on.

Seems like that motors are underpowered too.

Prices starting from $3.73 without delivery:

[www.aliexpress.com]

[www.aliexpress.com]

[www.aliexpress.com]

[www.aliexpress.com]

And so on.

|

Re: Pololu geared DC motor 30g prototype extruder March 04, 2017 04:51PM |

Registered: 7 years ago Posts: 2 |

Quote

matthock

Progress report:

75:1 Pololu motor experiment has thus far failed. Not enough torque - it can run the filament in an aggressive extrude/retract cycle without the hot end for ages without the heat problem with the fan mounted on there, but once you add the hot end, it stalls.

Part of it may be the geometry. When I shifted the motors to the inside of the filament paths, I think it made things a bit too tight - it bites the filament too much, cuts notches, and these are catching on the hot end side of the PTFE path. That's not really a fixable problem with the 30mm design, so I'm going to need to revert to the older 40mm design so that I have more flexibility with the hob positioning relative to the filament path. I'll see if this is enough for the 75:1 to work. If not, there is also a 100:1 I can try as a midpoint between the known working 150:1 and the so far not working 75:1.

Another possible path of exploration is finding a way to retrofit the encoder onto the Pololu 20D motors, which are still compact but significantly more powerful than the tiny ones. They use 130 sized motors, so I may be able to scrounge up a dual-shaft 12v 130 motor to replace the stock one and be able to use an encoder more easily. This also might ease the pain of replacing it when brushes wear out, since 130 motors are only a couple of dollars each if you don't also need to replace the gearbox.

I've also been doing some more research into the idea of using a brushless motor. Attempts to find a small sensored brushless have thus far not worked out. Smallest one I've been able to find is 380 sized, which would be a lot larger than the Pololu motors, but small enough to be worth trying... except it isn't produced any more. Smallest active production one I can find is 540 size, which would be heavier than just using a NEMA17 pancake stepper.

However, I did find a part I'd like to play with - the DFRobot FIT0441. It's a pre-canned brushless gearmotor/controller combination with feedback which comes in at 69gm. Unfortunately the feedback isn't quadrature, but it may be close enough to be worth a try.

Hi, this project is the reason I signed up on this site so thank you for the inspiration ! I too dream of a tiny direct drive extruder

I have not bought the dfrobot to confirm but am pretty sure that motor is a Nidec 13H Data sheet linked below, looks like dfrobot attached the gearbox. I have seen just the motor on ebay and aliexpress for less than $5-$10

I have not bought the dfrobot to confirm but am pretty sure that motor is a Nidec 13H Data sheet linked below, looks like dfrobot attached the gearbox. I have seen just the motor on ebay and aliexpress for less than $5-$10 [www.dynetics.eu]

I have used the Nidec 22H for another and have been very happy with it at 24v. The driver is internal and the tachometer output is "digital" so there was no need for a second encoder channel for my previous applications. It outputs 18 pulses per revolution and I did not have any issues with it losing direction or missing "steps" (verified with a coupled quadrature encoder). The only real problem I had with it was heat at 24v it gets hot quickly so you might run into issues if the gear ratio is not optimized for the needed torque and rpm.

I have a spare 22H laying around and while its too big for an extruder, will see if I can make a geared extruder out of it before ordering the geared version.

|

Re: Pololu geared DC motor 30g prototype extruder March 04, 2017 05:00PM |

Registered: 7 years ago Posts: 2 |

|

Re: Pololu geared DC motor 30g prototype extruder April 07, 2017 11:21PM |

Registered: 8 years ago Posts: 11 |

I've been a bit stalled on this - I couldn't get it to both work and meet my speed requirements with the old specs.

Taking a new tack. I didn't realize this before, but the next size of Pololu motors, the 20Ds, also have encoders available. Don't know if this is new, or if I just missed it before. Much worse power to weight ratio (40gm vs 10gm for about twice the power), but it's still a lot better than steppers, even a pancake stepper is 150gm. I've ordered a couple of these and I'm going to have another go with the bigger motors. Plus, that's the power at 6V - as long as I cool them and run current limiting, they might run at 12v, in which case they'd easily be powerful enough. Also, I do believe these are standard-ish 130 motors, so there might be another motor I can swap on and reuse the gearbox. Perhaps even use a sensorless brushless with one of the higher gear ratios.

Taking a new tack. I didn't realize this before, but the next size of Pololu motors, the 20Ds, also have encoders available. Don't know if this is new, or if I just missed it before. Much worse power to weight ratio (40gm vs 10gm for about twice the power), but it's still a lot better than steppers, even a pancake stepper is 150gm. I've ordered a couple of these and I'm going to have another go with the bigger motors. Plus, that's the power at 6V - as long as I cool them and run current limiting, they might run at 12v, in which case they'd easily be powerful enough. Also, I do believe these are standard-ish 130 motors, so there might be another motor I can swap on and reuse the gearbox. Perhaps even use a sensorless brushless with one of the higher gear ratios.

|

Re: Pololu geared DC motor 30g prototype extruder April 12, 2017 03:06PM |

Registered: 8 years ago Posts: 11 |

So that's why I missed the 20D encoders before - they introduced them *after* my December post! They look like they'll be fantastic for this role, though. Yeah, it won't be 30gm, but the performance will be up there with anything else in common use.

I'm going with a slightly different path forward this time. I'm running a Titan extruder on my current printer. Instead of replacing the whole thing, I'm just going to swap the pancake stepper with the DC motor and an adapter plate. The shafts are a slightly different size (4mm vs 5mm), but some 5mm OD 0.5mm wall brass tube should fix that right up. If that works, then I'll move on to a full lightweight extruder design (since the Titan gearing is a bit overkill after the existing geartrain), but I seriously want to get the electronics proved out first.

I'm going with a slightly different path forward this time. I'm running a Titan extruder on my current printer. Instead of replacing the whole thing, I'm just going to swap the pancake stepper with the DC motor and an adapter plate. The shafts are a slightly different size (4mm vs 5mm), but some 5mm OD 0.5mm wall brass tube should fix that right up. If that works, then I'll move on to a full lightweight extruder design (since the Titan gearing is a bit overkill after the existing geartrain), but I seriously want to get the electronics proved out first.

|

Re: Pololu geared DC motor 30g prototype extruder April 30, 2017 08:16PM |

Registered: 8 years ago Posts: 93 |

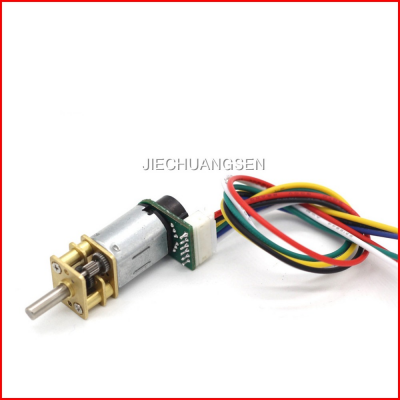

Almost complete solution (except encoder). Steppers for gearboxes of the same size are also available on Aliexpress (I have provided the links above on this page).

[www.aliexpress.com]

[www.aliexpress.com]

[www.aliexpress.com]

P.S. popular RobotDigg site selling this motors for $7: [www.robotdigg.com]

P.P.S.: motors with encoder. It seems for me that it's possible to transplant extruder part to this motor:

Edited 2 time(s). Last edit at 05/01/2017 11:06AM by roboprint.

[www.aliexpress.com]

[www.aliexpress.com]

[www.aliexpress.com]

P.S. popular RobotDigg site selling this motors for $7: [www.robotdigg.com]

P.P.S.: motors with encoder. It seems for me that it's possible to transplant extruder part to this motor:

Edited 2 time(s). Last edit at 05/01/2017 11:06AM by roboprint.

|

Re: Pololu geared DC motor 30g prototype extruder February 03, 2020 07:54AM |

Registered: 4 years ago Posts: 3 |

Sorry but up theme...

Its rghit way...

If you can see Statasys patent for Mojo 3D extruder, it have not any encoders on the motor! Motor is drive by CCW/CW only. All calculation in the Filament Control Module (FCM) (you can see it over X&Y motors in Mojo). FCM calculate LENGTH by odometer against STEPS for classics extruder. It has higher accuracy, close loop. Close loop can control break or end of filament. Also FCM can control diameter of filament. Speed of filaments slow, that good for control on the Arduino about 600ppr with 10-12mm wheel for encoder.

Extruder with STEP/DIR logic:

This have not control.

It can control missings.

For RepRap its simple for creation. Can use N20-gear-motor without any changes, and other any low percision DC motor. With Mosquito hotend it cool choice. But need update Marlin or other software for change logic.

Edited 6 time(s). Last edit at 02/04/2020 10:17AM by sendel.

Quote

roboprint

Almost complete solution (except encoder). Steppers for gearboxes of the same size are also available on Aliexpress (I have provided the links above on this page).

Its rghit way...

Its wrong way.Quote

roboprint

P.S. popular RobotDigg site selling this motors for $7: [www.robotdigg.com]

P.P.S.: motors with encoder. It seems for me that it's possible to transplant extruder part to this motor:

If you can see Statasys patent for Mojo 3D extruder, it have not any encoders on the motor! Motor is drive by CCW/CW only. All calculation in the Filament Control Module (FCM) (you can see it over X&Y motors in Mojo). FCM calculate LENGTH by odometer against STEPS for classics extruder. It has higher accuracy, close loop. Close loop can control break or end of filament. Also FCM can control diameter of filament. Speed of filaments slow, that good for control on the Arduino about 600ppr with 10-12mm wheel for encoder.

Extruder with STEP/DIR logic:

Marlin (steps/dir) -> Stepping driver (steps/dir) -> Stepping motor(rotate)

This have not control.

Extruder with LENGTH/DIR logic:

Marlin (length/dir) ->| FCM board (dir)| -> DC Motor

| | <-(length/pulse) Encoder FCM

| <-(alram) FCM board

It can control missings.

For RepRap its simple for creation. Can use N20-gear-motor without any changes, and other any low percision DC motor. With Mosquito hotend it cool choice. But need update Marlin or other software for change logic.

Edited 6 time(s). Last edit at 02/04/2020 10:17AM by sendel.

Sorry, only registered users may post in this forum.