Extruder Rate (request for crackpot ideas)

Posted by degroof

|

Extruder Rate (request for crackpot ideas) November 27, 2007 04:49PM |

Registered: 16 years ago Posts: 447 |

Seems like the limiting factor on the RepRap -- on any FDM machine -- is the extrusion rate. The axes can move a lot faster than they do now but the plastic comes out at only, what, 10 mm/s or so?

So, say you have a RepRap all assembled, tested and extruding at 10 mm/s. What would you do to "overclock" it?

So, say you have a RepRap all assembled, tested and extruding at 10 mm/s. What would you do to "overclock" it?

|

Re: Extruder Rate (request for crackpot ideas) November 27, 2007 07:26PM |

Registered: 17 years ago Posts: 97 |

Use it make molds rather than the parts themselves.

Make the extruder out of a thermoset (or even alumium) and heat the thing to a much higher temp so that the plastic practically flows in a continous stream.

Use a thicker filiment and then a pressure nozzle to force the material out at a higher rate. Frankly you could do what they do in cake decorating and make the nozzle changeable so that you could make thin sheets, star shaped filiments, or streams of various sizes. A slight angluar shape would likley help with the sagging since the material would grip the lower layer as it flowed into the voids. Less sagging could allow you to up the tempature and therefor the flow rates.

Mike

Make the extruder out of a thermoset (or even alumium) and heat the thing to a much higher temp so that the plastic practically flows in a continous stream.

Use a thicker filiment and then a pressure nozzle to force the material out at a higher rate. Frankly you could do what they do in cake decorating and make the nozzle changeable so that you could make thin sheets, star shaped filiments, or streams of various sizes. A slight angluar shape would likley help with the sagging since the material would grip the lower layer as it flowed into the voids. Less sagging could allow you to up the tempature and therefor the flow rates.

Mike

|

Re: Extruder Rate (request for crackpot ideas) November 27, 2007 09:28PM |

Admin Registered: 17 years ago Posts: 7,879 |

My experience with HDPE is that you can run the axes faster than the filament flow to get a finer thread. E.g. I can comfortably extrude a 0.5mm filament at 16mm/s through a 0.5mm hole.

The limiting factor is the grip on the incoming filament. If I go too fast it strips the thread it has cut. A shorter hole in the nozzle would help a bit.

Temperature has liitle effect on flow rate once you get clear of the melting point.

To scale up I think you would need to start with a bigger feed filament, a bigger screw and a more powerful motor.

[www.hydraraptor.blogspot.com]

The limiting factor is the grip on the incoming filament. If I go too fast it strips the thread it has cut. A shorter hole in the nozzle would help a bit.

Temperature has liitle effect on flow rate once you get clear of the melting point.

To scale up I think you would need to start with a bigger feed filament, a bigger screw and a more powerful motor.

[www.hydraraptor.blogspot.com]

|

Re: Extruder Rate (request for crackpot ideas) November 27, 2007 11:12PM |

Registered: 16 years ago Posts: 622 |

|

Re: Extruder Rate (request for crackpot ideas) November 28, 2007 09:09AM |

Registered: 16 years ago Posts: 120 |

|

Re: Extruder Rate (request for crackpot ideas) November 28, 2007 11:16AM |

Registered: 16 years ago Posts: 447 |

|

Re: Extruder Rate (request for crackpot ideas) November 28, 2007 11:32AM |

Registered: 16 years ago Posts: 447 |

nophead Wrote:

-------------------------------------------------------

> The limiting factor is the grip on the incoming

> filament. If I go too fast it strips the thread it

> has cut. A shorter hole in the nozzle would help a

> bit.

How about a continuous taper on the internal bore? Basically eliminate the "shelf" altogether.

> Temperature has liitle effect on flow rate once

> you get clear of the melting point.

Seems like the amount of heat transferred to the filament would decrease as the speed increased (i.e. less time spent in the heater barrel). Maybe a longer barrel would help there.

> To scale up I think you would need to start with a

> bigger feed filament, a bigger screw and a more

> powerful motor.

I wonder what the upper end of that would be. Say you had plastic stock the diameter of a hot glue stick. Could you heat it up sufficiently to extrude it? Maybe at that point the granule-and-auger approach [reprap.org] becomes more practical.

Edited 1 time(s). Last edit at 11/28/2007 11:32AM by Steve DeGroof.

-------------------------------------------------------

> The limiting factor is the grip on the incoming

> filament. If I go too fast it strips the thread it

> has cut. A shorter hole in the nozzle would help a

> bit.

How about a continuous taper on the internal bore? Basically eliminate the "shelf" altogether.

> Temperature has liitle effect on flow rate once

> you get clear of the melting point.

Seems like the amount of heat transferred to the filament would decrease as the speed increased (i.e. less time spent in the heater barrel). Maybe a longer barrel would help there.

> To scale up I think you would need to start with a

> bigger feed filament, a bigger screw and a more

> powerful motor.

I wonder what the upper end of that would be. Say you had plastic stock the diameter of a hot glue stick. Could you heat it up sufficiently to extrude it? Maybe at that point the granule-and-auger approach [reprap.org] becomes more practical.

Edited 1 time(s). Last edit at 11/28/2007 11:32AM by Steve DeGroof.

|

Re: Extruder Rate (request for crackpot ideas) November 29, 2007 07:21AM |

Registered: 16 years ago Posts: 161 |

Any attempt to increase print speed will have a cost. The most obvious is to increase the feed rate by raising the pressure and probably the temperature in the nozzle. The cost is an increase in price and power consumption, and probably complexity of the head. This sort of problem tends to manifest the cube/square law so that raising output from 1 to 4 will require raising price from 1 to 8. (And raising output from 1 to 9 raises costs from 1 to 27) The same problem of diminishing returns affects a single nozzle which prints varying widths, due the complexity required to implement it. Either some mechanical device must operate with very fine control in very little space at the tip or an asymmetrical nozzle needs to be kept oriented re: the direction of travel of the printhead.

Running multiple print heads simultaneously is also an obvious solution but while the cost is only additive (twice as many heads only cost twice as much) you need to include the cost of the structure to move the heads and the fact that avoiding collisions between multiple heads while achieving good adhesion between their outputs is far from trivial.

A better result is probably achieved by mounting multiple nozzles on a single head and using more or fewer as required. The costs here are mostly additive but there would be an increase in power draw when operating multiple nozzles. The other cost would be in software compexification. One nozzle extruding a round thread can be treated as a point for most operations, but a set of, say 3 nozzles running left to right has a definite size, shape and orientation, all of which need to be accounted for in relation to the object to be printed, the direction of printhead motion and the dimensions of the table.

With the advent of the automatic tool changer it becomes possible to have an outline head and a fill head. This approach probably has the best ROI of any of the above methods. Aside from the actual (minimal) cost of the new head the cost in software complexity would be the main problem; each slice would need to be broken into outline and narrow areas (first pass) and then wide fill areas. Also some provision would need to be made to compensate for or prevent the nozzles cooling while not in use.

The current method for dealing with large areas is to use cross hatching and fill the area with mesh rather than solid plastic. Reports are that 50% mesh coverage is as strong and stiff as complete infill. Obviously any new toolhead should take this into account.

Running multiple print heads simultaneously is also an obvious solution but while the cost is only additive (twice as many heads only cost twice as much) you need to include the cost of the structure to move the heads and the fact that avoiding collisions between multiple heads while achieving good adhesion between their outputs is far from trivial.

A better result is probably achieved by mounting multiple nozzles on a single head and using more or fewer as required. The costs here are mostly additive but there would be an increase in power draw when operating multiple nozzles. The other cost would be in software compexification. One nozzle extruding a round thread can be treated as a point for most operations, but a set of, say 3 nozzles running left to right has a definite size, shape and orientation, all of which need to be accounted for in relation to the object to be printed, the direction of printhead motion and the dimensions of the table.

With the advent of the automatic tool changer it becomes possible to have an outline head and a fill head. This approach probably has the best ROI of any of the above methods. Aside from the actual (minimal) cost of the new head the cost in software complexity would be the main problem; each slice would need to be broken into outline and narrow areas (first pass) and then wide fill areas. Also some provision would need to be made to compensate for or prevent the nozzles cooling while not in use.

The current method for dealing with large areas is to use cross hatching and fill the area with mesh rather than solid plastic. Reports are that 50% mesh coverage is as strong and stiff as complete infill. Obviously any new toolhead should take this into account.

|

Re: Extruder Rate (request for crackpot ideas) November 29, 2007 11:34AM |

Registered: 16 years ago Posts: 622 |

BDolge,

I agree on all but one point. The software complexity issue for multiple heads isn't as hard as it could be. Once the problem has been solved once, we just copy the result and others don't have that problem. Even if we wanted to extend the system, once we have solved the general case it ceases to be that much of an issue for the future even if we mess with the design. Multiple print heads is the way to go.

Think about a line of extruder nozzles placed on a rotating head so that you could change the orientation of the line with respect to its translation in the x-y plane so that you can do interesting--quick--fill patterns and multiple layer laydown simultaneously. That would require quite a bit of software solving but it should be doable.

Demented

I agree on all but one point. The software complexity issue for multiple heads isn't as hard as it could be. Once the problem has been solved once, we just copy the result and others don't have that problem. Even if we wanted to extend the system, once we have solved the general case it ceases to be that much of an issue for the future even if we mess with the design. Multiple print heads is the way to go.

Think about a line of extruder nozzles placed on a rotating head so that you could change the orientation of the line with respect to its translation in the x-y plane so that you can do interesting--quick--fill patterns and multiple layer laydown simultaneously. That would require quite a bit of software solving but it should be doable.

Demented

|

Re: Extruder Rate (request for crackpot ideas) November 29, 2007 09:49PM |

Registered: 17 years ago Posts: 32 |

You asked for crackpot....

It seems to me the limiting factor on an extruder nozzle is its dimensionality. The tip of an extruder has (fractally speaking) nearly a dimension of zero, a single point.

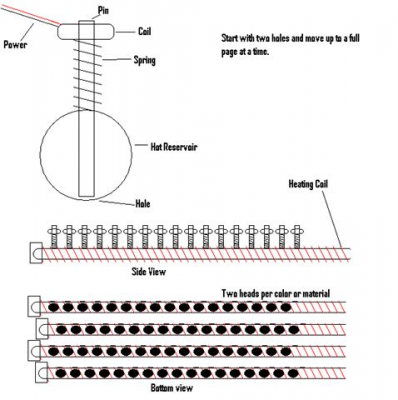

So how about you stretch out the extruder, making it a line instead? A wide, thin nozzle like those used by cake decorators to make flower petals. That way you could lay down much more line at once. By placing movable blockers, solenoid pins for instance you could split or narrow the extruded ribbon. A single point extrusion would just be a subset of the possible extrusion settings.

Of course, this would entail changes to the software, extra hardware to drive the solenoid pins, precision issues and a new method for driving the plastic down into the now linear heating area of the head.

The Guy

It seems to me the limiting factor on an extruder nozzle is its dimensionality. The tip of an extruder has (fractally speaking) nearly a dimension of zero, a single point.

So how about you stretch out the extruder, making it a line instead? A wide, thin nozzle like those used by cake decorators to make flower petals. That way you could lay down much more line at once. By placing movable blockers, solenoid pins for instance you could split or narrow the extruded ribbon. A single point extrusion would just be a subset of the possible extrusion settings.

Of course, this would entail changes to the software, extra hardware to drive the solenoid pins, precision issues and a new method for driving the plastic down into the now linear heating area of the head.

The Guy

|

Re: Extruder Rate (request for crackpot ideas) November 30, 2007 12:44AM |

Registered: 16 years ago Posts: 161 |

Demented:

I was thinking in terms of several independently moving heads writing different parts of a piece at the same time. In that sort of situation keeping the heads out of each others way would be VERY tricky and hardware dependent.

I have been thinking about infill heads, they would definitely be good areas for 2nd or 3rd stage development. My idea is similar to yours involving 3 or 5 nozzles in a line, spaced to provide 50% coverage (ie .5mm nozzles .5 mm apart), possibly fed by a single heater, mounted on a platform that can rotate 135 degrees. This rotation would allow it to lay down 3 (or 5) lines of plastic parallel to the direction of head travel regardless of what that direction was, so you could create meshes either aligned with the x-y axis or 45 degrees to it.

I'm not sure I want to get as dynamic with the head as you seem to however. My plan would involve software that, if the infill head was specified (either by the model or the user), would modify the way the outline head drew the boundaries, using it to create a series of "steps" on the inside of the boundary, each one infill head across and aligned with the tool path used to create the crosshatch. Then the infill tool would simply line up with these steps and lay down a series of parallel lines. Solid areas would be created by going back over the same area on an offset path (ie .5mm left). Small areas would be infilled with the outline (single) nozzle.

You seem to be talking about dynamically following the curves etc. of the outline by rotating the nozzle bar while the printhead travels. While this is certainly possible I would tend to favor a system design that emphasizes simplicity, even at some costs in capability. The design I am thinking of (head orientation set at the beginning of a straight move and maintained throughout that move) would allow you to orient the printhead with only 4 pieces of info (xrate,yrate,xdir,ydir) provided once per move. All the calculations and controls could be done by a pic on the printhead. The dynamic printhead, on the other hand, would have to be under continuous control from the central PC even when performing simple moves. This makes the comms function much more critical while increasing bandwidth demands. By keeping the computational load low and modularizing most functions in the toolhead it becomes a simple matter to add new tools to a given machine or to the RepRap family, not to mention the increased ease of writing and maintaining software.

Also, the current software processes slices by tracing an outline and then filling it with straight lines of x width. This is all fairly simple stuff. Creating software to generate infill patterns based on variable line widths between x and z constrained by the rate of width and orientation change relative to tool speed is not going to be simple. I believe simplicity should be a key goal for this project. The ultimate goal, as I understand it is to give everyone access to a tool which allows them to create the means of their own life without unsought dependence. Thus the tool must be as robust and user serviceable as possible.

I was thinking in terms of several independently moving heads writing different parts of a piece at the same time. In that sort of situation keeping the heads out of each others way would be VERY tricky and hardware dependent.

I have been thinking about infill heads, they would definitely be good areas for 2nd or 3rd stage development. My idea is similar to yours involving 3 or 5 nozzles in a line, spaced to provide 50% coverage (ie .5mm nozzles .5 mm apart), possibly fed by a single heater, mounted on a platform that can rotate 135 degrees. This rotation would allow it to lay down 3 (or 5) lines of plastic parallel to the direction of head travel regardless of what that direction was, so you could create meshes either aligned with the x-y axis or 45 degrees to it.

I'm not sure I want to get as dynamic with the head as you seem to however. My plan would involve software that, if the infill head was specified (either by the model or the user), would modify the way the outline head drew the boundaries, using it to create a series of "steps" on the inside of the boundary, each one infill head across and aligned with the tool path used to create the crosshatch. Then the infill tool would simply line up with these steps and lay down a series of parallel lines. Solid areas would be created by going back over the same area on an offset path (ie .5mm left). Small areas would be infilled with the outline (single) nozzle.

You seem to be talking about dynamically following the curves etc. of the outline by rotating the nozzle bar while the printhead travels. While this is certainly possible I would tend to favor a system design that emphasizes simplicity, even at some costs in capability. The design I am thinking of (head orientation set at the beginning of a straight move and maintained throughout that move) would allow you to orient the printhead with only 4 pieces of info (xrate,yrate,xdir,ydir) provided once per move. All the calculations and controls could be done by a pic on the printhead. The dynamic printhead, on the other hand, would have to be under continuous control from the central PC even when performing simple moves. This makes the comms function much more critical while increasing bandwidth demands. By keeping the computational load low and modularizing most functions in the toolhead it becomes a simple matter to add new tools to a given machine or to the RepRap family, not to mention the increased ease of writing and maintaining software.

Also, the current software processes slices by tracing an outline and then filling it with straight lines of x width. This is all fairly simple stuff. Creating software to generate infill patterns based on variable line widths between x and z constrained by the rate of width and orientation change relative to tool speed is not going to be simple. I believe simplicity should be a key goal for this project. The ultimate goal, as I understand it is to give everyone access to a tool which allows them to create the means of their own life without unsought dependence. Thus the tool must be as robust and user serviceable as possible.

|

Re: Extruder Rate (request for crackpot ideas) November 30, 2007 01:56AM |

Registered: 16 years ago Posts: 622 |

BDolge,

I agree about simplicity--especially in this first iteration. However, for the machine to evolve, it must get more complex. For the machine to be useful, it must become more capable, faster, and more efficient. All of these criteria lead to greater computational demand at the very least. I think keeping mechanical designs simple is a must simply from a maintenance point of view. Code, however, is something different. It only takes one smart/capable person to solve the hard problem and an army of the rest of us to tweak it into something usable and stable. From there, it is easy to copy, install, and run. Maybe I'm too optimistic.

Demented

I agree about simplicity--especially in this first iteration. However, for the machine to evolve, it must get more complex. For the machine to be useful, it must become more capable, faster, and more efficient. All of these criteria lead to greater computational demand at the very least. I think keeping mechanical designs simple is a must simply from a maintenance point of view. Code, however, is something different. It only takes one smart/capable person to solve the hard problem and an army of the rest of us to tweak it into something usable and stable. From there, it is easy to copy, install, and run. Maybe I'm too optimistic.

Demented

|

Re: Extruder Rate (request for crackpot ideas) November 30, 2007 01:46PM |

Registered: 16 years ago Posts: 447 |

TheGuy Wrote:

> So how about you stretch out the extruder, making

> it a line instead? A wide, thin nozzle like those

> used by cake decorators to make flower petals.

> That way you could lay down much more line at

> once. By placing movable blockers, solenoid pins

> for instance you could split or narrow the

> extruded ribbon. A single point extrusion would

> just be a subset of the possible extrusion

> settings.

So, a sort of dot-matrix extruder? Might be interesting to see in action. Your feed rate would have to vary according to the number of active pins. But, as long as you had a cheap way to block the flow, it'd be a relatively inexpensive way to multiply up the extrusion rate.

> So how about you stretch out the extruder, making

> it a line instead? A wide, thin nozzle like those

> used by cake decorators to make flower petals.

> That way you could lay down much more line at

> once. By placing movable blockers, solenoid pins

> for instance you could split or narrow the

> extruded ribbon. A single point extrusion would

> just be a subset of the possible extrusion

> settings.

So, a sort of dot-matrix extruder? Might be interesting to see in action. Your feed rate would have to vary according to the number of active pins. But, as long as you had a cheap way to block the flow, it'd be a relatively inexpensive way to multiply up the extrusion rate.

|

Re: Extruder Rate (request for crackpot ideas) November 30, 2007 02:52PM |

Registered: 16 years ago Posts: 447 |

See, the reason I'm thinking along these lines is that, given the current extrusion rate, it would take 5 days of continuous extrusion (not counting breaks) to produce all of the rp parts for a RepRap. That's based on the parts being roughly 1000cc and an extrusion cross-section of 0.25 square mm.

The RepRap build volume is a 30 cm cube. Just for fun, I calculated the time it would take to fill that with plastic. I came up with 4 months.

I hope I'm doing these calculations right. If not, feel free to correct them.

Of course, you'd never actually make a 1-foot cube but it does underscore the extrusion rate as the limiting factor.

Now, a typical desktop pen plotter could do about 300 mm/s. If you could pump the plastic that fast, the build times would drop to 4 hours for the rp parts kit and 4 days for the 1-foot cube.

The RepRap build volume is a 30 cm cube. Just for fun, I calculated the time it would take to fill that with plastic. I came up with 4 months.

I hope I'm doing these calculations right. If not, feel free to correct them.

Of course, you'd never actually make a 1-foot cube but it does underscore the extrusion rate as the limiting factor.

Now, a typical desktop pen plotter could do about 300 mm/s. If you could pump the plastic that fast, the build times would drop to 4 hours for the rp parts kit and 4 days for the 1-foot cube.

|

Re: Extruder Rate (request for crackpot ideas) November 30, 2007 02:57PM |

"Seems like the limiting factor on the RepRap -- on any FDM machine -- is the extrusion rate."

Not sure I would agree. Extrusion rate becomes a practical limit at some size of object, but right now RepRap's output is very primitive even when the object does not take an unacceptably long time to extrude. Right now it seems to me that the quality, precision, and durability of the extruded outputs are a far more crucial issue. If it can't make good small objects slowly, there really isn't much point to making poor large objects rapidly.

Not sure I would agree. Extrusion rate becomes a practical limit at some size of object, but right now RepRap's output is very primitive even when the object does not take an unacceptably long time to extrude. Right now it seems to me that the quality, precision, and durability of the extruded outputs are a far more crucial issue. If it can't make good small objects slowly, there really isn't much point to making poor large objects rapidly.

|

Re: Extruder Rate (request for crackpot ideas) November 30, 2007 04:00PM |

Admin Registered: 17 years ago Posts: 1,487 |

i agree with colin: we need to figure out how to reliably, and repeatably create small objects. only after that should we focus on speeding up that process.

however, once we do get to the point where we can reliably print things, then we should really focus on getting that print time down. that is what will really help us spread our project.

however, once we do get to the point where we can reliably print things, then we should really focus on getting that print time down. that is what will really help us spread our project.

|

Re: Extruder Rate (request for crackpot ideas) December 01, 2007 12:54AM |

Registered: 16 years ago Posts: 161 |

Hi DC,

Yes and no on the complexity issue. Certainly increasing complexity goes along with increasing capability (assuming other capabilities are not traded off) but there are ways to manage complexity and decrease it's potential damage. The trick is they need to be implemented at the beginning if they are to be really effective. That's why I want to have these discussions now.

The most effective way to decrease complexity is to decrease capability. While it may get me branded a heretic, I think this is a method worth considering. If doubling the complexity of RepRap would make it 10 times faster than at present I would be for it. But if doubling the speed after that required making it ten times as complex I would be opposed. (This is not an uncommon pattern, large improvements are cheap at first, but later even small gains are costly.) Do we want RepRap to work with non-thermoplastics? subtractively as well as additively? should it include a 3D scanner? a dishwasher?

The most efficient way to manage complexity is modularity. This is the approach I am pushing most for software (an area in which I admit I am little actual help, all my real coding was done in BASIC twenty years ago.) Consider the virtues of Linux, which I am told is highly modular, stable, maintainable, and otherwise virtuous (I just know it runs on my antique machinery), as opposed to Windows which originated as a monolithic chunk of code, gained power and flexibility from the lack of boundaries between processes but quickly became unstable, occult, and an icon of tech failure. If the smart/capable people write clean code which does specific things effectively and plays well with others, then yes, complex code is OK and easily payed for in terms of capability. Sloppy code on the other hand, will kill this project faster than sloppy bearings.

The best way to maintain modularity in this software is, I think, to maintain the link between software and hardware. Thus the cartesian machine should move the printhead around with as little interest in what the head is doing as possible. All it needs to know is that the printhead needs to move from here to there within these parameters (min/max speed) and that it is ready to do so. If the head wants to do things like exchange information with the slice handling program, the cartesian machine just passes it through. The cartisian machine simply follows the paths given it by the slice handling routine/machine. This generates paths and selects tools based on the model it is given and data it has regarding available tools and materials. It does not care how fast material 3 is laid down or whether it is plastic or solder. The tool/printhead doesn't care where it is or what it is making it just wants to know when to print and when to stop. While all of these routines might pass messages back and forth, the more discrete the processes remain the more stable, and understandable the code will remain. To the point of this thread, a printhead which dynamically reconfigures its' width and flow rate in response to the path it is following and the purpose of the part being printed would be nifty and possibly have many advantages over a set of 2 or 3 heads each of which does one particular thing, but it would also require very complex code interlocking lots of processes which would be vastly more likely to fail inexplicably.

P.S. I understand that in an open source effort like this nothing can stop someone from making arbitrarily complex code, tools, etc. and that in the long run this is a virtue. I also feel that community norms and practices can have a huge effect on the way things are done and the outcomes that are accepted. Finally I believe that this project could be world changing in it's implications or it could be a pointless geek toy. Which it will be depends not only on it's capability but its' widespread adoption. Capability will only increase over time, but for adoption there is often an early window that is make or break, and adoption is largely a function of user experience, and that means reliability and ease of use.

Yes and no on the complexity issue. Certainly increasing complexity goes along with increasing capability (assuming other capabilities are not traded off) but there are ways to manage complexity and decrease it's potential damage. The trick is they need to be implemented at the beginning if they are to be really effective. That's why I want to have these discussions now.

The most effective way to decrease complexity is to decrease capability. While it may get me branded a heretic, I think this is a method worth considering. If doubling the complexity of RepRap would make it 10 times faster than at present I would be for it. But if doubling the speed after that required making it ten times as complex I would be opposed. (This is not an uncommon pattern, large improvements are cheap at first, but later even small gains are costly.) Do we want RepRap to work with non-thermoplastics? subtractively as well as additively? should it include a 3D scanner? a dishwasher?

The most efficient way to manage complexity is modularity. This is the approach I am pushing most for software (an area in which I admit I am little actual help, all my real coding was done in BASIC twenty years ago.) Consider the virtues of Linux, which I am told is highly modular, stable, maintainable, and otherwise virtuous (I just know it runs on my antique machinery), as opposed to Windows which originated as a monolithic chunk of code, gained power and flexibility from the lack of boundaries between processes but quickly became unstable, occult, and an icon of tech failure. If the smart/capable people write clean code which does specific things effectively and plays well with others, then yes, complex code is OK and easily payed for in terms of capability. Sloppy code on the other hand, will kill this project faster than sloppy bearings.

The best way to maintain modularity in this software is, I think, to maintain the link between software and hardware. Thus the cartesian machine should move the printhead around with as little interest in what the head is doing as possible. All it needs to know is that the printhead needs to move from here to there within these parameters (min/max speed) and that it is ready to do so. If the head wants to do things like exchange information with the slice handling program, the cartesian machine just passes it through. The cartisian machine simply follows the paths given it by the slice handling routine/machine. This generates paths and selects tools based on the model it is given and data it has regarding available tools and materials. It does not care how fast material 3 is laid down or whether it is plastic or solder. The tool/printhead doesn't care where it is or what it is making it just wants to know when to print and when to stop. While all of these routines might pass messages back and forth, the more discrete the processes remain the more stable, and understandable the code will remain. To the point of this thread, a printhead which dynamically reconfigures its' width and flow rate in response to the path it is following and the purpose of the part being printed would be nifty and possibly have many advantages over a set of 2 or 3 heads each of which does one particular thing, but it would also require very complex code interlocking lots of processes which would be vastly more likely to fail inexplicably.

P.S. I understand that in an open source effort like this nothing can stop someone from making arbitrarily complex code, tools, etc. and that in the long run this is a virtue. I also feel that community norms and practices can have a huge effect on the way things are done and the outcomes that are accepted. Finally I believe that this project could be world changing in it's implications or it could be a pointless geek toy. Which it will be depends not only on it's capability but its' widespread adoption. Capability will only increase over time, but for adoption there is often an early window that is make or break, and adoption is largely a function of user experience, and that means reliability and ease of use.

|

Re: Extruder Rate (request for crackpot ideas) December 01, 2007 07:54PM |

BDolge makes an interesting point about user experience.

It is easy to get people excited about something that is inherently exciting. The Wright brothers sold out stadiums to see their plane fly, but when they were pedaling scale models around tied to the handlebars of their bicycles, they were a couple of weirdos. Now, of course, it makes perfect sense, but in their time, steam boilers connected to flapping wings seemed more plausible to many.

The Wrights understood that successful flight required the successful integration of several distinct challenges: specifically lift, control, and power. In many ways they were not really the masters of any of these individually: they didn't invent the airfoil, their control system was quickly obsoleted by far better ones, and their engine was far from the best of its day. This is not to say they didn't innovate: they were among the first to understand propellers as wings rather than fans; a crucial insight. But, it was really their systematic refinement of each piece in turn that made them a success.

My sense is that right now there is a lot of wing-flapping going on, when what we need is a lot of dull and careful measurement. We need to understand this plastic stuff a lot better than we do, what it does as it is squeezed out the nozzle, how to bind it to a surface, how to layer it on top of itself, how it behaves as it cools. I'm not the least bit concerned about the software, because it feels to me that right now we aren't quite sure what we should be telling the software to do.

What I think is interesting in this is that a lot of science is transactional in nature--rolling thousands of marbles down thousands of ramps, as a scientist friend of mine likes to say--and this is something where a large community of enthusiasts really can foster progress. But, there needs to be leadership, there needs to be direction, or the thousand monkeys at their thousand typewriters will produce nothing.

As an open-source project, anyone is free to do as they please, but simply building a RepStrap doesn't really do anything to bring us closer to the finish line than watching Star Trek helps to figure out how to travel faster than light. It is, however, the first step down that road.

It is easy to get people excited about something that is inherently exciting. The Wright brothers sold out stadiums to see their plane fly, but when they were pedaling scale models around tied to the handlebars of their bicycles, they were a couple of weirdos. Now, of course, it makes perfect sense, but in their time, steam boilers connected to flapping wings seemed more plausible to many.

The Wrights understood that successful flight required the successful integration of several distinct challenges: specifically lift, control, and power. In many ways they were not really the masters of any of these individually: they didn't invent the airfoil, their control system was quickly obsoleted by far better ones, and their engine was far from the best of its day. This is not to say they didn't innovate: they were among the first to understand propellers as wings rather than fans; a crucial insight. But, it was really their systematic refinement of each piece in turn that made them a success.

My sense is that right now there is a lot of wing-flapping going on, when what we need is a lot of dull and careful measurement. We need to understand this plastic stuff a lot better than we do, what it does as it is squeezed out the nozzle, how to bind it to a surface, how to layer it on top of itself, how it behaves as it cools. I'm not the least bit concerned about the software, because it feels to me that right now we aren't quite sure what we should be telling the software to do.

What I think is interesting in this is that a lot of science is transactional in nature--rolling thousands of marbles down thousands of ramps, as a scientist friend of mine likes to say--and this is something where a large community of enthusiasts really can foster progress. But, there needs to be leadership, there needs to be direction, or the thousand monkeys at their thousand typewriters will produce nothing.

As an open-source project, anyone is free to do as they please, but simply building a RepStrap doesn't really do anything to bring us closer to the finish line than watching Star Trek helps to figure out how to travel faster than light. It is, however, the first step down that road.

|

Re: Extruder Rate (request for crackpot ideas) December 02, 2007 04:17AM |

Registered: 16 years ago Posts: 161 |

Colin,

I think you're correct with your Wright brothers analogy, and about our need to understand our basic operating parameters, but I disagree about the usefulness of building a RepRap at this point. Each machine built is somebody else with the capability and motivation to do experiments about the way plastic acts and how to optimize code and how to integrate other materials. While I agree we need to try to stay focused on fixing the important problems first I'm not too concerned about all that random flapping. There seems to be strong agreement on where we want to go and what our central problems are, and as long as we have that we should be able to move forward effectively, if not efficiently.

I think you're correct with your Wright brothers analogy, and about our need to understand our basic operating parameters, but I disagree about the usefulness of building a RepRap at this point. Each machine built is somebody else with the capability and motivation to do experiments about the way plastic acts and how to optimize code and how to integrate other materials. While I agree we need to try to stay focused on fixing the important problems first I'm not too concerned about all that random flapping. There seems to be strong agreement on where we want to go and what our central problems are, and as long as we have that we should be able to move forward effectively, if not efficiently.

|

Re: Extruder Rate (request for crackpot ideas) December 02, 2007 06:29AM |

Admin Registered: 16 years ago Posts: 13,886 |

... a main difference to the time, when the Wright-brothers presented their planes is the actual presence of professional, fully developed 3D-RP-printers.

So the reprap isn't a really new and exciting gadget, but 'only a coarse 3D-fabber'.

This lowers a bit the excitement of the people, as some would say "Why invest time and money in this garbage-assembly, when perfect/better ones already there?"

You have to explain the possible consequences of an open-source project in respect to comercially common (proprietary) RP-systems and the enorm potential in free evolving (in an exponential growth-curve) the reprap over the next years ...

Viktor

So the reprap isn't a really new and exciting gadget, but 'only a coarse 3D-fabber'.

This lowers a bit the excitement of the people, as some would say "Why invest time and money in this garbage-assembly, when perfect/better ones already there?"

You have to explain the possible consequences of an open-source project in respect to comercially common (proprietary) RP-systems and the enorm potential in free evolving (in an exponential growth-curve) the reprap over the next years ...

Viktor

|

Re: Extruder Rate (request for crackpot ideas) December 02, 2007 11:02AM |

BDolge- sorry if I overstated things--I agree that individuals getting involve and contributing is the point, and that is my interest as well. Along with micro-manufacturing, I'm really interested in space elevators. There, however, there are not really any serious problems within the reach of amateurs, or event professionals without serious funding.

Viktor- your point about existing prototypers is valid, but when they cost as much as a new car, I think it's fairly easy to get people excited about one that costs as much as a new computer.

Viktor- your point about existing prototypers is valid, but when they cost as much as a new car, I think it's fairly easy to get people excited about one that costs as much as a new computer.

|

Re: Extruder Rate (request for crackpot ideas) December 02, 2007 11:59AM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi Colin,

... it's my experience with some individuals, i disputed about home-brewed-3D-fabbers in the last years.

They argued with 'low-cost' (actually from 15.000 to 25.000 Euros) 3D-fabbers, already present in the market - as the EZPrinter (LOM), the printers from Dimension-printing, ZCorp and so on, which output 'perfect and usable' parts.

Another counter-argument was the 'ready-to-assemble' kits from fab@home for 2.500USD, so for wealthier people the reprap-project is a bit like 'kid-work' as some scool-projects.

My argument, that with a bit time, experience and evolving this would overcome some limitations, actual 3D-RP-sstems have (free materials or so), mostly isn't interesting enough - common reply: "... maybe in some years"

So i have to wait, until i have some real good results, if i want to point it out more detailed ...

Viktor

... it's my experience with some individuals, i disputed about home-brewed-3D-fabbers in the last years.

They argued with 'low-cost' (actually from 15.000 to 25.000 Euros) 3D-fabbers, already present in the market - as the EZPrinter (LOM), the printers from Dimension-printing, ZCorp and so on, which output 'perfect and usable' parts.

Another counter-argument was the 'ready-to-assemble' kits from fab@home for 2.500USD, so for wealthier people the reprap-project is a bit like 'kid-work' as some scool-projects.

My argument, that with a bit time, experience and evolving this would overcome some limitations, actual 3D-RP-sstems have (free materials or so), mostly isn't interesting enough - common reply: "... maybe in some years"

So i have to wait, until i have some real good results, if i want to point it out more detailed ...

Viktor

|

Re: Extruder Rate (request for crackpot ideas) December 02, 2007 07:39PM |

Registered: 16 years ago Posts: 622 |

I'm in agreement about the careful testing of the small bits of knowledge. We need to have some sort of organization to our testing. Say, along the lines of brute-force methods that someone else suggested--somewhere else or here!--in the forums. Say, run through every combination of parameters--in five or ten increment jumps only!--and see what a graph of the results looks like. Based on information gather of that sort we can certainly narrow down our guess and check system of fine tuning.

Demented

Demented

|

Re: Extruder Rate (request for crackpot ideas) December 03, 2007 02:57AM |

Registered: 16 years ago Posts: 161 |

Just a note on the (pre) existence of "affordable" fabbers. If custom manufacturing were in fact affordable to a wide base of people there would already be dozens of working RepRaps out there. The stl files for the plastic parts have been available for some time now. Anyone who can afford to can send them out to be made by any of a number of professional prototyping companies. As I recall the price was a little north of $1,500.00. Any takers?

|

Re: Extruder Rate (request for crackpot ideas) December 03, 2007 11:11PM |

"It's the materials, stupid" is my motto. I've never liked Fab@Home because I think it optimizes all the wrong things. If you want precise 3D positioning, why not buy a CNC Sherline milling machine for $1500, and use it to make a RepRap extruder? The F@H approach simply blows too much money on the wrong part of the problem.

RepRap is taking longer to build things because the FDM process is harder to master than the use of liquid resins, particularly at room-temperature. The payoff however is far larger, particularly if we can transition it to other thermoplastics like HDPE and PVC. XYZ positioning is not the problem. Software is not the problem. Materials are the problem.

I'm happy to see the move towards the molded components and even the McWire mill because to me these keep the focus where it needs to be. Actually the McWire mill is not very good as a mill but for RepRap it's plenty rigid.

RepRap is taking longer to build things because the FDM process is harder to master than the use of liquid resins, particularly at room-temperature. The payoff however is far larger, particularly if we can transition it to other thermoplastics like HDPE and PVC. XYZ positioning is not the problem. Software is not the problem. Materials are the problem.

I'm happy to see the move towards the molded components and even the McWire mill because to me these keep the focus where it needs to be. Actually the McWire mill is not very good as a mill but for RepRap it's plenty rigid.

|

Re: Extruder Rate (request for crackpot ideas) December 04, 2007 10:19AM |

Admin Registered: 17 years ago Posts: 1,487 |

i agree with you on the materials colin, but i slightly disagree that it is the *only* issue.

the other major issue is getting a standard, well documented, and *cheap* 3-axis positioning system out there. if the mcwire design succeeds, the first generation ones are going to be available for ~$400. lowering the barrier in to entry is very important when you consider that we have tons of smart people what want to work on things like laser sintering, pcb creation, etc. but dont have the skills to design their own cartesian bot (or the cash to buy a sherline)

anyway, once we have those platforms out there, the real focus will be on mastering FDM and then from there the sky is the limit.

the other major issue is getting a standard, well documented, and *cheap* 3-axis positioning system out there. if the mcwire design succeeds, the first generation ones are going to be available for ~$400. lowering the barrier in to entry is very important when you consider that we have tons of smart people what want to work on things like laser sintering, pcb creation, etc. but dont have the skills to design their own cartesian bot (or the cash to buy a sherline)

anyway, once we have those platforms out there, the real focus will be on mastering FDM and then from there the sky is the limit.

|

Re: Extruder Rate (request for crackpot ideas) December 04, 2007 10:53AM |

Registered: 16 years ago Posts: 447 |

When I think of rapid prototyping, I can't help comparing it to clay sculpture. No sculptor in their right mind would build en entire work out of tiny threads of clay. It'd take forever. What they do is rough in the general shape, then add and remove bits, refining the shape until they get the desired result.

The machine equivalent of this would be something with three heads:

1. a high-volume extruder that roughs in the general shapes

2. a low volume extruder that adds fine details

3. a milling head that removes excess material

The machine equivalent of this would be something with three heads:

1. a high-volume extruder that roughs in the general shapes

2. a low volume extruder that adds fine details

3. a milling head that removes excess material

|

Anonymous User

Re: Extruder Rate (request for crackpot ideas) December 04, 2007 11:07AM |

Try to build something like this with hollow tube or all thread. I would if I have time but I am still just buying parts for my Repstrap.

Jim

Jim

|

Re: Extruder Rate (request for crackpot ideas) December 04, 2007 09:00PM |

Registered: 16 years ago Posts: 246 |

Steve. I'm with you.

I think the best way to work in One material is four heads. One to rough, one to carve, one to add fine detail, and one to fill voids to allow for arbitrary overhangs.

Additionally, I'd modify the two working material extruder heads so they could work with five threads, not one. One thick, (relatively speaking,) head for the material, and four thin ones so loaded with pigments they barely hold together as plastic. CYMK.

Of course, that's just for making solid objects. I still want one that'll print its own motors and control microcircuits.

I think the best way to work in One material is four heads. One to rough, one to carve, one to add fine detail, and one to fill voids to allow for arbitrary overhangs.

Additionally, I'd modify the two working material extruder heads so they could work with five threads, not one. One thick, (relatively speaking,) head for the material, and four thin ones so loaded with pigments they barely hold together as plastic. CYMK.

Of course, that's just for making solid objects. I still want one that'll print its own motors and control microcircuits.

|

Re: Extruder Rate (request for crackpot ideas) December 08, 2007 09:25PM |

Registered: 17 years ago Posts: 32 |

Ok, this is far from simple or easy or cheap but it is definitely crackpot.

I'm borrowing from 4 or 5 technologies for this idea.

fluidization: [en.wikipedia.org]

plasma spraying: [en.wikipedia.org]

electrospinning: [en.wikipedia.org]

cathode-ray displays: [en.wikipedia.org]

So what you can do is, following one of several different paths to it, get your polymer into a liquid state as per the usual extrusion step but as it emerges from the nozzle you apply a powerful electrostatic field to the stream of liquid. Then using either magnets or electrodes you can steer the stream of fluid in the patterns you would normally drive the mobile extruder head. Just as a tv tube steers a stream of electrons albeit not necessarily a raster scan. The extruder head itself is stationary and a foot or so from the work piece in this scenario. Electrospinning can produce fibers of about 100 nanometer sizes so that'd be the lower limit of your line width being laid down. Flow through would have to be very rapid due to the nature of electrospinning and the material cool rate.

By using fluidizing methods to drive powder base materials one could deliver metals, solid polymers, glass or ceramics and by heating the material with plasma arcs (the carrier gas would keep the polymer from being destroyed by the high heat, see the documents) One could lay down every sort of imaginable combination of materials. I suppose one could also drive liquid thermoset mers that would polymerize in flight to the work piece.

No idea how fast this'd be. From what I understand about electrospinning I'd guess multiple kilograms per hour. With high degrees of precision controlled by well characterized technology.

The Guy

I'm borrowing from 4 or 5 technologies for this idea.

fluidization: [en.wikipedia.org]

plasma spraying: [en.wikipedia.org]

electrospinning: [en.wikipedia.org]

cathode-ray displays: [en.wikipedia.org]

So what you can do is, following one of several different paths to it, get your polymer into a liquid state as per the usual extrusion step but as it emerges from the nozzle you apply a powerful electrostatic field to the stream of liquid. Then using either magnets or electrodes you can steer the stream of fluid in the patterns you would normally drive the mobile extruder head. Just as a tv tube steers a stream of electrons albeit not necessarily a raster scan. The extruder head itself is stationary and a foot or so from the work piece in this scenario. Electrospinning can produce fibers of about 100 nanometer sizes so that'd be the lower limit of your line width being laid down. Flow through would have to be very rapid due to the nature of electrospinning and the material cool rate.

By using fluidizing methods to drive powder base materials one could deliver metals, solid polymers, glass or ceramics and by heating the material with plasma arcs (the carrier gas would keep the polymer from being destroyed by the high heat, see the documents) One could lay down every sort of imaginable combination of materials. I suppose one could also drive liquid thermoset mers that would polymerize in flight to the work piece.

No idea how fast this'd be. From what I understand about electrospinning I'd guess multiple kilograms per hour. With high degrees of precision controlled by well characterized technology.

The Guy

Sorry, only registered users may post in this forum.