Started designing an efficient Horizontal XCarriage. Looking for your experience and input

Posted by realthor

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 02, 2016 07:35AM |

Registered: 9 years ago Posts: 1,035 |

Guys, I don't get it... linear bearings (LM8UU/etc) have some play in them due to tolerances, maybe to poor construction, etc. Whether they are encased in SC housings or the longer LM[...]LUUs are used, the play is there anyway. One could use pillow block bearings or adjustable preloading bearings but both solutions are costly (costlier then LM[...]UUs anyway).

It has been suggested that printed housings don't do a good job because they can throw the axial alignment out of perfect and thus the bearings will not function correctly and will have a certain amount of binding. BUT isn't that supposed to help with the play? That error can actually remove the play all-together right? Of course this isn't an engineering way of doing things but that should work right?

I am not thinking about using that approach but am thinking about having 3 LM[...]SUUs, the shortest variety of linear bearings and preloading one of them by an axial offset, so that any play in any of the bearings is taken away. This will wear the bearings mostly on those rows of ballbearings that are pressed against the shaft but they can be rotated from time to time to even out the wear. Could this be a low cost solution?

Edited 1 time(s). Last edit at 06/02/2016 07:37AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

It has been suggested that printed housings don't do a good job because they can throw the axial alignment out of perfect and thus the bearings will not function correctly and will have a certain amount of binding. BUT isn't that supposed to help with the play? That error can actually remove the play all-together right? Of course this isn't an engineering way of doing things but that should work right?

I am not thinking about using that approach but am thinking about having 3 LM[...]SUUs, the shortest variety of linear bearings and preloading one of them by an axial offset, so that any play in any of the bearings is taken away. This will wear the bearings mostly on those rows of ballbearings that are pressed against the shaft but they can be rotated from time to time to even out the wear. Could this be a low cost solution?

Edited 1 time(s). Last edit at 06/02/2016 07:37AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 02, 2016 08:01AM |

Registered: 12 years ago Posts: 1,450 |

The Kludge* has a long and honorable tradition in engineering, sometimes working astonishingly well. The downside is that nobody pats you on the back when it works and everybody mocks you when it doesn't.

Mike

* Correctly the Kluge, named after a German engineer - Norbert Kluge 1860 -1887 who died at the hands of his brother Hans who stole all his best ideas.

Mike

* Correctly the Kluge, named after a German engineer - Norbert Kluge 1860 -1887 who died at the hands of his brother Hans who stole all his best ideas.

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 02, 2016 08:07AM |

Registered: 9 years ago Posts: 1,035 |

Quote

leadinglights

The Kludge* has a long and honorable tradition in engineering, sometimes working astonishingly well. The downside is that nobody pats you on the back when it works and everybody mocks you when it doesn't.

Mike

* Correctly the Kluge, named after a German engineer - Norbert Kluge 1860 -1887 who died at the hands of his brother Hans who stole all his best ideas.

You learn something every day. If I think of it it's so much more consuming to find "Kludge" solutions than go with the mainstream. And you're always mocked by the mainstream ...

. Most of the time they are right but some of us are just too "sideways" to comfortably go with the mainstream

. Most of the time they are right but some of us are just too "sideways" to comfortably go with the mainstream

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 02, 2016 04:43PM |

Registered: 9 years ago Posts: 1,035 |

Guys, what's your experience with XRods of different diameters? I have previously calculated that for 340mm of X rod (about 310 unsupported), 8mm Rods is enough for a bowden but that is static loads only, nothing dynamic. Now if you push it for speed then the dynamic loads are a magnitude greater than the static ones and 8mm could not be enough. I have started "porting" the XCarriage design to LM10UUs and want to get the pulse of the community regarding this.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 02, 2016 05:03PM |

Registered: 9 years ago Posts: 1,873 |

Entirely anecdotal, but prodding at my build suggests the 8mm rods are by far the weakest link. The frame is made from 1" aluminum tube with steel plate for joints and has relatively little flex in comparison. I have one bearing with detectable play, but the rest are very good. In contrast, flex in the rods for the X axis permits +- 5mm of displacement at the nozzle for modest finger pressure.*

I priced up 10 and 12mm replacements and found better deals with 12, but it does mean more weight to go along with the increased stiffness. At least with a Prusa layout rod weight is not a factor, so it's just the bearings that are an issue, but for a core XY you have to shift one of the sets of rods as well.

* ok, that's an estimate from memory, so it may be an exaggeration. But memory suggests it's really horrible.

Edited 1 time(s). Last edit at 06/02/2016 05:04PM by JamesK.

I priced up 10 and 12mm replacements and found better deals with 12, but it does mean more weight to go along with the increased stiffness. At least with a Prusa layout rod weight is not a factor, so it's just the bearings that are an issue, but for a core XY you have to shift one of the sets of rods as well.

* ok, that's an estimate from memory, so it may be an exaggeration. But memory suggests it's really horrible.

Edited 1 time(s). Last edit at 06/02/2016 05:04PM by JamesK.

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 02, 2016 06:36PM |

Registered: 9 years ago Posts: 1,035 |

Yeah I am trying to "port" the 8mm XCarriage previously shown here to 10mm rods/LM10UUs ... I will not go larger than that unless I'll do something and use 1515 or carbon fibre tube concotion

BTW: would be interested to see your machine as I also plan to use alu tube for the frame (as well as 2020 as all parts are designed with the proper holes for 2020 extrusion)

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

BTW: would be interested to see your machine as I also plan to use alu tube for the frame (as well as 2020 as all parts are designed with the proper holes for 2020 extrusion)

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 02, 2016 07:42PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 03, 2016 03:28AM |

Registered: 9 years ago Posts: 1,035 |

lol, there's no such thing  ... I like better to see WIP projects than shiny stuff. Many do. We take it for inspiration. Tha't one more reason I post my WIP designs on thingiverse, specifying that they are not tested but are there so others could get some ideas or see flaws and avoid them .. nevertheless there's power in having a large pool of projects to pick whatever one needs...

... I like better to see WIP projects than shiny stuff. Many do. We take it for inspiration. Tha't one more reason I post my WIP designs on thingiverse, specifying that they are not tested but are there so others could get some ideas or see flaws and avoid them .. nevertheless there's power in having a large pool of projects to pick whatever one needs...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

... I like better to see WIP projects than shiny stuff. Many do. We take it for inspiration. Tha't one more reason I post my WIP designs on thingiverse, specifying that they are not tested but are there so others could get some ideas or see flaws and avoid them .. nevertheless there's power in having a large pool of projects to pick whatever one needs...

... I like better to see WIP projects than shiny stuff. Many do. We take it for inspiration. Tha't one more reason I post my WIP designs on thingiverse, specifying that they are not tested but are there so others could get some ideas or see flaws and avoid them .. nevertheless there's power in having a large pool of projects to pick whatever one needs...RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 03, 2016 11:20AM |

Registered: 9 years ago Posts: 1,035 |

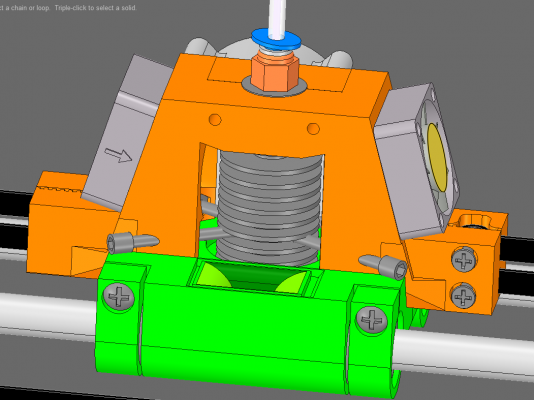

So I have re-designed my 8mm carriage and "ported" it to 10mm rods. It was quite tricky to keep the nozzle at the same spot (center of the YCarriage as well as at the YRods axis) and the belts' insertion points onto the XCarriage so I don't modify anything on the printer frame/etc.

Finally this is what the SCOUTcorexy 10mm XCarriage looks like:

The base (green) is 73mm (compared to 62mm of the 8mm flavor), the rest of the measurements are exactly the same. YCarriages have also been altered a bit to accommodate the 10mm Rods.

Here's the Sketchfab link: [sketchfab.com]

Also on thingiverse: [www.thingiverse.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Finally this is what the SCOUTcorexy 10mm XCarriage looks like:

The base (green) is 73mm (compared to 62mm of the 8mm flavor), the rest of the measurements are exactly the same. YCarriages have also been altered a bit to accommodate the 10mm Rods.

Here's the Sketchfab link: [sketchfab.com]

Also on thingiverse: [www.thingiverse.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 04, 2016 10:07AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 04, 2016 11:08AM |

Registered: 9 years ago Posts: 1,035 |

They are expensive for what I am doing. Down the road, when prices will drop 50% I will consider them.

Now I am thinking of SF-1 10mm bushings instead of the massive LM10UU. Are they really worse than LM10UU from china?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Now I am thinking of SF-1 10mm bushings instead of the massive LM10UU. Are they really worse than LM10UU from china?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 04, 2016 12:30PM |

Registered: 8 years ago Posts: 1,671 |

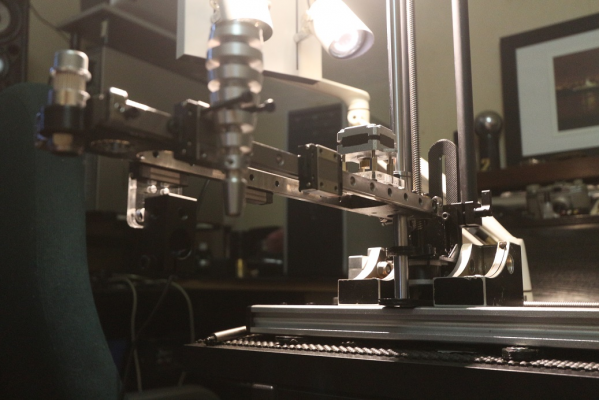

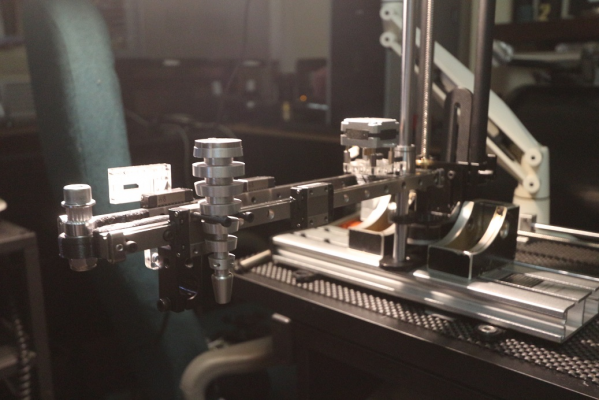

I got 3 for £60, saves a lot of work, getting them cheap is great, but even paying a little extra for them is still worth it, and because of these rails, a design that's lay dormant(crainium hemi-sync)a couple of years has started to take shape, dual x rails, 4 head, minimalistic design, not quite how the renders looked, a more evolved beast.

|

Re: Started designing an efficient Horizontal XCarriage. Looking for your experience and input June 04, 2016 03:45PM |

Registered: 9 years ago Posts: 1,035 |

It's like we are in Matrix ... looks badass.

... looks badass.

But for my SCOUTcorexy experiment I think I am going with SF-1 1012 bushings ... skipping LM10UUs altogether. I wonder if there are better variants of bushings that will keep tight tolerances and would not wear out as fast as sintered bronze bushings. But Ultimaker uses them, they must be good enough.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

... looks badass.

... looks badass.But for my SCOUTcorexy experiment I think I am going with SF-1 1012 bushings ... skipping LM10UUs altogether. I wonder if there are better variants of bushings that will keep tight tolerances and would not wear out as fast as sintered bronze bushings. But Ultimaker uses them, they must be good enough.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.