E3D V6 Nozzles are completely different from technical drawing

Posted by Sergio

|

E3D V6 Nozzles are completely different from technical drawing June 02, 2016 04:37PM |

Registered: 8 years ago Posts: 31 |

Hi all,

last year I bought a E3D Kranken with V6 Nozzles and had continuously back pressure issues that I could not really solve.

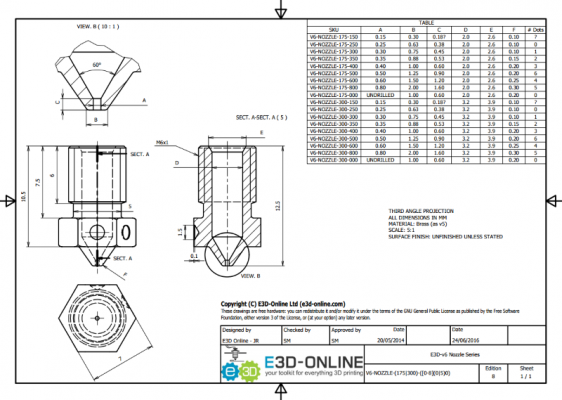

Analysing the Problem I noticed, that the inner geometry of the nozzle was different from the technical drawings, so I ordered some new ones.

The new ones did look exactly as the old ones.

It is simple to check the inner bore with a magnifying glass.

They are not made in a two-step drilling process, in fact there are manufactured in an one-step drilling process, missing the narrower bore shown in the technical drawings on the E3D-Online.com website.

I contacted E3D Online in February and they confirmed me, that the "new" V6 geometry is in fact made in a one-step drilling process and that the technical drawings are wrong.

That did surprise me a lot

I did not know that there is a "new" and an "old" V6 geometry.

I understood "old" means "as shown in the technical drawings".

I asked E3D if I could get a nozzle with the additional bore as shown in the technical drawing, but I never got an answer.

I also asked them to remove or replace the drawings, but since months nothing has happened.

I feel a little tricked by E3D, don't understand why they sell V6 nozzles that are completely different from the technical specification and description.

Maybe somebody can confirm the existence of V6 nozzles with a two step-drilling process as shown in the technical drawings.

Thought posting my findings here would maybe help other people not to do the same mistakes.

last year I bought a E3D Kranken with V6 Nozzles and had continuously back pressure issues that I could not really solve.

Analysing the Problem I noticed, that the inner geometry of the nozzle was different from the technical drawings, so I ordered some new ones.

The new ones did look exactly as the old ones.

It is simple to check the inner bore with a magnifying glass.

They are not made in a two-step drilling process, in fact there are manufactured in an one-step drilling process, missing the narrower bore shown in the technical drawings on the E3D-Online.com website.

I contacted E3D Online in February and they confirmed me, that the "new" V6 geometry is in fact made in a one-step drilling process and that the technical drawings are wrong.

That did surprise me a lot

I did not know that there is a "new" and an "old" V6 geometry.

I understood "old" means "as shown in the technical drawings".

I asked E3D if I could get a nozzle with the additional bore as shown in the technical drawing, but I never got an answer.

I also asked them to remove or replace the drawings, but since months nothing has happened.

I feel a little tricked by E3D, don't understand why they sell V6 nozzles that are completely different from the technical specification and description.

Maybe somebody can confirm the existence of V6 nozzles with a two step-drilling process as shown in the technical drawings.

Thought posting my findings here would maybe help other people not to do the same mistakes.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 07:23PM |

Registered: 9 years ago Posts: 1,873 |

You're refering to the section marked with diameter D? If so, can you estimate the length C in your nozzles? I suspect that is one of the more critical aspects of the design, and the primary purpose of the D bore is to set the length C. Length E gives you your melt volume, and it would be interesting to experiment with different values. Length C with bore diameter A are going to be the primary influencers of nozzle resistance. Short C would seem to be good for extrusion, but will reduce the lifetime of the nozzle. I would expect the length of the D bore to be relatively non-critical, which is consistent with it not being labelled on the drawing. If they've removed the D bore then I'm guessing they will have to increase length C because it's going to be too difficult to hit the same tolerances with the bigger drill. Removing D is almost certainly a cost cutting measure as it means one less operation, but will likely have increased nozzle pressure.

edit: From the table C was intended to be 2xA, a relationship which struck me as sounding "just right" when I first saw the drawing. Oh, and note that the larger bore nozzles were always single stage, as the D bore was the same as the melt chamber.

Edited 2 time(s). Last edit at 06/02/2016 07:28PM by JamesK.

edit: From the table C was intended to be 2xA, a relationship which struck me as sounding "just right" when I first saw the drawing. Oh, and note that the larger bore nozzles were always single stage, as the D bore was the same as the melt chamber.

Edited 2 time(s). Last edit at 06/02/2016 07:28PM by JamesK.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 07:33PM |

Registered: 9 years ago Posts: 517 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 08:27PM |

Registered: 13 years ago Posts: 268 |

Custom cutters get made all the time, we get them from time to time at work. Cost is not that much more than standard cutters, especially if you buy a few.Quote

ElmoC

They could also get the same two step bore with a special bit that has a cutter with both the A and D dimensions. Might be costly to get made, but could pay for itself in reduced labor.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 08:40PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 08:43PM |

Registered: 9 years ago Posts: 517 |

Quote

JamesK

Hadn't thought of that - showing my ignorance. Which does make you wonder why they simplified the design.

They might not have simplified it. If they are using a two stage cutter, the CS could have told you the truth, they are doing it in a single step. They may have thought the same way that if it was in a single step, there is only one bore diameter and thus the drawings are wrong.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 08:45PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 08:48PM |

Registered: 9 years ago Posts: 517 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 02, 2016 08:50PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 03, 2016 07:01PM |

Registered: 9 years ago Posts: 125 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 07, 2016 11:36AM |

Registered: 8 years ago Posts: 312 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 07, 2016 11:47AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 04:33AM |

Registered: 8 years ago Posts: 31 |

Sorry for my late response,

The nozzles I checked are brass 0.4.

There is no doubt on the removal of the inner smaller bore.

I have also an email from Sanjay confirming it.

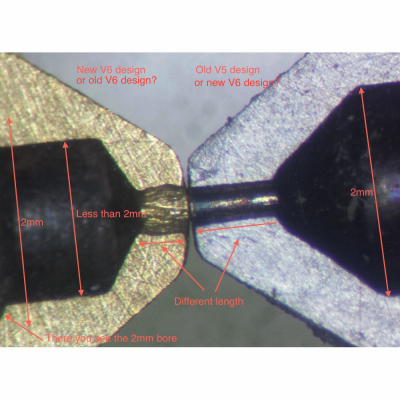

Look at the attached image taken from E3D Website with my comments.

All the new V6 brass nozzle I got from E3D look like the steel nozzle on on the right, without the second inner bore.

My questions are, why did they do it, and why is the website not updated, I told them 3 month ago and I bought my first V6 nozzle in November last year?

Is it possible to get the nozzle with the second inner bore, they exists as the picture proofs?

I got no response to these questions.

The nozzles I checked are brass 0.4.

There is no doubt on the removal of the inner smaller bore.

I have also an email from Sanjay confirming it.

Look at the attached image taken from E3D Website with my comments.

All the new V6 brass nozzle I got from E3D look like the steel nozzle on on the right, without the second inner bore.

My questions are, why did they do it, and why is the website not updated, I told them 3 month ago and I bought my first V6 nozzle in November last year?

Is it possible to get the nozzle with the second inner bore, they exists as the picture proofs?

I got no response to these questions.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 04:45AM |

Registered: 8 years ago Posts: 31 |

To JamesK:

Yes I'm referring to section D.

The Measured length of C in my nozzles seems to be 1.15mm +- 0.2.

Measured with a standard 2mm drill bit.

I bought this nozzles specially to reduce the back pressure.

In my opinion, they should say this clearly on their website, that the V6 design, they are selling now is not optimised to reduce the back pressure, as the former V6 design was as shown on the picture above was.

Yes I'm referring to section D.

The Measured length of C in my nozzles seems to be 1.15mm +- 0.2.

Measured with a standard 2mm drill bit.

I bought this nozzles specially to reduce the back pressure.

In my opinion, they should say this clearly on their website, that the V6 design, they are selling now is not optimised to reduce the back pressure, as the former V6 design was as shown on the picture above was.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 05:48AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 07:53AM |

Registered: 11 years ago Posts: 5,780 |

Sergio,

in your first post you said you had a "back-pressure problem" and in the last one you said you originally bought these nozzles specifically to reduce "back-pressure".

Three questions:

1) What constitutes a "back-pressure problem"?

2) How would anyone know that they have a "back-pressure" problem and not some other problem?

3) How does the geometric difference between the two different versions affect "back-pressure"?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

in your first post you said you had a "back-pressure problem" and in the last one you said you originally bought these nozzles specifically to reduce "back-pressure".

Three questions:

1) What constitutes a "back-pressure problem"?

2) How would anyone know that they have a "back-pressure" problem and not some other problem?

3) How does the geometric difference between the two different versions affect "back-pressure"?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 08:10AM |

Registered: 9 years ago Posts: 1,873 |

Quote

3) How does the geometric difference between the two different versions affect "back-pressure"?

That comes from standard fluid-flow physics, the pressure drop of a liquid through a tube is proportional to the length, or flipping it around, a given rate of flow will require a higher nozzle pressure for a longer tube. For printing, the length of the smallest bore in the nozzle will dominate, so the increase in length of the final bore that Sergio describes will have increased the required pressure by about 50%. The original E3D design calls for the length of the smallest bore to be twice the diameter, which is likely a nice trade-off between nozzle pressure and nozzle lifetime.

[en.wikipedia.org]

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 09:22AM |

Registered: 11 years ago Posts: 5,780 |

Does that apply to very short tubes and (presumably) high viscosity fluids?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 09:26AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 12:02PM |

Registered: 11 years ago Posts: 5,780 |

It's nice to look at the physics but without a deeper understanding of high temperature/pressure viscous fluid flow, and in the complete absence of data, a guess is just a guess.

Which brings me back to the first question: what constitutes a back pressure problem? How do you distinguish it from a too low temperature problem? Or a too low extruder push problem? Or a filament formulation problem?

If the filament won't flow, turn up the temperature to reduce viscosity and/or apply more pressure from the extruder (increased current, add a gear box, bigger motor, etc.). If that still doesn't do it, use thicker print layers and a bigger nozzle.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Which brings me back to the first question: what constitutes a back pressure problem? How do you distinguish it from a too low temperature problem? Or a too low extruder push problem? Or a filament formulation problem?

If the filament won't flow, turn up the temperature to reduce viscosity and/or apply more pressure from the extruder (increased current, add a gear box, bigger motor, etc.). If that still doesn't do it, use thicker print layers and a bigger nozzle.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 12:35PM |

Registered: 13 years ago Posts: 268 |

I've made a significant number of gates for multi cavity injection molds. Amongst many critical dimensions (lots of these are +/-.0002" or so) is the dimension being discussed here. In the particular one I'm thinking of the actual flat area of land is around .005" long and is absolutely critical to function. The length of the land of that diameter absolutely does matter in squirting molten plastic the way you want it squirted. I don't have the specific math on hand to quantify it, but simply changing pressure or temperature can't overcome the physics that happen in this particular region.Quote

the_digital_dentist

It's nice to look at the physics but without a deeper understanding of high temperature/pressure viscous fluid flow, and in the complete absence of data, a guess is just a guess.

Which brings me back to the first question: what constitutes a back pressure problem? How do you distinguish it from a too low temperature problem? Or a too low extruder push problem? Or a filament formulation problem?

If the filament won't flow, turn up the temperature to reduce viscosity and/or apply more pressure from the extruder (increased current, add a gear box, bigger motor, etc.). If that still doesn't do it, use thicker print layers and a bigger nozzle.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 12:41PM |

Registered: 9 years ago Posts: 517 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 02:55PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 03:02PM |

Registered: 9 years ago Posts: 517 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 10, 2016 03:29PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: E3D V6 Nozzles are completely different from technical drawing June 28, 2016 07:49AM |

Registered: 8 years ago Posts: 31 |

Quote

the_digital_dentist

Sergio,

in your first post you said you had a "back-pressure problem" and in the last one you said you originally bought these nozzles specifically to reduce "back-pressure".

Three questions:

1) What constitutes a "back-pressure problem"?

2) How would anyone know that they have a "back-pressure" problem and not some other problem?

3) How does the geometric difference between the two different versions affect "back-pressure"?

the_digital_dentist,

1) The best way is to feel it yourself when you push the filament by hand. The "back"-pressure builds up and if you increase the temp you will block the nozzle, because the molten plastic is pressed up the tube blocking the passage when it is high enough to cool down.

2) see 1) and you can try to change all other variables like temp or filament or force, with always the same result.

3) This is the most interesting question, but how can I test this? I cannot get the specified nozzles from E3D!

This is basically my problem.

If E3D promotes nozzles with internal geometric design, so that back pressure is reduced, why do you get the wrong ones when you order them?

I really tried hard to get ones promoted, but I had no luck.

I personally can't recommend to buy V6 nozzles from E3D, they are not what they promote.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 28, 2016 08:36AM |

Registered: 11 years ago Posts: 5,780 |

All this theorizing is great and wonderful, but in the end, it either works or it doesn't. I don't care what the profile of the nozzle is and whether it matches their engineering drawing (which may change at any time). All I care about is whether the plastic comes out when it is supposed to. I've used an E3D v6 with a BullDog XL extruder and recently installed a Lite 6 and Titan extruder on a printer. Both set-ups work fine.

If you're having trouble getting your extruder to work, maybe you're doing something wrong. Maybe the motor torque is insufficient (poor motor spec, insufficient current, etc.). Maybe the temperature in the block isn't what your printer indicates. Maybe the nozzle is clogged with debris. Maybe your filament has a higher melt temperature. Maybe you're trying to extrude too fast. How did you come to blame the nozzle profile for your extrusion troubles when there are so many other possible causes for failure?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you're having trouble getting your extruder to work, maybe you're doing something wrong. Maybe the motor torque is insufficient (poor motor spec, insufficient current, etc.). Maybe the temperature in the block isn't what your printer indicates. Maybe the nozzle is clogged with debris. Maybe your filament has a higher melt temperature. Maybe you're trying to extrude too fast. How did you come to blame the nozzle profile for your extrusion troubles when there are so many other possible causes for failure?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3D V6 Nozzles are completely different from technical drawing June 28, 2016 09:21AM |

Registered: 9 years ago Posts: 517 |

Have you actually cut one in half and inspected it? I wouldn't go by what some customer support person tells you.

As for your #1,this can happen with any nozzle. There is a maximum volume by feed rate that can be extruded for any nozzle. If you exceed that, you will get the filament creep you described. That rate can vary by design, but unless you have a way to measure it, you can't really know what it is. Pushing it through by hand is very likely going to exceed that max rate.

As for your #1,this can happen with any nozzle. There is a maximum volume by feed rate that can be extruded for any nozzle. If you exceed that, you will get the filament creep you described. That rate can vary by design, but unless you have a way to measure it, you can't really know what it is. Pushing it through by hand is very likely going to exceed that max rate.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 29, 2016 04:50AM |

Registered: 8 years ago Posts: 31 |

ElmoC,

I would not say that Sanjay is "some customer support person".

He confirmed my finding.

There is no need to cut open one.

As I said above, I have an email from him confirming that the geometry is different and on the same time telling me that the V6 has a new design without the D section and that the drawing are old.

Yes, I thought first he is joking but apparently he was not.

I would not say that Sanjay is "some customer support person".

He confirmed my finding.

There is no need to cut open one.

As I said above, I have an email from him confirming that the geometry is different and on the same time telling me that the V6 has a new design without the D section and that the drawing are old.

Yes, I thought first he is joking but apparently he was not.

|

Re: E3D V6 Nozzles are completely different from technical drawing June 29, 2016 02:51PM |

Registered: 11 years ago Posts: 5,780 |

"Reduced" is one of those magic marketing words that seems to have meaning but actually has none without something to compare. Reduced compared to some other company's nozzles? Reduced compared to a hole drilled in an acorn nut?

There are about 100 different causes for extrusion problems, but you've decided via an extremely inaccurate and imprecise test of manually pushing filament that the nozzle geometry and none of the other, more likely problems is the cause of your extrusion problem. What if, instead of saying in your first post that the nozzle geometry is causing extrusion problems for you, you described the actual problems you're experiencing, and then provide some relevant information such as the nozzle diameter, hot end, the heater power, the speed you're trying to print, layer thickness, and maybe a photo or two of the failed prints? I'll bet you'd get a lot of good answers that might help you find the real cause of the problem.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There are about 100 different causes for extrusion problems, but you've decided via an extremely inaccurate and imprecise test of manually pushing filament that the nozzle geometry and none of the other, more likely problems is the cause of your extrusion problem. What if, instead of saying in your first post that the nozzle geometry is causing extrusion problems for you, you described the actual problems you're experiencing, and then provide some relevant information such as the nozzle diameter, hot end, the heater power, the speed you're trying to print, layer thickness, and maybe a photo or two of the failed prints? I'll bet you'd get a lot of good answers that might help you find the real cause of the problem.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.