Bonding GT2 belts

Posted by leadinglights

|

Bonding GT2 belts June 03, 2016 10:02AM |

Registered: 12 years ago Posts: 1,450 |

Has anybody tried to bond GT2 belts? I want to bond two lengths of GT2 belt together and also bond some very short lengths to some aluminium. As the GT2 is supposedly made of neoprene it should bond very well with standard superglue but the bond is very weak. Guessing that there may be some surface treatment on the belt I cleaned it with isopropyl alcohol and abraded the surface but still no luck.

Mike

Mike

|

Re: Bonding GT2 belts June 03, 2016 10:09AM |

Registered: 11 years ago Posts: 5,780 |

Superglue dries hard. When the belt flexes, the glue breaks. You need an adhesive that dries flexible and sticks to rubber. Try contact cement.

I don't know if any adhesive is going to hold up when you put the belt under tension. Even if the glue holds, the belt will stretch in the location of the glued joint because the glass fibers are not attached there. That stretched joint area may cause some weird print artifacts.

If you need a closed loop belt, it's best to buy one that was manufactured that way.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't know if any adhesive is going to hold up when you put the belt under tension. Even if the glue holds, the belt will stretch in the location of the glued joint because the glass fibers are not attached there. That stretched joint area may cause some weird print artifacts.

If you need a closed loop belt, it's best to buy one that was manufactured that way.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Bonding GT2 belts June 03, 2016 10:40AM |

Registered: 12 years ago Posts: 1,450 |

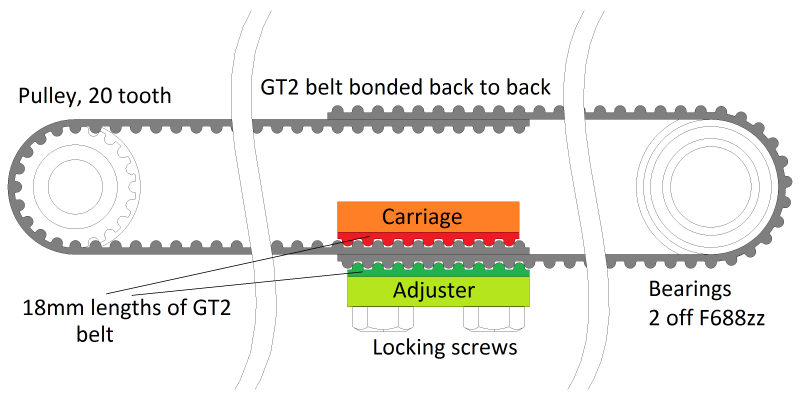

It's not for a closed belt, I normally use a twist in my belts but want to try an idea for avoiding this. As GT2 belt has a rounded profile it really needs either to go over a profiled pulley or round an idler on its back.

The GT2 to metal is so that I can adjust the belt tension in less than 2mm steps although I will probably go with machined parts instead as I am getting short of willge room for the adjuster locking screws.

Mike

The GT2 to metal is so that I can adjust the belt tension in less than 2mm steps although I will probably go with machined parts instead as I am getting short of willge room for the adjuster locking screws.

Mike

|

Re: Bonding GT2 belts June 03, 2016 10:48AM |

Registered: 8 years ago Posts: 916 |

Great idea, I might even steal it

Contact cement would be the go, or even a printed part would work just as well.

Alternatively, I've found polyurethane glue to work well where flexibility is required.

As others have said, non-flexible glues simply won't work. This rules out superglue, epoxy, and most other glues.

I'd glue the two belts so that the teeth mesh, rather than putting them back to back. This would mean that the glue is just holding them together, instead of requiring the glue to take all the belt tension.

Edited 1 time(s). Last edit at 06/03/2016 10:50AM by nebbian.

Contact cement would be the go, or even a printed part would work just as well.

Alternatively, I've found polyurethane glue to work well where flexibility is required.

As others have said, non-flexible glues simply won't work. This rules out superglue, epoxy, and most other glues.

I'd glue the two belts so that the teeth mesh, rather than putting them back to back. This would mean that the glue is just holding them together, instead of requiring the glue to take all the belt tension.

Edited 1 time(s). Last edit at 06/03/2016 10:50AM by nebbian.

|

Re: Bonding GT2 belts June 03, 2016 10:58AM |

Registered: 8 years ago Posts: 3,525 |

Why not just use a toothed idler?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bonding GT2 belts June 03, 2016 10:59AM |

Registered: 12 years ago Posts: 1,450 |

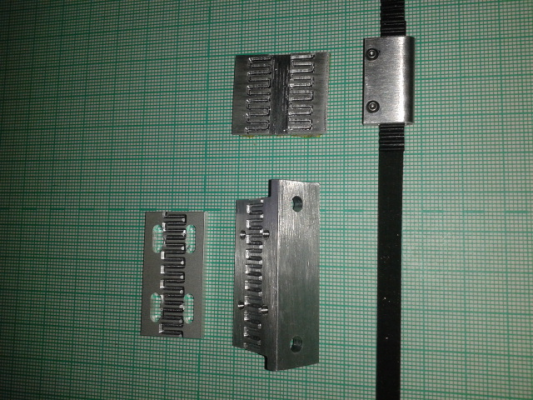

The printed part would just be extra mass. My first try after finding that superglue didn't work was to make a machined part and fold it over the belts but it is obviously too heavy.

Photo above shows the adjuster parts as well as the try at a joining piece. The wiggly line is cut with a repurposed PCB engraving tool cut short to give the trapezoidal profile.

Mike

Photo above shows the adjuster parts as well as the try at a joining piece. The wiggly line is cut with a repurposed PCB engraving tool cut short to give the trapezoidal profile.

Mike

|

Re: Bonding GT2 belts June 03, 2016 11:06AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Bonding GT2 belts June 03, 2016 12:01PM |

Registered: 13 years ago Posts: 268 |

|

Re: Bonding GT2 belts June 03, 2016 12:17PM |

Registered: 11 years ago Posts: 5,780 |

If you are going to glue, glue the two pieces with the teeth interdigitated. It will probably be a much stronger joint than gluing back to back.

You can easily clamp two pieces of GT2 together using a printed part. When you interdigitate the teeth the total thickness of the belt becomes 2.2 mm. All you need is a lightweight, U-shaped, printed clamp with a 2.2 mm slot. You won't need more than a few interdigitated teeth to hold it together under any tension you're ever going to use and you get the added advantage of being able to separate the belts easily by sliding the clamp off.

See [www.youmagine.com]

Edited 1 time(s). Last edit at 06/03/2016 12:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can easily clamp two pieces of GT2 together using a printed part. When you interdigitate the teeth the total thickness of the belt becomes 2.2 mm. All you need is a lightweight, U-shaped, printed clamp with a 2.2 mm slot. You won't need more than a few interdigitated teeth to hold it together under any tension you're ever going to use and you get the added advantage of being able to separate the belts easily by sliding the clamp off.

See [www.youmagine.com]

Edited 1 time(s). Last edit at 06/03/2016 12:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Bonding GT2 belts June 03, 2016 12:19PM |

Registered: 12 years ago Posts: 1,450 |

I have frequently used cyanoacrylate glues to bond neoprene O rings including ones that are used as drive belts - one on a tumbler is still O.K. after about 10 years. In the case of GT2 though, I don't think it will work as there is something more than neoprene - I think that it may be a matrix of neoprene, a plasticiser and a lubricant. I reached out to a contact who told me that the best bet is Scotch-Weld 80 and that he could sell me a can for £32 - a bit too much for a simple trial though. A second possibility is something called "Black Witch" which is specifically made for neoprene wet suit repair. I have ordered up a tube of that to try.

Mike

Mike

|

Re: Bonding GT2 belts June 03, 2016 12:28PM |

Registered: 12 years ago Posts: 1,450 |

Edit, Hi DD, just saw your edit. I did notice your joiner when I was searching for ideas but one of the reasons I don't want a twist is that I have run out of space for anything much more than a very compact join to pass the carriage.

The printer that I am rebuilding had interdigitated teeth of T2.5 belt and it never gave any problems. If the glue that I settle on is stronger than the belt though it will make very little difference but if not then interdigitated it will be.

Mike

Edited 1 time(s). Last edit at 06/03/2016 12:31PM by leadinglights.

The printer that I am rebuilding had interdigitated teeth of T2.5 belt and it never gave any problems. If the glue that I settle on is stronger than the belt though it will make very little difference but if not then interdigitated it will be.

Mike

Edited 1 time(s). Last edit at 06/03/2016 12:31PM by leadinglights.

|

Re: Bonding GT2 belts June 03, 2016 02:27PM |

Registered: 12 years ago Posts: 1,450 |

Quote

Koko76

Check Loctite's website. They have several CA formulas optimized specifically for rubber, higher peel strength and higher flexibility. They work OK.

After lots of browsing, Loctite 480 looks promising although at from £12 to £35 for a small bottle perhaps a little pricey.

Mike

|

Re: Bonding GT2 belts June 03, 2016 03:46PM |

Registered: 9 years ago Posts: 1,873 |

In your diagram, if the join and the carriage are on diametrically opposite sides of the loop then the join will never pass over the pulleys and there will be no concern with flexibility of the glue (as indeed there could not be if you used a printed or machined joint).

Edited 1 time(s). Last edit at 06/03/2016 03:48PM by JamesK.

Edited 1 time(s). Last edit at 06/03/2016 03:48PM by JamesK.

|

Re: Bonding GT2 belts June 03, 2016 04:05PM |

Registered: 9 years ago Posts: 1,035 |

I seen this on thingiverse yesterday and liked it... so it was an easy re-find: [www.thingiverse.com]

I agree with d_d on the extra elasticity of the flexible glue you are going tu use... it will basically introduce in the belt the very thing they are good at.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I agree with d_d on the extra elasticity of the flexible glue you are going tu use... it will basically introduce in the belt the very thing they are good at.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Bonding GT2 belts June 03, 2016 10:52PM |

Registered: 11 years ago Posts: 1,049 |

FWIW

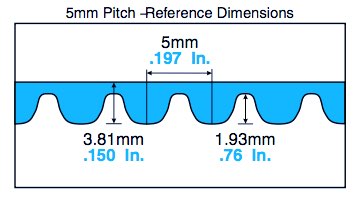

The teeth and spaces in a belt are NOT the same

so they do NOT interlock well

Gates Design Manual

[docs-europe.electrocomponents.com]

A look at construction may show what may be "glued up"

A neoprene base covering a tensile material (Fiberglass, Kevlar, etc)

neoprene molded teeth and a nylon cover over tooth surfaces, wear surface

neoprene to neoprene adhesion best with solvent that make neoprene sticky

and stick together

but

at best just glued together NOT load carrying neoprene.

Adhesive for Nylon -- that is not easy ---- flexible worse ---- ????

nylon to nylon nylon to neoprene

Thats why they don't glue together belts.

The teeth and spaces in a belt are NOT the same

so they do NOT interlock well

Gates Design Manual

[docs-europe.electrocomponents.com]

A look at construction may show what may be "glued up"

A neoprene base covering a tensile material (Fiberglass, Kevlar, etc)

neoprene molded teeth and a nylon cover over tooth surfaces, wear surface

neoprene to neoprene adhesion best with solvent that make neoprene sticky

and stick together

but

at best just glued together NOT load carrying neoprene.

Adhesive for Nylon -- that is not easy ---- flexible worse ---- ????

nylon to nylon nylon to neoprene

Thats why they don't glue together belts.

|

Re: Bonding GT2 belts June 03, 2016 11:32PM |

Registered: 9 years ago Posts: 425 |

|

Re: Bonding GT2 belts June 03, 2016 11:41PM |

Registered: 11 years ago Posts: 5,780 |

Quote

Mutley3D

why not two small cable ties?

..inelegant...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Bonding GT2 belts June 04, 2016 01:22AM |

Registered: 8 years ago Posts: 3,525 |

Elegant would be a manufactured closed loop belt with a metal toothed idler on the right side. Whilst all these other approaches will work that is the neat and long lasting way to do it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bonding GT2 belts June 04, 2016 05:15AM |

Registered: 12 years ago Posts: 1,450 |

My own personal take on elegance is that the best possible compromise is the most elegant while never compromising is both expensive and ugly.

@DjDemonD, Having a closed belt with a carriage attached creates two possible points of failure at each end of the carriage mount. As the same two points exist why not use the space between for a tension adjuster? As far as the toothed idler goes, the portion of belt which only runs over the idler is only a tension member so could be replaced with toothless belt - since that is not available then the smooth side of the belt will do just as well.

@Mutley3D, Holding a bearing like an LM8UU in a firm mounting with two cable ties is as good as mounting it in a titanium ultrastrongium alloy pillow block up to the point of the preload on the cable ties (say 10 lbs) That is the kind of kludge that I really like. Having said that, cable ties on belt -- nah, it doesn't turn me on.

@cozmicray, As you point out, the interlock is not great with GT2 although 2mm GT2 is much closer than the 5mm that your diagram shows. As far as I can make out with a microscope, the 2mm GT2 that I have got has no nylon on the tooth surface but the neoprene does not seem to be homogeneous but granular.

As far as gluing things together, I used to glue the wings of passenger aircraft together in the 1960s so I have no problem with gluing toothed belt together as long as it is the right glue.

The compromises that I need to make are:-

Mike

@DjDemonD, Having a closed belt with a carriage attached creates two possible points of failure at each end of the carriage mount. As the same two points exist why not use the space between for a tension adjuster? As far as the toothed idler goes, the portion of belt which only runs over the idler is only a tension member so could be replaced with toothless belt - since that is not available then the smooth side of the belt will do just as well.

@Mutley3D, Holding a bearing like an LM8UU in a firm mounting with two cable ties is as good as mounting it in a titanium ultrastrongium alloy pillow block up to the point of the preload on the cable ties (say 10 lbs) That is the kind of kludge that I really like. Having said that, cable ties on belt -- nah, it doesn't turn me on.

@cozmicray, As you point out, the interlock is not great with GT2 although 2mm GT2 is much closer than the 5mm that your diagram shows. As far as I can make out with a microscope, the 2mm GT2 that I have got has no nylon on the tooth surface but the neoprene does not seem to be homogeneous but granular.

As far as gluing things together, I used to glue the wings of passenger aircraft together in the 1960s so I have no problem with gluing toothed belt together as long as it is the right glue.

The compromises that I need to make are:-

- The pulley and the bearing have to be the same size or at least present the belt parallel to a line drawn between the axes of the motor and idler. The solution I have used does keep the belt very close to parallel using a 20 tooth GT2 pulley and F688Z bearings.

- A good tension adjuster is worth having as there are conflicts between the working loads of the belt and the stepper motor. The maximum working radial load on the stepper motor that I have is 28N, about 6lbs, Optimum working load for 6mm wide GT2 is also about 6lbs but two sides = 12 lbs. It is better to reduce the load per side to 3 lbs. I don't know what the step change in load is with just moving up a notch but it feels like a lot more than 3lbs.

- A brittle adhesive, like simple cyanoacrylate superglues is probably better bonded with no gap over a single area but multiple points can unzip after the first failure. Gap filling adhesives are a different matter.

- Gluing is better than a mechanical joiner as the join has to go close to multiple parts on the carriage. The closest gap is 5mm with a glued joint but room for a bit of flappage (??) should be allowed - even a metal joiner can nearly halve the gap.

Mike

|

Re: Bonding GT2 belts June 07, 2016 11:06AM |

Registered: 12 years ago Posts: 1,450 |

I received a tube of "Black Witch" neoprene contact cement and have tried it on GT2 belt for a back to back bond. The first trials were not very promising but with a bit of trial and error I believe that the bond is now as strong as the belt.

The necessary step was to scrupulously clean the belt as it seems to have a waxy substance as part of the make up of the neoprene. Simple abrasion didn't make much difference but 5 minutes of immersion of the ends of the belt in isopropyl alcohol followed by hot soapy water and then abrasion of the bonding surface seems to be O.K.. The early attempts appeared to be very strong against a pull (manual only, possibly about 30 to 40kg_ but could be peeled apart easily with the fingernails. The cleaned and roughened belt cannot be peeled apart with any reasonable persuasion.

A picture of the bonded belt and adjuster on one of the carriages of a Rostock printer.

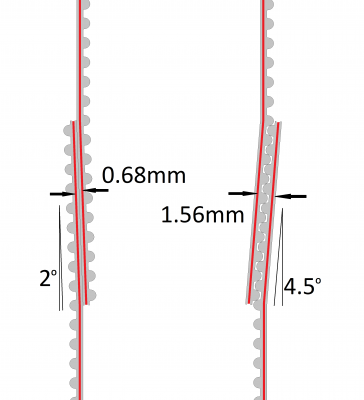

A drawing of why I don't like the idea of bonding tooth to tooth on the belt. Note that the scarf is at more than twice the angle on the tooth to tooth and the separation of the reinforcing cables is much greater.

I did try a very perfunctory trial of two short lengths bonded tooth to tooth but it failed with only a very light pull. The reason for failure was more likely to be that it is difficult to clean and that perfect mating with a contact type adhesive is difficult because of the teeth.

Mike

The necessary step was to scrupulously clean the belt as it seems to have a waxy substance as part of the make up of the neoprene. Simple abrasion didn't make much difference but 5 minutes of immersion of the ends of the belt in isopropyl alcohol followed by hot soapy water and then abrasion of the bonding surface seems to be O.K.. The early attempts appeared to be very strong against a pull (manual only, possibly about 30 to 40kg_ but could be peeled apart easily with the fingernails. The cleaned and roughened belt cannot be peeled apart with any reasonable persuasion.

A picture of the bonded belt and adjuster on one of the carriages of a Rostock printer.

A drawing of why I don't like the idea of bonding tooth to tooth on the belt. Note that the scarf is at more than twice the angle on the tooth to tooth and the separation of the reinforcing cables is much greater.

I did try a very perfunctory trial of two short lengths bonded tooth to tooth but it failed with only a very light pull. The reason for failure was more likely to be that it is difficult to clean and that perfect mating with a contact type adhesive is difficult because of the teeth.

Mike

|

Re: Bonding GT2 belts April 30, 2020 05:40AM |

Registered: 12 years ago Posts: 1,450 |

Revisiting an old thread form 2016. These belts have been in use now for almost 4 years.

Having time on my hands and looking for something to do I replaced the belts mentioned above then pulled a 600mm length with the join in the middle until it broke - the failure was in the belt, not the joint.

In 2016 I did try the same test with both interdigitated and back to back joints and found that the back to back joints never failed at the joint but the interdigitated ones sometimes un-zipped with the last few teeth shearing off.

Mike

Edited 1 time(s). Last edit at 04/30/2020 10:32AM by leadinglights.

Having time on my hands and looking for something to do I replaced the belts mentioned above then pulled a 600mm length with the join in the middle until it broke - the failure was in the belt, not the joint.

In 2016 I did try the same test with both interdigitated and back to back joints and found that the back to back joints never failed at the joint but the interdigitated ones sometimes un-zipped with the last few teeth shearing off.

Mike

Edited 1 time(s). Last edit at 04/30/2020 10:32AM by leadinglights.

|

Re: Bonding GT2 belts May 01, 2020 02:43AM |

Registered: 9 years ago Posts: 483 |

A toothed pulley with an 8mm bore, several MF85zz bearings, and a 5mm shoulder bolt would be simpler

|

Re: Bonding GT2 belts May 01, 2020 06:22AM |

Registered: 12 years ago Posts: 1,450 |

Quote

etfrench

A toothed pulley with an 8mm bore, several MF85zz bearings, and a 5mm shoulder bolt would be simpler

I disagree. A dab of glue is cheaper, simpler, stronger and lighter - and very acceptably reliable

Mike

|

Re: Bonding GT2 belts May 01, 2020 06:46AM |

Registered: 11 years ago Posts: 5,780 |

Can you be specific about exacly what type of glue you used? All the cyanoacrylate glue I've ever used crumbles into dust when you put it on something flexible and then flex it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Bonding GT2 belts May 01, 2020 07:47AM |

Registered: 12 years ago Posts: 1,450 |

I used "Black Witch". This is a Neoprene contact glue intended for wet suits. It does seem to be important that the substance does not have any lubricant in it as some of the rubber-based belts seem to have a granular wax mixed in with the rubber. The back of the belts I used seemed not to have lubricant on the backs so glued well. The "unzipping" mentioned above in the tooth to tooth glueing may have had a lot to do with lubricant in the rubber mix.

Mike

Mike

|

Re: Bonding GT2 belts May 01, 2020 08:12AM |

Registered: 6 years ago Posts: 1,007 |

Quote

the_digital_dentist

Can you be specific about exacly what type of glue you used? All the cyanoacrylate glue I've ever used crumbles into dust when you put it on something flexible and then flex it.

As explained a few years back about GT2 splicing, I use the Black flexible Loctite cyanoacrylate to bond these GT2 belts. This kind of glue is also used to make specific O rings from chord. Far superior to neoprene glue.

Works for rubber boots too

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Bonding GT2 belts May 01, 2020 09:58AM |

Registered: 12 years ago Posts: 1,450 |

I think I did try a flexible cyanoacrylate, not Loctite and not black, but it was not as good as the Black Witch: The cyanoacrylate may be stronger but was noticeably less flexible and the adhered area is so large that ultimate strength is less important. I have used cyanoacrylate to bond 'O' rings, including drive belts, but the lubricant in the rubber of toothed belts (at least the brand I use) made it less reliable on these.

Mike

Mike

|

Re: Bonding GT2 belts February 13, 2022 10:34PM |

Registered: 6 years ago Posts: 61 |

I needed to make a continuous loop for a laser Z stage that was larger than I could buy as a manufactured continuous loop. I ended up with a flexible CA glue (IC-2000) and a technique that worked very well. It bonds the cords together and runs fine through pulleys.

It is perhaps imperfect due to interdigitation being inconsistent from the tooth and gap profiles being different, but in practice it seems to line up very well.

I ended up making a 3D-printed tool for doing the splices.

[gitlab.com]

Pictures of a variant of the tool in use splicing some 5mm HTD 5M belt are at Maker Forums:

[forum.makerforums.info]

I have an untested design that uses filament as a hinge pin for 2GT belts also available. The design is in FreeCAD and is parametric so different hinge pin sizes isn't that hard.

It is perhaps imperfect due to interdigitation being inconsistent from the tooth and gap profiles being different, but in practice it seems to line up very well.

I ended up making a 3D-printed tool for doing the splices.

[gitlab.com]

Pictures of a variant of the tool in use splicing some 5mm HTD 5M belt are at Maker Forums:

[forum.makerforums.info]

I have an untested design that uses filament as a hinge pin for 2GT belts also available. The design is in FreeCAD and is parametric so different hinge pin sizes isn't that hard.

|

Re: Bonding GT2 belts February 14, 2022 05:52AM |

Registered: 12 years ago Posts: 1,450 |

I would worry that shaving the cords may substantially weaken them. Possibly using the same idea but feather edging so that the damage to the cords occurs mostly at the tips. Another way would be to cut the ends into long interdigitated teeth with the cords left intact.

By the way, the back-to-back glued joints I used earlier in this thread are still working well. Obviously not useful if the joint is going round a pulley though.

Mike

By the way, the back-to-back glued joints I used earlier in this thread are still working well. Obviously not useful if the joint is going round a pulley though.

Mike

|

Re: Bonding GT2 belts February 17, 2022 10:56PM |

Registered: 6 years ago Posts: 61 |

Quote

leadinglights

I would worry that shaving the cords may substantially weaken them.

Mike

Oh, the cords are exposed, but not noticeably shaved. The lapped joint is thicker than the rest of the belt by the thickness of the cords. Feather edging would just increase that excess thickness, and I've seen no evidence that it is necessary.

I did this earlier with 6mm GT2 belt, and I tried valiantly to pull the joint apart by hand and failed every time. I'm thinking of building a lever system to measure the force required to pull it apart, but it's definitely strong enough for real use. The HTD 5M belt I just spliced is under a lot of tension (it is moving a heavy Z stage in a large laser cutter build and I don't want any skipped teeth anywhere) and it is holding great. The HTD 5M, being larger, was easier to photograph without a macro lens. ☺

I used many of the pictures from my last post to illustrate instructions, so now the instructions on the original post in that forum thread will be easier to follow than the comment I linked to before:

[forum.makerforums.info]

Sorry, only registered users may post in this forum.