e3d v6 jamming

Posted by Thimo_98

|

e3d v6 jamming June 11, 2016 06:47PM |

Registered: 7 years ago Posts: 13 |

hallo

I have a big problem with my e3d v6 (bowden) it keeps jamming all the time. I'm printing pla on temperatures from 190 up to 230 degrees with speeds 20 up to 70 mm/s with layer heights from 0.05 to 0.2.

The fan is fw controlled from 20% till 100% I also tried connecting it to direct power (the heat sink always feels cold).

I'm also sure the ptfe tube is inserted well, I also tried oil with also no result. I have defined the right thermistor in Marlin and I am sure the steps/mm are right set. The retraction I use is 4,5 mm (the problem also occurs with 0 retraction).

The extruder motor cant be more powerful because then it will become to hot (its not to hot right now).

I really hope someone can help me out.

I have a big problem with my e3d v6 (bowden) it keeps jamming all the time. I'm printing pla on temperatures from 190 up to 230 degrees with speeds 20 up to 70 mm/s with layer heights from 0.05 to 0.2.

The fan is fw controlled from 20% till 100% I also tried connecting it to direct power (the heat sink always feels cold).

I'm also sure the ptfe tube is inserted well, I also tried oil with also no result. I have defined the right thermistor in Marlin and I am sure the steps/mm are right set. The retraction I use is 4,5 mm (the problem also occurs with 0 retraction).

The extruder motor cant be more powerful because then it will become to hot (its not to hot right now).

I really hope someone can help me out.

|

Re: e3d v6 jamming June 11, 2016 07:51PM |

Registered: 10 years ago Posts: 1,401 |

Few questions to eliminate some possibilities:

1. Original or clone?

2. Inner size and length of bowden tube?

3. The fan you mention is for the hotend or for the printed part? If for hotend it needs to be on all the time at 100%.

4. Whats your extruder feedrate?

5. Nozzle size.

6. Did you tightened the hotend at temperature or cold? Or you just used as it came?

7. The extruder stepper might be perfect, but what about the idle bearing, is it loose, too tight, perfect? Does it clicks before the hotend jams? Does it chews on the filament?

8. How old is the filament you are using? Have you left it few days outside the package?

Fyi going too hot on PLA is a perfect recipe for jamming.

1. Original or clone?

2. Inner size and length of bowden tube?

3. The fan you mention is for the hotend or for the printed part? If for hotend it needs to be on all the time at 100%.

4. Whats your extruder feedrate?

5. Nozzle size.

6. Did you tightened the hotend at temperature or cold? Or you just used as it came?

7. The extruder stepper might be perfect, but what about the idle bearing, is it loose, too tight, perfect? Does it clicks before the hotend jams? Does it chews on the filament?

8. How old is the filament you are using? Have you left it few days outside the package?

Fyi going too hot on PLA is a perfect recipe for jamming.

|

Re: e3d v6 jamming June 12, 2016 06:05AM |

Registered: 7 years ago Posts: 13 |

thanks for your reaction

it's an original e3d v6 hotend, the bowden tube has an inner size of 2 mm, an outer of 4 mm and a length of 900 mm (I also tried a length of 600 mm).

The fan is for both the hotend and the part i usually lower it because of the noise it always worked great till now.

The feedrate is 100% I also tried to lower it but it results in under extrusion and doesn't take away the problem.

I have an 0,4 mm nozzle withs kom with the hotend

I first tightened the nozzle cold and then I heated it and tightened again.

When the jamming occurs the stepper driver starts skipping steps, when there is no power on the stepper motor I can easily pool it by hand.

I use Real-filament that came just out of the box, I also tried different spools but all with the same problem.

The hotend printed well for a few monts with this settings but out of the bleu it stops. When I pull out the filamend after it got stuck the tip is a bit thicker but it seems to stuck in the meldzone of the hotend

I hope I gave enough information

Edited 2 time(s). Last edit at 06/12/2016 06:13AM by Thimo_98.

it's an original e3d v6 hotend, the bowden tube has an inner size of 2 mm, an outer of 4 mm and a length of 900 mm (I also tried a length of 600 mm).

The fan is for both the hotend and the part i usually lower it because of the noise it always worked great till now.

The feedrate is 100% I also tried to lower it but it results in under extrusion and doesn't take away the problem.

I have an 0,4 mm nozzle withs kom with the hotend

I first tightened the nozzle cold and then I heated it and tightened again.

When the jamming occurs the stepper driver starts skipping steps, when there is no power on the stepper motor I can easily pool it by hand.

I use Real-filament that came just out of the box, I also tried different spools but all with the same problem.

The hotend printed well for a few monts with this settings but out of the bleu it stops. When I pull out the filamend after it got stuck the tip is a bit thicker but it seems to stuck in the meldzone of the hotend

I hope I gave enough information

Edited 2 time(s). Last edit at 06/12/2016 06:13AM by Thimo_98.

|

Re: e3d v6 jamming June 12, 2016 06:38AM |

Registered: 8 years ago Posts: 88 |

Did you try this? [support.3dverkstan.se]

I've had your issue once and I was amazed about the junk I've pulled out. Now I do this every few days, especially when switching from PLA to higher temp filaments.

I've had your issue once and I was amazed about the junk I've pulled out. Now I do this every few days, especially when switching from PLA to higher temp filaments.

|

Re: e3d v6 jamming June 12, 2016 06:56AM |

Registered: 7 years ago Posts: 13 |

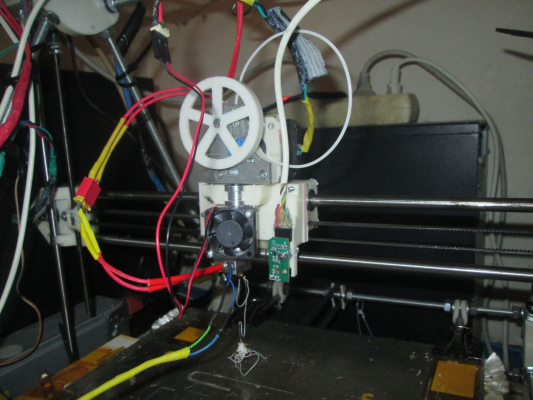

|

Re: e3d v6 jamming June 12, 2016 06:58AM |

Registered: 10 years ago Posts: 439 |

A dust filter on the filament input can help as blockages are sometimes caused by dust build up.

The cooling fan for the heatsink needs to be on all the time. I didn't like the small fan that came with the E3D so fitted a 40mm fan which is much quieter.

Heat creep and jamming can be caused by turning the fan off after printing. It should be kept on until the heatblock has cooled down.

The cooling fan for the heatsink needs to be on all the time. I didn't like the small fan that came with the E3D so fitted a 40mm fan which is much quieter.

Heat creep and jamming can be caused by turning the fan off after printing. It should be kept on until the heatblock has cooled down.

|

Re: e3d v6 jamming June 12, 2016 07:16AM |

Registered: 7 years ago Posts: 13 |

|

Re: e3d v6 jamming June 12, 2016 02:32PM |

Registered: 10 years ago Posts: 1,401 |

Ok thanks for the info, now two more things:

1. Have your disassemble yor hotend recently?

2. Have you switched type of filament recently?

I tend to disassemble my hotend at least once a month and do a complete cleanup of the nozzle and heat brake pipe, if I have used PLA I torch the nozzle several times and give it an acetone bath, once clean I use a drill bit to redo the orifice, for the pipe I use fine valve grinding compound dip a piece of filamen with it and using a slow drill speed run it inside a couple of times with acetone baths in between, once clean I lubricate it with castor oil.

Some times when switching from ABS to PLA I have had some jams and I believe the ABS some how leave a coating in the pipe that PLA likes to adhere to, when I switch types of filaments I dip my new filament with alcohol and run it hotter than normal and fast for at least a minute, then I lubricate a new piece and run it the same way until filament comes clean from the nozzle.

The length of your bowden tube is pretty long, but if it worked for you before it might not be the issue. You should also test your extruder, tight or loose your idle bearing and found its limits and clean the gear.

Check your thermistor and heating elements for gaps and play that can give you false readings.

1. Have your disassemble yor hotend recently?

2. Have you switched type of filament recently?

I tend to disassemble my hotend at least once a month and do a complete cleanup of the nozzle and heat brake pipe, if I have used PLA I torch the nozzle several times and give it an acetone bath, once clean I use a drill bit to redo the orifice, for the pipe I use fine valve grinding compound dip a piece of filamen with it and using a slow drill speed run it inside a couple of times with acetone baths in between, once clean I lubricate it with castor oil.

Some times when switching from ABS to PLA I have had some jams and I believe the ABS some how leave a coating in the pipe that PLA likes to adhere to, when I switch types of filaments I dip my new filament with alcohol and run it hotter than normal and fast for at least a minute, then I lubricate a new piece and run it the same way until filament comes clean from the nozzle.

The length of your bowden tube is pretty long, but if it worked for you before it might not be the issue. You should also test your extruder, tight or loose your idle bearing and found its limits and clean the gear.

Check your thermistor and heating elements for gaps and play that can give you false readings.

|

Re: e3d v6 jamming June 13, 2016 03:06AM |

Registered: 7 years ago Posts: 13 |

I tried cleaning everything yesterday and let it print during the night bud sadly when I wake up it was jammed again.

I didn't chance filament recently but I dit dissemble but this was a while before the jamming started. Maybe I can order an nieuw nozzle just to be sure that isn't the problem.

Thanks for al the ideas so far

I didn't chance filament recently but I dit dissemble but this was a while before the jamming started. Maybe I can order an nieuw nozzle just to be sure that isn't the problem.

Thanks for al the ideas so far

|

Re: e3d v6 jamming June 13, 2016 12:58PM |

Registered: 9 years ago Posts: 294 |

i am getting clogs too. I am printing abs and thought it would be easier with tthis hotend . Anyway i am trying different things but none seems to really help . If you ll short it out please update the post.

what nozzle is urs ? i am printing at 0.4mm

Edited 1 time(s). Last edit at 06/13/2016 12:59PM by Gaou.

Delta Printer

Duet 0.8.5 firmware 1.19

what nozzle is urs ? i am printing at 0.4mm

Edited 1 time(s). Last edit at 06/13/2016 12:59PM by Gaou.

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: e3d v6 jamming June 13, 2016 02:38PM |

Registered: 7 years ago Posts: 13 |

|

Re: e3d v6 jamming June 15, 2016 12:57PM |

Registered: 7 years ago Posts: 13 |

Hello

Today I received and tested the new nozzles. I all tested them whit the same settings and a layer height of 25% of the nozzle size.

As expected the 0,3 mm nozzle gets jammed first but then unexpected the 0,6 mm nozzle was the second one that gets jammed the last one that gets jammed was the 0,4 mm nozzle.

I really don't know what to do next I hope you guys have some ideas.

Today I received and tested the new nozzles. I all tested them whit the same settings and a layer height of 25% of the nozzle size.

As expected the 0,3 mm nozzle gets jammed first but then unexpected the 0,6 mm nozzle was the second one that gets jammed the last one that gets jammed was the 0,4 mm nozzle.

I really don't know what to do next I hope you guys have some ideas.

|

Re: e3d v6 jamming June 15, 2016 01:01PM |

Registered: 15 years ago Posts: 537 |

How about replace it with a genuine J-Head from [www.hotends.com] ? They don't jam unless the filament is bad.

|

Re: e3d v6 jamming June 15, 2016 01:32PM |

Registered: 7 years ago Posts: 13 |

|

Re: e3d v6 jamming June 15, 2016 03:24PM |

Registered: 9 years ago Posts: 294 |

Quote

reifsnyderb

How about replace it with a genuine J-Head from [www.hotends.com] ? They don't jam unless the filament is bad.

i dont know if this is true. i got one to replace my rpp quickset and i got disappointed seen that the rpp gets jam less than the e3d . Of course i am using the same filament on both printers.

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: e3d v6 jamming June 16, 2016 03:23AM |

Registered: 10 years ago Posts: 341 |

Quote

Thimo_98

Hello

Today I received and tested the new nozzles. I all tested them whit the same settings and a layer height of 25% of the nozzle size.

As expected the 0,3 mm nozzle gets jammed first but then unexpected the 0,6 mm nozzle was the second one that gets jammed the last one that gets jammed was the 0,4 mm nozzle.

I really don't know what to do next I hope you guys have some ideas.

Have you tried using the thermal compound as mentioned in the E3D Assembly Guide?

I bought my v6 before the thermal compound was included as part of the kit, and it printed well for a couple of months and then suddenly started jamming (both ABS and PLA). It got to the point where it would jam after just 5-10min. After discovering they now include thermal compound in their kits, I gave it a try and since then it has been printing jam free for months now.

|

Re: e3d v6 jamming June 16, 2016 03:45AM |

Registered: 7 years ago Posts: 13 |

yes I have tried the thermal compound but I din't notice any chances.

Yesterday I tried to make the ptfe pipe as short as possible it was about 300 mm and tried a print but the result was bad again. Then I tried to lower the microstepping from 1/32 to 1/16 and higher the voltage to 0.6 v but it got still jammed .

.

Yesterday I tried to make the ptfe pipe as short as possible it was about 300 mm and tried a print but the result was bad again. Then I tried to lower the microstepping from 1/32 to 1/16 and higher the voltage to 0.6 v but it got still jammed

.

.

|

Re: e3d v6 jamming June 16, 2016 07:33AM |

Registered: 7 years ago Posts: 7 |

Hello Thimo_98,

Recently, I purchased myself a new genuine e3d v6 as well and I had the same problems as yours. Tried everything to solve it as you mentioned but none has helped. I was using the gray REAL filament that I used in my other printer with a jhead and I did not have any problems before.

What solved my problem is switching to another brand of filament. I changed it to 123-3D nude filament which apparently solved my issues. No jams so far and still going without a problem ever since. Don't know why but it seems that the nude filament from 123-3D seems to be smoother (it shines more than the gray).

My guess is that the REAL gray has a too much thermal expansion and expans in the heatbreak. That combined with the smoothness causes the jam, I think.... It seems to be more vulnerable to heatcreep even with a 40mm fan blowing 100% on the heatsink. The nude filament doesn't expand as much and it would even seem that with the e3d and this filament, I even have a higher extrusion rate. My Jhead could only extrude about 3.5mm/s before the motor starts skipping. Now I can even output about 8-9 mm/s before it starts skipping and it haven't jammed yet.

I hope this helps, I understand your frustation as I've worked on the same issues for a week.

Recently, I purchased myself a new genuine e3d v6 as well and I had the same problems as yours. Tried everything to solve it as you mentioned but none has helped. I was using the gray REAL filament that I used in my other printer with a jhead and I did not have any problems before.

What solved my problem is switching to another brand of filament. I changed it to 123-3D nude filament which apparently solved my issues. No jams so far and still going without a problem ever since. Don't know why but it seems that the nude filament from 123-3D seems to be smoother (it shines more than the gray).

My guess is that the REAL gray has a too much thermal expansion and expans in the heatbreak. That combined with the smoothness causes the jam, I think.... It seems to be more vulnerable to heatcreep even with a 40mm fan blowing 100% on the heatsink. The nude filament doesn't expand as much and it would even seem that with the e3d and this filament, I even have a higher extrusion rate. My Jhead could only extrude about 3.5mm/s before the motor starts skipping. Now I can even output about 8-9 mm/s before it starts skipping and it haven't jammed yet.

I hope this helps, I understand your frustation as I've worked on the same issues for a week.

|

Re: e3d v6 jamming June 16, 2016 09:15AM |

Registered: 15 years ago Posts: 537 |

Was this with a genuine J-Head (5 rows of vents)?

Quote

minhan

Hello Thimo_98,

Recently, I purchased myself a new genuine e3d v6 as well and I had the same problems as yours. Tried everything to solve it as you mentioned but none has helped. I was using the gray REAL filament that I used in my other printer with a jhead and I did not have any problems before.

What solved my problem is switching to another brand of filament. I changed it to 123-3D nude filament which apparently solved my issues. No jams so far and still going without a problem ever since. Don't know why but it seems that the nude filament from 123-3D seems to be smoother (it shines more than the gray).

My guess is that the REAL gray has a too much thermal expansion and expans in the heatbreak. That combined with the smoothness causes the jam, I think.... It seems to be more vulnerable to heatcreep even with a 40mm fan blowing 100% on the heatsink. The nude filament doesn't expand as much and it would even seem that with the e3d and this filament, I even have a higher extrusion rate. My Jhead could only extrude about 3.5mm/s before the motor starts skipping. Now I can even output about 8-9 mm/s before it starts skipping and it haven't jammed yet.

I hope this helps, I understand your frustation as I've worked on the same issues for a week.

|

Re: e3d v6 jamming June 16, 2016 09:30AM |

Registered: 7 years ago Posts: 13 |

Thanks a lot minham I had some leftovers of the 123-3d filament and its now printing for 2 hours without any jam. however I don't think its the thermal expansion but I think it's the strengt of the filament the real filament is a lot stronger that is the reason why I use it.

I still want to solve the problem because it's not normal but for now I'm first going to do some printing.

I still want to solve the problem because it's not normal but for now I'm first going to do some printing.

|

Re: e3d v6 jamming June 16, 2016 10:18AM |

Registered: 7 years ago Posts: 7 |

@reifsnyderb

I don't believe it was a genuine actually...

Because it was my first printer to build, I've purchased it from a Dutch website 123-3D. (https://www.123-3d.nl/123-3D-J-Head-compatible-hotend-kit-1-75-mm-x-0-5-mm-i1029-t390.html)

First I believed it was genuine, but after I saw "compatible" I don't think it is genuine.

@ Thimo_98

Glad to hear you're printing again. What does the strenght of the filament has to do with the jamming?

When the filament jammed, I pulled it out and the head was about 2.05mm width and about 2-4mm long. However, it wasn't a knob but it had cilindershape as it has taken the shape of the heatbreak. That is why I believe it's due to the thermal expansion it keeps jamming.

Strangest part is that when I push the filament through the hotend by hand, no problems occured. When I extruded in the air, everything was ok as well. But when I started printing, the extruder jammed immediately. First I thought it was the bed was too close, but it wasn't.

I've noticed something when I slowly manually extruded. Notice that when you extrude with a bowden tube, there is some pressure on the filament. That is why your hotend is oozing. I've tried to reproduce that same pressure by hand and seemingly, it jammed. It seems to me that this filament will expand when some pressure is on it nearby the heated element. The plastic might conduct a bit of the heat and causing it to expand in the heatbreak.

Someone any idea? I'm still hoping I can solve this issue as I still have half a roll of this filament and it would be a waste to not use it.

Edited 1 time(s). Last edit at 06/16/2016 10:19AM by minhan.

I don't believe it was a genuine actually...

Because it was my first printer to build, I've purchased it from a Dutch website 123-3D. (https://www.123-3d.nl/123-3D-J-Head-compatible-hotend-kit-1-75-mm-x-0-5-mm-i1029-t390.html)

First I believed it was genuine, but after I saw "compatible" I don't think it is genuine.

@ Thimo_98

Glad to hear you're printing again. What does the strenght of the filament has to do with the jamming?

When the filament jammed, I pulled it out and the head was about 2.05mm width and about 2-4mm long. However, it wasn't a knob but it had cilindershape as it has taken the shape of the heatbreak. That is why I believe it's due to the thermal expansion it keeps jamming.

Strangest part is that when I push the filament through the hotend by hand, no problems occured. When I extruded in the air, everything was ok as well. But when I started printing, the extruder jammed immediately. First I thought it was the bed was too close, but it wasn't.

I've noticed something when I slowly manually extruded. Notice that when you extrude with a bowden tube, there is some pressure on the filament. That is why your hotend is oozing. I've tried to reproduce that same pressure by hand and seemingly, it jammed. It seems to me that this filament will expand when some pressure is on it nearby the heated element. The plastic might conduct a bit of the heat and causing it to expand in the heatbreak.

Someone any idea? I'm still hoping I can solve this issue as I still have half a roll of this filament and it would be a waste to not use it.

Quote

reifsnyderb

Was this with a genuine J-Head (5 rows of vents)?

Quote

minhan

Hello Thimo_98,

Recently, I purchased myself a new genuine e3d v6 as well and I had the same problems as yours. Tried everything to solve it as you mentioned but none has helped. I was using the gray REAL filament that I used in my other printer with a jhead and I did not have any problems before.

What solved my problem is switching to another brand of filament. I changed it to 123-3D nude filament which apparently solved my issues. No jams so far and still going without a problem ever since. Don't know why but it seems that the nude filament from 123-3D seems to be smoother (it shines more than the gray).

My guess is that the REAL gray has a too much thermal expansion and expans in the heatbreak. That combined with the smoothness causes the jam, I think.... It seems to be more vulnerable to heatcreep even with a 40mm fan blowing 100% on the heatsink. The nude filament doesn't expand as much and it would even seem that with the e3d and this filament, I even have a higher extrusion rate. My Jhead could only extrude about 3.5mm/s before the motor starts skipping. Now I can even output about 8-9 mm/s before it starts skipping and it haven't jammed yet.

I hope this helps, I understand your frustation as I've worked on the same issues for a week.

Edited 1 time(s). Last edit at 06/16/2016 10:19AM by minhan.

|

Re: e3d v6 jamming June 20, 2016 06:34AM |

Registered: 9 years ago Posts: 294 |

Quote

reifsnyderb

They don't jam unless the filament is bad.

you are absolutely right and i own an apology .

Quote

Gaou

i dont know if this is true..

my apology to the creator of the e3d as i was wrong. I removed my bowden tube as it was the problem due to thick ( 1.85mm-1.95mm) filament . From that day i didn't have and jams.

here is my direct extrusion mod

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: e3d v6 jamming June 20, 2016 04:50PM |

Registered: 7 years ago Posts: 13 |

hello minham

I think the 123 3d filament and the real filament have the same deformation but maybe the extruder motor is powerful a enough to deform the filament again in the right shape even when it's cold it's a lot harder to do that with the real filament.

what also can be a reason of the jamming is my ramps board, the themp_0sensor input just broke down and telling me its always 183 degrees or higher so I am going to order a new ramps.

I think the 123 3d filament and the real filament have the same deformation but maybe the extruder motor is powerful a enough to deform the filament again in the right shape even when it's cold it's a lot harder to do that with the real filament.

what also can be a reason of the jamming is my ramps board, the themp_0sensor input just broke down and telling me its always 183 degrees or higher so I am going to order a new ramps.

|

Re: e3d v6 jamming June 20, 2016 06:01PM |

Registered: 11 years ago Posts: 528 |

Thimo

you confirmed its the ramps/arduino pin that's gone or a break in the thermistor,, you swapped the bed sensor over to test?

and just for sanity you switching off when unplugging anything from the RAMPS

Quote

the temp_0 sensor input just broke down and telling me its always 183 degrees or higher

you confirmed its the ramps/arduino pin that's gone or a break in the thermistor,, you swapped the bed sensor over to test?

and just for sanity you switching off when unplugging anything from the RAMPS

|

Re: e3d v6 jamming June 21, 2016 03:52AM |

Registered: 7 years ago Posts: 13 |

|

Re: e3d v6 jamming June 21, 2016 04:57AM |

Registered: 7 years ago Posts: 7 |

Hi Thimo,

When the filament jams, you'll have to take out the filament. Can you make a close up picture of the tip? Try to make a picture of the other filament as well, so you can see how the tip deforms and possible causes it to jam.

For me, I don't think it is the extruder. I have printed more than half of the roll of the nude filament from 123-3D, and now I'm printing ABS without any jams at all.

When the filament jams, you'll have to take out the filament. Can you make a close up picture of the tip? Try to make a picture of the other filament as well, so you can see how the tip deforms and possible causes it to jam.

For me, I don't think it is the extruder. I have printed more than half of the roll of the nude filament from 123-3D, and now I'm printing ABS without any jams at all.

Quote

Thimo_98

hello minham

I think the 123 3d filament and the real filament have the same deformation but maybe the extruder motor is powerful a enough to deform the filament again in the right shape even when it's cold it's a lot harder to do that with the real filament.

what also can be a reason of the jamming is my ramps board, the themp_0sensor input just broke down and telling me its always 183 degrees or higher so I am going to order a new ramps.

Sorry, only registered users may post in this forum.