Filament feed indicator idea.

Posted by leadinglights

|

Filament feed indicator idea. June 17, 2016 07:55AM |

Registered: 12 years ago Posts: 1,450 |

I have seen some discussion on a number of threads lately about filament feed sensors. I was wondering if this idea is new.

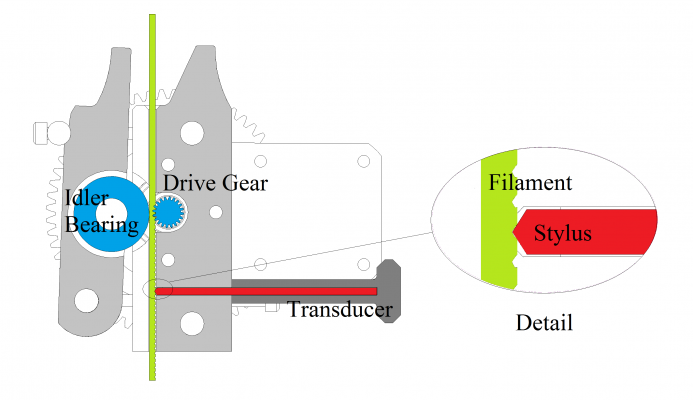

The thought is that the drive gear leaves an impression on the filament. If this could be used to generate pulses by tracking the indented surface with a stylus, the rate of pulses could be used to indicate correct feed or flag up a fault.

If this idea is not new, can anybody point me towards any reference. Otherwise the idea is protected by the full weight of the WTFPL [www.wtfpl.net]

Mike

The thought is that the drive gear leaves an impression on the filament. If this could be used to generate pulses by tracking the indented surface with a stylus, the rate of pulses could be used to indicate correct feed or flag up a fault.

If this idea is not new, can anybody point me towards any reference. Otherwise the idea is protected by the full weight of the WTFPL [www.wtfpl.net]

Mike

|

Re: Filament feed indicator idea. June 17, 2016 08:37AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: Filament feed indicator idea. June 17, 2016 10:05AM |

Admin Registered: 16 years ago Posts: 13,884 |

... some years ago we had some brainstorming about measuring the filament movement with the sensor of an optical mouse, sensing the 'dents' passing by ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Filament feed indicator idea. June 17, 2016 04:00PM |

Registered: 13 years ago Posts: 268 |

|

Re: Filament feed indicator idea. June 18, 2016 03:11AM |

Registered: 11 years ago Posts: 1,171 |

What about a small permanent magnet motor with a rubber pinch wheel over the filament (a lot like the extruder) and simply hook a small LED to the motor, it will intermittently act as a generator causing the LED to blink when the filament moves. If you see it's not blinking then it's jammed.

|

Re: Filament feed indicator idea. June 18, 2016 04:48AM |

Registered: 12 years ago Posts: 1,450 |

Hmm, maybe I should have had the subject as "Filament feed failure detector idea" as the visual indication of a failure is not always useful - stopping the system or pausing while raising an alarm would be much better.

To detect that the filament is not feeding right should be done after the feed mechanism (gear) as methods that look at the filament before this will miss filament finding another route out which does not involve the hot end. Very flexible filaments such as Ninjaflex seem to be escapologists par excellence, finding paths past the idler wheel or any other small gap. Putting a wheel between the drive and the hot end would leave another route for escape besides making it difficult to have only a very short route - which itself is desirable for flexible filaments.

One difficulty with the "read the dents" method is that the output will be far from a sine wave and will also have a frequency varying a lot with speed. It should be possible to kludge together a simple IIR or FIR filter with a low cost PIC16 (or similar) microcontroller. Another problem is to find a small cheap transducer that works at low frequencies.

Mike

To detect that the filament is not feeding right should be done after the feed mechanism (gear) as methods that look at the filament before this will miss filament finding another route out which does not involve the hot end. Very flexible filaments such as Ninjaflex seem to be escapologists par excellence, finding paths past the idler wheel or any other small gap. Putting a wheel between the drive and the hot end would leave another route for escape besides making it difficult to have only a very short route - which itself is desirable for flexible filaments.

One difficulty with the "read the dents" method is that the output will be far from a sine wave and will also have a frequency varying a lot with speed. It should be possible to kludge together a simple IIR or FIR filter with a low cost PIC16 (or similar) microcontroller. Another problem is to find a small cheap transducer that works at low frequencies.

Mike

|

Re: Filament feed indicator idea. June 18, 2016 09:51AM |

Admin Registered: 16 years ago Posts: 13,884 |

... the sensor of an optical mouse, read with an Arduino should work - the dents in the filament will change the 'contrast' enough, to get moving areas in the 19x19pixel-cam.

Then it would be as simple as "mouse" moving or not ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Then it would be as simple as "mouse" moving or not ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Filament feed indicator idea. June 18, 2016 01:09PM |

Registered: 11 years ago Posts: 1,049 |

WHY?

What will happen when a filament advance failure?

Will you be matching measured filament movement with commanded movement.

Will you account for retraction? and recovery after retraction.

A failure of filament advance:

---- pause print

----- run full diagnostic routine on extruder

flash LED

sound buzzer

---- move ruined print off bed --- restart print

Yes discovery of filament movement failure is great

but what to do next --- the real challenge

What will happen when a filament advance failure?

Will you be matching measured filament movement with commanded movement.

Will you account for retraction? and recovery after retraction.

A failure of filament advance:

---- pause print

----- run full diagnostic routine on extruder

flash LED

sound buzzer

---- move ruined print off bed --- restart print

Yes discovery of filament movement failure is great

but what to do next --- the real challenge

|

Re: Filament feed indicator idea. June 18, 2016 03:13PM |

Registered: 12 years ago Posts: 1,450 |

Quote

cozmicray

WHY?

What will happen when a filament advance failure?

Will you be matching measured filament movement with commanded movement.

Will you account for retraction? and recovery after retraction.

A failure of filament advance:

---- pause print

----- run full diagnostic routine on extruder

flash LED

sound buzzer

---- move ruined print off bed --- restart print

Yes discovery of filament movement failure is great

but what to do next --- the real challenge

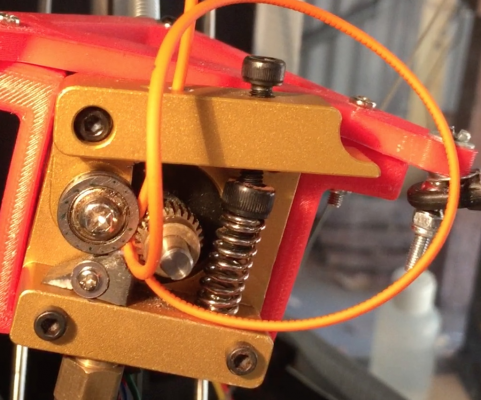

One of the most severe outcomes of a failure to feed filament through the hot end is that it has been fed out of the extruder through a gap between the extruder body and the idler carrier resulting in the loss of quite a bit of a 1kg roll of Ninjaflex.

The first order of business is to stop the print when it seems to have gone wrong. The next thing is for the printer to tell the boss via Octoprint or whatever that something is amiss. Truly elegant recovery strategies I will leave to somebody much smarter than me.

edit: cosmicray asked

Quote

Will you be matching measured filament movement with commanded movement.

The output from any transducer that follows the lumps in the filament will be far from an ideal pulse so needs filtering. A simple digital filter can be made if you know what to expect, perhaps using a copy of the step pulse to the extruder motor. If I decide to try this I will try to explain more at a later date, but the answer is yes.

Mike

Edited 1 time(s). Last edit at 06/18/2016 03:50PM by leadinglights.

|

Re: Filament feed indicator idea. June 19, 2016 01:32PM |

Registered: 11 years ago Posts: 1,049 |

Spooling thru 500m of filament?

Is this a first order failure of your extruder?

Have never heard of it?

extruder jam probably top problem

extruder not squirting another

So if extruder is commanded to extrude 100mm of filament

and detector gets 156 pulses

Is this OK or a failure

This detector can't detect retraction vs extrusion

Once again What is "the FAILURE"

when 100m of ninjaflex (120,000 pulses) passes by without a commanded extrusion.

If the probe sticks in filament and stops extrusion --- filament indicator the problem

Perhaps a non-evasive IR or Ultrasonic motion sensor (even use doppler)

I suppose you could run 100 feet of wire up to your living room

and watch a light blink

and run over to printer when it's not blinking

What about just use an ip cam on printer and you can see a printer problem on your smart phone

Detector useless without solution

I wonder if strasys or the new HP printer has a filament movement system?

I wonder why not?

Is this a first order failure of your extruder?

Have never heard of it?

extruder jam probably top problem

extruder not squirting another

So if extruder is commanded to extrude 100mm of filament

and detector gets 156 pulses

Is this OK or a failure

This detector can't detect retraction vs extrusion

Once again What is "the FAILURE"

when 100m of ninjaflex (120,000 pulses) passes by without a commanded extrusion.

If the probe sticks in filament and stops extrusion --- filament indicator the problem

Perhaps a non-evasive IR or Ultrasonic motion sensor (even use doppler)

I suppose you could run 100 feet of wire up to your living room

and watch a light blink

and run over to printer when it's not blinking

What about just use an ip cam on printer and you can see a printer problem on your smart phone

Detector useless without solution

I wonder if strasys or the new HP printer has a filament movement system?

I wonder why not?

Quote

leadinglights

One of the most severe outcomes of a failure to feed filament through the hot end is that it has been fed out of the extruder through a gap between the extruder body and the idler carrier resulting in the loss of quite a bit of a 1kg roll of Ninjaflex.

|

Re: Filament feed indicator idea. June 19, 2016 01:44PM |

Admin Registered: 16 years ago Posts: 13,884 |

... it's no problem to set a small Arduino beside, which will count the step-pulses for the extruder-motor and correlate it to the feedback of a motion-sensor.

With a bit more effort it could even check the DIR-pin -- and there are several options to define the moving direction of the filament too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

With a bit more effort it could even check the DIR-pin -- and there are several options to define the moving direction of the filament too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Filament feed indicator idea. June 19, 2016 02:26PM |

Registered: 12 years ago Posts: 1,450 |

@cosmicray, O.K., I guess that I have to draw a picture.

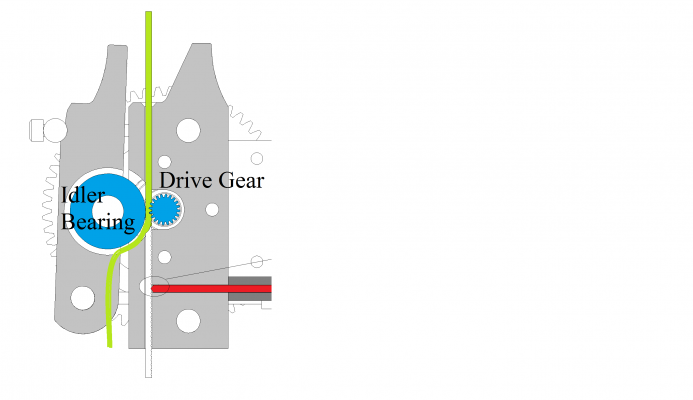

At no point did I say that the feed had not been commanded. "the FAILURE" mentioned is shown on the picture below - not unique to myself as I have seen pictures of this on this very forum. The proximal cause of this failure is usually a blocked hot end but could be others.

The lower part of the green line shows where the filament went out sideways past the bearing. Motion detectors which look at the filament before the extruder would miss the failure shown above.

As far as the rest of your posting and the general tone, I am afraid that I found it completely incoherent and could make no sense of it. For the moment I acknowledge that some of your answers in other threads show some knowledge and I will, for the moment at least, refrain from suggesting that you crawl back under the bridge with the other trolls.

Mike

At no point did I say that the feed had not been commanded. "the FAILURE" mentioned is shown on the picture below - not unique to myself as I have seen pictures of this on this very forum. The proximal cause of this failure is usually a blocked hot end but could be others.

The lower part of the green line shows where the filament went out sideways past the bearing. Motion detectors which look at the filament before the extruder would miss the failure shown above.

As far as the rest of your posting and the general tone, I am afraid that I found it completely incoherent and could make no sense of it. For the moment I acknowledge that some of your answers in other threads show some knowledge and I will, for the moment at least, refrain from suggesting that you crawl back under the bridge with the other trolls.

Mike

|

Re: Filament feed indicator idea. June 19, 2016 02:41PM |

Registered: 12 years ago Posts: 1,450 |

@VDX At the moment I am looking only at the use of a mechanical stylus to send pulses to the jam detect input of a RAMPS board using Repetier firmware. The problem I envisage is that the indentations on the filament are not likely to give a very clean signal so will need cleaning up before being sent to the RAMPS board. Because of the wide range of feed speeds and hence signal frequencies the cleaning up may be difficult - but like Baldrick, I have a cunning plan.

The PIC is because I have some skills with assembly but none on high level languages.

Mike

The PIC is because I have some skills with assembly but none on high level languages.

Mike

|

Re: Filament feed indicator idea. June 19, 2016 05:47PM |

Registered: 11 years ago Posts: 1,049 |

Quote

leadinglights

The lower part of the green line shows where the filament went out sideways past the bearing. Motion detectors which look at the filament before the extruder would miss the failure shown above.

That is pure design / manufacture problem

to allow space between filament and idler or filament and gear to be big enough to allow

filament to escape.

Most good extruders provide a very tight lead from gear exit to hotend entrance

Your pin may just help the filament to take an errant route.

Hummm --- a wheel with light and dark segments that are detected by photo-detector

can count / sec or so and get some better info?

This gets to be a warm area (if not Bowden) and filament gets soft.

Also I did not know that extruder gear or hobbed bolt must leave clean indentations.

Where did I say sensor is before the gear?

A feeler for filament science fair neat experiment but perhaps you should look at whole system or solution

and learn from a failure or bad idea and move on to a better idea

or just keep smashing your head against a wall

--- why not just hook it up to vinyl record stylus

and play a tune --- no tune --- no filament movement

Maybe a new genre of music Filament disco?

Right your getting so much feedback --- I won't comment anymore!!!

|

Re: Filament feed indicator idea. June 20, 2016 03:51AM |

Registered: 12 years ago Posts: 1,450 |

Quote

cozmicray

............................................................................................

............................................

Right your getting so much feedback --- I won't comment anymore!!!

You won't comment anymore!!! ever???

Does this mean that I will be denied forever the challenge of trying to make sense of your random stream of consciousness utterances.

Mike

|

Re: Filament feed indicator idea. February 15, 2017 11:42PM |

Registered: 8 years ago Posts: 916 |

I'm going to rename TPE as "Houdini".

A filament sensor that can detect this sort of failure, and immediately pause the print, would make the difference between having to restart a print, vs clearing the issue and resuming the print.

A filament sensor that can detect this sort of failure, and immediately pause the print, would make the difference between having to restart a print, vs clearing the issue and resuming the print.

|

Re: Filament feed indicator idea. February 15, 2017 11:47PM |

Registered: 8 years ago Posts: 916 |

|

Re: Filament feed indicator idea. February 16, 2017 03:09AM |

Registered: 8 years ago Posts: 5,232 |

I think filament indication is a useful thing to have for overnight printing.

I doubt that an optical mouse sensor can detect the non existent dents in super soft black TPU/TPE filament. ( the only flex filament I've tried so far )

The transducer could be a simple piezo microphone. It "hears" a scratching from the stylus when the filament goes the right path, it is silent ( more or less ) when the filament path is wrong.

Problem is to separate the good noise from background noise ( fan and stepper humming ).

I doubt that an optical mouse sensor can detect the non existent dents in super soft black TPU/TPE filament. ( the only flex filament I've tried so far )

The transducer could be a simple piezo microphone. It "hears" a scratching from the stylus when the filament goes the right path, it is silent ( more or less ) when the filament path is wrong.

Problem is to separate the good noise from background noise ( fan and stepper humming ).

|

Re: Filament feed indicator idea. February 16, 2017 03:34AM |

Registered: 8 years ago Posts: 312 |

|

Re: Filament feed indicator idea. February 16, 2017 03:58AM |

Registered: 8 years ago Posts: 916 |

Quote

o_lampe

I doubt that an optical mouse sensor can detect the non existent dents in super soft black TPU/TPE filament. ( the only flex filament I've tried so far )

In the picture above, the dents in TPE are clearly visible.

I'm leaning more and more towards an implementation of the parent idea, with a stylus that pokes into the filament. Perhaps an optical endstop could be used to detect motion of the stylus, in and out. An issue I can see is that the stylus might poke too far into the feed tube when first loading the filament. It would need to be tuned.

|

Re: Filament feed indicator idea. February 16, 2017 05:20AM |

Registered: 8 years ago Posts: 3,525 |

I think I can see what cozmicray is saying....

Is this to stop/pause the print if filament/hotend jams, kinks, gets tangled on the spool, all of the usual causes of returning to a mess rather than a beautiful object - or is this an attempt at closed loop filament control?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Is this to stop/pause the print if filament/hotend jams, kinks, gets tangled on the spool, all of the usual causes of returning to a mess rather than a beautiful object - or is this an attempt at closed loop filament control?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Filament feed indicator idea. February 16, 2017 08:49AM |

Registered: 12 years ago Posts: 1,450 |

And I had it down with the great cozmic mysteries along with dark matter, dark energy and oh so many things.Quote

DjDemonD

I think I can see what cozmicray is saying....

My main interest is in getting a diagnostic record - it is easier to take the right action or make design changes if you have good evidence that if you are just left with your best guess. In the case of the filament feed indicator: Were there periods of poor feeding? If the print failed, what happened immediately before?Quote

Is this to stop/pause the print if filament/hotend jams, kinks, gets tangled on the spool, all of the usual causes of returning to a mess rather than a beautiful object - or is this an attempt at closed loop filament control?

Mike

Sorry, only registered users may post in this forum.