Using a DC booster for 24V on the heated bed only

Posted by icefire

|

Using a DC booster for 24V on the heated bed only June 19, 2016 04:15PM |

Registered: 8 years ago Posts: 168 |

So I want to upgrade my heated bed so that I can print bigger objects (current build platform is just 200 x 200mm)

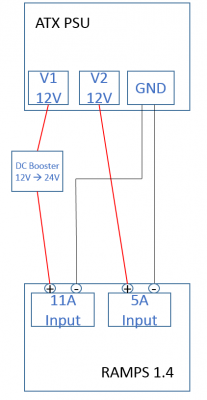

My current setup includes a PCB bed heater and a 12V computer PSU that has two 12V rails - V1 and V2. I use V1 for the heated bed (11A input on the RAMPS) and V2 for everything else (5A input). However, the new heated bed I would like to use is this one - which needs 24V because it is considerably bigger.

Of course, I could use a 24V PSU instead of the ATX PSU I have now, but that would mean to change practically everything: Hot end heater, fans, LED circuits, etc.

So I was thinking of using a small DC booster on the V1 rail in order to supply 24V for the heated bed and 12V for everything else:

Do you think this would work? The PSU supplies 480W on the 12V rails.

Of course, V1 and V2 have common ground when connected to the RAMPS. Is this going to be a problem?

Thanks for your help!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

My current setup includes a PCB bed heater and a 12V computer PSU that has two 12V rails - V1 and V2. I use V1 for the heated bed (11A input on the RAMPS) and V2 for everything else (5A input). However, the new heated bed I would like to use is this one - which needs 24V because it is considerably bigger.

Of course, I could use a 24V PSU instead of the ATX PSU I have now, but that would mean to change practically everything: Hot end heater, fans, LED circuits, etc.

So I was thinking of using a small DC booster on the V1 rail in order to supply 24V for the heated bed and 12V for everything else:

Do you think this would work? The PSU supplies 480W on the 12V rails.

Of course, V1 and V2 have common ground when connected to the RAMPS. Is this going to be a problem?

Thanks for your help!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only June 19, 2016 05:27PM |

Registered: 8 years ago Posts: 3,525 |

So the device you show above is a step up transformer 12v dc to 24v dc? I am not sure that's the right way to go, you will still have to supply it via the ramps board so you're still pulling 11A through the ramps, and we all know how much they like that, and that's your limit.

The way I did this for my enlarged smartrapcore alu with 300x200 bed is to run the heated bed output to a fused automotive mechanical relay, set bang bang control in the firmware so the relay isn't switching on/off too fast and then use a second 24v psu via the relay to the bed. As a result I get 250w @ 24vdc for my bed (which I have connected via its 12v connectors so it draws the maximum 12A from the 24v PSU), it heats up within 5 minutes to 120 deg C, I am not pulling 11A through the ramps board so much less worry about heat/fire/etc, and I have downgraded my 12v PSU to a laptop style unit which is more than enough for motors/hot end heater and some LEDs. The only criticism I got for this approach, which incidentally has been working flawlessly for months now, is that the relay clicking on/off would be annoying, which depends on your point of view, I like to hear it working, and I know when to go and remove the insulation from on top of the bed when I hear the relay click off at the end of heating. Plus if I wanted more power I'd just change the 24v PSU or consider going to mains heating.

Or use a DC-DC SSR to do the same as I have done above with 2 PSU's but now you can have PID control of the bed (pointless IMHO with a well insulated bed or even better an enclosed build volume - bang bang gives really good control). The SSR will usually need some sort of heatsink (so not that efficient if its losing energy as heat). They are more expensive and I am sure more prone to failure than a good ol' fashioned relay which cost a few $, so even if it does fail and it should fail-safe, I just swap in another one (I bought 2). I have used one for mains powered heating of a build chamber.

Moving everything over to 24v does have its appeal, 24v for steppers is supposed to be a much better prospect and I would consider this on a completely new printer build rather than on an upgrade to an existing 12v machine.

EDIT - you mean running this unit direct off the powersupply and then feeding its output into the bed power connector on the ramps?

Edited 2 time(s). Last edit at 06/19/2016 05:35PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

The way I did this for my enlarged smartrapcore alu with 300x200 bed is to run the heated bed output to a fused automotive mechanical relay, set bang bang control in the firmware so the relay isn't switching on/off too fast and then use a second 24v psu via the relay to the bed. As a result I get 250w @ 24vdc for my bed (which I have connected via its 12v connectors so it draws the maximum 12A from the 24v PSU), it heats up within 5 minutes to 120 deg C, I am not pulling 11A through the ramps board so much less worry about heat/fire/etc, and I have downgraded my 12v PSU to a laptop style unit which is more than enough for motors/hot end heater and some LEDs. The only criticism I got for this approach, which incidentally has been working flawlessly for months now, is that the relay clicking on/off would be annoying, which depends on your point of view, I like to hear it working, and I know when to go and remove the insulation from on top of the bed when I hear the relay click off at the end of heating. Plus if I wanted more power I'd just change the 24v PSU or consider going to mains heating.

Or use a DC-DC SSR to do the same as I have done above with 2 PSU's but now you can have PID control of the bed (pointless IMHO with a well insulated bed or even better an enclosed build volume - bang bang gives really good control). The SSR will usually need some sort of heatsink (so not that efficient if its losing energy as heat). They are more expensive and I am sure more prone to failure than a good ol' fashioned relay which cost a few $, so even if it does fail and it should fail-safe, I just swap in another one (I bought 2). I have used one for mains powered heating of a build chamber.

Moving everything over to 24v does have its appeal, 24v for steppers is supposed to be a much better prospect and I would consider this on a completely new printer build rather than on an upgrade to an existing 12v machine.

EDIT - you mean running this unit direct off the powersupply and then feeding its output into the bed power connector on the ramps?

Edited 2 time(s). Last edit at 06/19/2016 05:35PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Using a DC booster for 24V on the heated bed only June 19, 2016 08:19PM |

Registered: 8 years ago Posts: 601 |

Quote

DjDemonD

So the device you show above is a step up transformer 12v dc to 24v dc? I am not sure that's the right way to go, you will still have to supply it via the ramps board so you're still pulling 11A through the ramps, and we all know how much they like that, and that's your limit.

The way I did this for my enlarged smartrapcore alu with 300x200 bed is to run the heated bed output to a fused automotive mechanical relay, set bang bang control in the firmware so the relay isn't switching on/off too fast and then use a second 24v psu via the relay to the bed. As a result I get 250w @ 24vdc for my bed (which I have connected via its 12v connectors so it draws the maximum 12A from the 24v PSU), it heats up within 5 minutes to 120 deg C, I am not pulling 11A through the ramps board so much less worry about heat/fire/etc, and I have downgraded my 12v PSU to a laptop style unit which is more than enough for motors/hot end heater and some LEDs. The only criticism I got for this approach, which incidentally has been working flawlessly for months now, is that the relay clicking on/off would be annoying, which depends on your point of view, I like to hear it working, and I know when to go and remove the insulation from on top of the bed when I hear the relay click off at the end of heating. Plus if I wanted more power I'd just change the 24v PSU or consider going to mains heating.

Or use a DC-DC SSR to do the same as I have done above with 2 PSU's but now you can have PID control of the bed (pointless IMHO with a well insulated bed or even better an enclosed build volume - bang bang gives really good control). The SSR will usually need some sort of heatsink (so not that efficient if its losing energy as heat). They are more expensive and I am sure more prone to failure than a good ol' fashioned relay which cost a few $, so even if it does fail and it should fail-safe, I just swap in another one (I bought 2). I have used one for mains powered heating of a build chamber.

Moving everything over to 24v does have its appeal, 24v for steppers is supposed to be a much better prospect and I would consider this on a completely new printer build rather than on an upgrade to an existing 12v machine.

EDIT - you mean running this unit direct off the powersupply and then feeding its output into the bed power connector on the ramps?

Why not use an SSR and a transformer to supply 12v to ramps, 24v to bed? Still much better than 2 bulky power supplies, especially if your power supply can hack it

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 12:54AM |

Registered: 8 years ago Posts: 177 |

Quote

icefire

Of course, I could use a 24V PSU instead of the ATX PSU I have now, but that would mean to change practically everything: Hot end heater, fans, LED circuits, etc.

Thanks for your help!

Actually no, you could do the reverse of your original post, using a 24v -12v DC DC step down. your using a lot less current for fans, hotend, etc meaning a 100w step down unit would be heaps

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 07:38AM |

Registered: 8 years ago Posts: 3,525 |

Maybe it's because the printer I'm referring to is quite large but I could fit 8 power supplies in the box under it so I never really think they are that bulky and unwieldy. There must be a psu on offer from China somewhere that has 12v and 24v rails.

Maybe we could make one?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Maybe we could make one?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 08:15AM |

Registered: 11 years ago Posts: 5,780 |

If you use the bed size they recommend, 32 x 25 cm, that heater will use only 0.275 W/cm^2. That's pretty low and may take a long time to heat up to 105C. I use 0.5 W/cm^2 in my printer and it takes about 5 minutes to reach 105C. If you don't intend to print ABS it shouldn't be an issue- heating time to 60 or 80 C should be reasonable.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 09:40AM |

Registered: 8 years ago Posts: 168 |

Quote

DjDemonD

So the device you show above is a step up transformer 12v dc to 24v dc?

Yes, it is. The idea would be to do something like this:

What you suggest with an automotive relay or a solid state relay is basically the same with the additional advantage that I am not pulling that much current through the RAMPS. My question is if I could avoid using two separate power supplies and use the 12V ATX PSU with the DC DC converter on the one 12V rail. If I was to use an external relay then I could go hardcore and connect the heated bed to the mains power. The current would be considerably lower and the bed would reach 110 deg. in 2-3 min.

Quote

aussiephil

Actually no, you could do the reverse of your original post, using a 24v -12v DC DC step down. your using a lot less current for fans, hotend, etc meaning a 100w step down unit would be heaps

Also an interesting idea. This can work as well. A disadvantage in my case is that I don't have a working 24V PSU at the moment so I need to buy one.

@the_digital_dentist: Actually I intend to print more ABS than other materials. I wouldn't bother me to have to wait about 20 min to reach 110 degrees.. Do you think the heater in question wiuld be even slower? The bed size I am aiming at is approx. 240x320mm.. So I couldn't find a better alternative... Furthermore, 0,5W/cm^2 would mean about 400W for the heated bed which means about 16,5 amps of current.. the ramps will not like this without an external SSR.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 09:48AM |

Registered: 8 years ago Posts: 177 |

Quote

DjDemonD

Maybe it's because the printer I'm referring to is quite large but I could fit 8 power supplies in the box under it so I never really think they are that bulky and unwieldy. There must be a psu on offer from China somewhere that has 12v and 24v rails.

Maybe we could make one?

A quick browse on Meanwells site and Aliexpress did not show up any Dual Rail supplies, no doubt they exist but not in the budget most reprap people would like or afford

Easier by far to just use [www.ebay.com] one of those with a simple down converter to drive the 12 rail [www.ebay.com]

Seriously 2 x 350W units are only bigger in one dimension than a ATX power supply and not by a big amount once you take into account of the rats nest of cables coming out of most ATX supplies.

I've got a bunch of those 100W adjustable units for use with other things and they work fine, just don't have them to enclosed.

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 09:58AM |

Registered: 8 years ago Posts: 177 |

Quote

icefire

@the_digital_dentist: Actually I intend to print more ABS than other materials. I wouldn't bother me to have to wait about 20 min to reach 110 degrees.. Do you think the heater in question wiuld be even slower? The bed size I am aiming at is approx. 240x320mm.. So I couldn't find a better alternative... Furthermore, 0,5W/cm^2 would mean about 400W for the heated bed which means about 16,5 amps of current.. the ramps will not like this without an external SSR.

I'm going to chime in and support DD and also recommend using a bigger better heater... I've got nearly 5,000 print hours on ABS and trust me if I was waiting 20 minutes i'd be super frustrated, 5 minutes and under should always be the goal.

Note the 0.5W/cm CUBED of your bed assuming aluminium.

240x320 = 768 square centimetres

Thickness of 6mm = 460W

400W is likely more than enough though but you will then need to use a DC-DC SSR and some nice thick wiring for the 17A current draw.

Edited 1 time(s). Last edit at 06/20/2016 09:58AM by aussiephil.

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 09:58AM |

Registered: 11 years ago Posts: 5,780 |

Quote

icefire

@the_digital_dentist: Actually I intend to print more ABS than other materials. I wouldn't bother me to have to wait about 20 min to reach 110 degrees.. Do you think the heater in question wiuld be even slower? The bed size I am aiming at is approx. 240x320mm.. So I couldn't find a better alternative... Furthermore, 0,5W/cm^2 would mean about 400W for the heated bed which means about 16,5 amps of current.. the ramps will not like this without an external SSR.

If you don't mind waiting, that heater may get hot enough. You could use a line powered heater with an SSR driven by the controller. Then you wouldn't have to buy another power supply. You would have to take some extra precautions for safety...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 05:52PM |

Registered: 8 years ago Posts: 168 |

So, back to the subject, I guess no one is in favor of a dc step up converter in combination of the PSU. The other way around may be a better alternative (24V PSU with a dc step down converter) so this is probably the better way to go.

About the heated bed itself, if 0,5W/cm^2 is a decent value for a fast heated bed, this would mean that no heated bed bigger than 200x200mm could be powered directly through the RAMPS. For a bigger heated bed, like 240x320mm, I would need an SSR and some pretty thick wires, provided I even find such a bed heater on the market (can anyone please suggest where I can buy such a thing?).

This makes me wonder how commercial, "ready-to-use" printers like the real Mendelmax 2, Lulzbot Taz 6, Ultimaker 2, etc. are designed. All of them have larger than 200x200 build platforms and, from what I gather looking at pictures, I do not see any ultra thick wires (which would indicate high currents to avoid massive voltage drops). Are they all slow in terms of heating or am I missing something? Of course, most of the commercial solutions have not published detailed description of their inner workings but still, It would be interesting to know if someone has seen or experienced them.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

About the heated bed itself, if 0,5W/cm^2 is a decent value for a fast heated bed, this would mean that no heated bed bigger than 200x200mm could be powered directly through the RAMPS. For a bigger heated bed, like 240x320mm, I would need an SSR and some pretty thick wires, provided I even find such a bed heater on the market (can anyone please suggest where I can buy such a thing?).

This makes me wonder how commercial, "ready-to-use" printers like the real Mendelmax 2, Lulzbot Taz 6, Ultimaker 2, etc. are designed. All of them have larger than 200x200 build platforms and, from what I gather looking at pictures, I do not see any ultra thick wires (which would indicate high currents to avoid massive voltage drops). Are they all slow in terms of heating or am I missing something? Of course, most of the commercial solutions have not published detailed description of their inner workings but still, It would be interesting to know if someone has seen or experienced them.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only June 20, 2016 06:08PM |

Registered: 10 years ago Posts: 14,672 |

I think you will find that most good 3D printers with beds larger than 200 x 200mm use 24V-capable electronics and power everything from 24V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Using a DC booster for 24V on the heated bed only June 21, 2016 02:56PM |

Registered: 8 years ago Posts: 168 |

Quote

dc42

I think you will find that most good 3D printers with beds larger than 200 x 200mm use 24V-capable electronics and power everything from 24V.

My point exactly. But if you do a small calculation and take 0,5 W/cm^2 as basis you would quickly come to the conclusion that 200x200mm would pretty much be the limit because of the high current. So I was wondering how commercial 3D printers are designed - do they use a lower power density like for example 0,3 W/cm^2 or do they have an SSR and pretty thick cables?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only June 21, 2016 04:43PM |

Registered: 10 years ago Posts: 14,672 |

I reckon on 0.4W/cm^2. You can get away with as little as 0.25W/cm^2 if you don't mind longer heating times. The maximum heated bed current that controller boards can supply varies from about 10A (RAMPS on a cold day) to 15A. So a 200mm square bed can make do with 12V @ 10A (0.3W/cm^2) and a 300mm square bed can use 24V @ 11A (nearly 0.3 again). You can only go a little larger before you need to use an SSR to switch the bed heater; and at that point a mains voltage bed heater is usually the best option technically.

Edited 1 time(s). Last edit at 06/21/2016 04:43PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 06/21/2016 04:43PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Using a DC booster for 24V on the heated bed only June 24, 2016 01:28PM |

Registered: 8 years ago Posts: 168 |

How about using a mosFET to hook up the larger heated bed?

There are a bunch or aliexpress sellers who can make a custom size silicone heater. So for 370W heated bed @24V I would get about 16 Amps of current.

A decent DC SSR can be pretty expensive and I fear that the cheap ones on aliexpress have a huge voltage drop.

So how about a mosFET? Anyone with experience?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

There are a bunch or aliexpress sellers who can make a custom size silicone heater. So for 370W heated bed @24V I would get about 16 Amps of current.

A decent DC SSR can be pretty expensive and I fear that the cheap ones on aliexpress have a huge voltage drop.

So how about a mosFET? Anyone with experience?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only June 24, 2016 01:37PM |

Registered: 9 years ago Posts: 425 |

icefire

Easiest quickest cheapest least hassle most reliable approach in my view would be to acquire a 24v PSU for the heatbed, and run it through a sevenswitch

Connect the 24v PSU and heatbed through the sevenswitch, and use the 12v heatbed output from the RAMPs to drive the sevenswitch.

HTH

Easiest quickest cheapest least hassle most reliable approach in my view would be to acquire a 24v PSU for the heatbed, and run it through a sevenswitch

Connect the 24v PSU and heatbed through the sevenswitch, and use the 12v heatbed output from the RAMPs to drive the sevenswitch.

HTH

|

Re: Using a DC booster for 24V on the heated bed only June 24, 2016 06:09PM |

Registered: 8 years ago Posts: 168 |

Wow, this seems to be a great solution.

One question though: The wiki page suggests the SevenSwitch is capable of switching currents up to 15 Amps. In my case, if I go for 0,5 W/cm^2 on the heated bed, I would have a current of almost 17 Amps. I actually do not see any problem with this current. The datasheet of IRLB8743 states an RDS(on) of just 32 mOhm so temperature shouldn't be a problem.

Provided that the wire terminals are thick enough and support 2,5 mm^2 wires I guess it could work. However, I am not sure if the PCB would handle that sort of current... What do you think?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

One question though: The wiki page suggests the SevenSwitch is capable of switching currents up to 15 Amps. In my case, if I go for 0,5 W/cm^2 on the heated bed, I would have a current of almost 17 Amps. I actually do not see any problem with this current. The datasheet of IRLB8743 states an RDS(on) of just 32 mOhm so temperature shouldn't be a problem.

Provided that the wire terminals are thick enough and support 2,5 mm^2 wires I guess it could work. However, I am not sure if the PCB would handle that sort of current... What do you think?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only June 25, 2016 11:10AM |

Registered: 9 years ago Posts: 425 |

|

Re: Using a DC booster for 24V on the heated bed only June 25, 2016 11:35AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Mutley3D

Maybe Traumflug can chime in on this.

Current limiting on the SevenSwitch isn't the MOSFET (good for 150 A ignoring the package, good for 70 A taking the package into account) and also not the PCB (really wide tracks there), but the screw terminals. These can warm up due to not optimal contacts; make sure to use not only thick wires, but also well cleaned wire ends.

That said, these theoretical 17 A mentioned above apply only for a short time. As the bed warms up, resistance raises and current lowers. It's said (didn't measure it) that heating to 100 °C doubles copper resistance, so you'd have only 9 A after a few minutes. As soon as temperature is reached and PWM kicks in, heating power reduces significantly anyways.

Before you ask on how to connect a SevenSwitch to a RAMPS, see: [www.reprap-diy.com]

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Using a DC booster for 24V on the heated bed only June 26, 2016 08:53AM |

Registered: 8 years ago Posts: 168 |

Quote

Traumflug

Current limiting on the SevenSwitch isn't the MOSFET (good for 150 A ignoring the package, good for 70 A taking the package into account) and also not the PCB (really wide tracks there), but the screw terminals. These can warm up due to not optimal contacts; make sure to use not only thick wires, but also well cleaned wire ends.

Thanks! So I am going to get some nice wire contacts, capable of screwing down a 2,5 mm^2 wire. I always use a crimp tool on wire ends to improve the electrical contact. Alternatively, I could solder the thick wires directly to the PCB tracks and avoid the risk of bad wire contact.

So I guess a SevenSwitch would be the best way to go.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only August 19, 2016 08:45PM |

Registered: 8 years ago Posts: 168 |

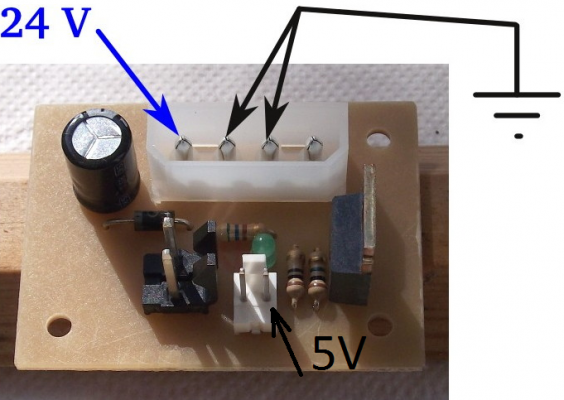

So before ordering "the real thing" I soldered the components on to a prototype circuit board according to the seven switch schematics: [github.com]

But I have a slight problem. I did the following tests:

- tried with 24V input voltage, no load - everything is fine

- tried triggering with 5V signal - all good, the LED lights up

- tried connecting the heated bed (24V 400W) and triggering the switch with the 5V signal. Initially it worked for like 5 seconds. After that the FET started getting very hot and eventually burned out in smoke.

After disconnecting it I found out that the pull down resistor (R3, 1MOhm) was measuring 0 Ohms. If I unsolder it and measure it again, the resistance starts falling and the resistor starts getting hot just as a result of measuring it. Maybe it had the wrong power rating... What would be the recommended power rating for the three resistors? I am using 24V. At the moment all three are rated 0,25W... if there are 24V across each resistor I cannot imagine that the power rating was an issue...

Edited 3 time(s). Last edit at 08/19/2016 09:14PM by icefire.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

But I have a slight problem. I did the following tests:

- tried with 24V input voltage, no load - everything is fine

- tried triggering with 5V signal - all good, the LED lights up

- tried connecting the heated bed (24V 400W) and triggering the switch with the 5V signal. Initially it worked for like 5 seconds. After that the FET started getting very hot and eventually burned out in smoke.

After disconnecting it I found out that the pull down resistor (R3, 1MOhm) was measuring 0 Ohms. If I unsolder it and measure it again, the resistance starts falling and the resistor starts getting hot just as a result of measuring it. Maybe it had the wrong power rating... What would be the recommended power rating for the three resistors? I am using 24V. At the moment all three are rated 0,25W... if there are 24V across each resistor I cannot imagine that the power rating was an issue...

Edited 3 time(s). Last edit at 08/19/2016 09:14PM by icefire.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only August 20, 2016 04:06AM |

Registered: 13 years ago Posts: 7,616 |

Bye bye IRLB8743. Maximum input voltage 20V.Quote

icefire

- tried with 24V input voltage, no load - everything is fine

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Using a DC booster for 24V on the heated bed only August 20, 2016 04:41AM |

Registered: 8 years ago Posts: 168 |

Quote

Traumflug

Bye bye IRLB8743. Maximum input voltage 20V.

What I meant was that I tested with 24V applied to CONN1 and nothing else connected to the board. The voltage applied to the IRLB8743 was never more than 5V. I used one of your pictures to avoid a misunderstanding:

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only August 25, 2016 12:52PM |

Registered: 8 years ago Posts: 168 |

Ok, after smoking two MosFETs i finally found out what the problem was. The FET just can't handle 13-15A @24V without a heatsink even though it would be theoretically possible according to the datasheet.

Attaching the MosFET to a thick aluminum sheet solves the issue.

Traumflug, i guess it is a good idea to recommend in the official documentation using a heatsink with higher currents.

Edited 1 time(s). Last edit at 08/25/2016 01:14PM by icefire.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Attaching the MosFET to a thick aluminum sheet solves the issue.

Traumflug, i guess it is a good idea to recommend in the official documentation using a heatsink with higher currents.

Edited 1 time(s). Last edit at 08/25/2016 01:14PM by icefire.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Using a DC booster for 24V on the heated bed only August 26, 2016 07:16PM |

Registered: 10 years ago Posts: 469 |

Quote

icefire

Quote

DjDemonD

So the device you show above is a step up transformer 12v dc to 24v dc?

Yes, it is. The idea would be to do something like this:

What you suggest with an automotive relay or a solid state relay is basically the same with the additional advantage that I am not pulling that much current through the RAMPS. My question is if I could avoid using two separate power supplies and use the 12V ATX PSU with the DC DC converter on the one 12V rail. If I was to use an external relay then I could go hardcore and connect the heated bed to the mains power. The current would be considerably lower and the bed would reach 110 deg. in 2-3 min.

Quote

aussiephil

Actually no, you could do the reverse of your original post, using a 24v -12v DC DC step down. your using a lot less current for fans, hotend, etc meaning a 100w step down unit would be heaps

Also an interesting idea. This can work as well. A disadvantage in my case is that I don't have a working 24V PSU at the moment so I need to buy one.

@the_digital_dentist: Actually I intend to print more ABS than other materials. I wouldn't bother me to have to wait about 20 min to reach 110 degrees.. Do you think the heater in question wiuld be even slower? The bed size I am aiming at is approx. 240x320mm.. So I couldn't find a better alternative... Furthermore, 0,5W/cm^2 would mean about 400W for the heated bed which means about 16,5 amps of current.. the ramps will not like this without an external SSR.

You can feed the ramps with 24v on the hot bed side. Leave the rest to 12v. It works and works well. Now the down side is that those buck converters are noisy and require active cooling. You also have to modify the buck converter to work with this setup if you plan on drawing 200W or so from it. Mainly you will pop the fuse that comes with it. I bypassed the factory fuse using a thick copper wire and desoldered the fuse holder all together. You still want a fuse however. A automitve 20A fuse is what I use on the 12v side. You also have to modify the ramps. Remove the self resetting fuse for the heated bed as now you have the 20A fuse before the buck converter and those self resetting fuses do not like 24v operation. With that said, the freaking converter does sing quite a bit (Think of crickets at full song in the hot sun), especially since I am using it to over-volt the bed to ~ 28.5v (this steps the 3.6ohm 24v bed from ~160w to ~225w), use thicker than necessary wires and do not leave your printer unattended if you plan on pushing more than 200W from a 12v source with that buck converter. Its really designed to not suck more than 10A and up-convert it, with inefficiencies, it probably sucks up around 15-16A.

EDIT: I should have read the entire thread. I see your putting allot more amps on that fet than designed for. There is a fet compatible that will handle over 100A, I have a pack of them somewhere around here. With that said my fets are actively cooled with sinks on them. They do not get more than mildly warm, before they would go into the 50c range without sinks but actively cooled. My ramps has always been actively cooled honestly. Using the PSU fan as a sucker fan with a small 80mm fan in the case to help cool ramps.

Edited 1 time(s). Last edit at 08/26/2016 07:21PM by jaguarking11.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

Sorry, only registered users may post in this forum.