Annealing ideas

Posted by RPearce

|

Annealing ideas June 21, 2016 05:30PM |

Registered: 9 years ago Posts: 73 |

Hey guys i ran into a material that requires annealing, similar process to hardening for steel just at lower heat, i need to have my items sit in a heat chamber at 100c for 1 hour then cool, my thoughts are, that i could get away with this by using a small toaster oven, rather then using my oven in my kitchen, and its small enough to fit in my office. what do you guys think about this or do you have any other ideas that could work while still being affordable?

|

Re: Annealing ideas June 21, 2016 05:41PM |

Admin Registered: 16 years ago Posts: 13,884 |

... how big are your parts?

If small enough, then you can put them in a metal box and in a pot with cooking water, what's near enough to 100c ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

If small enough, then you can put them in a metal box and in a pot with cooking water, what's near enough to 100c ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Annealing ideas June 21, 2016 05:44PM |

Registered: 9 years ago Posts: 73 |

Quote

VDX

... how big are your parts?

If small enough, then you can put them in a metal box and in a pot with cooking water, what's near enough to 100c ...

Well, i would like a 12" cube to work in since my largest machine will do a 10" cube, but in the instructions for annealing from polymaker, they said use a normal convection oven, i was wondering if a smaller toaster over or something like that could work, something the size of say a microwave would be perfect as long as it could maintain a 100 degree temp for 1 hour.

|

Re: Annealing ideas June 22, 2016 01:32AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Annealing ideas June 22, 2016 01:35AM |

Registered: 9 years ago Posts: 73 |

Quote

MechaBits

not sure microwave would be a solution, the way it creates the heat is a little different...but I could be wrong.

wasnt going to use a microwave, i picked up a Black and Decker CounterTop Convection oven today for $55 Canadian. im going to give it a go, it looks like it will have a fairly good size for the job.

|

Re: Annealing ideas June 22, 2016 01:52AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Annealing ideas June 22, 2016 01:57AM |

Registered: 9 years ago Posts: 73 |

will do, im expanding from my home here soon to an office space that has power included in a fixed rate rent. so it wont be so bad running 4-5 machines plus this oven.Quote

MechaBits

Keep us posted on results.....I was thinking of using a george forman grill press for some of my parts,

or a trouser press, or a pannini press or something...to bind the layers, and flatten the buggers out.

|

Re: Annealing ideas June 22, 2016 03:00AM |

Registered: 9 years ago Posts: 483 |

|

Re: Annealing ideas June 22, 2016 11:01AM |

Registered: 7 years ago Posts: 44 |

Interesting, are you going to anneal your parts to improve layer bonding?

I feel like a toaster oven, as others suggested, would do the trick. Plastics don't have a precise temperature where properties drastically changes like metals, so a bit of variation in temperature shouldn't be a problem.

I feel like a toaster oven, as others suggested, would do the trick. Plastics don't have a precise temperature where properties drastically changes like metals, so a bit of variation in temperature shouldn't be a problem.

|

Re: Annealing ideas June 22, 2016 02:53PM |

Registered: 11 years ago Posts: 1,049 |

I have not seen a toaster oven (small oven) that can be set near 100c or 200f and hold that temperature

A high end in the wall oven with digital controls, can be set at 250f but temp actually varies greatly.

You should really invest in a probe and meter to actually measure temp.

They recommend convection oven because the hot air is circulated

providing even temperature across heated object?

Make your own dehydrator with a heating element, fan and good controller!

I don't know about annealing polymer.

but

if metal has great temperature differences along the annealed part --- you get JUNK!!!

well at least a part that won't pass Milspec or other metalurgical process

A high end in the wall oven with digital controls, can be set at 250f but temp actually varies greatly.

You should really invest in a probe and meter to actually measure temp.

They recommend convection oven because the hot air is circulated

providing even temperature across heated object?

Make your own dehydrator with a heating element, fan and good controller!

I don't know about annealing polymer.

but

if metal has great temperature differences along the annealed part --- you get JUNK!!!

well at least a part that won't pass Milspec or other metalurgical process

|

Re: Annealing ideas June 22, 2016 05:15PM |

Registered: 11 years ago Posts: 14 |

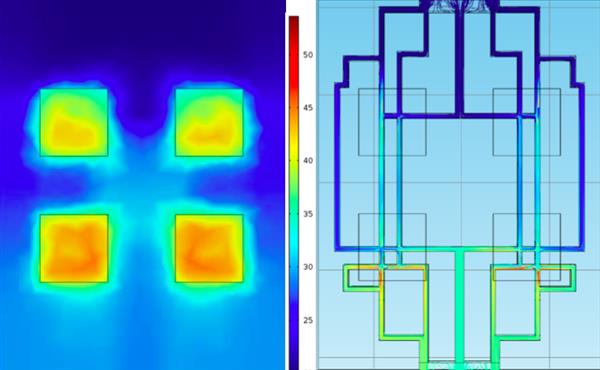

Here are a couple pictures from a recent experiment I did with Natureworks PLA 3D850 that claims increased crystallization with heat treat. I used a wall oven to heat treat the parts at 200F but did not verify with a second thermometer.

Picture: 2016-06-20 16.41.53

The three parts on the left are not heat treated and the three on the right are heat treated at 200F for 15 minutes. I placed the parts into a cold oven and let the oven heat to temp and maintained temp for 15 minutes then removed the parts to air cool. The color change and warping happened while the parts were in the oven not after they were removed.

The top two parts were made with one perimeter (0.48mm width). The center two are two perimeters and the bottom two have three perimeters. Interestingly enough the part with two perimeters warped the least. I also heat treated a couple objects with more structural integrity and found little to no warping (small 5" Moai statue and the re3D logo placard).

I think the next steps are to control the rate of heating to see if the amount of warping can be reduced. Would love to hear other's experience with heat treating the PLA 3D850.

Picture: 2016-06-20 16.41.53

The three parts on the left are not heat treated and the three on the right are heat treated at 200F for 15 minutes. I placed the parts into a cold oven and let the oven heat to temp and maintained temp for 15 minutes then removed the parts to air cool. The color change and warping happened while the parts were in the oven not after they were removed.

The top two parts were made with one perimeter (0.48mm width). The center two are two perimeters and the bottom two have three perimeters. Interestingly enough the part with two perimeters warped the least. I also heat treated a couple objects with more structural integrity and found little to no warping (small 5" Moai statue and the re3D logo placard).

I think the next steps are to control the rate of heating to see if the amount of warping can be reduced. Would love to hear other's experience with heat treating the PLA 3D850.

|

Re: Annealing ideas June 24, 2016 03:45PM |

Registered: 8 years ago Posts: 3,525 |

What do you make of this [www.google.co.uk]

I only ask as the author observed that annealing had no real benefits? I was hoping it would it stands to reason but not it appears experimentation.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I only ask as the author observed that annealing had no real benefits? I was hoping it would it stands to reason but not it appears experimentation.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Annealing ideas June 24, 2016 03:55PM |

Registered: 10 years ago Posts: 564 |

Quote

DjDemonD

What do you make of this [www.google.co.uk]

I only ask as the author observed that annealing had no real benefits? I was hoping it would it stands to reason but not it appears experimentation.

It looks like the paper only examined the part strength. My impression is that the annealing to promote crystallization is mostly done to raise the heat deflection temperature. Also, I'm guessing that you need to use filament specially formulated for annealing rather than garden variety PLA.

Edited 1 time(s). Last edit at 06/24/2016 03:56PM by LoboCNC.

|

Re: Annealing ideas July 08, 2016 11:37AM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.