|

High temperature insulation for hotend July 01, 2016 01:04PM |

Registered: 12 years ago Posts: 1,450 |

Can anybody recommend a high temperature thermal insulation which I could use to replace cuttlefish bone that I presently use in my hot ends. I have heard about cellular glass but know nothing about it - can it be cut into shapes with 2mm thick walls, where can it be purchased etc.. Are there any other similar materials?

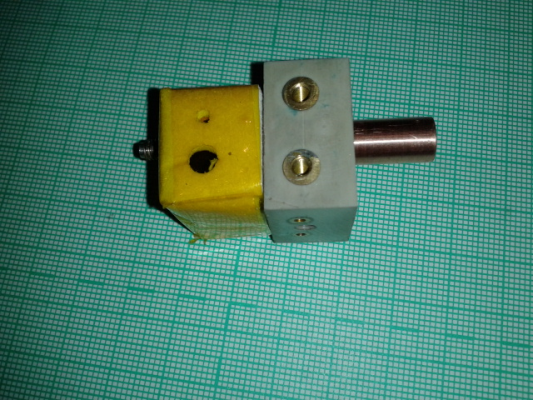

The existing cuttlefish insulators are shown in the photo below in white - they are protected in a box made from thin brass sheet which is also the guide for cooling air to the print.

The requirement has arisen because I want to fit interchangeable nozzles to the hot ends on my printers. Cuttlefish bone has many exceptional properties but it is unbelievably fragile and changing a nozzle would turn it from a solid to a powder quite rapidly.

Mike

The existing cuttlefish insulators are shown in the photo below in white - they are protected in a box made from thin brass sheet which is also the guide for cooling air to the print.

The requirement has arisen because I want to fit interchangeable nozzles to the hot ends on my printers. Cuttlefish bone has many exceptional properties but it is unbelievably fragile and changing a nozzle would turn it from a solid to a powder quite rapidly.

Mike

|

Re: High temperature insulation for hotend July 01, 2016 02:25PM |

Registered: 8 years ago Posts: 601 |

|

Re: High temperature insulation for hotend July 01, 2016 02:59PM |

Registered: 12 years ago Posts: 2,470 |

Check this thread in the german subforum

[forums.reprap.org]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[forums.reprap.org]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: High temperature insulation for hotend July 01, 2016 03:24PM |

Registered: 12 years ago Posts: 1,450 |

|

Re: High temperature insulation for hotend July 01, 2016 03:29PM |

Registered: 12 years ago Posts: 2,470 |

The source is quoted in the thread and on my website, but it is from germany. Just check local sources for silicone for tin casting.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: High temperature insulation for hotend July 01, 2016 04:08PM |

Registered: 8 years ago Posts: 367 |

Ceramic tape might be another option: [www.amazon.com]. I have some but have not tried it yet.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: High temperature insulation for hotend July 02, 2016 09:15AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: High temperature insulation for hotend July 02, 2016 03:14PM |

Registered: 8 years ago Posts: 3,525 |

Would these work, [www.ebay.co.uk] I've got some mk8 hot ends with this material applied but I have never used them.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: High temperature insulation for hotend July 04, 2016 02:51PM |

Registered: 7 years ago Posts: 44 |

Mica band can be another economic solution.

With the proper thickness, Kapton can hold it without problems.

DYZE DESIGN

Hotends, Extruders, Liquid Cooling and Accessories.

With the proper thickness, Kapton can hold it without problems.

DYZE DESIGN

Hotends, Extruders, Liquid Cooling and Accessories.

|

Re: High temperature insulation for hotend July 06, 2016 02:47PM |

Registered: 12 years ago Posts: 1,450 |

In the end I adopted a method which combines some of the earlier suggestions. The insulation material was what is called Kiln Paper used to put glass on for fusing in a kiln. Ordered from ebay [www.ebay.co.uk] it turned out to be a sort of woolen batting made from a ceramic fiber. It cuts easily and cleanly with a sharp scalpel so I was able to form it into a box with chamfered edges which I folded round the heater block. Pictures below show the parts including the cut insulation, the insulating box assembled with Kapton tape and the hot end assembled with shroud and replaceable nozzle.

Mike

Mike

|

Re: High temperature insulation for hotend July 06, 2016 03:05PM |

Registered: 8 years ago Posts: 367 |

That looks good and very neat. Your description of kiln paper sounds very like the ceramic tape that I bought with a soft and slightly woollen feel to it. I fitted some at the weekend and it has helped keep the temperature stable, particularly when the cooling fan is running at full speed (mostly just for bridging).

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: High temperature insulation for hotend July 07, 2016 03:51AM |

Registered: 8 years ago Posts: 3,525 |

Does anyone have a link for Srek's guide to making a silicone sleeve?

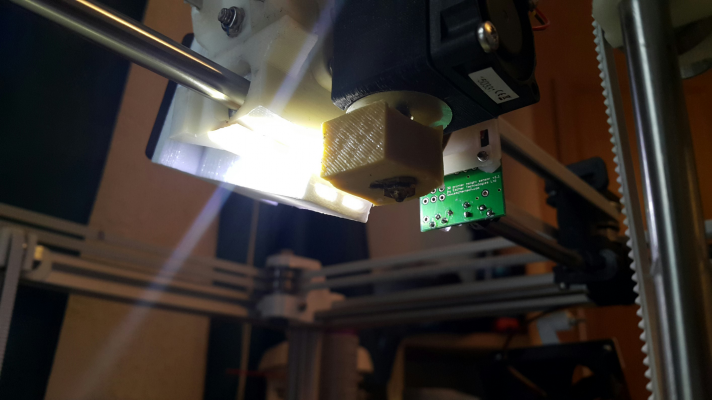

If I was going to do this, I'd design and print a mould to fit around the hotend, then fill it with high temperature silicone. Then remove the mould. It seems easy enough in theory. The only thing that might save a lot of trial and error is a recommendation on which silicone to use and to know whether when it needs to be removed, how straightforward this is.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

If I was going to do this, I'd design and print a mould to fit around the hotend, then fill it with high temperature silicone. Then remove the mould. It seems easy enough in theory. The only thing that might save a lot of trial and error is a recommendation on which silicone to use and to know whether when it needs to be removed, how straightforward this is.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: High temperature insulation for hotend July 07, 2016 04:26AM |

Registered: 12 years ago Posts: 1,450 |

I haven't found the actual guide but there is this [www.thingiverse.com]

When I checked the actual conductivity with some silicone rubber I was pleasantly surprised and think that it would do well for most hot ends. Having said that, my hot ends are a little unusual as the cooling air for the print is directed through an air ring around the nozzle and low thermal conductivity was more important than toughness. Using the best engineering "wild guess" strategy, I think that ceramic wool has about one tenth of the conductivity of silicone rubber.

Mike

When I checked the actual conductivity with some silicone rubber I was pleasantly surprised and think that it would do well for most hot ends. Having said that, my hot ends are a little unusual as the cooling air for the print is directed through an air ring around the nozzle and low thermal conductivity was more important than toughness. Using the best engineering "wild guess" strategy, I think that ceramic wool has about one tenth of the conductivity of silicone rubber.

Mike

|

Re: High temperature insulation for hotend July 07, 2016 05:13AM |

Registered: 12 years ago Posts: 2,470 |

You should find most stuff here

[b.bonkers.de]

[b.bonkers.de]

[b.bonkers.de]

Try using a separation agent like vaseline or PTFE spray, due to the fine layer structure of 3D printed molds the silicone can stick quite good.

The silicone used is advertised for tin casting, you will find a source in germany in the links above.

Edited 1 time(s). Last edit at 07/07/2016 05:15AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[b.bonkers.de]

[b.bonkers.de]

[b.bonkers.de]

Try using a separation agent like vaseline or PTFE spray, due to the fine layer structure of 3D printed molds the silicone can stick quite good.

The silicone used is advertised for tin casting, you will find a source in germany in the links above.

Edited 1 time(s). Last edit at 07/07/2016 05:15AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: High temperature insulation for hotend July 07, 2016 06:11AM |

Registered: 8 years ago Posts: 3,525 |

Thank you very much this looks very interesting.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: High temperature insulation for hotend July 07, 2016 08:14AM |

Registered: 7 years ago Posts: 1 |

In addition to the air flow from the fan, convection currents will naturally arise next to the hot part, and carry heat away. Anything you can do to stop this flow, or slow it down, will probably help.

Unix Shell Scripting Training | Angularjs Training | Informatica Training | Tableau Training | Hadoop Training

Unix Shell Scripting Training | Angularjs Training | Informatica Training | Tableau Training | Hadoop Training

|

Re: High temperature insulation for hotend July 14, 2016 06:05PM |

Registered: 8 years ago Posts: 3,525 |

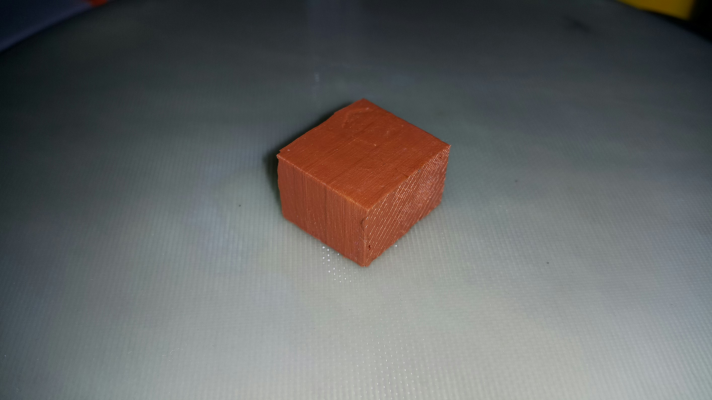

So it is possible to make a silicone sleeve for a hotend using condensation silicone such the type sold as instant gasket material, I tried Loctite SI 5990 which is rated for up to 350 deg C and has a nice copper colour.

The only thing is it takes about 4-5 days to set as there is only a tiny bit of air (and moisture which it needs to set) getting to it through a 3d printed mould which is in this case, thankfully porous.

I've made a mould for a v5 hotend based on Sreks design (above) just trying it out now, but using the two part mix addition cured silicone instead (much messier but a lot quicker).

Seems it does work, have hosted it here, thanks to Srek for the original design/idea.

Edited 2 time(s). Last edit at 07/15/2016 03:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

The only thing is it takes about 4-5 days to set as there is only a tiny bit of air (and moisture which it needs to set) getting to it through a 3d printed mould which is in this case, thankfully porous.

I've made a mould for a v5 hotend based on Sreks design (above) just trying it out now, but using the two part mix addition cured silicone instead (much messier but a lot quicker).

Seems it does work, have hosted it here, thanks to Srek for the original design/idea.

Edited 2 time(s). Last edit at 07/15/2016 03:16PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.