Copper slip as thermal paste

Posted by deckingman

|

Copper slip as thermal paste July 03, 2016 04:15PM |

Registered: 8 years ago Posts: 622 |

Way back in a previous life when I worked in the automotive industry, we used to use a product called Copper Slip as an anti-seize compound in high temperature situations, and I got to wondering if it would be any good as a thermal transfer paste around heater cartridges due to its high copper content and the fact that it's rated to around 1,100 deg C.

To test the hypothesis, I hooked up an experiment using a spare Diamond hot end and 24v heater cartridge. I wired the cartridge directly to a 24v power supply and put a K type thermocouple in the hole where the thermistor would normally go, held in place with a bit of Kapton tape. The hot end was just the brass part with no heat sinks attached. I put the hot end on an old quarry tile with some insulation underneath but there were no fans or cooling other than the free air air around it.. Then I switched on and noted the time it took to get from ambient (about 24-27degC) to 50,100,150,200,250,300,350 and 400 degrees. The reason I went so high was that someone had commented that the grease in the Copper Slip had a flash point of about 250deg C and would therefore boil off. I wanted to make sure that this would happen to get a reasonable indication of how the stuff would perform over time. I did 3 tests with no paste, just the cartridge loosely fitted in the hole. After each run, I let the thing cool right down to ambient. The results were pretty repeatable. Then I removed the cartridge, smeared it will with Copper slip and refitted it. Then I did 3 more runs as before. On the first run, at something just over 250 deg C, there was a fair bit of smoke which I reckon was the grease part burning off but by the time the temperature reached about 300 to 350 deg C, the smoke stopped. There was no more smoke for the other two runs. It's fair to say that the first run with copper slip was better than the other two but those 2 were repeatable and better than no paste at all.

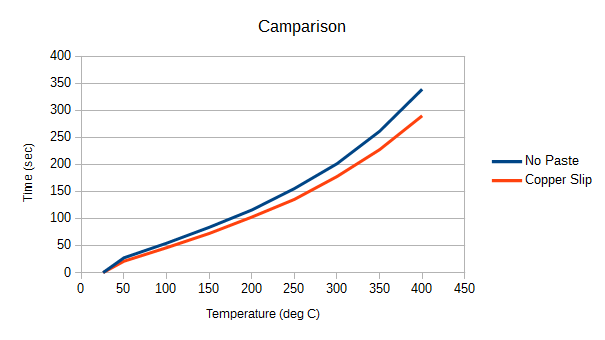

The results are all in the attached spread sheet. Here is a graph of the averages

Note that time is the Y axis and temperature is the X axis so it's kind of back to front. The lower, red line shows a shorter time to reach a given temperature. I guess I should have noted the temperature at fixed time intervals rather than the time at fixed temperature intervals.

In summary, that data appears to show an improvement in the time to reach a given temperature of about 12% under those test conditions, but a bit less if you go over 250 deg C and boil off the grease. I've no idea how this compares with other high temperature thermal pastes but I do know that it's considerably cheaper to buy (although you do have to buy quite a large tube).

This is in no way a recommendation or otherwise. I'm merely reporting my findings.

To test the hypothesis, I hooked up an experiment using a spare Diamond hot end and 24v heater cartridge. I wired the cartridge directly to a 24v power supply and put a K type thermocouple in the hole where the thermistor would normally go, held in place with a bit of Kapton tape. The hot end was just the brass part with no heat sinks attached. I put the hot end on an old quarry tile with some insulation underneath but there were no fans or cooling other than the free air air around it.. Then I switched on and noted the time it took to get from ambient (about 24-27degC) to 50,100,150,200,250,300,350 and 400 degrees. The reason I went so high was that someone had commented that the grease in the Copper Slip had a flash point of about 250deg C and would therefore boil off. I wanted to make sure that this would happen to get a reasonable indication of how the stuff would perform over time. I did 3 tests with no paste, just the cartridge loosely fitted in the hole. After each run, I let the thing cool right down to ambient. The results were pretty repeatable. Then I removed the cartridge, smeared it will with Copper slip and refitted it. Then I did 3 more runs as before. On the first run, at something just over 250 deg C, there was a fair bit of smoke which I reckon was the grease part burning off but by the time the temperature reached about 300 to 350 deg C, the smoke stopped. There was no more smoke for the other two runs. It's fair to say that the first run with copper slip was better than the other two but those 2 were repeatable and better than no paste at all.

The results are all in the attached spread sheet. Here is a graph of the averages

Note that time is the Y axis and temperature is the X axis so it's kind of back to front. The lower, red line shows a shorter time to reach a given temperature. I guess I should have noted the temperature at fixed time intervals rather than the time at fixed temperature intervals.

In summary, that data appears to show an improvement in the time to reach a given temperature of about 12% under those test conditions, but a bit less if you go over 250 deg C and boil off the grease. I've no idea how this compares with other high temperature thermal pastes but I do know that it's considerably cheaper to buy (although you do have to buy quite a large tube).

This is in no way a recommendation or otherwise. I'm merely reporting my findings.

|

Re: Copper slip as thermal paste July 03, 2016 11:31PM |

Registered: 11 years ago Posts: 1,049 |

Almost all hot ends are aluminum block with a steel threaded tube for filament.

Heater cart fits tightly --- press fit -- or held in with bolts ?

Cartridge case is commonly aluminum

so aluminum to aluminum contact best for thermal transfer.

So the smoke that came out? Did the canary flop off the perch?

This "Slip" is an anti-seize compound with

soft copper powder providing anti-seize agent --- NOT thermal tranfer.

Look at cpu thermal paste --- usually a silver oxide or silver paste

specifically formulated for heat transfer.

Heater cart fits tightly --- press fit -- or held in with bolts ?

Cartridge case is commonly aluminum

so aluminum to aluminum contact best for thermal transfer.

So the smoke that came out? Did the canary flop off the perch?

This "Slip" is an anti-seize compound with

soft copper powder providing anti-seize agent --- NOT thermal tranfer.

Look at cpu thermal paste --- usually a silver oxide or silver paste

specifically formulated for heat transfer.

|

Re: Copper slip as thermal paste July 04, 2016 04:34AM |

Registered: 12 years ago Posts: 1,450 |

Almost all??? Brass and even copper are also used in heater blocksQuote

cozmicray

Almost all hot ends are aluminum block with a steel threaded tube for filament.......

A brief perusal of ebay and my old cartridge cases shows no aluminium - only stainless steel.Quote

Cartridge case is commonly aluminum....

If this were the case, aluminium to aluminium push fit is a really BAD idea and edit

Irrelevant. Does it do the job is the only questionQuote

soft copper powder providing anti-seize agent --- NOT thermal tranfer.

And definitely not intended for use at hotend temperaturesQuote

Look at cpu thermal paste --- usually a silver oxide or silver paste specifically formulated for heat transfer.

Mike

edit add p.s. thanks deckingman for the original post. Trying something is always much more productive than simply accepting the received wisdom of others.

Edited 2 time(s). Last edit at 07/04/2016 05:15AM by leadinglights.

|

Re: Copper slip as thermal paste July 04, 2016 07:00AM |

Registered: 10 years ago Posts: 14,672 |

deckingman, thanks for taking the trouble to try this out and take measurements.

I have a tube of copper anti seize compound somewhere, and I will be using it next time I install a heater cartridge. It stands to reason that the thermal conductivity of copper paste will be better than air, and your measurements confirm this.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I have a tube of copper anti seize compound somewhere, and I will be using it next time I install a heater cartridge. It stands to reason that the thermal conductivity of copper paste will be better than air, and your measurements confirm this.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Copper slip as thermal paste July 04, 2016 11:03AM |

Registered: 8 years ago Posts: 3,525 |

I use copper slip on the threads between the nozzle and heater block but not on the threads between the throat/heatbreak and heater block, in case it allows more heat transfer from the block to the throat. I use CPU thermal paste between throat and heatsink. Copper slip definitely helps me get nozzles out more easily when I want/need to change one (since the nozzle is most of the thread in the heater block). It smokes on the first heat up but stops soon afterwards. I also put it on the grub screw holding the heater cartridge in, these tend to weld themselves in after a while.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Copper slip as thermal paste July 04, 2016 01:18PM |

Registered: 8 years ago Posts: 622 |

|

Re: Copper slip as thermal paste July 04, 2016 06:10PM |

Registered: 8 years ago Posts: 177 |

Knew I had seen a very comprehensive test in this years ago and it just took me a while to find it

See [forums.extremeoverclocking.com] that thread at extremeoverclockers including a full chemical analysts.

Cozmicray you may want to read this as the chemical analysts shows its just the same stuff with a different carrier and it is widely used in industry for exactly thermal transfer.

A key thing to remember is that any of these metallic based pastes will be electrically conductive.

Thanks deckingman for expanding knowledge on this forum

See [forums.extremeoverclocking.com] that thread at extremeoverclockers including a full chemical analysts.

Cozmicray you may want to read this as the chemical analysts shows its just the same stuff with a different carrier and it is widely used in industry for exactly thermal transfer.

A key thing to remember is that any of these metallic based pastes will be electrically conductive.

Thanks deckingman for expanding knowledge on this forum

|

Re: Copper slip as thermal paste July 05, 2016 12:53PM |

Registered: 8 years ago Posts: 622 |

Quote

cozmicray

Look at cpu thermal paste --- usually a silver oxide or silver paste

specifically formulated for heat transfer.

[www.arcticsilver.com]

Extract from the link above:

"Specifications:

Extended Temperature Limits:

Peak: –50°C to >180°C

Long-Term: –50°C to 130°C"

Looks just the job for a heater cartridge where filaments need to be heated to between about 190 and 280 deg C.

|

Re: Copper slip as thermal paste July 05, 2016 01:49PM |

Registered: 12 years ago Posts: 1,450 |

I fear that cozmicray has a bit of "run off at the mouth keyboard" syndrome. A brief perusal of his posts shows that he is not entirely devoid of knowledge; nonetheless he seems to delight in putting down any ideas that are in the least bit novel - usually without giving them a moment of consideration or checking of his facts. As he has become a danger to the temper of the wise and the confidence of newbies he should be gently encouraged to stay under the bridge with the other trolls.

Mike

Mike

|

Re: Copper slip as thermal paste July 05, 2016 04:24PM |

Registered: 8 years ago Posts: 622 |

|

Re: Copper slip as thermal paste July 05, 2016 07:35PM |

Registered: 9 years ago Posts: 483 |

Quote

deckingman

Quote

cozmicray

Look at cpu thermal paste --- usually a silver oxide or silver paste

specifically formulated for heat transfer.

[www.arcticsilver.com]

Extract from the link above:

"Specifications:

Extended Temperature Limits:

Peak: –50°C to >180°C

Long-Term: –50°C to 130°C"

Looks just the job for a heater cartridge where filaments need to be heated to between about 190 and 280 deg C.

How do you get from a limit of 130°C to using it at 280°C ?

|

Re: Copper slip as thermal paste July 05, 2016 07:38PM |

Registered: 8 years ago Posts: 3,525 |

I think a little sarcasm might have been employed.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Copper slip as thermal paste July 06, 2016 01:14AM |

Registered: 9 years ago Posts: 288 |

Quote

etfrench

Quote

deckingman

Quote

cozmicray

Look at cpu thermal paste --- usually a silver oxide or silver paste

specifically formulated for heat transfer.

[www.arcticsilver.com]

Extract from the link above:

"Specifications:

Extended Temperature Limits:

Peak: –50°C to >180°C

Long-Term: –50°C to 130°C"

Looks just the job for a heater cartridge where filaments need to be heated to between about 190 and 280 deg C.

How do you get from a limit of 130°C to using it at 280°C ?

[Sarcasm]Isn't that why they inserted the push fit air gap? [/Sarcasm]

Thanks for sharing, I have a few tubes around in the black hole that is my workshop, just wish I knew where I put them.

Sorry, only registered users may post in this forum.