Medusa Mendel (5-7 material Mendel project)

Posted by Eric,W

|

Medusa Mendel (5-7 material Mendel project) August 15, 2016 05:00PM |

Registered: 8 years ago Posts: 2 |

Hello All,

I am a long time lurker on the forums here. This my first post because I want to show you what I have been working on. I have and old 2013 reprappro tricolor. It has served me well in the last years but calibration of 3 separate extruders always annoyed me. When I read this news post from Adrian: [reprappro.com] I thought that would be the perfect solution. One nozzle far less problems.

Unfortunately I realized that with my machine filament stringing while retracting the filament would be an mayor problem. Adrian also seem to have abandoned the idea for this reason: [reprapltd.com] A solution to this would be to cut the filament right before the extruder so there is always a clean filament tip that retracts reliably.

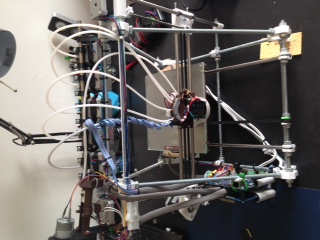

To achieve this I made a design that should be able to use 5 different filaments (the dual melzli configuration has two extra unused stepper drivers). I finished building the machine but I am very inexperienced in firmware reconfiguration so I am hoping for some support in this area.

I included pictures and designs below. The designs are all made in designspark mechanical: [www.rs-online.com]

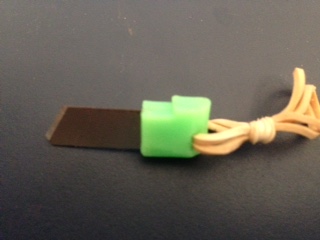

Some notes about the design: The knife is a snip off from a standard utility knife and is pulled back by a rubber band. The design uses a standard reprappro hotend (one of 3 that I obviously have). I cutoff the Bowden tube and stretched it open a bit. In the cutting zone the filament is cut so it can be retracted cleanly.

The knife is actuated with a linear actuator which transfers its power to a leveler with a Bowden tube and a Dynema kite line. I salvaged the motor from an old scanner. The actuator has more than enough power but is still need to program the melzli to actually use it. Until now I have only written a simple script for the Melzli to test it. Its seems that the cutting system works very reliable but integrating it into the firmware is a bit much for my novice programming skills.

As I said before the main hurdle I am facing now is programming the dual Melzli’s to use the upgrades. I am seriously thinking about buying a upgrade board (DUET wifi) their firmware should support my kind of setup (minus the linear actuator). A pro of this board is that it supports 7 extruder drives. This means that I could upgrade the scope to 7 materials instead of 5. The extra functions of the duet wifi are also very nice. The only question is how hard it would be to ad support for the linear actuator to this board (I am guessing not hard at all if you are familiar with the firmware my script is really simple).

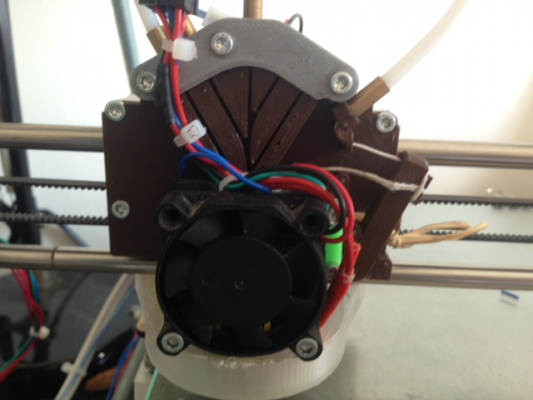

The Printing head with with 5 possible atachment points for the extruders:

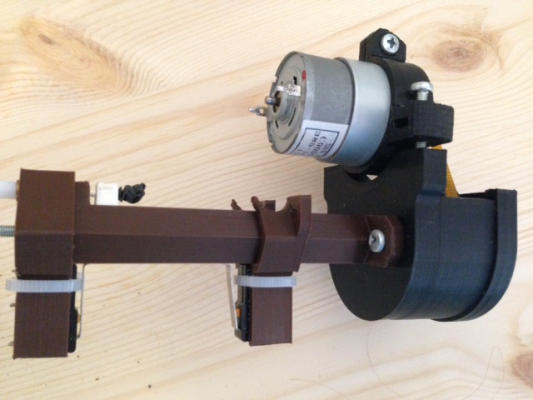

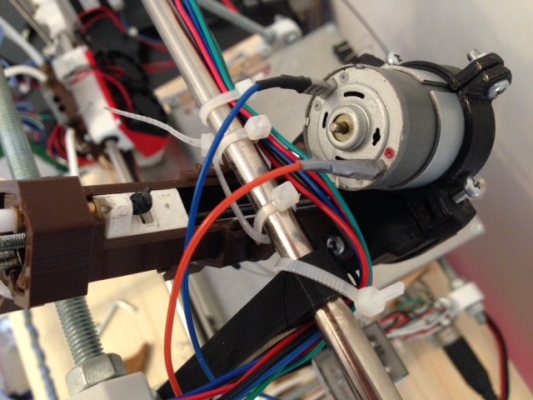

The (dumb) liniar actuator fitted and not fitted:

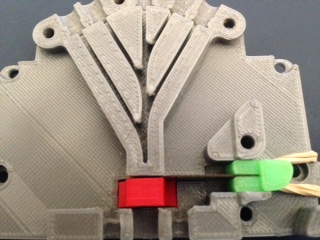

An old version of the cutting system and the knife sled (the red part was used for quick iteration of the cutting to hot end area):

When I am done i would like the tool change G code to simply change the drive and a separate G code command that activates the cutter and freezes the printer operation until the cutting is done.

Todo list:

Ad two missing extruders (waiting for parts)

Reconfigure the firmware or use electronics that support multiple extruders for one hot end.

I hope you guys can give some input on this project: Does any one know some one who has gotten this type of multimaterial extrusion to work? Who could help me with the code? If i get the Duet WIFI would it be (easilly) adjustable to this setup?

Greetings:

Eric

PS: If this works I am calling this Mendel variation the medusa mendel.

PPS: Any ideas for nice projects with two melzli printer controllers that I might have left over.

Edited 2 time(s). Last edit at 08/16/2016 12:20PM by Eric,W.

I am a long time lurker on the forums here. This my first post because I want to show you what I have been working on. I have and old 2013 reprappro tricolor. It has served me well in the last years but calibration of 3 separate extruders always annoyed me. When I read this news post from Adrian: [reprappro.com] I thought that would be the perfect solution. One nozzle far less problems.

Unfortunately I realized that with my machine filament stringing while retracting the filament would be an mayor problem. Adrian also seem to have abandoned the idea for this reason: [reprapltd.com] A solution to this would be to cut the filament right before the extruder so there is always a clean filament tip that retracts reliably.

To achieve this I made a design that should be able to use 5 different filaments (the dual melzli configuration has two extra unused stepper drivers). I finished building the machine but I am very inexperienced in firmware reconfiguration so I am hoping for some support in this area.

I included pictures and designs below. The designs are all made in designspark mechanical: [www.rs-online.com]

Some notes about the design: The knife is a snip off from a standard utility knife and is pulled back by a rubber band. The design uses a standard reprappro hotend (one of 3 that I obviously have). I cutoff the Bowden tube and stretched it open a bit. In the cutting zone the filament is cut so it can be retracted cleanly.

The knife is actuated with a linear actuator which transfers its power to a leveler with a Bowden tube and a Dynema kite line. I salvaged the motor from an old scanner. The actuator has more than enough power but is still need to program the melzli to actually use it. Until now I have only written a simple script for the Melzli to test it. Its seems that the cutting system works very reliable but integrating it into the firmware is a bit much for my novice programming skills.

As I said before the main hurdle I am facing now is programming the dual Melzli’s to use the upgrades. I am seriously thinking about buying a upgrade board (DUET wifi) their firmware should support my kind of setup (minus the linear actuator). A pro of this board is that it supports 7 extruder drives. This means that I could upgrade the scope to 7 materials instead of 5. The extra functions of the duet wifi are also very nice. The only question is how hard it would be to ad support for the linear actuator to this board (I am guessing not hard at all if you are familiar with the firmware my script is really simple).

The Printing head with with 5 possible atachment points for the extruders:

The (dumb) liniar actuator fitted and not fitted:

An old version of the cutting system and the knife sled (the red part was used for quick iteration of the cutting to hot end area):

When I am done i would like the tool change G code to simply change the drive and a separate G code command that activates the cutter and freezes the printer operation until the cutting is done.

Todo list:

Ad two missing extruders (waiting for parts)

Reconfigure the firmware or use electronics that support multiple extruders for one hot end.

I hope you guys can give some input on this project: Does any one know some one who has gotten this type of multimaterial extrusion to work? Who could help me with the code? If i get the Duet WIFI would it be (easilly) adjustable to this setup?

Greetings:

Eric

PS: If this works I am calling this Mendel variation the medusa mendel.

PPS: Any ideas for nice projects with two melzli printer controllers that I might have left over.

Edited 2 time(s). Last edit at 08/16/2016 12:20PM by Eric,W.

|

Re: Medusa Mendel (5-7 material Mendel project) September 04, 2016 03:13PM |

Registered: 8 years ago Posts: 2 |

Hello All,

I finished upgrading the printer with a Duet and Duex4 controller and i finished fitting all the hardware and duet configuration:

After communicating with Adrian Bowyer he thinks the cutting mechanism can be controlled with the M42 G-code command for switching pins high or low and with the M583 command (wait for pin) that he still wants to implement.

Unfortunately the M42 command does not support heater pins on the Duex 4 controller which are the ideal pins to wire the DC motor and the relay to. Does some one here know a solution to this problem?

(am i correct that the duet schematics read that the pins 65 and 66 control the heater outputs of heater H2 and H3 onde the duex expansion board?)

schematics: [github.com]

Futhermore i think that the M582 command proposed by Ardian can be replaced with a M577 (wait until end stop is triggered) command for the extruder end stops. Could this work?

I really would love some advice on this project. and i would love to hear from some one who has experience in using the M42 command or the M577 command in projects.

Greetings,

Eric

I finished upgrading the printer with a Duet and Duex4 controller and i finished fitting all the hardware and duet configuration:

After communicating with Adrian Bowyer he thinks the cutting mechanism can be controlled with the M42 G-code command for switching pins high or low and with the M583 command (wait for pin) that he still wants to implement.

Unfortunately the M42 command does not support heater pins on the Duex 4 controller which are the ideal pins to wire the DC motor and the relay to. Does some one here know a solution to this problem?

(am i correct that the duet schematics read that the pins 65 and 66 control the heater outputs of heater H2 and H3 onde the duex expansion board?)

schematics: [github.com]

Futhermore i think that the M582 command proposed by Ardian can be replaced with a M577 (wait until end stop is triggered) command for the extruder end stops. Could this work?

I really would love some advice on this project. and i would love to hear from some one who has experience in using the M42 command or the M577 command in projects.

Greetings,

Eric

Sorry, only registered users may post in this forum.