Most used / easiest way to print abs

Posted by Reacher

|

Most used / easiest way to print abs September 04, 2016 02:22PM |

Registered: 7 years ago Posts: 9 |

Hello everyone, Reacher from Italy here.

I know this is a newb question, but after google searches I'm getting a lot of different way to do the same thing.

In short, I want to start printing abs with my Geeetech (which is giving me pretty consistent results with pla). Also my printer is enclosed, so I can get the bed up to 100°.

What is the most used / easiest way to have abs stick to the bed?

I'm seeing people using abs juice/slurry, white glue, vinyl glue, hairspray, blue tape, high temp tape...

Really don't know where to start.

Any suggestions?

I know this is a newb question, but after google searches I'm getting a lot of different way to do the same thing.

In short, I want to start printing abs with my Geeetech (which is giving me pretty consistent results with pla). Also my printer is enclosed, so I can get the bed up to 100°.

What is the most used / easiest way to have abs stick to the bed?

I'm seeing people using abs juice/slurry, white glue, vinyl glue, hairspray, blue tape, high temp tape...

Really don't know where to start.

Any suggestions?

|

Re: Most used / easiest way to print abs September 04, 2016 04:32PM |

Registered: 10 years ago Posts: 1,401 |

Well it mostly depend on your printer but you can start with the simplest and work your way up until you find the best adhesion system for you.

I use plain glass and purple glue stick from Elmers, if you don't use glass, clean your aluminum or PCB plate with alcohol and give it a try, if doesn't work add the glue, if still doesn't work add kapton tape, you can keep on going all the way up to the builtak and PEI materials. Just be methodical about it.

Bed temperature between 100 and 110, hotend between 240 and 260 degrees and keep the enclosure at least at 50 degrees, I use a 150 watts bulb and my enclosure stays near 90. As usual print slow and close to the bed for the first layer.

I use plain glass and purple glue stick from Elmers, if you don't use glass, clean your aluminum or PCB plate with alcohol and give it a try, if doesn't work add the glue, if still doesn't work add kapton tape, you can keep on going all the way up to the builtak and PEI materials. Just be methodical about it.

Bed temperature between 100 and 110, hotend between 240 and 260 degrees and keep the enclosure at least at 50 degrees, I use a 150 watts bulb and my enclosure stays near 90. As usual print slow and close to the bed for the first layer.

|

Re: Most used / easiest way to print abs September 04, 2016 11:12PM |

Registered: 12 years ago Posts: 799 |

User natural white ABS, it does have the best adhesion.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: Most used / easiest way to print abs September 05, 2016 02:45AM |

Registered: 12 years ago Posts: 2,470 |

I use two different methods that both work just fine for me. One is a PEI coated plate, the other just blank aluminum with 3dlac sprayed on.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Most used / easiest way to print abs September 05, 2016 09:02AM |

Registered: 8 years ago Posts: 3,525 |

Printbite. It a real revelation. Buy a sheet stick it on evenly. Make sure you have the surface of the printbite up to 120 deg C and the ABS coming out of the nozzle at 250-255, after the first layer you can drop bed to 110-115 and filament to whatever temp you can print with. You might need to beef up your bed heater. But you apply the sheet. You print on it and 6-9 months later its still working just like it did to start with, in fact probably better. The occasional wipe with acetone sometimes helps. When cold the prints simply pop off.

No glue, no tape, no replacing it every 10 prints.

I used to use glass/hairspray, aluminium/hairspray and whilst it works, its messy and takes time to do between prints.

It does not remove the need to keep the air temperature around the print fairly high 40-50 degC so cover the printer in a bag/cardboard or even better build a nice acrylic enclosure around the print volume and heat it, but it does stop long thin parts pulling off the print bed.

I printed the Maker's Muse Warpinator 5000 on my corexy with print bite, one of only 2-3 in the world printed without warp in ABS.

Edited 1 time(s). Last edit at 09/05/2016 10:10AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

No glue, no tape, no replacing it every 10 prints.

I used to use glass/hairspray, aluminium/hairspray and whilst it works, its messy and takes time to do between prints.

It does not remove the need to keep the air temperature around the print fairly high 40-50 degC so cover the printer in a bag/cardboard or even better build a nice acrylic enclosure around the print volume and heat it, but it does stop long thin parts pulling off the print bed.

I printed the Maker's Muse Warpinator 5000 on my corexy with print bite, one of only 2-3 in the world printed without warp in ABS.

Edited 1 time(s). Last edit at 09/05/2016 10:10AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Most used / easiest way to print abs September 06, 2016 10:11AM |

Registered: 10 years ago Posts: 770 |

|

Re: Most used / easiest way to print abs September 06, 2016 05:08PM |

Registered: 11 years ago Posts: 5,780 |

Contrary to common belief, ABS is easy to print. The problem is most people aren't willing to do what is needed (more specifically, to spend the money for the right stuff). You need an adequately and evenly heated, flat, level bed with appropriate covering, and an enclosure for the printer.

An aluminum bed will heat evenly. Cast tooling plate is flat enough- regular aluminum sheet is not. 3 point leveling will let you quickly and easily level the bed without bending it or the undercarriage that supports it. heater power of 0.4 W/cm^2 will provide adequate heat. Kapton PET, or PEI will ll work fine for the layer that covers the bed.

The bed needs to hit 105C. If you are using glass and the controller reads 100C, there's a good chance that the bed isn't close to 100C. Verify the bed surface temperature by measuring it with a thermocouple in contact with the bed surface. If the temperature is too low you'll have trouble keeping ABS stuck to the bed.

I like clean kapton tape. Prints stick well, sometimes too well.

The temperature inside the enclosure needs to get to 45-50C to prevent delamination. Leave the printer heated up for a while and plot the enclosure temperature over time. If it takes more than 15-20 minutes to reach 45C, the bed heater alone may not be sufficient. If you find it isn't, try replacing whatever you used for the enclosure with foam insulation board. If that doesn't work or you want more visibility, add a supplemental heater for the enclosure.

Edited 1 time(s). Last edit at 09/06/2016 05:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

An aluminum bed will heat evenly. Cast tooling plate is flat enough- regular aluminum sheet is not. 3 point leveling will let you quickly and easily level the bed without bending it or the undercarriage that supports it. heater power of 0.4 W/cm^2 will provide adequate heat. Kapton PET, or PEI will ll work fine for the layer that covers the bed.

The bed needs to hit 105C. If you are using glass and the controller reads 100C, there's a good chance that the bed isn't close to 100C. Verify the bed surface temperature by measuring it with a thermocouple in contact with the bed surface. If the temperature is too low you'll have trouble keeping ABS stuck to the bed.

I like clean kapton tape. Prints stick well, sometimes too well.

The temperature inside the enclosure needs to get to 45-50C to prevent delamination. Leave the printer heated up for a while and plot the enclosure temperature over time. If it takes more than 15-20 minutes to reach 45C, the bed heater alone may not be sufficient. If you find it isn't, try replacing whatever you used for the enclosure with foam insulation board. If that doesn't work or you want more visibility, add a supplemental heater for the enclosure.

Edited 1 time(s). Last edit at 09/06/2016 05:13PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Most used / easiest way to print abs September 07, 2016 07:16AM |

Registered: 12 years ago Posts: 2,470 |

Everything he ^ said.

ABS is realy simple to print if you follow procedure.

Trying to print even only medium sized items without a heated chamber is a sure way to frustration.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

ABS is realy simple to print if you follow procedure.

Trying to print even only medium sized items without a heated chamber is a sure way to frustration.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Most used / easiest way to print abs September 07, 2016 02:07PM |

Registered: 7 years ago Posts: 9 |

|

Re: Most used / easiest way to print abs September 07, 2016 02:10PM |

Registered: 8 years ago Posts: 3,525 |

Just to check you have plenty of insulation under the bed? Cork or foil bubble wrap works or both. Also place some on top of the bed to help get up to temperature quicker, but it also helps to heat soak the glass or bulldtak/PrintBite.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Most used / easiest way to print abs September 07, 2016 11:26PM |

Registered: 11 years ago Posts: 5,780 |

IR thermometers are almost useless on glass because they are not calibrated to the emissivity of a smooth glass sheet. Smooth glass sheet is as reflective at IR as it is for visible light. You should check with a contact-type thermocouple or similar accurate temperature measuring sensor. If you don't have such a thing available to you, just experiment with the bed temperature settings to find one that sticks the ABS securely. It doesn't take too long to experiment by raising the bed temperature 5C at a time and restarting your print to make sure the first layer is sticking. Once you find a temperature that works, write it down somewhere, maybe on a tag on the printer or a post-it on your slicing computer, or even a note in your phone.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Most used / easiest way to print abs September 09, 2016 05:19AM |

Registered: 7 years ago Posts: 9 |

Still wasn't able to print a single layer.

Improved the insulation a little bit. Added foil bubble wrap under the bed and outside the cardboard box. Now the bed gets to 110° (controller read) a lot quicker and temperature inside the box is higher. I'm using a 75w light bulb.

Had to completely redo the bed leveling after heating up.

Made some abs juice with the 10/10 formula. Put a tiny layer on the glass with a paper towel when it was hot.

The filament didn't even stick for half second, just curled up and stick to the nozzle.

What to do next?

The only products I can find on amazon.it are 3m ScotchBlue and BuildTak.

Improved the insulation a little bit. Added foil bubble wrap under the bed and outside the cardboard box. Now the bed gets to 110° (controller read) a lot quicker and temperature inside the box is higher. I'm using a 75w light bulb.

Had to completely redo the bed leveling after heating up.

Made some abs juice with the 10/10 formula. Put a tiny layer on the glass with a paper towel when it was hot.

The filament didn't even stick for half second, just curled up and stick to the nozzle.

What to do next?

The only products I can find on amazon.it are 3m ScotchBlue and BuildTak.

|

Re: Most used / easiest way to print abs September 09, 2016 08:01AM |

Registered: 7 years ago Posts: 9 |

|

Re: Most used / easiest way to print abs September 09, 2016 08:31AM |

Registered: 8 years ago Posts: 3,525 |

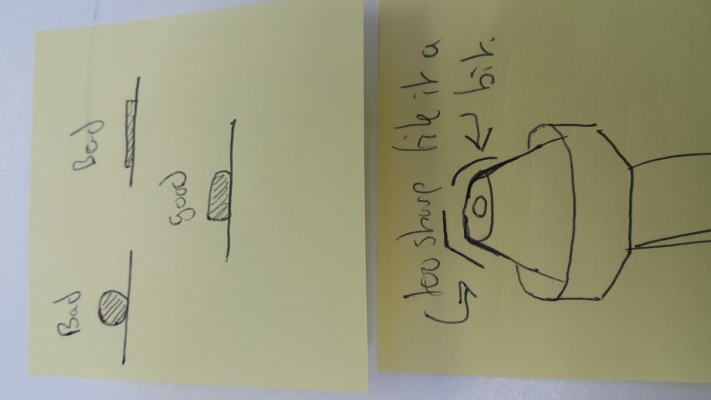

Check your nozzle to bed distance for your first layer. Too tight and it wont work, too loose and it won't work. If you are using a firmware that has babystepping on the z axis babystep the nozzle down whilst printing a skirt, until you are getting some squash-down of the filament but not to the point where it is basically flat on the build plate.

Try to get the glass surface temperature to 110 Deg C, get the filament to its upper range or even beyond 240 Deg C or 250 deg C, too hot will not make adhesion worse. An IR thermometer will work if you paint a section of the corner of the glass in matt black paint. If the corner is 110 then the middle will be 115-120.

Make sure your nozzle is not of the type with a very sharp edge between the flat area with the actual hole in it and the conical slope leading away from it. I've had super sharp nozzles like this that lift the filament as its laid down, this only happens on the first layer.

Make sure you use thick first layers so if you've got a 0.4 nozzle use 0.4 first layer height, but squash it down slightly. Make sure you first layer speed is very slow 20mm/s or so. It might help to turn the speed for travel moves down as well if you're printing something with an intricate first layer, the rapid moves pull the filament from the build plate before it has chance to adhere.

Click the image to get it the right way around.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Try to get the glass surface temperature to 110 Deg C, get the filament to its upper range or even beyond 240 Deg C or 250 deg C, too hot will not make adhesion worse. An IR thermometer will work if you paint a section of the corner of the glass in matt black paint. If the corner is 110 then the middle will be 115-120.

Make sure your nozzle is not of the type with a very sharp edge between the flat area with the actual hole in it and the conical slope leading away from it. I've had super sharp nozzles like this that lift the filament as its laid down, this only happens on the first layer.

Make sure you use thick first layers so if you've got a 0.4 nozzle use 0.4 first layer height, but squash it down slightly. Make sure you first layer speed is very slow 20mm/s or so. It might help to turn the speed for travel moves down as well if you're printing something with an intricate first layer, the rapid moves pull the filament from the build plate before it has chance to adhere.

Click the image to get it the right way around.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Most used / easiest way to print abs September 09, 2016 10:44AM |

Registered: 10 years ago Posts: 770 |

Dont use a .4mm 1st layer with a .4mm nozzle.

Use .3mm max for first layer and use baby stepping to get the first layer to grab.

I can home my printer and its exactly .1mm from the nozzle in the center but when I start a print it ALWAYS ends up being off (normally too low) and I have to baby step it up anywhere from .1mm - .5mm while its printing the skirt to get a good first layer.

I do ABS on 110c bed and 240c nozzle. .4mm nozzle and .3mm layers for "fast" and .2mm layers for slow.

Use .3mm max for first layer and use baby stepping to get the first layer to grab.

I can home my printer and its exactly .1mm from the nozzle in the center but when I start a print it ALWAYS ends up being off (normally too low) and I have to baby step it up anywhere from .1mm - .5mm while its printing the skirt to get a good first layer.

I do ABS on 110c bed and 240c nozzle. .4mm nozzle and .3mm layers for "fast" and .2mm layers for slow.

|

Re: Most used / easiest way to print abs September 09, 2016 11:10AM |

Registered: 8 years ago Posts: 3,525 |

I appreciate the nozzle width to layer height ratio, but the first layer is squashed so it's far less relevant than subsequent layers.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Most used / easiest way to print abs September 09, 2016 02:16PM |

Registered: 7 years ago Posts: 9 |

|

Re: Most used / easiest way to print abs September 09, 2016 02:28PM |

Registered: 8 years ago Posts: 3,525 |

What printer/firmware are you using. If it has a marlin 1.1.0 RC firmware then you access babystepping from the tune menu. The latest bugfix versions will give you a readout in mm how much you stepped. So you can use it as an offset in future prints.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Most used / easiest way to print abs September 09, 2016 02:42PM |

Registered: 12 years ago Posts: 2,470 |

Make sure to calibrate the nozzle distance when the whole machine including heatbed and nozzle is heated up to working temperature.Quote

Reacher

Was finally able to get my first printed item. For sure quality sucks. But it's a start.

For what I'm seeing my problem with the first layer is that the bed come a lot closer to the nozzle when things eat up.

Guess I'm gonna need to learn how to do this baby step thing.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Most used / easiest way to print abs September 09, 2016 05:03PM |

Registered: 9 years ago Posts: 1,873 |

Just as a data point for others wondering about abs, I print mostly abs without an enclosure on a horribly non-flat mk2 pcb heatbed with mirror glass and elmers purple glue stick. No doubt that an enclosure and properly flat Al heat bed would help, but it is possible without. Layer height is critical, and using a slow first layer speed helps (15 mm/s). I've let the glue stick build up into a thick layer and just patch up thin areas where it pulls off with the print, it takes only seconds. Old glue does need to be washed off the bottom of the prints to make them look good, and the surface doesn't achieve the high gloss that is possible with kapton, but for functional parts it's a very workable approach. As far as print de-lamination goes, there seems to be a lot of variation between different spools of ABS, but de-lamination seems to be mostly avoidable by a combination of slow prints speeds (30mm/s), high-ish nozzle temps and careful part design. That said, I don't print many tall single walled objects, although I do print quite a few full-bed parts (~7" on at least one side, typically 1 to 2" tall).

|

Re: Most used / easiest way to print abs September 09, 2016 10:17PM |

Registered: 11 years ago Posts: 5,780 |

Tall, single-walled objects like vases print fine without an enclosure: Printing a vase.

When you get to bulkier objects that are more than a few cm tall you'll start having delamination problems without an enclosure. Example:

Guess which one was printed in an enclosure and which wasn't...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

When you get to bulkier objects that are more than a few cm tall you'll start having delamination problems without an enclosure. Example:

Guess which one was printed in an enclosure and which wasn't...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Most used / easiest way to print abs September 10, 2016 02:24PM |

Registered: 10 years ago Posts: 580 |

I've found a few things that make the first layer 100% reliable for me with ABS. I know kapton directly on the heatbed would be faster to heat than with glass on top, with less maintenance, etc., probably better, but this method just always work for me, and I didn't want to apply kapton to such a large area. I never even think about the first layer, except to smile.

My personal preference is to print on a piece of custom mirror glass.

Every 6 to 8 prints in the same spot I use the following procedure (5 minutes):

I clean the glass twice with Windex. (It dissolves the hairspray easily). Absolutely squeaky clean.

I spray on a very thin layer of Aquanet extra hold hairspray (purple can). I do this away from the printer (keep the printer clean!). That's it.

I never ever allow any oil near the printbed or filament - including fingerprints.

I have the bed set to 106C (the thermistor is near an edge!).

I print the first layer (and all layers) at 260C.

My heated chamber is at 58C, with no drafts. There is some active cooling on the part - no it does not warp.

Nozzle diameter .72mm

Filament is 3mm.

First layer height .32mm, width .82mm, at 55mms. Yes 55mms - it sticks fine so why not use near the same speed as the rest of the part?

My bed probe sets the level to around .02mm. Sometimes I do not bother leveling it, and it's still close enough. It still needs to be well leveled - but doesn't need to be perfect because I've overcome the following:

A printer that starts with a depressurized nozzle will have difficulty getting the start of the extrusion to stick. Keep in mind that I have a bowden extruder with a very long tube (over 800 mm), so pressurization takes longer, and the retracted filament is cold. If the filament in the nozzle is not well melted there will be a cold start - obvious if you think about it.

I add gcode to the beginning to pressurize the nozzle (using my post-processor). It automatically places this "pressurization line" 5mm below the print.

This takes the nozzle from being completely depressurized (it may have sat there oozing for a half hour) to well pressurized and well melted - ready when it prints the first perimeter segment with no fuss.

The following priming gcode prints a thick line in three segments. It slowly speeds up as it moves left. .

The filament used in each equally sized segment goes from large to small. The amount extruded for other hot-ends would certainly be less.

This pressurization line is better than printing a skirt in several ways.

- The slow start gives the filament time to heat/melt within the nozzle so it is working at the proper melt rate.

- That extruded filament is now at the right temp to stick really well to the first perimeter - it is not doing a cold start after an un-retract.

- The hot-end is pressurized at the very start of the first perimeter, not part way through the skirt.

- Since all printing is at the right pressure (and height), it is all squished into the bed nicely - no strings of skirt come loose.

You can achieve some of this by just extruding a bit into the air just before printing - but that is messy and the nozzle is still not pressurized - I still had problems.

The extra 1.42mm of filament added to the unretract is for pressure compensation - something my post processor does to adjust the extrusion rate at the beginning of each loop - less pressure is needed for 5 mm3/sec than for 20mm3/sec for instance. This eliminates under or over extrusion when the extrusion rate changes - something that is especially needed with a long bowden tube. In this case I added a large amount of compensation - as if going from a pressure of 0. I'm still developing and testing this.

Here is a video of the start of a large print (over 14" across, about a foot tall) when the bed was not particularly level. I printed 4 of these in a row.

[youtu.be]

Edited 2 time(s). Last edit at 09/10/2016 02:30PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

My personal preference is to print on a piece of custom mirror glass.

Every 6 to 8 prints in the same spot I use the following procedure (5 minutes):

I clean the glass twice with Windex. (It dissolves the hairspray easily). Absolutely squeaky clean.

I spray on a very thin layer of Aquanet extra hold hairspray (purple can). I do this away from the printer (keep the printer clean!). That's it.

I never ever allow any oil near the printbed or filament - including fingerprints.

I have the bed set to 106C (the thermistor is near an edge!).

I print the first layer (and all layers) at 260C.

My heated chamber is at 58C, with no drafts. There is some active cooling on the part - no it does not warp.

Nozzle diameter .72mm

Filament is 3mm.

First layer height .32mm, width .82mm, at 55mms. Yes 55mms - it sticks fine so why not use near the same speed as the rest of the part?

My bed probe sets the level to around .02mm. Sometimes I do not bother leveling it, and it's still close enough. It still needs to be well leveled - but doesn't need to be perfect because I've overcome the following:

A printer that starts with a depressurized nozzle will have difficulty getting the start of the extrusion to stick. Keep in mind that I have a bowden extruder with a very long tube (over 800 mm), so pressurization takes longer, and the retracted filament is cold. If the filament in the nozzle is not well melted there will be a cold start - obvious if you think about it.

I add gcode to the beginning to pressurize the nozzle (using my post-processor). It automatically places this "pressurization line" 5mm below the print.

This takes the nozzle from being completely depressurized (it may have sat there oozing for a half hour) to well pressurized and well melted - ready when it prints the first perimeter segment with no fuss.

The following priming gcode prints a thick line in three segments. It slowly speeds up as it moves left. .

;--- Prime --- G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion G28 ; home G1 X85.531 Y-183.2 Z0.320 F15000 ; Move to first prime pos G1 E6.7 F5700 ; Unretract G1 X28.510 Y-183.2 E6.792 F840 ; Prime 1 - going left Very Slow - 14mms G1 X-28.51 Y-183.2 E3.308 F1680 ; Prime 2 - going left Faster - 28mms G1 X-85.53 Y-183.2 E2.843 F1938 ; Prime 3 Fastest - 32mms G1 E-6.7 F7800 ; retract (this saves the pressure while the move is happening) G1 X-145.397 Y53.065 Z0.350 F6000 ; Move to first perimeter point G1 E8.1217 F5700 ; Unretract + 1.42mm pressure compensation ; (first perimeter)

The filament used in each equally sized segment goes from large to small. The amount extruded for other hot-ends would certainly be less.

This pressurization line is better than printing a skirt in several ways.

- The slow start gives the filament time to heat/melt within the nozzle so it is working at the proper melt rate.

- That extruded filament is now at the right temp to stick really well to the first perimeter - it is not doing a cold start after an un-retract.

- The hot-end is pressurized at the very start of the first perimeter, not part way through the skirt.

- Since all printing is at the right pressure (and height), it is all squished into the bed nicely - no strings of skirt come loose.

You can achieve some of this by just extruding a bit into the air just before printing - but that is messy and the nozzle is still not pressurized - I still had problems.

The extra 1.42mm of filament added to the unretract is for pressure compensation - something my post processor does to adjust the extrusion rate at the beginning of each loop - less pressure is needed for 5 mm3/sec than for 20mm3/sec for instance. This eliminates under or over extrusion when the extrusion rate changes - something that is especially needed with a long bowden tube. In this case I added a large amount of compensation - as if going from a pressure of 0. I'm still developing and testing this.

Here is a video of the start of a large print (over 14" across, about a foot tall) when the bed was not particularly level. I printed 4 of these in a row.

[youtu.be]

Edited 2 time(s). Last edit at 09/10/2016 02:30PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Most used / easiest way to print abs September 13, 2016 04:33AM |

Registered: 7 years ago Posts: 9 |

Thanks to all your advices was finally able to almost print something good.

I said almost because my insulated cardboard box and the 75w lightbulb I’m using generated a bit too much eat. Also I left my printer unattended while making dinner.

Then I found that the belt bracket, which is the only 3d printed part present in my printer, was starting to melt. The belt was completely loose.

Also the motors where really hot, at the point that I cannot keep my hand on them for more than a second.

However, the good part is that the print was sticking 100% to the bed and no delamination was visible.

So I’m almost there. Also I’ve learned (for the thousandth time) a precious lesson: don’t leave the printer unattended while doing something complex or for the first time.

I said almost because my insulated cardboard box and the 75w lightbulb I’m using generated a bit too much eat. Also I left my printer unattended while making dinner.

Then I found that the belt bracket, which is the only 3d printed part present in my printer, was starting to melt. The belt was completely loose.

Also the motors where really hot, at the point that I cannot keep my hand on them for more than a second.

However, the good part is that the print was sticking 100% to the bed and no delamination was visible.

So I’m almost there. Also I’ve learned (for the thousandth time) a precious lesson: don’t leave the printer unattended while doing something complex or for the first time.

|

Re: Most used / easiest way to print abs September 13, 2016 05:54AM |

Registered: 8 years ago Posts: 3,525 |

Good advice. Heated Chambers are another level of problems to solve. My first was just a box around an i3, same problems, a few pla parts melted, my heat source was radiated heat like your light bulb.

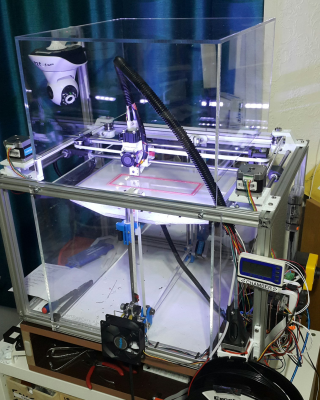

My current enclosed printer is this one.

Motors and electronics not in the chamber, 250w heatbed is the only heater and the chamber runs at 55 deg C. No pla in there either, there is some petg which might be an issue. I've only had the acrylic top for a few days so haven't really put it through its paces.

But I'm looking forward to printing some relatively massive things in abs.

The fan at the front comes on when the print finishes and there are gaps in the acrylic for the x axis so it vents the heat out faster, if it is a very warp prone part I'd leave it to cool very slowly.

Edited 1 time(s). Last edit at 09/13/2016 05:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

My current enclosed printer is this one.

Motors and electronics not in the chamber, 250w heatbed is the only heater and the chamber runs at 55 deg C. No pla in there either, there is some petg which might be an issue. I've only had the acrylic top for a few days so haven't really put it through its paces.

But I'm looking forward to printing some relatively massive things in abs.

The fan at the front comes on when the print finishes and there are gaps in the acrylic for the x axis so it vents the heat out faster, if it is a very warp prone part I'd leave it to cool very slowly.

Edited 1 time(s). Last edit at 09/13/2016 05:57AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Most used / easiest way to print abs September 14, 2016 10:01AM |

Registered: 7 years ago Posts: 9 |

Still having some adhesion problems. After several tries, extruder is at 235°, bed 120°, enclosure 40°.

I've noticed that printing the first layer at a very low speed will make it stick. Problem is that the brim will be printed much faster, and will not stick at all.

Is there a way to set brim speed in repetier?

I've noticed that printing the first layer at a very low speed will make it stick. Problem is that the brim will be printed much faster, and will not stick at all.

Is there a way to set brim speed in repetier?

|

Re: Most used / easiest way to print abs October 05, 2016 05:42AM |

Registered: 7 years ago Posts: 9 |

Finally managed to print abs reliably. It wasn't really that difficult, but I had to replace a lot of parts on my printer. Also juice didn't work for my bed, but slurry did.

I'm still amazed at how durable 3d printed abs parts are.

Edited 1 time(s). Last edit at 10/05/2016 05:43AM by Reacher.

I'm still amazed at how durable 3d printed abs parts are.

Edited 1 time(s). Last edit at 10/05/2016 05:43AM by Reacher.

Sorry, only registered users may post in this forum.