[Q]About threaded rods and leadscrews for 8mm diameter

Posted by sarf2k4

|

[Q]About threaded rods and leadscrews for 8mm diameter September 07, 2016 10:12AM |

Registered: 9 years ago Posts: 476 |

I would like to ask information regarding the a number of leadscrews out there and from what I understand that leadscrews are also can be comprehended as acme (with squarish shaped threads) and I stumbled upon some leadscrew title or name saying like "TR8*8", "THSL 8", "TR8*4", "TR8*8/4". There might be more of them though.

1. What I wanted to know is that if I am going to key into the prusa calculators for optimal z layer, do I have to put pitch or lead?

2. What are the meaning of those terms above?

3. I wanted to replace my current threaded rod that might be giving me backlash on my prints, should I go for leadscrew or another threaded rods?

4. Can I cut the brass nut supplied to be shorter for the smaller sleeve there?

I guess my threaded rods currently are already bent and sometimes can hear squeaking noise upon homing and moving.

I need your knowledge in this, the printer I use is geeetech i3b

P.S

As for number 4 above, Reason being is to give a bit more of z travel by lowering the bed and currently I had to use a printed 5 to 8mm coupler and when positioned at z0, there's a little gap left between the brass nut and the printed coupler by about 2mm left, also I'm using anti backlash for it underneath the geeetech's part there. But I do remember that printing something at my friend's 3d printer that I built for him also somewhat got the same pattern as mine, almost like backlash effect on printed object but his printer uses leadscrew, at top of the leadscrew are loose bracket.

1. What I wanted to know is that if I am going to key into the prusa calculators for optimal z layer, do I have to put pitch or lead?

2. What are the meaning of those terms above?

3. I wanted to replace my current threaded rod that might be giving me backlash on my prints, should I go for leadscrew or another threaded rods?

4. Can I cut the brass nut supplied to be shorter for the smaller sleeve there?

I guess my threaded rods currently are already bent and sometimes can hear squeaking noise upon homing and moving.

I need your knowledge in this, the printer I use is geeetech i3b

P.S

As for number 4 above, Reason being is to give a bit more of z travel by lowering the bed and currently I had to use a printed 5 to 8mm coupler and when positioned at z0, there's a little gap left between the brass nut and the printed coupler by about 2mm left, also I'm using anti backlash for it underneath the geeetech's part there. But I do remember that printing something at my friend's 3d printer that I built for him also somewhat got the same pattern as mine, almost like backlash effect on printed object but his printer uses leadscrew, at top of the leadscrew are loose bracket.

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 07, 2016 10:33AM |

Registered: 11 years ago Posts: 5,780 |

Pitch is the spacing between "ridges". Lead is the distance the screw will move the nut in one rev. If the screw is "single start", pitch = lead. If the screw is 2 start, lead = 2x pitch, etc.

Backlash can be caused by many things, but in general, for low or zero backlash on a screw you have to use antibacklash nuts. They consist of two threaded pieces with a spring between them. The spring forces threads engagement at all times, thus reducing backlash. Spring tension determines how effective it is, and also creates friction that the driving motor has to overcome to turn the screw. Higher tension also leads to faster wear.

Lead screws will almost always perform better than threaded rods.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Backlash can be caused by many things, but in general, for low or zero backlash on a screw you have to use antibacklash nuts. They consist of two threaded pieces with a spring between them. The spring forces threads engagement at all times, thus reducing backlash. Spring tension determines how effective it is, and also creates friction that the driving motor has to overcome to turn the screw. Higher tension also leads to faster wear.

Lead screws will almost always perform better than threaded rods.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 07, 2016 10:38AM |

Registered: 9 years ago Posts: 476 |

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 07, 2016 11:33PM |

Registered: 11 years ago Posts: 5,780 |

A single start screw is like a threaded rod- there is a single spiral thread down the entire length of the screw. A two start screw has two separate spirals that run the length of the screw. A four start screw has four spirals...

If you look at the screw from the end you can see how many starts it has: starts = the number of grooves you see at the circumferential edge of the screw. See: [www.cncroutersource.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you look at the screw from the end you can see how many starts it has: starts = the number of grooves you see at the circumferential edge of the screw. See: [www.cncroutersource.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 08, 2016 03:50AM |

Registered: 8 years ago Posts: 622 |

To elaborate on what DD has said, imagine an 8mm diameter screw with a single 8mm pitch thread. It would look very much like a cork screw. The ridges would be 8mm apart. One turn of the screw would move a nut with the same thread 8mm along the screw. The trouble with that arrangement is that there is very little contact between the nut and the screw so it would be easy to "strip" the thread and the nut would be quite "sloppy". Now imagine another 8mm pitch thread on the same screw but starting opposite the first (180 degrees offset). The ridges on each thread are still 8mm apart but because we have another thread in between the first, the ridges between each thread are 4mm apart. So now, 1 revolution of the screw would still move a nut with the same thread 8mm but we have twice the contact area so it would be less easy to strip the thread. That would be a 2 start screw. Now imagine we put 2 more threads on the screw, one between each of the others so that we have a 4 start screw. Again, 1 revolution still gives us 8mm of travel but we now have 4 times the contact are of a single start screw. In this case the ridges between each thread would be 2mm (because there are 4 of them, each with an 8mm pitch). So, in summary a multi-start screw has a course thread but the same contact area as a fine thread and is ideally suited to applications where a large linear movement is required for a given angular movement.

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 08, 2016 05:40AM |

Registered: 9 years ago Posts: 483 |

What's with everyone using the term 'leadscrew' as though it described a particular thread form? Acme threads in imperial and trapezoidal threads in metric are the most common forms, however triangular and square threads can also be used. Acme and metric trapezoidal are similar but have slightly different thread angles, 29* vs 30*.

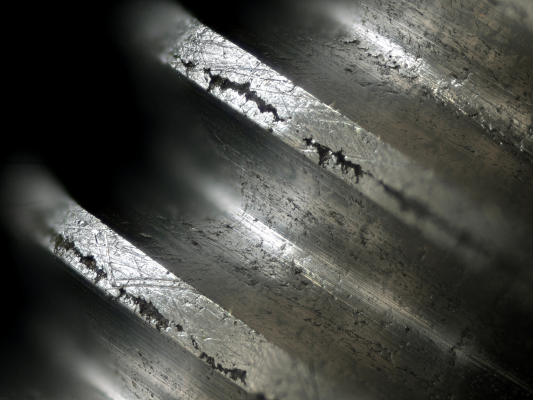

Triangular threads (aka threaded rod) can be just as accurate as Acme or trapezoidal threads in small sizes. Unfortunately, the hardware store variety of threaded rod isn't made very well. Here's a photo of an M6x1 threaded rod that looked really nice until viewed closeup:

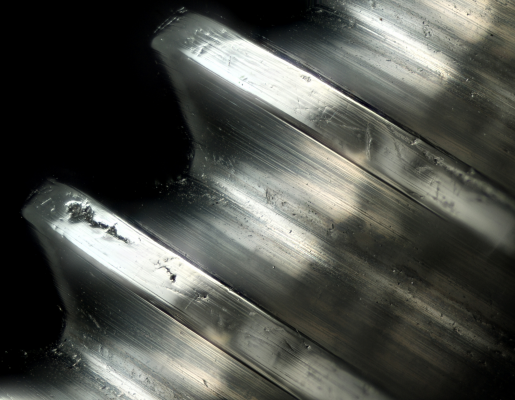

Here's the same threaded rod after lapping it for several hours:

This threaded rod is being used in a linear slide and can reliably make moves <1 micron.

Your threaded rod is probably not the source of the backlash which is more likely to be from the nut. You can make your nut shorter, but that would likely make the backlash worse. Spring loaded double nuts is the most common method for reducing backlash. Slitting one side of the nut, and compressing it works well. The cross slide on my lathe uses three setscrews to twist the nut which reduces the backlash. All of these methods increase the friction which may affect how fast you can drive that axis.

DumpsterCNC makes anti-backlash nuts and seems to have a good reputation: [www.dumpstercnc.com]

Triangular threads (aka threaded rod) can be just as accurate as Acme or trapezoidal threads in small sizes. Unfortunately, the hardware store variety of threaded rod isn't made very well. Here's a photo of an M6x1 threaded rod that looked really nice until viewed closeup:

Here's the same threaded rod after lapping it for several hours:

This threaded rod is being used in a linear slide and can reliably make moves <1 micron.

Your threaded rod is probably not the source of the backlash which is more likely to be from the nut. You can make your nut shorter, but that would likely make the backlash worse. Spring loaded double nuts is the most common method for reducing backlash. Slitting one side of the nut, and compressing it works well. The cross slide on my lathe uses three setscrews to twist the nut which reduces the backlash. All of these methods increase the friction which may affect how fast you can drive that axis.

DumpsterCNC makes anti-backlash nuts and seems to have a good reputation: [www.dumpstercnc.com]

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 08, 2016 09:44AM |

Registered: 9 years ago Posts: 476 |

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 08, 2016 02:31PM |

Registered: 12 years ago Posts: 1,450 |

Agreed with what etfrench said about "can be as accurate" but the main problem with threaded rod is guarantee of accuracy. A bunch of ground or rolled leadscrews will be checked against specification and the allowed error will be quite small. If any of the test samples are out than the whole batch may be rejected. Conversely, a bunch of threaded rods may be out by whatever the manufacturer determines is a limit past which a nut cannot be freely run - this may be as much as 3% or 30mm over a meter.

Many years ago I had a quantity of 500 resistors to check, the specification was 22,000 Ohm 2%. None was more than 0.1% in error - the machine had a very good day. Same with threaded rod, It is made on a machine very similar to that used to make normal (not best quality) leadscrews so it is probably about the same tolerance but no guarantees. Just a little caveat, hot dipped galvanizing will always mess it up so go for stainless if you must use threaded rod.

Mike

Many years ago I had a quantity of 500 resistors to check, the specification was 22,000 Ohm 2%. None was more than 0.1% in error - the machine had a very good day. Same with threaded rod, It is made on a machine very similar to that used to make normal (not best quality) leadscrews so it is probably about the same tolerance but no guarantees. Just a little caveat, hot dipped galvanizing will always mess it up so go for stainless if you must use threaded rod.

Mike

|

Re: [Q]About threaded rods and leadscrews for 8mm diameter September 09, 2016 12:38PM |

Registered: 9 years ago Posts: 476 |

It's hard to get a good threaded rods here in my place, as for my supplied threaded rods, both of them at the end of the threaded rods were bent slightly, I don't know why, this is one of the main reason why I am considering to change to leadscrews, found one 8mm diameter with 1mm pitch and 1mm lead

Sorry, only registered users may post in this forum.