An alternative to buying a bad kit for $300-500

Posted by the_digital_dentist

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 08:56AM |

Registered: 7 years ago Posts: 55 |

I have my Cubex roughly put together. I printed a test cube over the weekend, but my Bowden extruder and the knock off chimera hot end just weren't performing. I ordered an E3D Titan and v6 hot end, and they should be here today or tomorrow. I wanted to do Bowden, but I'll probably be printing with Ninjaflex more than anything.

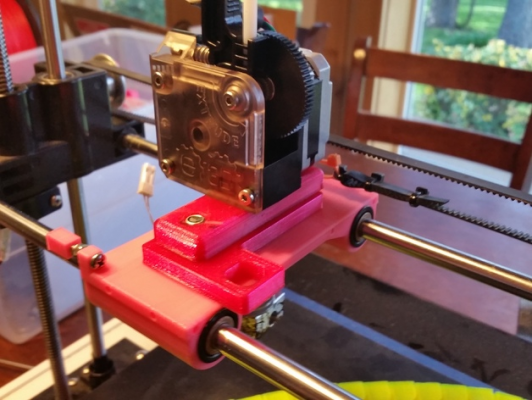

Here's what I'm going for (Titan with short NEMA 17)

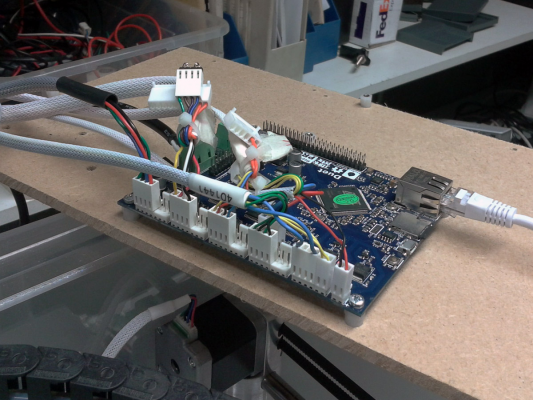

It took a while, but I'm about 90% with setting up the code for the Replicape... I had some issues getting the two Y motors to cooperate, so for now, they're wired in parallel. You can barely hear the steppers while it's printing... the cooling fans are actually louder. So far I'm pleased!

Edited 1 time(s). Last edit at 11/07/2016 08:56AM by Dancook.

Here's what I'm going for (Titan with short NEMA 17)

It took a while, but I'm about 90% with setting up the code for the Replicape... I had some issues getting the two Y motors to cooperate, so for now, they're wired in parallel. You can barely hear the steppers while it's printing... the cooling fans are actually louder. So far I'm pleased!

Edited 1 time(s). Last edit at 11/07/2016 08:56AM by Dancook.

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 03:48PM |

Registered: 7 years ago Posts: 363 |

I just received replacement KH1228 bearings from China. Hopefully the tolerances are good, they physically appear to be of good quality. I'll be using them with printed guides for conversion to CoreXY movement. I need to finish calibration of the initial conversion so I can print the new pieces since this is my only printer.

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 03:55PM |

Registered: 7 years ago Posts: 363 |

For anyone curious, I'll be converting by rotating the two y axis motors vertically to facilitate the correct linear belt motion. I'll machine off the upper part of the corner pieces to Mount the pulleys and steppers with printed parts. Eventually I'll print them with a carbon fiber composite filament for better dimensional stability. Right now I'm more interested in successfully completing the conversion. I think the reduced weight on the carriage from Bowden extrusion setup will help offset the difference between using printed parts in place of machined aluminium. Of course I'm trying to do this on a very low budget and with limited resources.

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 03:57PM |

Registered: 7 years ago Posts: 363 |

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 03:58PM |

Registered: 7 years ago Posts: 558 |

Quote

Dancook

I have my Cubex roughly put together. I printed a test cube over the weekend, but my Bowden extruder and the knock off chimera hot end just weren't performing. I ordered an E3D Titan and v6 hot end, and they should be here today or tomorrow. I wanted to do Bowden, but I'll probably be printing with Ninjaflex more than anything.

If your planning to print Ninjaflex with the Titan E3D, you'll probably need to go 3mm filament. I've run into the Titan E3D not feeding 1.75 filament consistently and I am currently building a new CoreXY with the Flexion extruder specifically for 1.75 Ninjaflex. From what I ran into, the Titan has a flat idle wheel that can cause the 1.75 mm filament to stick to it and then force it out very small gap between the support tube and drive wheel.

Edited 1 time(s). Last edit at 11/07/2016 04:00PM by PDBeal.

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 05:19PM |

Registered: 11 years ago Posts: 5,780 |

I think you can somewhat reduce the whine from the DRV8825s by changing the decay mode and the current. Unfortunately, both those changes may affect performance.

In my experience printing TPU filament, you have to reduce the pinch wheel pressure in the extruder and then print very slowly. If the pinch wheel pressure is too high, the filament "squirms" as it comes off the drive gear and won't travel straight. I can print 1.75 mm TPU using my Bulldog XL even though there is a pretty wide gap between the drive gear and the tube going to the hot-end. The Titan has a tube that comes right up to the drive gear so you should be able to feed flexible filament as long as you keep the print speed down. Try 15-20 mm/sec, and minimize retractions. I have found that printing TPU at 240C works very well because it flows easily at that temperature. Layer to layer bonding is extremely strong- I've had 300 lb guys try to pull apart a 0.5 mm thick single walled TPU vase and fail miserably.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In my experience printing TPU filament, you have to reduce the pinch wheel pressure in the extruder and then print very slowly. If the pinch wheel pressure is too high, the filament "squirms" as it comes off the drive gear and won't travel straight. I can print 1.75 mm TPU using my Bulldog XL even though there is a pretty wide gap between the drive gear and the tube going to the hot-end. The Titan has a tube that comes right up to the drive gear so you should be able to feed flexible filament as long as you keep the print speed down. Try 15-20 mm/sec, and minimize retractions. I have found that printing TPU at 240C works very well because it flows easily at that temperature. Layer to layer bonding is extremely strong- I've had 300 lb guys try to pull apart a 0.5 mm thick single walled TPU vase and fail miserably.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 05:34PM |

Registered: 7 years ago Posts: 558 |

Even trying to print 1.75 Ninjaflex with the Titan E3D with the tension screw backed off to nothing at 5mm/s wouldn't take enough filament while trying to do the 100mm calibration, and then slowly giving it 1/4 turns it would then start sticking to the idler and making its way outside the captured path. I managed to create some Ninjaflex parts, but I highly doubt they were not underextruded based on the attempts I had trying to calibrate the Titan E3D extruder with 1.75 Ninjaflex filament. From what I've seen and read, Ninjaflex 3mm works with the first tension setting, but 1.75 is a crap shoot if you can get it working reliably and consistent at all with the Titan.

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 06:10PM |

Registered: 7 years ago Posts: 55 |

Quote

PDBeal

Even trying to print 1.75 Ninjaflex with the Titan E3D with the tension screw backed off to nothing at 5mm/s wouldn't take enough filament while trying to do the 100mm calibration, and then slowly giving it 1/4 turns it would then start sticking to the idler and making its way outside the captured path. I managed to create some Ninjaflex parts, but I highly doubt they were not underextruded based on the attempts I had trying to calibrate the Titan E3D extruder with 1.75 Ninjaflex filament. From what I've seen and read, Ninjaflex 3mm works with the first tension setting, but 1.75 is a crap shoot if you can get it working reliably and consistent at all with the Titan.

Are you using Bowden or direct feed? I bought sample rolls of the ninja flex, so I may go for a 3mm set up instead.

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2016 08:39PM |

Registered: 7 years ago Posts: 558 |

Initially I was trying it with a bowden Titan E3D setup. That one doesn't work at all for Ninjaflex 1.75mm.

I changed my brackets for my hotend to hold the motor instead of the E3D V6 and converted it to a direct drive, which is where I had limited success with the Titan extruding 1.75mm Ninjaflex.

Edited 1 time(s). Last edit at 11/07/2016 08:40PM by PDBeal.

I changed my brackets for my hotend to hold the motor instead of the E3D V6 and converted it to a direct drive, which is where I had limited success with the Titan extruding 1.75mm Ninjaflex.

Edited 1 time(s). Last edit at 11/07/2016 08:40PM by PDBeal.

|

Re: An alternative to buying a bad kit for $300-500 November 08, 2016 08:19AM |

Registered: 10 years ago Posts: 38 |

Good Morning.

I have a problem. The person that I purchased the Cube Pro from must have miscalculated shipping that was posted in the auction. Turns out it is substantially more. The dimensions of the Cube Pro are 22.75 x 22.75 x 23.25 inches. It is hard to tell what the size will be after packaging. I tried the UPS calculator and ran some numbers and it look like prices really jump after 26 inches. Any of you ever use USHIP.com? Or any other? What are your packaging suggestions?

As always, thank you.

Edited 1 time(s). Last edit at 11/08/2016 09:50AM by Kasahabo.

I have a problem. The person that I purchased the Cube Pro from must have miscalculated shipping that was posted in the auction. Turns out it is substantially more. The dimensions of the Cube Pro are 22.75 x 22.75 x 23.25 inches. It is hard to tell what the size will be after packaging. I tried the UPS calculator and ran some numbers and it look like prices really jump after 26 inches. Any of you ever use USHIP.com? Or any other? What are your packaging suggestions?

As always, thank you.

Edited 1 time(s). Last edit at 11/08/2016 09:50AM by Kasahabo.

|

Re: An alternative to buying a bad kit for $300-500 November 08, 2016 10:07AM |

Registered: 11 years ago Posts: 471 |

|

Re: An alternative to buying a bad kit for $300-500 November 08, 2016 01:05PM |

Registered: 7 years ago Posts: 55 |

|

Re: An alternative to buying a bad kit for $300-500 November 10, 2016 02:45PM |

Registered: 7 years ago Posts: 55 |

Would anyone skilled with CAD be willing to draw up an X assembly that can house two E3D v6 hot ends and Titan extruders on top for the Cubex? I'm wondering if it would be easier to print an assembly that houses the bearings or one that just bolts to the top of the two existing bearing housings.

Something along these lines: [www.thingiverse.com]

Edited 1 time(s). Last edit at 11/10/2016 02:54PM by Dancook.

Something along these lines: [www.thingiverse.com]

Edited 1 time(s). Last edit at 11/10/2016 02:54PM by Dancook.

|

Re: An alternative to buying a bad kit for $300-500 November 10, 2016 04:01PM |

Registered: 7 years ago Posts: 363 |

|

Re: An alternative to buying a bad kit for $300-500 November 11, 2016 09:12AM |

Registered: 7 years ago Posts: 363 |

|

Re: An alternative to buying a bad kit for $300-500 November 11, 2016 10:18AM |

Registered: 7 years ago Posts: 55 |

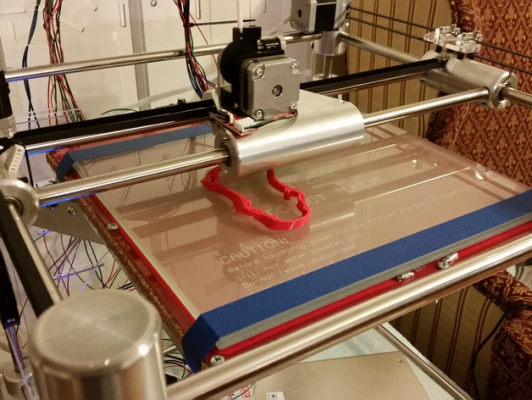

Update on my FrankenCube...

First actual print was a success with the E3D v6 and Titan extruder... I need to work on cleaning up the wires and mount the electronics. Also need to work on some cooling fans for the print. The printer is super quiet! Well, it was until I turned on the cooling fan for the v6 cool end... that things sounds like an F16! I'll be replacing it soon... the Titan and v6 are like butter! I'm going to look into a dual extruding X assembly like the one I linked above... I'm not sure of the dimensions and build-up of the e3d BigBox printer, but it looks very similar to the Cubex, so I'm sure that design can be adjusted to work with the Cubex...

Anyways, here's a picture of the printer in action, and the finished product which shows that I need to do some tweaking to the printer.

First actual print was a success with the E3D v6 and Titan extruder... I need to work on cleaning up the wires and mount the electronics. Also need to work on some cooling fans for the print. The printer is super quiet! Well, it was until I turned on the cooling fan for the v6 cool end... that things sounds like an F16! I'll be replacing it soon... the Titan and v6 are like butter! I'm going to look into a dual extruding X assembly like the one I linked above... I'm not sure of the dimensions and build-up of the e3d BigBox printer, but it looks very similar to the Cubex, so I'm sure that design can be adjusted to work with the Cubex...

Anyways, here's a picture of the printer in action, and the finished product which shows that I need to do some tweaking to the printer.

|

Re: An alternative to buying a bad kit for $300-500 November 11, 2016 12:11PM |

Registered: 7 years ago Posts: 47 |

Hi, where did you soldered these diodes? Mine is still under construction as I don't have all the parts yet, but in the mean time I read as much as I can on this conversion build.

B.T.W. thanks to All of you that sharing there info here, much appreciated.

Edited 1 time(s). Last edit at 11/11/2016 12:12PM by fg dude.

B.T.W. thanks to All of you that sharing there info here, much appreciated.

Edited 1 time(s). Last edit at 11/11/2016 12:12PM by fg dude.

|

Re: An alternative to buying a bad kit for $300-500 November 11, 2016 02:56PM |

Registered: 7 years ago Posts: 363 |

I cut the stepper wires about 6 inches from the controller and soldered one diode circuit for each motor loop (2 in total). I used the outside wires from the connector so I wouldn't cross them somehow. Got clean solder joints but the wiring doesn't look particularly clean. Stepper noise is pretty much gone now though.

|

Re: An alternative to buying a bad kit for $300-500 November 15, 2016 07:55PM |

Registered: 8 years ago Posts: 318 |

What voltage should you use for drv8825s? Mine are getting really hot quite quickly, tried an a4988 as well with same result..

edit: around .6 V is the lowest I can go and still move my Z axis, turns out it does not get hot at this temp, I had mistaken which way to turn the pot. to decrease voltage

Edited 1 time(s). Last edit at 11/15/2016 08:17PM by DaGameFace.

edit: around .6 V is the lowest I can go and still move my Z axis, turns out it does not get hot at this temp, I had mistaken which way to turn the pot. to decrease voltage

Edited 1 time(s). Last edit at 11/15/2016 08:17PM by DaGameFace.

|

Re: An alternative to buying a bad kit for $300-500 November 16, 2016 07:30AM |

Registered: 7 years ago Posts: 47 |

Quote

DaGameFace

What voltage should you use for drv8825s? Mine are getting really hot quite quickly, tried an a4988 as well with same result..

edit: around .6 V is the lowest I can go and still move my Z axis, turns out it does not get hot at this temp, I had mistaken which way to turn the pot. to decrease voltage

I had the same problem, but after tuning my step/min and speed the problem was solved.

I have my stepper (a4988) drivers now at 0.65V and they seem to stay below 50°, no missing steps on the motors by manual commands.

My printer is still a work in progress and no printing done yet.

|

Re: An alternative to buying a bad kit for $300-500 November 16, 2016 08:19PM |

Registered: 8 years ago Posts: 105 |

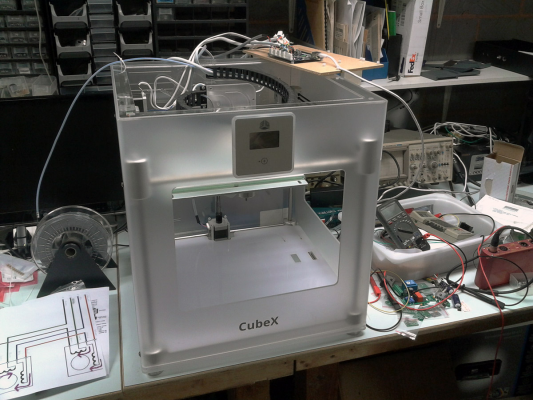

Got mine last Friday, tried it with Simplify3d BFB file output then Codex to create the encrypted cubex print file. Worked ok, but print quality was nothing special for the amount of time it took me to get it to accept the file, anyway was a relatively fun evening!

Stripped out all the electronics from the base, and flipped the acrylic base over so there is no gap between the sides and the bottom to let draughts in. Decided for the moment to make use of the existing power supply to power the Duet board. Moved all the wiring to the top for easy access, thinking I will probably make a hole in the acrylic cover on the back near the left Y motor to pass the cable through.

Wiring was fairly easy as I have 4 way molex shells for the motor connections and the crimp terminals are the same, so just push the pins out and put them in the correct order in the shells. The Y motors are running in series with a header creating links.

I am dumping the waste bin and have the 0,0 set at the front left corner so it's easy to access the head.

Left the circuit board linker for the hot end in place as it does no harm. Reused part of the wiring loom to connect up the cooling fan to a 317 regulator board dropping the 15.5V to 12 so the fan doesn't expire. Have quick and dirty wired up one of the part cooling fans to the Duet. As the voltage is higher 75% fan in the slicer software equals 100% actual.

Did a couple of test prints this evening and all looks good so far, still have to set up a Z limit and build the heated bed.

Will post full wiring plan and config files if anyone wants to go the same route.

Thanks to everyone who posted on the thread, saved me a lot of time calculating steps and setting the hot end up

Stripped out all the electronics from the base, and flipped the acrylic base over so there is no gap between the sides and the bottom to let draughts in. Decided for the moment to make use of the existing power supply to power the Duet board. Moved all the wiring to the top for easy access, thinking I will probably make a hole in the acrylic cover on the back near the left Y motor to pass the cable through.

Wiring was fairly easy as I have 4 way molex shells for the motor connections and the crimp terminals are the same, so just push the pins out and put them in the correct order in the shells. The Y motors are running in series with a header creating links.

I am dumping the waste bin and have the 0,0 set at the front left corner so it's easy to access the head.

Left the circuit board linker for the hot end in place as it does no harm. Reused part of the wiring loom to connect up the cooling fan to a 317 regulator board dropping the 15.5V to 12 so the fan doesn't expire. Have quick and dirty wired up one of the part cooling fans to the Duet. As the voltage is higher 75% fan in the slicer software equals 100% actual.

Did a couple of test prints this evening and all looks good so far, still have to set up a Z limit and build the heated bed.

Will post full wiring plan and config files if anyone wants to go the same route.

Thanks to everyone who posted on the thread, saved me a lot of time calculating steps and setting the hot end up

|

Re: An alternative to buying a bad kit for $300-500 November 17, 2016 08:10PM |

Registered: 7 years ago Posts: 363 |

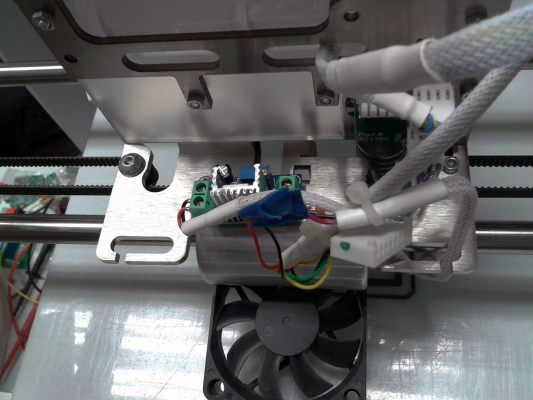

My setup looks so much more sketchy, but all electrical connections are sound with clean solder joints and heat shrink. Finally started a test print off 3d benchy hope it measures out well. I haven't really tweaked the calibration yet.

[sendvid.com] <--- short video of it in action. I noticed an immediate and notable improvement in print quality with my normal calibration object. This is the benchy print in its early layers.

Edited 1 time(s). Last edit at 11/17/2016 08:19PM by obelisk79.

[sendvid.com] <--- short video of it in action. I noticed an immediate and notable improvement in print quality with my normal calibration object. This is the benchy print in its early layers.

Edited 1 time(s). Last edit at 11/17/2016 08:19PM by obelisk79.

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 11:14AM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 02:42PM |

Registered: 7 years ago Posts: 9 |

Hello #Dancook,

I have a 3Dtouch BFB.

I plan to convert it into a reprap but I confess to be a little lost.

I do not know anything about programming and I am sending to remove the basic electronics and extruders but I do not know how and how to make it work!

As you carry out such an operation, could you help me?

Toni

I have a 3Dtouch BFB.

I plan to convert it into a reprap but I confess to be a little lost.

I do not know anything about programming and I am sending to remove the basic electronics and extruders but I do not know how and how to make it work!

As you carry out such an operation, could you help me?

Toni

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 02:47PM |

Registered: 7 years ago Posts: 9 |

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 02:58PM |

Registered: 7 years ago Posts: 9 |

# Obelisk79, # Firefox3D,

Super conversion of CubeX.

Feel free to share your list of changed components.

If you have configuration files too, it would be cool.

A question for you # obelisk79, are you happy with your extruder assembly? It does not pull the filament?

In this regard, would it be complicated to program the new electronics to do as the new prusa multicolor update?

A bientot ! Best regards

Super conversion of CubeX.

Feel free to share your list of changed components.

If you have configuration files too, it would be cool.

A question for you # obelisk79, are you happy with your extruder assembly? It does not pull the filament?

In this regard, would it be complicated to program the new electronics to do as the new prusa multicolor update?

A bientot ! Best regards

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 05:14PM |

Registered: 8 years ago Posts: 105 |

toto08 I will post full wiring details and the config files in the week, the printer is at my workshop and I'm working on other things this weekend.

Ordering parts for the heated bed, 750W 30cm x 30cm mains powered silicone heater connected via a 10amp SSR.

One thing I noticed doing a test print with small rapid movements of the Y carriage is you can see/feel the printer moving due to the high centre of gravity. I pinned it by leaning on it while it printed a test piece then let it carry on without me damping it. I can see considerably more noise in the print where I wasn't stopping it from moving, this was only at around 20-30mm/s. I think of anchoring the printer to the wall at the top of the posts by the Y motors. Something simple like pressed steel shelf brackets.

Jon

Edited 1 time(s). Last edit at 11/18/2016 05:16PM by Firefox3D.

Ordering parts for the heated bed, 750W 30cm x 30cm mains powered silicone heater connected via a 10amp SSR.

One thing I noticed doing a test print with small rapid movements of the Y carriage is you can see/feel the printer moving due to the high centre of gravity. I pinned it by leaning on it while it printed a test piece then let it carry on without me damping it. I can see considerably more noise in the print where I wasn't stopping it from moving, this was only at around 20-30mm/s. I think of anchoring the printer to the wall at the top of the posts by the Y motors. Something simple like pressed steel shelf brackets.

Jon

Edited 1 time(s). Last edit at 11/18/2016 05:16PM by Firefox3D.

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 05:37PM |

Registered: 11 years ago Posts: 5,780 |

The acrylic cabinet for the printer stiffened the whole assembly. If you operate without the cabinet, the frame will wobble unless you keep acceleration and speed down. It should be easy to stabilize it by adding side panels that use the acrylic cabinet's screw holes. Someone here said they were going to try tensioned wires running diagonally from corner to corner.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 06:04PM |

Registered: 7 years ago Posts: 9 |

Hi John,

I was thinking of redoing the case completely.

Already because I actually think it is part of the structure.

The left and right sides ensure the connection and squareness of the posts.

Then because the bed does not go through the window!

For my part, I thought to make an aluminum casing 2mm thick or dibond 3mm.

A plus !

Toni

I was thinking of redoing the case completely.

Already because I actually think it is part of the structure.

The left and right sides ensure the connection and squareness of the posts.

Then because the bed does not go through the window!

For my part, I thought to make an aluminum casing 2mm thick or dibond 3mm.

A plus !

Toni

|

Re: An alternative to buying a bad kit for $300-500 November 18, 2016 06:13PM |

Registered: 8 years ago Posts: 105 |

I have the acrylic cabinet screwed on, what I am talking about is caused by the fact the moving carriage mass is essentially rocking the printer. The test I was doing with small rapid movements was worst case scenario but it was clearly visible that's what was happening. I can't show you exactly what I am talking about as the test piece is at the workshop.

I think wires wouldn't necessarily help as it would require considerable tension and they will have a ringing frequency. I think I have some aluminium angle I can fit from rear top to bottom front as a test, and replacing the thin piece of rear acrylic with aluminium as there are mount points already on all 4 rear aluminium corners to stiffen it in the Y-Z plane.

I think wires wouldn't necessarily help as it would require considerable tension and they will have a ringing frequency. I think I have some aluminium angle I can fit from rear top to bottom front as a test, and replacing the thin piece of rear acrylic with aluminium as there are mount points already on all 4 rear aluminium corners to stiffen it in the Y-Z plane.

Sorry, only registered users may post in this forum.