An alternative to buying a bad kit for $300-500

Posted by the_digital_dentist

|

Re: An alternative to buying a bad kit for $300-500 January 22, 2017 06:15AM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 January 22, 2017 07:27AM |

Registered: 11 years ago Posts: 5,780 |

Interesting... Are you aware that a lot of people have problems with the graphic LCD overloading the 5V regulator on the RAMPS board? Why autoleveling? Autoleveling is great for machines that can't maintain the bed leveling, but these Cubex machines are stable and don't require releveling once they are set up (at least mine hasn't).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 January 22, 2017 07:40AM |

Registered: 7 years ago Posts: 47 |

Quote

the_digital_dentist

Interesting... Are you aware that a lot of people have problems with the graphic LCD overloading the 5V regulator on the RAMPS board? Why autoleveling? Autoleveling is great for machines that can't maintain the bed leveling, but these Cubex machines are stable and don't require releveling once they are set up (at least mine hasn't).

No, did not know that, so far I have no indication that there is something going on, so far so good. (I have a spare Ramps board for ''just in case''.)

My bed was not that stable, I have a original heated bed and the front point sits loose on a screw, every time I get a print of my table it has shifted a bit, now this problem is solved with auto leveling.

|

Re: An alternative to buying a bad kit for $300-500 January 23, 2017 06:50PM |

Registered: 7 years ago Posts: 55 |

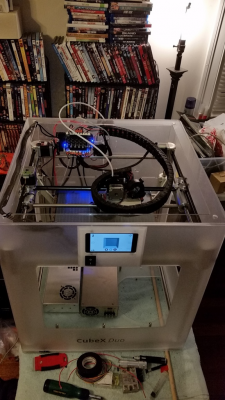

Cubex is almost back together... currently printing corners for a Delta.

|

Re: An alternative to buying a bad kit for $300-500 January 24, 2017 05:21AM |

Registered: 9 years ago Posts: 59 |

Just in case any Cube3/Pro owners read this thread, the firmwares have been hacked to allow third party filament

[www.print3dforum.com]!!!

[www.print3dforum.com]!!!

|

Re: An alternative to buying a bad kit for $300-500 January 24, 2017 08:02AM |

Registered: 7 years ago Posts: 47 |

Quote

bolsoncerrado

Just in case any Cube3/Pro owners read this thread, the firmwares have been hacked to allow third party filament

[www.print3dforum.com]!!!

|

Re: An alternative to buying a bad kit for $300-500 January 24, 2017 08:24AM |

Registered: 11 years ago Posts: 5,780 |

The Cube 3 is a different printer than the ones we're modifying here. Does the Cube 3 use the same controller board as the CubeX machines?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 January 24, 2017 08:31AM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 January 24, 2017 09:19AM |

Registered: 9 years ago Posts: 59 |

|

Re: An alternative to buying a bad kit for $300-500 January 24, 2017 10:26PM |

Registered: 8 years ago Posts: 318 |

|

Re: An alternative to buying a bad kit for $300-500 January 27, 2017 08:35AM |

Registered: 7 years ago Posts: 55 |

Quote

the_digital_dentist

Why autoleveling? Autoleveling is great for machines that can't maintain the bed leveling, but these Cubex machines are stable and don't require releveling once they are set up (at least mine hasn't).

My Duo has been very fickle lately about the bed leveling... not sure why... one print, it's fine, the next, I'll get the dreaded extruder clicking because the bed is too high. Maybe it's the crazy weather and my (probably too thick) cork bed?

I ordered these for the Kossel I'm building: [www.ultibots.com]

I'm excited to get it built... maybe I'll retire the Duo...

|

Re: An alternative to buying a bad kit for $300-500 January 27, 2017 08:53AM |

Registered: 7 years ago Posts: 47 |

Quote

DaGameFace

Anyone try to remove the X axis yet? Ideally I would like to remove a ton of weight from it but not sure that I can take the smooth rods of the X axis out of the blocks that are the Y axis without tearing down the whole printer.

I think you have no other choice than to remove one side of the printer completely.

|

Re: An alternative to buying a bad kit for $300-500 January 27, 2017 09:30AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Dancook

My Duo has been very fickle lately about the bed leveling... not sure why... one print, it's fine, the next, I'll get the dreaded extruder clicking because the bed is too high. Maybe it's the crazy weather and my (probably too thick) cork bed?

I ordered these for the Kossel I'm building: [www.ultibots.com]

I'm excited to get it built... maybe I'll retire the Duo...

Early on I found that the three, weird little rubber bumpers the bed sits on tend to lift themselves out of the bed support plate and cause the bed level to shift. Get rid of those things and replace them with almost anything that will stay put. I contact-cemented some rubber o-rings to the support plate, but almost anything will work. In fact, those little things aren't entirely necessary because the bed leveling is done by adjusting the bed support plate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 January 27, 2017 11:14AM |

Registered: 8 years ago Posts: 318 |

Quote

fg dude

Quote

DaGameFace

Anyone try to remove the X axis yet? Ideally I would like to remove a ton of weight from it but not sure that I can take the smooth rods of the X axis out of the blocks that are the Y axis without tearing down the whole printer.

I think you have no other choice than to remove one side of the printer completely.

Yeah, I thought so, was hoping I overlooked something.

|

Re: An alternative to buying a bad kit for $300-500 January 27, 2017 11:35AM |

Registered: 7 years ago Posts: 55 |

Quote

the_digital_dentist

Quote

Dancook

My Duo has been very fickle lately about the bed leveling... not sure why... one print, it's fine, the next, I'll get the dreaded extruder clicking because the bed is too high. Maybe it's the crazy weather and my (probably too thick) cork bed?

I ordered these for the Kossel I'm building: [www.ultibots.com]

I'm excited to get it built... maybe I'll retire the Duo...

Early on I found that the three, weird little rubber bumpers the bed sits on tend to lift themselves out of the bed support plate and cause the bed level to shift. Get rid of those things and replace them with almost anything that will stay put. I contact-cemented some rubber o-rings to the support plate, but almost anything will work. In fact, those little things aren't entirely necessary because the bed leveling is done by adjusting the bed support plate.

Yeah, I trashed the entire bed assembly and have an aluminum plate sitting on top of the original springs... cork on top of plate, heated bed on top of cork, and glass build plate on top of that. Adjustable height from the bottom.

I'll have to look through my pics to see if any show it.

Here's the latest video I made:

[www.youtube.com]

Edited 1 time(s). Last edit at 01/27/2017 11:36AM by Dancook.

|

Re: An alternative to buying a bad kit for $300-500 February 03, 2017 10:38PM |

Registered: 7 years ago Posts: 45 |

|

Re: An alternative to buying a bad kit for $300-500 March 01, 2017 05:43PM |

Registered: 9 years ago Posts: 59 |

Quote

Dancook

Cubex is almost back together... currently printing corners for a Delta.

@DanCook whats that GUI seen on the LCD?

Cheers

|

Re: An alternative to buying a bad kit for $300-500 March 01, 2017 05:53PM |

Registered: 7 years ago Posts: 55 |

[youtu.be]

It's "Toggle"...

It's Replicape board specific... we are developing a new screen as well.

[www.thing-printer.com]

Edited 1 time(s). Last edit at 03/01/2017 05:54PM by Dancook.

It's "Toggle"...

It's Replicape board specific... we are developing a new screen as well.

[www.thing-printer.com]

Edited 1 time(s). Last edit at 03/01/2017 05:54PM by Dancook.

|

Re: An alternative to buying a bad kit for $300-500 March 05, 2017 03:35PM |

Registered: 7 years ago Posts: 45 |

Anyone have, or thought about adding a blower/ radial fans to to replace the 3 large print cooling fans? I was mainly interested in it as a possible way to clean up the carriage and give better view of the print area. The three fans that are there now are too powerful as it is (at least for me). I had to wrap my E3D volcanos with silicone in order for them not to send a fault to my duet wifi. It would detect a heating issue,and I could turn them on and i could actually see the temp of the heating block cooling while it was trying to heat. But that's all been solved due to the silicone wrap of the heating block.

I have 2 ideas for the radial blow fan. One is the have the fan sitting where the third extruder would be, print out a cooling duct that would direct the air flow down to the print area. Second idea is for it to mount were the original extruder fans are(I'm currently using the E3D fans). The E3D fans actually sit/and clear the old fan mounts, but wonder if it'll effect the air flow going into the E3D fan as it would be close.

On another note, got my printer pretty much done. Got a lot of mods done and the duet wifi pretty well dialed in. There's a few issues I need to work out though. In Simplify3d I try to set PWM fan 0 to turn on after the first layer(or any layer) and it doesn't. So I need to look into that more. Also my prints are mirrored. I printed something the other day with my wife's name on it. Instead of saying "WHITNEY" it said "YENTIHW" with the E and N also backwards. I'm guessing the X axis needs to be reversed.

Edited 1 time(s). Last edit at 03/05/2017 03:36PM by advancedrescue.

I have 2 ideas for the radial blow fan. One is the have the fan sitting where the third extruder would be, print out a cooling duct that would direct the air flow down to the print area. Second idea is for it to mount were the original extruder fans are(I'm currently using the E3D fans). The E3D fans actually sit/and clear the old fan mounts, but wonder if it'll effect the air flow going into the E3D fan as it would be close.

On another note, got my printer pretty much done. Got a lot of mods done and the duet wifi pretty well dialed in. There's a few issues I need to work out though. In Simplify3d I try to set PWM fan 0 to turn on after the first layer(or any layer) and it doesn't. So I need to look into that more. Also my prints are mirrored. I printed something the other day with my wife's name on it. Instead of saying "WHITNEY" it said "YENTIHW" with the E and N also backwards. I'm guessing the X axis needs to be reversed.

Edited 1 time(s). Last edit at 03/05/2017 03:36PM by advancedrescue.

|

Re: An alternative to buying a bad kit for $300-500 March 06, 2017 03:50PM |

Registered: 7 years ago Posts: 55 |

Quote

advancedrescue

Anyone have, or thought about adding a blower/ radial fans to to replace the 3 large print cooling fans? I was mainly interested in it as a possible way to clean up the carriage and give better view of the print area. The three fans that are there now are too powerful as it is (at least for me). I had to wrap my E3D volcanos with silicone in order for them not to send a fault to my duet wifi. It would detect a heating issue,and I could turn them on and i could actually see the temp of the heating block cooling while it was trying to heat. But that's all been solved due to the silicone wrap of the heating block.

On another note, got my printer pretty much done. Got a lot of mods done and the duet wifi pretty well dialed in. There's a few issues I need to work out though. In Simplify3d I try to set PWM fan 0 to turn on after the first layer(or any layer) and it doesn't. So I need to look into that more. Also my prints are mirrored. I printed something the other day with my wife's name on it. Instead of saying "WHITNEY" it said "YENTIHW" with the E and N also backwards. I'm guessing the X axis needs to be reversed.

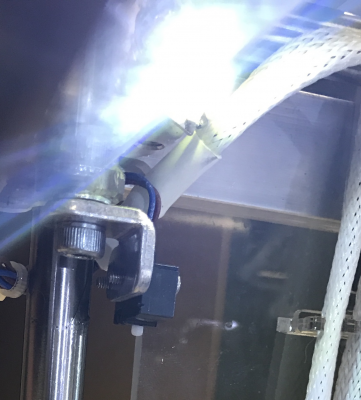

I use a radial fan with some flex tubing to blow air directly under my tip... it may not be sufficient cooling, but it's working well for PETG at the moment.

It looks like you need to invert your X and Y... you should have X0, Y0 at the front left corner.

|

Re: An alternative to buying a bad kit for $300-500 March 06, 2017 06:12PM |

Registered: 7 years ago Posts: 45 |

Right now I have mine setup to zero in back left. I got my y endstop in the back right, and x endstop on the left. So when homing it raises hitting the z endstop, then left to hit x endstop, then back to hit the y endstop. After zeroing out homing ithe extruder position is off the actual print bed. Then the extruders move forward to the back left corner of the bed, then via g code it sets that to the zero position

So if the proper position is front left instead of my back left, does that mean I need to flip the y and that correct my mirrored?

I have the mechanical endstops used and mounts from the cubepro. I can take pictures of it tomorrow when at the fire station when I'm on duty.

Edited 1 time(s). Last edit at 03/06/2017 06:14PM by advancedrescue.

So if the proper position is front left instead of my back left, does that mean I need to flip the y and that correct my mirrored?

I have the mechanical endstops used and mounts from the cubepro. I can take pictures of it tomorrow when at the fire station when I'm on duty.

Edited 1 time(s). Last edit at 03/06/2017 06:14PM by advancedrescue.

|

Re: An alternative to buying a bad kit for $300-500 March 07, 2017 07:23AM |

Registered: 7 years ago Posts: 47 |

Quote

advancedrescue

Right now I have mine setup to zero in back left. I got my y endstop in the back right, and x endstop on the left. So when homing it raises hitting the z endstop, then left to hit x endstop, then back to hit the y endstop. After zeroing out homing ithe extruder position is off the actual print bed. Then the extruders move forward to the back left corner of the bed, then via g code it sets that to the zero position

So if the proper position is front left instead of my back left, does that mean I need to flip the y and that correct my mirrored?

I have the mechanical endstops used and mounts from the cubepro. I can take pictures of it tomorrow when at the fire station when I'm on duty.

Flip the Y wont work, if you try it, keep your finger on the on/off switch when homing.

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 01:00AM |

Registered: 7 years ago Posts: 45 |

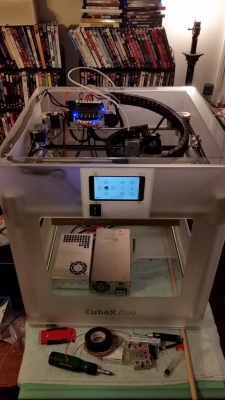

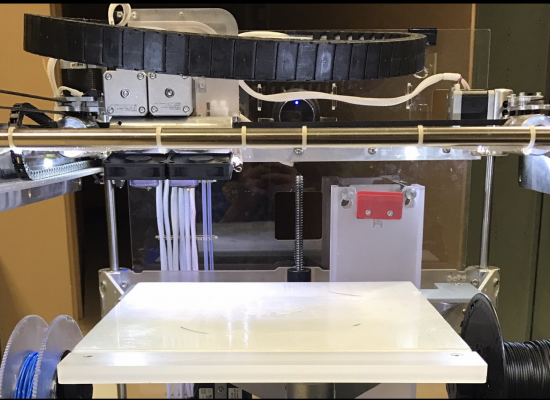

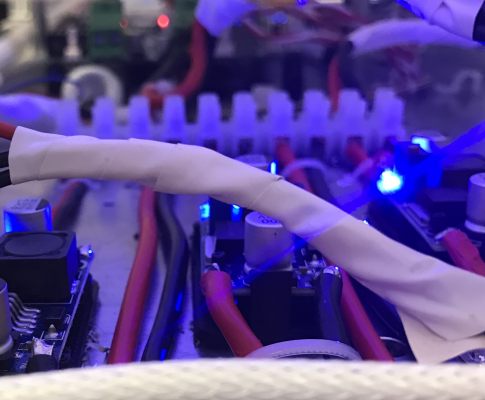

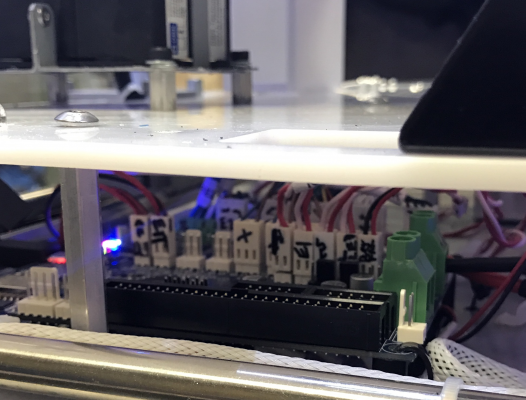

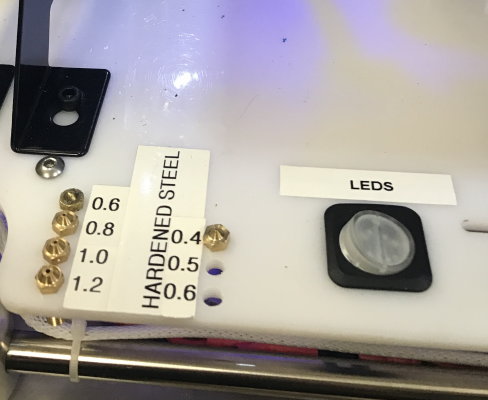

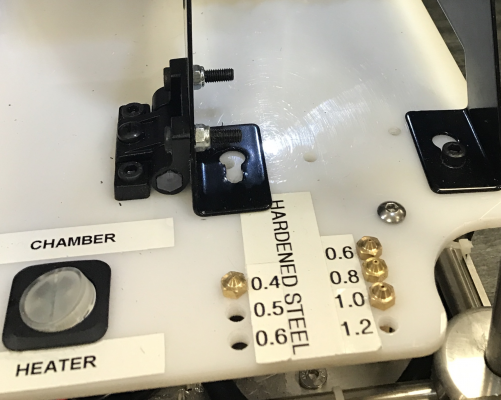

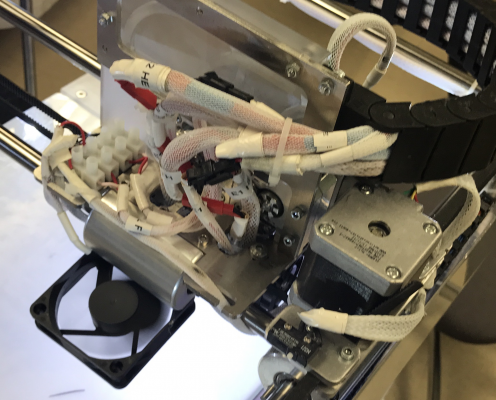

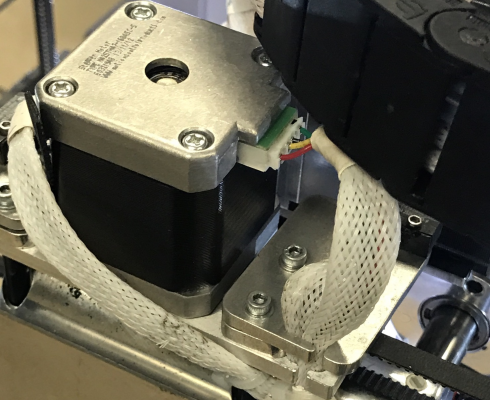

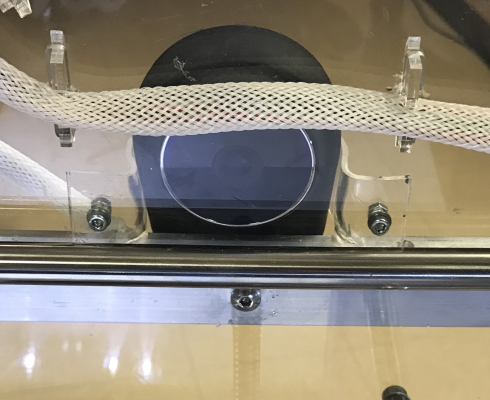

Here's some updates on my build.

I have the exterior shell of the cubepro, but didn't take a picture of it installed.

Quick list of mods and parts:

*Duet wifi, and panel due

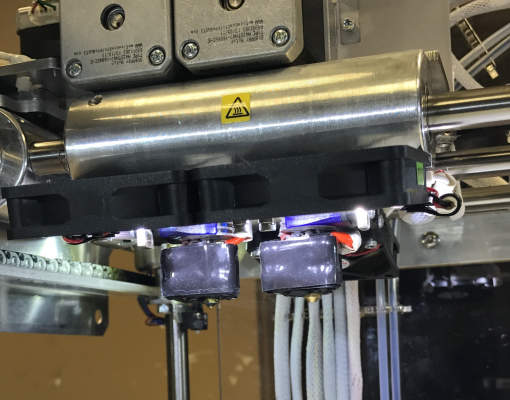

*2 E3D 24v volcano hotends

-- I then drilled and taped the bottom cover plate so that the extra nozzles screw down.

---I used TheJones mod to mount the hot ends, and also his mod for the Bowden tubes going into the extruders. Both have worked out flawlessly.

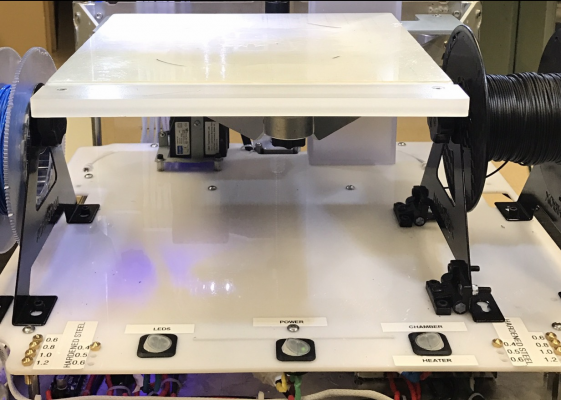

*24 volt power supply, with buck converters for various items below

*Switch for the main 24v going to the duet wifi for easy on and off.

*Wifi security camera mounted on the back of machine

--wired to the buck converter to drop down to required 5v.

*LEDs wired to each top corner of printer

--these are super bright but only require 3.3v, so they are regulated by a buck converter and then can be switch on or off via switch on bottom cover plate. These lights are separate from the carriage lights.

*Extra terminal for possible future parts dropped down to 12v via buck converter.

*On the build plate frame I cut grooves out and installed Knobs for easy tightening and loosening of the leveling bolts.

*Chamber heater from the cube pro, and a switch on bottom cover plate.

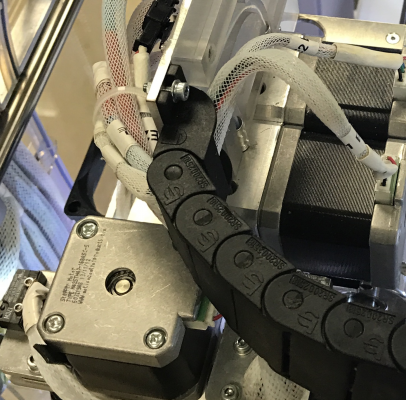

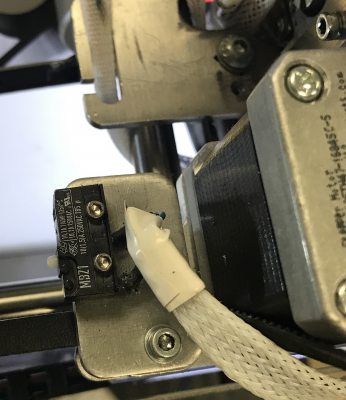

*Mech end stop switches and mounts from cube pro, also belt clamps from the cubepro

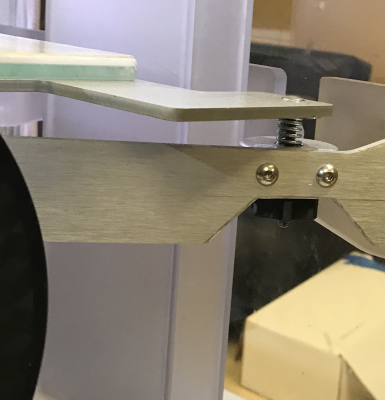

*Waste bin modded. Original wiper would hangs on nozzles and was kind of rough when going over the wiper. So I found a silicone spatula from Walmart rated for I believe over 400 degrees. I cut it to size and mounted it. You can see in the pictures, but in the pictures the spring that pushes the wiper up wasn't on it.

*Rewired all the cubex breaded wire sleeves for various changes.

*Installed hatchbox spool holders onto build plate. Able to fit full size roll on the right side, and mounted the left base using hinges from original cubepro filament holder for easy install and removal. Wish I had another set of hinges for the left spool holder. I modified the left spool holder to use a smaller filament roll by cutting the center bar. The spools used are from the cube 3 I have. Perfect width, and I have around 15 rolls and can reload in the future.

*The right filament goes thru the Bowden and feeds the 1st primary extruder now and the left goes to the 2nd extruder.

*The E3D, therm, fans have have plugs for easier removal if needed.

*Wrapped the hotends with silicone tape found from autozone. Tape is made for use in engine compartments on cars, and has a very high temp rating. So far has worked flawlessly and helping regulate temp, and I removed the first wrap to see if it left anything possibly melted to hot end, but hot end looked new.

*Cubepro base plate and side supports that also is needed for mounting the pro exterior shell.

*PEI sheet on top of the print plate.

Edited 3 time(s). Last edit at 03/10/2017 08:11AM by advancedrescue.

I have the exterior shell of the cubepro, but didn't take a picture of it installed.

Quick list of mods and parts:

*Duet wifi, and panel due

*2 E3D 24v volcano hotends

-- I then drilled and taped the bottom cover plate so that the extra nozzles screw down.

---I used TheJones mod to mount the hot ends, and also his mod for the Bowden tubes going into the extruders. Both have worked out flawlessly.

*24 volt power supply, with buck converters for various items below

*Switch for the main 24v going to the duet wifi for easy on and off.

*Wifi security camera mounted on the back of machine

--wired to the buck converter to drop down to required 5v.

*LEDs wired to each top corner of printer

--these are super bright but only require 3.3v, so they are regulated by a buck converter and then can be switch on or off via switch on bottom cover plate. These lights are separate from the carriage lights.

*Extra terminal for possible future parts dropped down to 12v via buck converter.

*On the build plate frame I cut grooves out and installed Knobs for easy tightening and loosening of the leveling bolts.

*Chamber heater from the cube pro, and a switch on bottom cover plate.

*Mech end stop switches and mounts from cube pro, also belt clamps from the cubepro

*Waste bin modded. Original wiper would hangs on nozzles and was kind of rough when going over the wiper. So I found a silicone spatula from Walmart rated for I believe over 400 degrees. I cut it to size and mounted it. You can see in the pictures, but in the pictures the spring that pushes the wiper up wasn't on it.

*Rewired all the cubex breaded wire sleeves for various changes.

*Installed hatchbox spool holders onto build plate. Able to fit full size roll on the right side, and mounted the left base using hinges from original cubepro filament holder for easy install and removal. Wish I had another set of hinges for the left spool holder. I modified the left spool holder to use a smaller filament roll by cutting the center bar. The spools used are from the cube 3 I have. Perfect width, and I have around 15 rolls and can reload in the future.

*The right filament goes thru the Bowden and feeds the 1st primary extruder now and the left goes to the 2nd extruder.

*The E3D, therm, fans have have plugs for easier removal if needed.

*Wrapped the hotends with silicone tape found from autozone. Tape is made for use in engine compartments on cars, and has a very high temp rating. So far has worked flawlessly and helping regulate temp, and I removed the first wrap to see if it left anything possibly melted to hot end, but hot end looked new.

*Cubepro base plate and side supports that also is needed for mounting the pro exterior shell.

*PEI sheet on top of the print plate.

Edited 3 time(s). Last edit at 03/10/2017 08:11AM by advancedrescue.

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 01:41AM |

Registered: 7 years ago Posts: 45 |

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 03:01AM |

Registered: 9 years ago Posts: 59 |

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 05:04AM |

Registered: 9 years ago Posts: 59 |

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 07:19AM |

Registered: 11 years ago Posts: 5,780 |

I like everything except the electrical tape on the wires. It always leaves sticky residue on everything it touches. Get some heat shrink!

Is the silicone tape on the heater blocks the kind of stuff that fuses to itself but doesn't stick to other things?

I really like the silicone blade on the scraper- I want to use the scraper but it's barely functional with the part that came on there. I'll be doing some shopping later today...

Edited 1 time(s). Last edit at 03/10/2017 07:21AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Is the silicone tape on the heater blocks the kind of stuff that fuses to itself but doesn't stick to other things?

I really like the silicone blade on the scraper- I want to use the scraper but it's barely functional with the part that came on there. I'll be doing some shopping later today...

Edited 1 time(s). Last edit at 03/10/2017 07:21AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 08:10AM |

Registered: 7 years ago Posts: 45 |

Around 90 percent has heat sink, the ones that have electrical tape I have to go back and do the heat sink. I agree I'm not crazy about it. Yeah the silicone tape does. Main reason went with it was the print cooling fans would kick on and make the heat blocks drop temp suddenly and would send a fault to the board. No problems now. In autozone you can find it where the tubes of silicone are.

Edited 1 time(s). Last edit at 03/11/2017 04:00PM by advancedrescue.

Edited 1 time(s). Last edit at 03/11/2017 04:00PM by advancedrescue.

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 08:13AM |

Registered: 7 years ago Posts: 45 |

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 08:49AM |

Registered: 7 years ago Posts: 55 |

I've been getting a nasty Z-line in my prints about every 9-10mm... it's consistent enough that I'm questioning the Z screw...

I'm about 90% finished with my delta printer... mainly just waiting for the new touchscreen.

I'm probably going to give the FrankenCube an overhaul. The thing has litterally been printing every night for 8-9 months...

Any suggestions on my issue?

Edited 1 time(s). Last edit at 03/10/2017 08:51AM by Dancook.

I'm about 90% finished with my delta printer... mainly just waiting for the new touchscreen.

I'm probably going to give the FrankenCube an overhaul. The thing has litterally been printing every night for 8-9 months...

Any suggestions on my issue?

Edited 1 time(s). Last edit at 03/10/2017 08:51AM by Dancook.

Sorry, only registered users may post in this forum.