An alternative to buying a bad kit for $300-500

Posted by the_digital_dentist

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 09:09AM |

Registered: 11 years ago Posts: 5,780 |

I don't see any lines in the Z axis of prints made on my CubeX. I don't think it's the screw.

Edited 1 time(s). Last edit at 03/10/2017 09:09AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 03/10/2017 09:09AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 09:14AM |

Registered: 7 years ago Posts: 55 |

Quote

the_digital_dentist

I don't see any lines in the Z axis of prints made on my CubeX. I don't think it's the screw.

It happens in every print... I've sliced with three different slicers (Cura, Slic3r, S3D) with the same results... different resolutions... It has to be something physical with the printer... I also considered "heat banding" from the bed, but that kitten was printed without heat.

Edited 1 time(s). Last edit at 03/10/2017 09:15AM by Dancook.

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 10:40AM |

Registered: 11 years ago Posts: 5,780 |

Try disconnecting the screw and manually move the bed up and down- maybe there's something binding.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 11:17AM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 11:24AM |

Registered: 7 years ago Posts: 47 |

Quote

Dancook

It happens in every print... I've sliced with three different slicers (Cura, Slic3r, S3D) with the same results... different resolutions... It has to be something physical with the printer... I also considered "heat banding" from the bed, but that kitten was printed without heat.

Did you check the rear Z rods where the bed glides up and down on, there could be a flat side on the back of the rod.

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 11:45AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Dancook

Quote

the_digital_dentist

I don't see any lines in the Z axis of prints made on my CubeX. I don't think it's the screw.

It happens in every print... I've sliced with three different slicers (Cura, Slic3r, S3D) with the same results... different resolutions... It has to be something physical with the printer... I also considered "heat banding" from the bed, but that kitten was printed without heat.

I can't see the picture because it requires login to whatever hosting service you posted to.

You previously said you had problems with the leveling or zeroing not being consistent. It sounds like you have some mechanical problem with the Z axis. Check the motor mount, check the shaft coupler screws, check the Z axis bearings.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 11:57AM |

Registered: 7 years ago Posts: 55 |

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 12:05PM |

Registered: 7 years ago Posts: 55 |

That happens with any print job, filament, multiple slicers, multiple temps, it's basically going to happen... so I'm thinking it's physical. My only other thought is maybe PIDs, since the hot end is the only other thing that's constant? But I'm thinking that's even a long shot. It's more of an under extrusion kind of like a missed step... I can pull prints apart some times. You can see the ear in the pic above looks more like a missed step. (It's not a missed step...)

|

Re: An alternative to buying a bad kit for $300-500 March 10, 2017 06:39PM |

Registered: 7 years ago Posts: 45 |

Quote

Dancook

That happens with any print job, filament, multiple slicers, multiple temps, it's basically going to happen... so I'm thinking it's physical. My only other thought is maybe PIDs, since the hot end is the only other thing that's constant? But I'm thinking that's even a long shot. It's more of an under extrusion kind of like a missed step... I can pull prints apart some times. You can see the ear in the pic above looks more like a missed step. (It's not a missed step...)

Strange, mines been spot on. Talking about the steps on the extruder only issue I had was mine were a little sensitive to the amp being pushed to it. I believe mine were way high and it would spin then stop, accompanied with a sound like it was locked up. I backed the amps down and found a sweet spot that seems to work. I know yours isn't doing the same tho.

I'll try to think a little when I get home. Y'all are typically way above my head on this stuff tho lol. I have to say I'm glad I built this printer for multiple reasons. It forced me to learn the mechanic and the coding, which I wanted to do.

|

Re: An alternative to buying a bad kit for $300-500 March 11, 2017 03:55PM |

Registered: 7 years ago Posts: 45 |

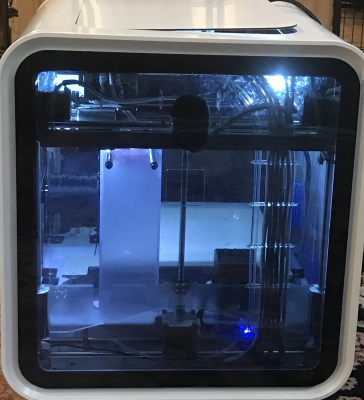

Here's a few from today in the cubepro housing. I really wish I could find a way to either make the little screen work or get another screen that fits there. Would be nice to get maybe a pause/play/stop, and or time remaining. Anything really.

For the most part I'll probably use the printer out of the housing unles I start using it for ABS. It's in the housing now because I had to bring it home from the fire station. I probably won't have time to mess with it for awhile at home so for the time being I'll leave it in the housing to protect it.

Edited 1 time(s). Last edit at 03/11/2017 03:57PM by advancedrescue.

For the most part I'll probably use the printer out of the housing unles I start using it for ABS. It's in the housing now because I had to bring it home from the fire station. I probably won't have time to mess with it for awhile at home so for the time being I'll leave it in the housing to protect it.

Edited 1 time(s). Last edit at 03/11/2017 03:57PM by advancedrescue.

|

Re: An alternative to buying a bad kit for $300-500 March 11, 2017 04:32PM |

Registered: 11 years ago Posts: 5,780 |

Unless you don't mind printing extra slow, it would be better to leave it in the housing. The housing really improves the structural rigidity.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 March 12, 2017 06:02AM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 March 13, 2017 08:24AM |

Registered: 7 years ago Posts: 55 |

Quote

advancedrescue

For the most part I'll probably use the printer out of the housing unles I start using it for ABS. It's in the housing now because I had to bring it home from the fire station. I probably won't have time to mess with it for awhile at home so for the time being I'll leave it in the housing to protect it.

I think that Pro housing looks really nice, and Digital Dentist is spot on with the rigidity... I can see my X Duo bouncing back & forth side to side without the housing attached.

I cleaned up my Z-Axis screw, bearings, rods, etc. over the weekend, and I'm still getting the lines. I think it's narrowed down to a possible stepper issue. I think I'll order another stepper and see if that fixes the issue.

|

Re: An alternative to buying a bad kit for $300-500 March 13, 2017 09:53PM |

Registered: 7 years ago Posts: 45 |

Sadly I think I'm done with the printer here for alittle while. I usually work on it while at the fire station but as of this past week had to get it out of the station due to someone being butt hurt over another issue and complained. Bad thing was I was literally working out one of my last code issued when I was informed of the complaint and I had to remove it. Also the printer wasn't even what the guy was upset about and complained, he did it to get us pissed. My chief didn't care, in fact thought it was cool. But when someone complains they always revert to completely removing the issue of the complaint, which means by driver and myself lose our hobby. The fire dept is like a high school. When I'm off from the station I don't have time or the place to work on it effectively. So it will probably sit in my garage, which is one reason I'm glad it's in the case.

I've printed a lot with it and it prints great, but need to figure out why the layer fans don't come on. Has something to do with Simplify3d. I can type in M106 P0 in the duet web interface and they come on as they should, just can't get them to respond from S3D. Also got to figure out the mirrored print.

I'm building a new house for myself in the near future and will have a shop with my extensive tools, workbench, TV and my computer. I'll have plenty of space to set it up in there. It's essentially an extra car bay that'll be attached to my garage, but walled off from the other vehicles, also heated and air conditioned. So I highly look forward to having this as a nice addition sitting next to all my other tools just waiting for use.

Next I want to build a CNC machine and possible a lathe to go with both.

Edited 1 time(s). Last edit at 03/13/2017 09:58PM by advancedrescue.

I've printed a lot with it and it prints great, but need to figure out why the layer fans don't come on. Has something to do with Simplify3d. I can type in M106 P0 in the duet web interface and they come on as they should, just can't get them to respond from S3D. Also got to figure out the mirrored print.

I'm building a new house for myself in the near future and will have a shop with my extensive tools, workbench, TV and my computer. I'll have plenty of space to set it up in there. It's essentially an extra car bay that'll be attached to my garage, but walled off from the other vehicles, also heated and air conditioned. So I highly look forward to having this as a nice addition sitting next to all my other tools just waiting for use.

Next I want to build a CNC machine and possible a lathe to go with both.

Edited 1 time(s). Last edit at 03/13/2017 09:58PM by advancedrescue.

|

Re: An alternative to buying a bad kit for $300-500 March 14, 2017 01:37PM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 March 14, 2017 07:27PM |

Registered: 8 years ago Posts: 105 |

Quote

advancedrescue

I've printed a lot with it and it prints great, but need to figure out why the layer fans don't come on. Has something to do with Simplify3d. I can type in M106 P0 in the duet web interface and they come on as they should, just can't get them to respond from S3D. Also got to figure out the mirrored print.

Have you checked what's in the gcode, you should be able to see what S3D is outputting, especially if you add a change at say layer 2.

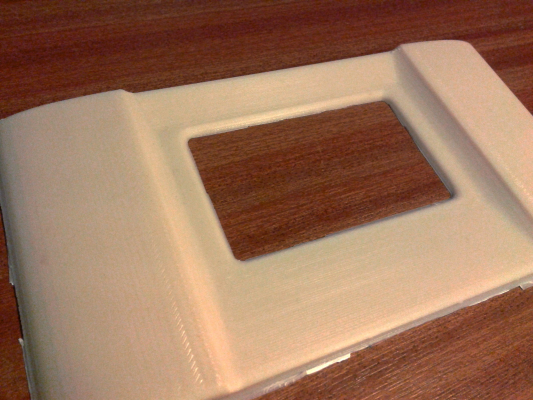

Realised I hadn't posted anything I had printed.

This is ASA but ABS prints as well, could not print these before as they always warped, the part is 210mm x 105mm

Edited 1 time(s). Last edit at 03/14/2017 07:27PM by Firefox3D.

|

Re: An alternative to buying a bad kit for $300-500 March 15, 2017 01:03AM |

Registered: 7 years ago Posts: 45 |

Quote

fg dude

sorry to heare that story, I hope you get along with the guy in the future and everyting gets ok again.

Yeah it's caused a huge issue in the dept as a whole. Guy broke the chain of command to do so, and it in turn screwed a lot of other people from being able to enjoy their hobbys. So even though I'm extremely pissed about the situation I believe it shows his true colors. Luckily the guys on another shift and I don't see him much, and I would really have to watch myself as I'm a Lieutenant.

Fox, the printer is still in the house for the time being so tomorrow I'll try and get the S3d g codes. I would like to get the last few small issues resolved, I fear I'll forget what I'm doing if the things put away for awhile. Plus if it's 100% complete I can leave it out of site and out of mind of the wife but still be able to use.

Preciate everyone's help once again. You guys have been great, and I've really learned a lot thru this process because of you all.

|

Re: An alternative to buying a bad kit for $300-500 March 15, 2017 07:50AM |

Registered: 8 years ago Posts: 105 |

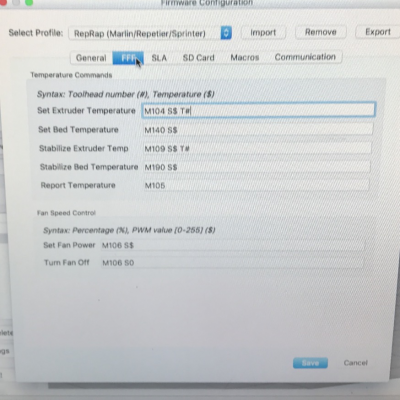

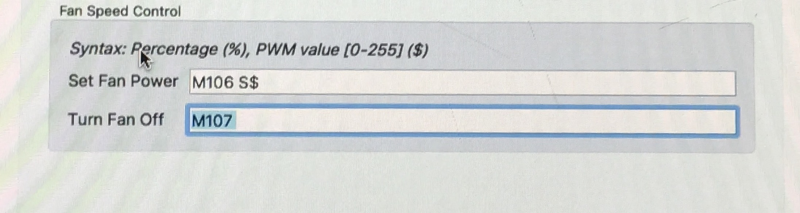

Think I have found the answer to your problem, in S3D go to Tools, Firmware configuration, then the FFF tab.

In the Fan speed control section you probably have M106 S$ in Set fan power, think you need to make it either M106 P0 S$ or M106 P1 S$ seems to be that P0 is generally the hot end fan and P1 cooling fan, but depends on hardware config on the board. If it's not a PWM controlled fan the S$ (power setting) is irrelevant as it's either on or off.

Edited 1 time(s). Last edit at 03/15/2017 07:55AM by Firefox3D.

In the Fan speed control section you probably have M106 S$ in Set fan power, think you need to make it either M106 P0 S$ or M106 P1 S$ seems to be that P0 is generally the hot end fan and P1 cooling fan, but depends on hardware config on the board. If it's not a PWM controlled fan the S$ (power setting) is irrelevant as it's either on or off.

Edited 1 time(s). Last edit at 03/15/2017 07:55AM by Firefox3D.

|

Re: An alternative to buying a bad kit for $300-500 March 15, 2017 05:10PM |

Registered: 10 years ago Posts: 14,672 |

If you send M106 without the P parameter, then the fan mapping defined in the M563 command F parameter for the current tool is used. If there is no F parameter in the M563 command that defines the current tool, or no tool is selected, then it uses fan 0. That's how it is supposed to work. Let me know if you think it is doing something else.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: An alternative to buying a bad kit for $300-500 March 19, 2017 03:50PM |

Registered: 7 years ago Posts: 45 |

Got to play a little with it some more as I'm limited on time. Tho I did make some progress on the layer fan.

Up infill the other day no matter what I did in S3D, including making changes to the FFF firmware configurations like you mentioned fox didn't do anything. I even checked the g code from all the prints before, and it never attempted to turn the fans(no M106 codes in the file). There's a bunch of older prints that I sliced with S3D and I'll admit I might have actually randomly checked ones that I didn't actually have the FFF altered, but I doubt:/.

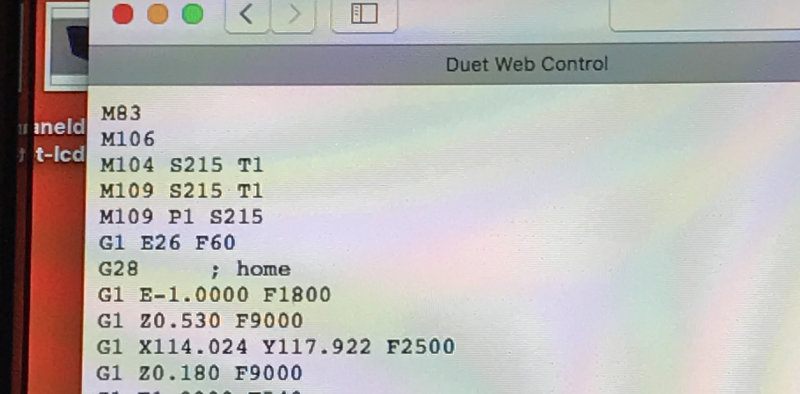

So now I made sure the FFF was set to M106 P0, although not sure what the S_ should be. I tried S0 and S255 for max. I then went into the duet config file and actually defined fan 0 as P0 via M563 codes. Now the print file code from S3D actually puts the M106 code in at the beginning of the second layer as it should, as a simple "M106", but not including P0.

Here exactly the current point I'm at, as I tend to ramble and this maybe help cut down on confusion.

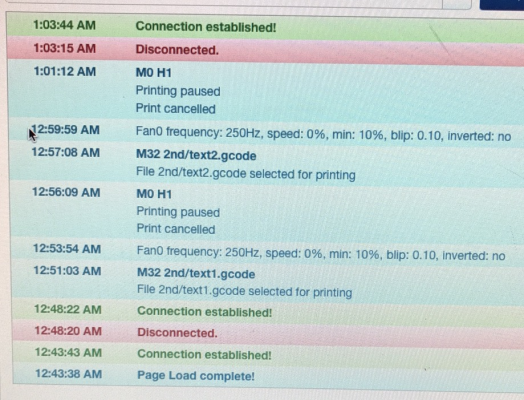

-With the FFF defined as M106 P0 S0 or S255, and duet config fan 0 defined via M563 the code appears in the print file g code as "M106" at the appropriate start point I set. The fan still doesn't turn on. I monitored the duet g code console to see the commands in real time and it did send the M106 command like the print file intended.

I believe the problem is I need to define more in the duet config or the FFF. If it's the duet config perhaps I need to define the perimeters, or if it's the S3D FFF need to figure out exactly what to do with the S value. The FFF has S$ and S% in the description. So perhaps I should put it as S$ or S% but with it defined as M106 PO S$ or S%. If I set up M106 P0 in the duet config file I can manually enter in the M107 P0 and it will shut off and M106 P0 will turn it back on. I took this out of the config file though because it being in the config file turned them on when the machine powers up of course. So right now the only M106 codes I have in the config file is for the 2 E3D cooling fans and the work like intended by coming on once the HE get over 45.

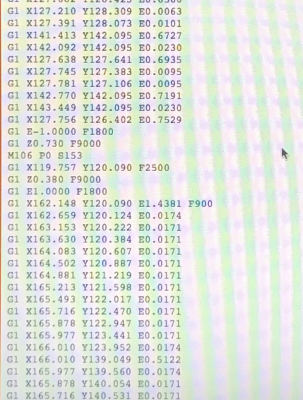

Here's a picture of the S3D firmware configuration FFF, how it's set up before I made the changes, but shows the description I'm talking about. Also a picture of the duet live gcode console showing it trying to execute the M106 command. This gives a lot of insight as it shows the values. In the pictures it shows numerous starts and cancels from my attempts.

Thanks guys again for putting up with me, hopefully one day I might be able to return the favor. Sorry for not posting the codes, I'm currently not on the computer, if really needed I'll do that ASAP.

Up infill the other day no matter what I did in S3D, including making changes to the FFF firmware configurations like you mentioned fox didn't do anything. I even checked the g code from all the prints before, and it never attempted to turn the fans(no M106 codes in the file). There's a bunch of older prints that I sliced with S3D and I'll admit I might have actually randomly checked ones that I didn't actually have the FFF altered, but I doubt:/.

So now I made sure the FFF was set to M106 P0, although not sure what the S_ should be. I tried S0 and S255 for max. I then went into the duet config file and actually defined fan 0 as P0 via M563 codes. Now the print file code from S3D actually puts the M106 code in at the beginning of the second layer as it should, as a simple "M106", but not including P0.

Here exactly the current point I'm at, as I tend to ramble and this maybe help cut down on confusion.

-With the FFF defined as M106 P0 S0 or S255, and duet config fan 0 defined via M563 the code appears in the print file g code as "M106" at the appropriate start point I set. The fan still doesn't turn on. I monitored the duet g code console to see the commands in real time and it did send the M106 command like the print file intended.

I believe the problem is I need to define more in the duet config or the FFF. If it's the duet config perhaps I need to define the perimeters, or if it's the S3D FFF need to figure out exactly what to do with the S value. The FFF has S$ and S% in the description. So perhaps I should put it as S$ or S% but with it defined as M106 PO S$ or S%. If I set up M106 P0 in the duet config file I can manually enter in the M107 P0 and it will shut off and M106 P0 will turn it back on. I took this out of the config file though because it being in the config file turned them on when the machine powers up of course. So right now the only M106 codes I have in the config file is for the 2 E3D cooling fans and the work like intended by coming on once the HE get over 45.

Here's a picture of the S3D firmware configuration FFF, how it's set up before I made the changes, but shows the description I'm talking about. Also a picture of the duet live gcode console showing it trying to execute the M106 command. This gives a lot of insight as it shows the values. In the pictures it shows numerous starts and cancels from my attempts.

Thanks guys again for putting up with me, hopefully one day I might be able to return the favor. Sorry for not posting the codes, I'm currently not on the computer, if really needed I'll do that ASAP.

|

Re: An alternative to buying a bad kit for $300-500 March 19, 2017 06:11PM |

Registered: 10 years ago Posts: 14,672 |

The "M106 S$" config you have in S3D should work. You don't need the P0 parameter because that is the default. S3D should output M106 S255 to turn the fan full on. There is no way that S3D should output M106 with no parameters at all, there should always be an S parameter included in the command.

Edited 1 time(s). Last edit at 03/19/2017 06:11PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 03/19/2017 06:11PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: An alternative to buying a bad kit for $300-500 March 20, 2017 07:30AM |

Registered: 7 years ago Posts: 45 |

Quote

dc42

The "M106 S$" config you have in S3D should work. You don't need the P0 parameter because that is the default. S3D should output M106 S255 to turn the fan full on. There is no way that S3D should output M106 with no parameters at all, there should always be an S parameter included in the command.

Check, I'll give it a go.

|

Re: An alternative to buying a bad kit for $300-500 March 20, 2017 03:38PM |

Registered: 7 years ago Posts: 1 |

|

Re: An alternative to buying a bad kit for $300-500 March 21, 2017 08:58AM |

Registered: 7 years ago Posts: 45 |

|

Re: An alternative to buying a bad kit for $300-500 March 24, 2017 09:28PM |

Registered: 7 years ago Posts: 45 |

layer fan success!!

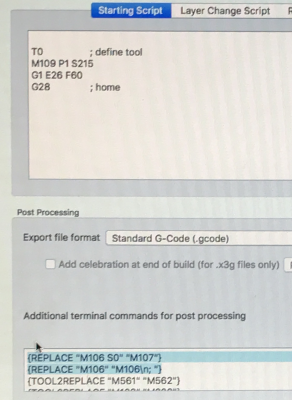

Nothing I did in the FFF firmware still helped the fan situation, at least on its own it didn't. From googling I found where someone mentioned something about the M106 codes in the S3D scripts. To get to where I'm talking about you go to -edit process setting/scripts/starting scripts, then in the bottom half of this page you'll see post processing section. S3D has some "additional terminal commands" entered here already.

Mine had:

{REPLACE "M106 S0" "M107"}

{REPLACE "M106" "M106\n;"}

And then more additional commands in not sure if I actually need.

Solution:

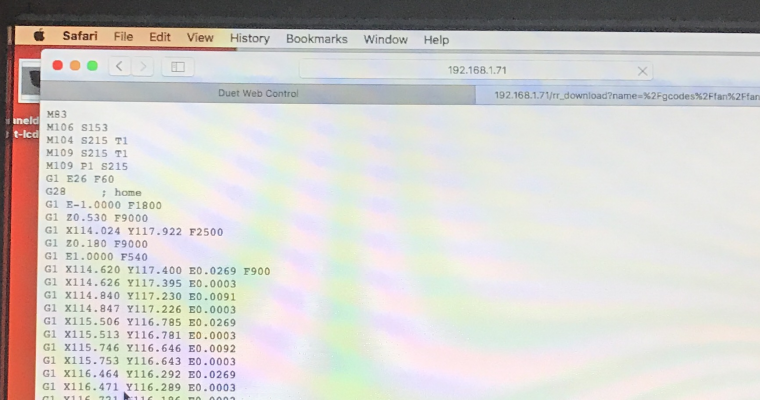

I simply removed these codes, also set the FFF to M106 P0 S$ and now everything works as it should. I can set the the speed and print layer in which I want the layer cooling fan to turn on.

When I kept the FFF set to M106 S$ without the P0 it would for some reason shut my E3D fans off when the print would hit the M106 S153(the speed set). So adding the P0 to the FFF fixed that and is also visible in the g code pictures.

Picture of the FFF the way it was preset

The preset S3D commands under the scripts/start scripts. These are the codes I removed later.

The print file gcode. The simple M106 by itself did nothing, also lacks the fan speed defined from S3D cooling options I'd set

Here's the print file gcode without the addition commands in the start script, but with the FFF set to the default M106 S$. This would actually turn my E3D fans off mentioned earlier.

Finally the end result where it's working as it should. M106 P0 S$ entered in the FFF settings, with the additional commands involving the M106 removed completely from the scripts in the process settings.

Nothing I did in the FFF firmware still helped the fan situation, at least on its own it didn't. From googling I found where someone mentioned something about the M106 codes in the S3D scripts. To get to where I'm talking about you go to -edit process setting/scripts/starting scripts, then in the bottom half of this page you'll see post processing section. S3D has some "additional terminal commands" entered here already.

Mine had:

{REPLACE "M106 S0" "M107"}

{REPLACE "M106" "M106\n;"}

And then more additional commands in not sure if I actually need.

Solution:

I simply removed these codes, also set the FFF to M106 P0 S$ and now everything works as it should. I can set the the speed and print layer in which I want the layer cooling fan to turn on.

When I kept the FFF set to M106 S$ without the P0 it would for some reason shut my E3D fans off when the print would hit the M106 S153(the speed set). So adding the P0 to the FFF fixed that and is also visible in the g code pictures.

Picture of the FFF the way it was preset

The preset S3D commands under the scripts/start scripts. These are the codes I removed later.

The print file gcode. The simple M106 by itself did nothing, also lacks the fan speed defined from S3D cooling options I'd set

Here's the print file gcode without the addition commands in the start script, but with the FFF set to the default M106 S$. This would actually turn my E3D fans off mentioned earlier.

Finally the end result where it's working as it should. M106 P0 S$ entered in the FFF settings, with the additional commands involving the M106 removed completely from the scripts in the process settings.

|

Re: An alternative to buying a bad kit for $300-500 April 02, 2017 03:43AM |

Registered: 7 years ago Posts: 3 |

Hi Guys

New to this printer. Just bought a Duo and have read this long thread multiple times. To be honest I am none the wiser as to which way to go. I would have thought by now that maybe someone would have redesigned (printed) a whole new print head assembly. To me it seems that may be the easiest thing to do but of course I may be wrong. That with a couple or 3 e3d v6 on a custom print head assembly would be ideal but correct me if I am wrong. Also I'd want to move the print bed itself into the center so all 3 heads had the same coverage and add a heater.

Has anyone documented any of the connectors and wiring harnesses anywhere. I guess I can trace all the wring back to the controller but clearly it's been done before many times.

I feel there will be more people finding considering you can pick up this printer for next to nothing.

Anyway hi and look forward to giving this a go.

Kman

New to this printer. Just bought a Duo and have read this long thread multiple times. To be honest I am none the wiser as to which way to go. I would have thought by now that maybe someone would have redesigned (printed) a whole new print head assembly. To me it seems that may be the easiest thing to do but of course I may be wrong. That with a couple or 3 e3d v6 on a custom print head assembly would be ideal but correct me if I am wrong. Also I'd want to move the print bed itself into the center so all 3 heads had the same coverage and add a heater.

Has anyone documented any of the connectors and wiring harnesses anywhere. I guess I can trace all the wring back to the controller but clearly it's been done before many times.

I feel there will be more people finding considering you can pick up this printer for next to nothing.

Anyway hi and look forward to giving this a go.

Kman

|

Re: An alternative to buying a bad kit for $300-500 April 02, 2017 04:55AM |

Registered: 7 years ago Posts: 47 |

Quote

KmanOz

Hi Guys

New to this printer. Just bought a Duo and have read this long thread multiple times. To be honest I am none the wiser as to which way to go. I would have thought by now that maybe someone would have redesigned (printed) a whole new print head assembly. To me it seems that may be the easiest thing to do but of course I may be wrong. That with a couple or 3 e3d v6 on a custom print head assembly would be ideal but correct me if I am wrong. Also I'd want to move the print bed itself into the center so all 3 heads had the same coverage and add a heater.

Has anyone documented any of the connectors and wiring harnesses anywhere. I guess I can trace all the wring back to the controller but clearly it's been done before many times.

I feel there will be more people finding considering you can pick up this printer for next to nothing.

Anyway hi and look forward to giving this a go.

Kman

Hi Kman, welcome.

Don't understand, I have done the conversion, I did find anything needed to do so here and what I did not find I ask for, and help was not far away, so if you have questions allong you conversion, just ask here.

Just go step by step and you be fine.

Cheers.

|

Re: An alternative to buying a bad kit for $300-500 April 02, 2017 11:11AM |

Registered: 7 years ago Posts: 55 |

Quote

KmanOz

Has anyone documented any of the connectors and wiring harnesses anywhere. I guess I can trace all the wring back to the controller but clearly it's been done before many

Kman

Kman,

I would suggest getting a new controller... we've documented several kinds in this forum... Smoothieboard, Duet, Replicape, etc... I'd certainly go with a 32 bit option.

Dan

Edited 1 time(s). Last edit at 04/02/2017 11:12AM by Dancook.

|

Re: An alternative to buying a bad kit for $300-500 April 04, 2017 07:47AM |

Registered: 7 years ago Posts: 3 |

Quote

Dancook

Quote

KmanOz

Has anyone documented any of the connectors and wiring harnesses anywhere. I guess I can trace all the wring back to the controller but clearly it's been done before many

Kman

Kman,

I would suggest getting a new controller... we've documented several kinds in this forum... Smoothieboard, Duet, Replicape, etc... I'd certainly go with a 32 bit option.

Dan

That is number 1 on the list. I want a DuetWifi and 5" touch screen. What I also want to do is move the position of the print bed and centre it in the printer. To do so needs a re-design of the plate holding the bed but shouldn't be too hard considering the Z arm holding the bed is actually built to centre. I want a heated bed as well so a silicon heater is on the cards. A re-design of the print carriage with 2 (or possibly 3) e3dv6 and a good power supply. I also want to create some removable plexiglass sides and front door and mod the top so it traps heat. Some form of extraction for ABS as well. I think that's it. I have a heavily modified Anet A8 at the moment that is producing stellar prints with PLA but that's where I want to leave it. Want this printer for larger prints and different material other than PLA.

Anyway thanks again.

Kman

Edited 3 time(s). Last edit at 04/04/2017 07:49AM by KmanOz.

|

Re: An alternative to buying a bad kit for $300-500 April 04, 2017 08:06AM |

Registered: 11 years ago Posts: 5,780 |

The bed is shifted to one side to make room for 2 filament spools on one side of the machine (and one spool on the other side). It should be pretty easy to move the bed plate over on the existing platform, but if you're going to heat it you'll lose some Z volume because you'll have to stand the bed plate up off the support plate.

The extruders that come with the machine are not especially good- they seem to have a large heated volume that oozes filament constantly. I have almost given up on them and will be replacing them at some point soon. The way the extruder mount is designed, with the hot end located between the massive X axis bearings, makes it very hard to see what's going on at the extruder nozzle(s). I find that very frustrating.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The extruders that come with the machine are not especially good- they seem to have a large heated volume that oozes filament constantly. I have almost given up on them and will be replacing them at some point soon. The way the extruder mount is designed, with the hot end located between the massive X axis bearings, makes it very hard to see what's going on at the extruder nozzle(s). I find that very frustrating.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.