An alternative to buying a bad kit for $300-500

Posted by the_digital_dentist

|

Re: An alternative to buying a bad kit for $300-500 April 04, 2017 08:21AM |

Registered: 7 years ago Posts: 3 |

Quote

the_digital_dentist

The bed is shifted to one side to make room for 2 filament spools on one side of the machine (and one spool on the other side). It should be pretty easy to move the bed plate over on the existing platform, but if you're going to heat it you'll lose some Z volume because you'll have to stand the bed plate up off the support plate.

The extruders that come with the machine are not especially good- they seem to have a large heated volume that oozes filament constantly. I have almost given up on them and will be replacing them at some point soon. The way the extruder mount is designed, with the hot end located between the massive X axis bearings, makes it very hard to see what's going on at the extruder nozzle(s). I find that very frustrating.

Yes I plan on taking the spools out of there. I figured that's why they did it. Personally I think the filament path and length was a little crazy, but that's just me. I think the bearnings need to stay there but a whole redsign of the head is on the cards. I haven;t started yet but will very soon and really get my head around it.

|

Re: An alternative to buying a bad kit for $300-500 April 07, 2017 08:07PM |

Registered: 8 years ago Posts: 6 |

|

Re: An alternative to buying a bad kit for $300-500 April 07, 2017 08:07PM |

Registered: 8 years ago Posts: 6 |

|

Re: An alternative to buying a bad kit for $300-500 April 08, 2017 06:57AM |

Registered: 7 years ago Posts: 47 |

Quote

jmar896

Would anyone be kind enough to share their firmware for their CubeX or CubePro? I have finally completed my build of my CubePro, but have been struggling tuning in things like the jerk. I would really appreciate it.

No problem, its for Marlin, hope you can use it.

Cheers.

|

Re: An alternative to buying a bad kit for $300-500 April 22, 2017 11:26PM |

Registered: 6 years ago Posts: 8 |

Hi to all I am new to this forum.

I am in the process of converting my CubePro Duo with a MKS Gen 1.4 control board, using the original power supply, hotends,etc... the 2-Y axis steppers motor are run in parallel using a single DRV 8825 stepper drivers. I am having issues with Y-axis miss steps on my prints. The Refer voltage on all the stepper drives are set a .8 volts, I am considering increasing the voltage on the Y- stepper driver to 1.2 volts. Any guidance with this problem would be welcome.

Cheers

Hisforhack

I am in the process of converting my CubePro Duo with a MKS Gen 1.4 control board, using the original power supply, hotends,etc... the 2-Y axis steppers motor are run in parallel using a single DRV 8825 stepper drivers. I am having issues with Y-axis miss steps on my prints. The Refer voltage on all the stepper drives are set a .8 volts, I am considering increasing the voltage on the Y- stepper driver to 1.2 volts. Any guidance with this problem would be welcome.

Cheers

Hisforhack

|

Re: An alternative to buying a bad kit for $300-500 April 23, 2017 05:00AM |

Registered: 7 years ago Posts: 47 |

Quote

hisforhack

Hi to all I am new to this forum.

I am in the process of converting my CubePro Duo with a MKS Gen 1.4 control board, using the original power supply, hotends,etc... the 2-Y axis steppers motor are run in parallel using a single DRV 8825 stepper drivers. I am having issues with Y-axis miss steps on my prints. The Refer voltage on all the stepper drives are set a .8 volts, I am considering increasing the voltage on the Y- stepper driver to 1.2 volts. Any guidance with this problem would be welcome.

Cheers

Hisforhack

Hi, maybe its not a bad idea to bump up the voltage or replace the stepper driver to begin with.

I had the same with my Z drive and it was a faulty stepper.

Good luck.

Cheers.

w

|

Re: An alternative to buying a bad kit for $300-500 April 24, 2017 07:13AM |

Registered: 11 years ago Posts: 5,780 |

DRV8825s are known to cause problems. See: [www.engineerination.com]#!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 April 24, 2017 07:14AM |

Registered: 9 years ago Posts: 59 |

Easy to fix tho.

|

Re: An alternative to buying a bad kit for $300-500 April 25, 2017 11:41PM |

Registered: 7 years ago Posts: 363 |

|

Re: An alternative to buying a bad kit for $300-500 April 26, 2017 07:09AM |

Registered: 11 years ago Posts: 5,780 |

This sounds an awful lot like using SketchUp to design parts for 3D printing. "but it's easy to repair the STL files"...

Is there some advantage that DRV8825 drivers confer that's worth the trouble of fixing them, when there are so many others out there that don't require repair before use?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Is there some advantage that DRV8825 drivers confer that's worth the trouble of fixing them, when there are so many others out there that don't require repair before use?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 April 26, 2017 09:06AM |

Registered: 9 years ago Posts: 59 |

|

Re: An alternative to buying a bad kit for $300-500 May 12, 2017 10:43PM |

Registered: 6 years ago Posts: 8 |

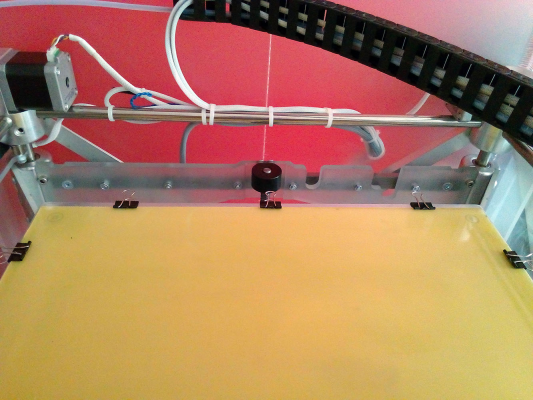

A quick update on the problem of the Y axis missed steps and shifting.(photo)

My Pi Cube is Cubepro Duo Conversion with MKS GEN 1.4 MB, 5 DVR8825/A4988, Smart LCD Screen, MKS 28 LCD Touch screen. (Photo)

I increased the ref V to the DVR8825 with no improvement.

I Lubricated all the bearings and rods, I released some of tension on the Y axis belt. The Y axis appeared to move smoother but no improvement in the miss step on the Y axis.

I replaced the 5 DVR8825 with 5 A4988 stepper motor drivers. There was not improvement of the Y axis shifting (Photo)

Final Solution

I wired the two Y axis stepper motors separately and used the Y axis A4925 stepper driver and 01 Extruder A4925 stepper driver to drive the each Y axis motors.

This resulted in my first 20mm cube .02mm layer, final measurements 20.65mm(X) x 20.36mm(Y) x 20.66(Z) (photo)

Now the problem is that I can only use one extruder. After some more testing I will be looking into upgrading to a "Rumba Board" so can set up the second extruded.

Thanks for all the suggest

My Pi Cube is Cubepro Duo Conversion with MKS GEN 1.4 MB, 5 DVR8825/A4988, Smart LCD Screen, MKS 28 LCD Touch screen. (Photo)

I increased the ref V to the DVR8825 with no improvement.

I Lubricated all the bearings and rods, I released some of tension on the Y axis belt. The Y axis appeared to move smoother but no improvement in the miss step on the Y axis.

I replaced the 5 DVR8825 with 5 A4988 stepper motor drivers. There was not improvement of the Y axis shifting (Photo)

Final Solution

I wired the two Y axis stepper motors separately and used the Y axis A4925 stepper driver and 01 Extruder A4925 stepper driver to drive the each Y axis motors.

This resulted in my first 20mm cube .02mm layer, final measurements 20.65mm(X) x 20.36mm(Y) x 20.66(Z) (photo)

Now the problem is that I can only use one extruder. After some more testing I will be looking into upgrading to a "Rumba Board" so can set up the second extruded.

Thanks for all the suggest

|

Re: An alternative to buying a bad kit for $300-500 May 13, 2017 05:39AM |

Registered: 7 years ago Posts: 47 |

Quote

hisforhack

A quick update on the problem of the Y axis missed steps and shifting.(photo)

Now the problem is that I can only use one extruder. After some more testing I will be looking into upgrading to a "Rumba Board" so can set up the second extruded.

Thanks for all the suggest

Glad you find the solution and share it here for others.

Have fun on the upgrade in the future.

Cheers.

|

Re: An alternative to buying a bad kit for $300-500 May 13, 2017 11:56AM |

Registered: 9 years ago Posts: 59 |

|

Re: An alternative to buying a bad kit for $300-500 May 13, 2017 10:23PM |

Registered: 6 years ago Posts: 8 |

|

Re: An alternative to buying a bad kit for $300-500 May 13, 2017 11:57PM |

Registered: 6 years ago Posts: 8 |

Attached are the stl files for the two internal spool holders and filament guide

The right spool holder is made up of two printed parts. two bearings, 2 washers, 3 nuts, threaded rod. (I printed 2 plastic bearing.)

The left spool holder is fixed without bearings. Both spool holders bolt to internal frame with existing bolts.

The Filament Lead (guide) bolt into holes left after removing the 3 cartridge holders.

The second extruder feed tube is moved and lined up with the third extruder slot. This allows the left spool holder, filament leads, filament feed tube, to line up. It is a bit of a stretch move the tubing but it can be held in place with wire ties

All parts were printed on the original CubePro in ABS. before gutted the printer.

Cheers

The right spool holder is made up of two printed parts. two bearings, 2 washers, 3 nuts, threaded rod. (I printed 2 plastic bearing.)

The left spool holder is fixed without bearings. Both spool holders bolt to internal frame with existing bolts.

The Filament Lead (guide) bolt into holes left after removing the 3 cartridge holders.

The second extruder feed tube is moved and lined up with the third extruder slot. This allows the left spool holder, filament leads, filament feed tube, to line up. It is a bit of a stretch move the tubing but it can be held in place with wire ties

All parts were printed on the original CubePro in ABS. before gutted the printer.

Cheers

|

Re: An alternative to buying a bad kit for $300-500 May 14, 2017 04:01AM |

Registered: 9 years ago Posts: 59 |

|

Re: An alternative to buying a bad kit for $300-500 May 16, 2017 10:44AM |

Registered: 6 years ago Posts: 8 |

Hi to all

I would to thank this forum and all the other forums that have been a wealth information on the conversion of my CubePro Duo.

I have finally got my Cubepro Duo printing reasonably well, Everything is original except the Control board and LDC screen (MKS gen 1.4 & Smart LCD screen).

I design two internal spool holders.

I replaced the Chamber Thermistor with a 100 k Thermistor,

I replaced the defected LED lighting with two 12v units connected in series for 24V

I am printing ABS @ 230c, speed 40mm per sec, the Chamber temperature set @ 50c (CubePro chamber is heated with a 110v heater/ 24v fan controlled by relay connected to the MKS Gen 1.4 Heated bed terminals. The Heat Bed PID is off. set to bang- bang on to control the relay.)

I have good bed adhesion using the "Cube glue"

Commends, Questions and Suggests Welcome

Cheers

These are the settings I am using on my "Pi Cube" (CubePro Duo convert)

// MOVEMENT SETTINGS

// @section motion

//

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {86,86,1090,83}

#define DEFAULT_MAX_FEEDRATE {300, 300, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {3000,3000,100,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 1500 // X, Y, Z and E acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 3000 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 10.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

I would to thank this forum and all the other forums that have been a wealth information on the conversion of my CubePro Duo.

I have finally got my Cubepro Duo printing reasonably well, Everything is original except the Control board and LDC screen (MKS gen 1.4 & Smart LCD screen).

I design two internal spool holders.

I replaced the Chamber Thermistor with a 100 k Thermistor,

I replaced the defected LED lighting with two 12v units connected in series for 24V

I am printing ABS @ 230c, speed 40mm per sec, the Chamber temperature set @ 50c (CubePro chamber is heated with a 110v heater/ 24v fan controlled by relay connected to the MKS Gen 1.4 Heated bed terminals. The Heat Bed PID is off. set to bang- bang on to control the relay.)

I have good bed adhesion using the "Cube glue"

Commends, Questions and Suggests Welcome

Cheers

These are the settings I am using on my "Pi Cube" (CubePro Duo convert)

// MOVEMENT SETTINGS

// @section motion

//

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {86,86,1090,83}

#define DEFAULT_MAX_FEEDRATE {300, 300, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {3000,3000,100,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 1500 // X, Y, Z and E acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 3000 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 10.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

|

Re: An alternative to buying a bad kit for $300-500 May 28, 2017 12:27PM |

Registered: 8 years ago Posts: 105 |

Was going to make a whole new Z bed support part as the digital dentist did early on, then thought it might be worth trying a cheapskate method first.

Picked up a piece of 15 x 10mm steel off-cut, cut the right length with slightly angled ends to fit inside the rounded aluminium parts then drilled through and bolted it on. It has removed a fair amount of the slop from the bed, flexes a tiny amount in the Y axis when you push on the black plastic Z-nut, but way better.

To hopefully completely stop the bed play, and support the increased weight of the new bed, going to add front outrigger arms (40mm steel angle) to these bearings on the front 12mm uprights

Update - done some test printing and the z-variation/stepping have gone, maybe the front bearings will be overkill.

Edited 1 time(s). Last edit at 05/28/2017 09:43PM by Firefox3D.

Picked up a piece of 15 x 10mm steel off-cut, cut the right length with slightly angled ends to fit inside the rounded aluminium parts then drilled through and bolted it on. It has removed a fair amount of the slop from the bed, flexes a tiny amount in the Y axis when you push on the black plastic Z-nut, but way better.

To hopefully completely stop the bed play, and support the increased weight of the new bed, going to add front outrigger arms (40mm steel angle) to these bearings on the front 12mm uprights

Update - done some test printing and the z-variation/stepping have gone, maybe the front bearings will be overkill.

Edited 1 time(s). Last edit at 05/28/2017 09:43PM by Firefox3D.

|

Re: An alternative to buying a bad kit for $300-500 May 29, 2017 11:50AM |

Registered: 6 years ago Posts: 8 |

Another Update.

I re-installed the DRV8825 stepper drivers, set at 32 micro steps. I started to have problems with X-Axis shifting now! When I reduced the speed of the to 30 mm/sec the problem when away, at or above 50 mm/sec the X-Axis shifting appears. I am spoiled with the speed of my Delta 100 mm/sec plus all day long.

Future plans

I have order a Diode board for the X-Axis stepper driver, also order a external stepper driver board and DRV8825 to connect to the Jc pins of the Y-Axis controller (like this Photo). Hopefully these modification will solve the Axis shifting problems and will allow me to re-connect E1 to my second extruder so I can start printing using "support material".

I am open to all or any comments or advice.

Cheers

Derek

I re-installed the DRV8825 stepper drivers, set at 32 micro steps. I started to have problems with X-Axis shifting now! When I reduced the speed of the to 30 mm/sec the problem when away, at or above 50 mm/sec the X-Axis shifting appears. I am spoiled with the speed of my Delta 100 mm/sec plus all day long.

Future plans

I have order a Diode board for the X-Axis stepper driver, also order a external stepper driver board and DRV8825 to connect to the Jc pins of the Y-Axis controller (like this Photo). Hopefully these modification will solve the Axis shifting problems and will allow me to re-connect E1 to my second extruder so I can start printing using "support material".

I am open to all or any comments or advice.

Cheers

Derek

|

Re: An alternative to buying a bad kit for $300-500 May 29, 2017 12:21PM |

Registered: 8 years ago Posts: 105 |

I think the max printing speed unless you reduce the moving mass considerably is around 40mm/s if you want good quality foolproof prints.

Having said that my movement speed is at 100mm/s and it doesn't skip.

I was thinking of reducing the moving mass by shaving the aluminium pieces down, not sure if that would make a massive amount of difference. Or convert the drive to a core x-y system which helps as one motor pushes and the other pulls so there is a more consistent tension on the belts, don't think it would be that hard to do

Edited 2 time(s). Last edit at 05/29/2017 01:46PM by Firefox3D.

Having said that my movement speed is at 100mm/s and it doesn't skip.

I was thinking of reducing the moving mass by shaving the aluminium pieces down, not sure if that would make a massive amount of difference. Or convert the drive to a core x-y system which helps as one motor pushes and the other pulls so there is a more consistent tension on the belts, don't think it would be that hard to do

Edited 2 time(s). Last edit at 05/29/2017 01:46PM by Firefox3D.

|

Re: An alternative to buying a bad kit for $300-500 May 30, 2017 12:54PM |

Registered: 6 years ago Posts: 8 |

Last night My Pi Cubepro was printing ABS very well at 35 mm/sec, 230c, heated build chamber at 55c. "NO heated bed". Problem now is, it prints the part as a mirror image in the X-Axis, I need to change firmware and stepper motor cable tomorrow. I have CubeX frame and slides for parts, how hard is it to change to a Core X-Y? have you done it?

Cheers

Derek

Cheers

Derek

|

Re: An alternative to buying a bad kit for $300-500 May 30, 2017 03:07PM |

Registered: 11 years ago Posts: 5,780 |

Your mirror image problem can be solved without converting to coreXY.

Mirroring is usually caused by assigning the home position to the wrong location. CAD and slicers use right hand rule coordinate space definition. That means your printer's 0,0,0 coordinate has to be in the left front or right rear corner. You can put the XY limit switches anywhere that's convenient, but the firmware has to know the coordinates at the switches. The CubeX Duo comes with the switches at the left side of the X axis, therefore your firmware should be set to home X to minimum (0 mm), and the back end of the Y axis, therefore the firmware should be set to "home to max" on the Y axis (about 300 mm- I don't recall the exact value). In the slicer the 0,0 coordinate is the front left or right rear corner of the extruder addressable space on the bed. If the printer's 0,0 coordinate is away from the bed, you'll use negative offsets in the slicer to map the bed properly. The physical size of the bed doesn't matter- when you tell the slicer how big the bed is, the numbers you enter are the extruder addressable dimensions. If you enter this information accurately, the slicer will drop the prints on the center of the addressable bed space and there won't be any mirroring of prints.

I'm not sure what it would take to convert to coreXY, but I'm pretty sure the cover isn't going to fit after you do. The frame gets a lot of its rigidity from the cover, so you'll be giving up some of that rigidity. The cantilevered bed tends to bounce if you try to print fast, even with the cover. I imagine it would be worse without it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Mirroring is usually caused by assigning the home position to the wrong location. CAD and slicers use right hand rule coordinate space definition. That means your printer's 0,0,0 coordinate has to be in the left front or right rear corner. You can put the XY limit switches anywhere that's convenient, but the firmware has to know the coordinates at the switches. The CubeX Duo comes with the switches at the left side of the X axis, therefore your firmware should be set to home X to minimum (0 mm), and the back end of the Y axis, therefore the firmware should be set to "home to max" on the Y axis (about 300 mm- I don't recall the exact value). In the slicer the 0,0 coordinate is the front left or right rear corner of the extruder addressable space on the bed. If the printer's 0,0 coordinate is away from the bed, you'll use negative offsets in the slicer to map the bed properly. The physical size of the bed doesn't matter- when you tell the slicer how big the bed is, the numbers you enter are the extruder addressable dimensions. If you enter this information accurately, the slicer will drop the prints on the center of the addressable bed space and there won't be any mirroring of prints.

I'm not sure what it would take to convert to coreXY, but I'm pretty sure the cover isn't going to fit after you do. The frame gets a lot of its rigidity from the cover, so you'll be giving up some of that rigidity. The cantilevered bed tends to bounce if you try to print fast, even with the cover. I imagine it would be worse without it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2017 06:37PM |

Registered: 7 years ago Posts: 45 |

Quote

hisforhack

Last night My Pi Cubepro was printing ABS very well at 35 mm/sec, 230c, heated build chamber at 55c. "NO heated bed". Problem now is, it prints the part as a mirror image in the X-Axis, I need to change firmware and stepper motor cable tomorrow. I have CubeX frame and slides for parts, how hard is it to change to a Core X-Y? have you done it?

Cheers

Derek

I had the same problem. My cube homed to the back left hand corner as that's where my end stops are. So I had to add gcode to my home all config file so that after it homes it moves forward the length of the print bed, then sets that point as 0. Might of had to make the change in S3D also as it has a setting to flip the axis, but I forget now.

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2017 06:40PM |

Registered: 7 years ago Posts: 45 |

Has anyone swapped out their stock glass build plate? Mine cracked cause inflammation it to not be completely level. I'll be putting a PEI sheet on top of it, thinking I could go with something other than glass but not be too heavy.

If anyone has can you provide a link? The CubexUpgrade's page appears to be down, thought they might have one.

If anyone has can you provide a link? The CubexUpgrade's page appears to be down, thought they might have one.

|

Re: An alternative to buying a bad kit for $300-500 August 27, 2017 11:57PM |

Registered: 8 years ago Posts: 5 |

|

Re: An alternative to buying a bad kit for $300-500 August 28, 2017 04:06AM |

Registered: 10 years ago Posts: 14,672 |

Config file for which firmware?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: An alternative to buying a bad kit for $300-500 February 16, 2018 04:12PM |

Registered: 6 years ago Posts: 2 |

Hey Everyone,

I'm brand new to this forum and honestly joined specifically for this topic. I just spent the last couple of days (like many before me) reading through this thread a couple of times since I just acquired a Cubepro Duo my company was getting rid of and I want to convert it to an open source machine. There is an amazing amount of information in this thread an I want to thank everybody for contributing! I am new to 3D printing besides running the Cubepro Duo while my company was still using it (with limited success) so everything here has been extremely helpful! I just wanted to refresh the thread since its gone stale for a while and see if people are still having good success with their converted machines. I'm still in the research phase of my project so I'm just trying to get as much info as I can before I strip down the machine and commit to anything.

A little background for myself, I am a mechanical engineer so I'm comfortable on that side of the machine but have limited experience with the electrical/programming side of it. That's one of the (many) reasons I want to strip this down and convert it; to get some exposure to the electrical side of things. I'm currently leaning toward the Duet Wifi board and swapping the extruder & hotend out for ones from E3D since it seams like others have had a good amount of success with those products; but like I said, i am new to this and am still in the research phase.

Thanks again everyone!

I'm brand new to this forum and honestly joined specifically for this topic. I just spent the last couple of days (like many before me) reading through this thread a couple of times since I just acquired a Cubepro Duo my company was getting rid of and I want to convert it to an open source machine. There is an amazing amount of information in this thread an I want to thank everybody for contributing! I am new to 3D printing besides running the Cubepro Duo while my company was still using it (with limited success) so everything here has been extremely helpful! I just wanted to refresh the thread since its gone stale for a while and see if people are still having good success with their converted machines. I'm still in the research phase of my project so I'm just trying to get as much info as I can before I strip down the machine and commit to anything.

A little background for myself, I am a mechanical engineer so I'm comfortable on that side of the machine but have limited experience with the electrical/programming side of it. That's one of the (many) reasons I want to strip this down and convert it; to get some exposure to the electrical side of things. I'm currently leaning toward the Duet Wifi board and swapping the extruder & hotend out for ones from E3D since it seams like others have had a good amount of success with those products; but like I said, i am new to this and am still in the research phase.

Thanks again everyone!

|

Re: An alternative to buying a bad kit for $300-500 February 16, 2018 04:27PM |

Registered: 8 years ago Posts: 49 |

|

Re: An alternative to buying a bad kit for $300-500 February 16, 2018 06:44PM |

Registered: 6 years ago Posts: 2 |

Thanks! I was planning on it; I'm a firm believer in spending a little extra to buy the proper equipment instead of spending more time to get lesser quality results on minimal savings.

As for my problems with the printer, the elephant in the room is the proprietary nature of the printer. The amount saved on filament and replacement parts will pay for the conversion in no time. And the quality of prints were never great. The PLA would constantly jam, the ABS (even with the heated chamber and their glue) wouldn't adhere to the bed. We had hotends fail and beds de-laminate (neither of which were cheap to replace). We also had a few software issues where the printer wouldn't accept our converted files from S3D. The list goes on from there.

In reality we were able to get A FEW good prints out of it but not at a reasonable percentage of failures. For our company every hour spent fixing were hours non billable to clients and money not earned so we need something more reliable/repeatable. We consistently resorted to using the ID departments MakerBot for prints instead of our own because it was out of commission for one reason or another.

And like you pointed out I'm a tinkerer and have wanted to do a project like this for a while!

(sorry for the somewhat of a vent...)

As for my problems with the printer, the elephant in the room is the proprietary nature of the printer. The amount saved on filament and replacement parts will pay for the conversion in no time. And the quality of prints were never great. The PLA would constantly jam, the ABS (even with the heated chamber and their glue) wouldn't adhere to the bed. We had hotends fail and beds de-laminate (neither of which were cheap to replace). We also had a few software issues where the printer wouldn't accept our converted files from S3D. The list goes on from there.

In reality we were able to get A FEW good prints out of it but not at a reasonable percentage of failures. For our company every hour spent fixing were hours non billable to clients and money not earned so we need something more reliable/repeatable. We consistently resorted to using the ID departments MakerBot for prints instead of our own because it was out of commission for one reason or another.

And like you pointed out I'm a tinkerer and have wanted to do a project like this for a while!

(sorry for the somewhat of a vent...)

Sorry, only registered users may post in this forum.