An alternative to buying a bad kit for $300-500

Posted by the_digital_dentist

|

Re: An alternative to buying a bad kit for $300-500 February 11, 2019 03:57AM |

Registered: 5 years ago Posts: 4 |

I wanted to post this here, this thread has been helpful for me while developing my new project:

A 32bit controller board for the CubePro

[reprap.org]

A 32bit controller board for the CubePro

[reprap.org]

|

Re: An alternative to buying a bad kit for $300-500 March 15, 2019 08:00PM |

Registered: 5 years ago Posts: 29 |

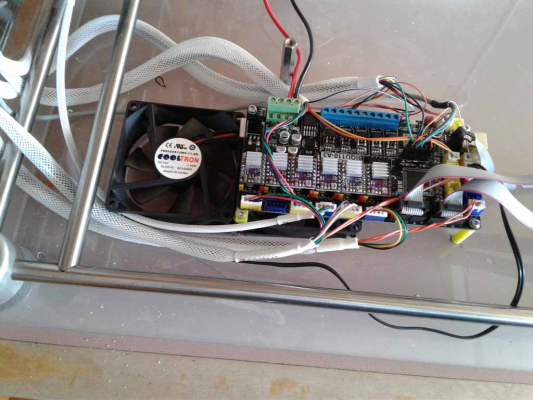

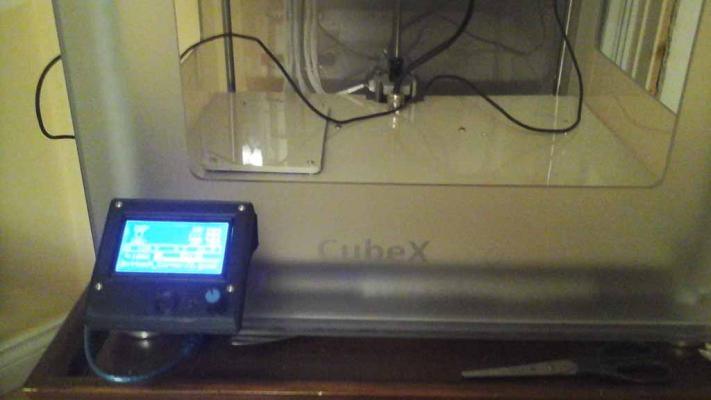

Nearly finished my Cubex duo reprap mod.

Using a Tango (modified version of Rumba). With DRV8255 drivers (6 of).

I re-used all existing wiring, just new connectors on the board end, and also reused the sensor boards and the existing breakout board on the carriage. Have E3DV6 style hotends but kept the original fans (two of the cheap 24 fans that came with the hot ends packed up within a week). Only one extruder in the center position.

Have reused the USB ports on the front and have used the Cubex filament run-out sensor (didn't bother with the filament movement sensors, although I believe the latest marlin may be able to use those too).

Have added micro switch Z end stop. Used the 6th driver (extruder 3) for the second Y axis stepper.

BL Touch style auto bed levelling.

24v Heated bed using the Ultrabase glass. For now I have gone with a 220x220 because that was readily available and cheap from amazon.

Am using Marlin 2.0 and Octoprint although I still print from SD rather than from the Pi. I have a webcam fitted to the back Z bracket that gives me a great view of the print from my study. Printer is in the basement.

Using Kisslicer and apart with problems with some cheap filaments from amazon, am now getting reasonably good results. Much better than I am getting with my other stock Duo.

Last couple of jobs (for now) is to print some hinges and cut some acrylic to add some doors to front and sides.

Although I have already been sidetracked into printing the parts for my next project - a MPCNC.

Edited 2 time(s). Last edit at 03/15/2019 08:08PM by jimboh3.

Using a Tango (modified version of Rumba). With DRV8255 drivers (6 of).

I re-used all existing wiring, just new connectors on the board end, and also reused the sensor boards and the existing breakout board on the carriage. Have E3DV6 style hotends but kept the original fans (two of the cheap 24 fans that came with the hot ends packed up within a week). Only one extruder in the center position.

Have reused the USB ports on the front and have used the Cubex filament run-out sensor (didn't bother with the filament movement sensors, although I believe the latest marlin may be able to use those too).

Have added micro switch Z end stop. Used the 6th driver (extruder 3) for the second Y axis stepper.

BL Touch style auto bed levelling.

24v Heated bed using the Ultrabase glass. For now I have gone with a 220x220 because that was readily available and cheap from amazon.

Am using Marlin 2.0 and Octoprint although I still print from SD rather than from the Pi. I have a webcam fitted to the back Z bracket that gives me a great view of the print from my study. Printer is in the basement.

Using Kisslicer and apart with problems with some cheap filaments from amazon, am now getting reasonably good results. Much better than I am getting with my other stock Duo.

Last couple of jobs (for now) is to print some hinges and cut some acrylic to add some doors to front and sides.

Although I have already been sidetracked into printing the parts for my next project - a MPCNC.

Edited 2 time(s). Last edit at 03/15/2019 08:08PM by jimboh3.

|

Re: An alternative to buying a bad kit for $300-500 March 16, 2019 09:03AM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 March 17, 2019 08:16PM |

Registered: 5 years ago Posts: 3 |

Hello everyone.

Ive bought a couple brand new Cubepro Duos to modify them and they should arrive Thur. I was just wanting to ask if anyone could let me know the LCD diagonal touch screen size is so that I can order a tft24, tft28, tft32, or a tft35 to arrive at the same time as all the other parts ive ordered.

Thank you in advance.........

Ive bought a couple brand new Cubepro Duos to modify them and they should arrive Thur. I was just wanting to ask if anyone could let me know the LCD diagonal touch screen size is so that I can order a tft24, tft28, tft32, or a tft35 to arrive at the same time as all the other parts ive ordered.

Thank you in advance.........

|

Re: An alternative to buying a bad kit for $300-500 March 28, 2019 12:16PM |

Registered: 5 years ago Posts: 3 |

Hey folks, long story short,

I have the opportunity to fix up a cubex trio at the local school of nursing.

Been thinking of converting a stratasys and cubepro to take spools for daily use for awhile.

He has already disabled extruders down to 1, wants to use spools, different interface/slicer and in heated boro bed.

Here is my plan of actions:

1) read more on various discussions here.

2) swap out electronics for duet.

3) sterilize carriage, add in Chinese extruder.

I want to move forward fail cheap fail fast style, to push things forward without altering the printer too much.

We'll think of adding in a better extruder and heated boro bed if above turns out useful enough.

What do you guys think?

Huge thanks to all here for the combined efforts!

I have the opportunity to fix up a cubex trio at the local school of nursing.

Been thinking of converting a stratasys and cubepro to take spools for daily use for awhile.

He has already disabled extruders down to 1, wants to use spools, different interface/slicer and in heated boro bed.

Here is my plan of actions:

1) read more on various discussions here.

2) swap out electronics for duet.

3) sterilize carriage, add in Chinese extruder.

I want to move forward fail cheap fail fast style, to push things forward without altering the printer too much.

We'll think of adding in a better extruder and heated boro bed if above turns out useful enough.

What do you guys think?

Huge thanks to all here for the combined efforts!

|

Re: An alternative to buying a bad kit for $300-500 March 28, 2019 12:37PM |

Registered: 11 years ago Posts: 5,780 |

The bed that's in it works fine, the extruders and hot-ends suck. Use Elmer's purple glue stick instead of the stuff that came with the printer. It's less messy, easier to clean up, and works fine.

I'd focus my efforts and $ on the controller board so you don't need proprietary filament cartridges and using a better extruder/hot-end. The E3D Titan and V6 hot end are OK, but short (the original hot-ends were pretty long) so you might need to adapt the extruder carriage or add an extension tube between the extruder and hot-end to make it work. The BMG extruder and E3d V6 hot end are a better combo., but again, you will need to lengthen it to make it work.

I've been using a Chinese hot-end in my printer for about a year and it has performed well. I did end up replacing the crappy fan that died pretty quickly with a good one (it didn't like the 50C chamber temperature when I print ABS). The fan mount is an aluminum bracket screwed to the hot-end heatsink. Unlike the E3D V6 set-up, the fan mount does not come loose, rotate, or melt.

I'm not a huge fan of the Chinese extruders, and no longer care much for the Titan. Too many problems. I put a BMG in my printer a few months ago and it fixes all the Titan's problems.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'd focus my efforts and $ on the controller board so you don't need proprietary filament cartridges and using a better extruder/hot-end. The E3D Titan and V6 hot end are OK, but short (the original hot-ends were pretty long) so you might need to adapt the extruder carriage or add an extension tube between the extruder and hot-end to make it work. The BMG extruder and E3d V6 hot end are a better combo., but again, you will need to lengthen it to make it work.

I've been using a Chinese hot-end in my printer for about a year and it has performed well. I did end up replacing the crappy fan that died pretty quickly with a good one (it didn't like the 50C chamber temperature when I print ABS). The fan mount is an aluminum bracket screwed to the hot-end heatsink. Unlike the E3D V6 set-up, the fan mount does not come loose, rotate, or melt.

I'm not a huge fan of the Chinese extruders, and no longer care much for the Titan. Too many problems. I put a BMG in my printer a few months ago and it fixes all the Titan's problems.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: An alternative to buying a bad kit for $300-500 March 28, 2019 01:18PM |

Registered: 5 years ago Posts: 3 |

Yeah not too concerned with the bed for now, thanks for mentioning it.

Saw a cheap bmg clone on amazon I was going to try.

Thanks a lot for confirming controller and extruder choice.

I'll talk to the person in charge again, order some parts.

Btw they are doing cool stuff with the printers, assistive tech, prosthetics...

Huge thanks to all here for the combined efforts!

Saw a cheap bmg clone on amazon I was going to try.

Thanks a lot for confirming controller and extruder choice.

I'll talk to the person in charge again, order some parts.

Btw they are doing cool stuff with the printers, assistive tech, prosthetics...

Huge thanks to all here for the combined efforts!

|

Re: An alternative to buying a bad kit for $300-500 April 04, 2019 12:08PM |

Registered: 5 years ago Posts: 29 |

I only use one E3DV6 on my modded Duo. It is in the middle position and I use the Duos extruder fan mounted on its bracket (with screws) and have a BL touch probe mounted to what would, on a trio be the third extruders bracket.

That is after both the chinese e3d small fans failed. The Cubex fans are better quality. I have had not problems with cooling with PLA. Haven't tried ABS yet.

I use a Tango (aka Rumba) that has 6 DRV8255s so I drive the second Z off E1 and E2 is spare.

I get very good prints at 2mm layers, the only issue being I sometimes get what looks like the layer is shifted in one direction by a fraction of a mm and continues from then on the same. No loss in strength as the layer adhesion is good. Wondering if this could be the step loss issue with the 8255s. Might try Some of the newer more expensive drivers later but am building a MPCNC at the moment.

Re the heated bed. I bought a 220x220 Utrabase heated bed and glass bed for $40CAD from Amazon (even cheaper for those of you in the states) and it's a huge improvement. So long as I heat the bed a good 5-10mins before hand (depending on model size) to allow the whole bed to reach temp, adhesion is great and no more glue.

I originally bought 1 working and 1 blown motherboard Duos for $250. I converted the faulty one. I was going to sell the worker, but I am now considering converting that one too and going for 3 Bowdens and a triple Diamond Hotend..... More fun!

I picked up a Monoprice Select Mini V2 on Kijiji for $100 including a new spool of PLA. Guy couldn't get it to print, turns out he had bought a couple of chinese E3D hotends but they were too long so he had like 3/4 inch of heat break/throat between heater block and heatsink so was getting jams in the break.

I moved the z endstop and made it adjustable so the nozzle would reach the bed and now it prints great. Its small and fairly quiet so that one stays in my study.

That is after both the chinese e3d small fans failed. The Cubex fans are better quality. I have had not problems with cooling with PLA. Haven't tried ABS yet.

I use a Tango (aka Rumba) that has 6 DRV8255s so I drive the second Z off E1 and E2 is spare.

I get very good prints at 2mm layers, the only issue being I sometimes get what looks like the layer is shifted in one direction by a fraction of a mm and continues from then on the same. No loss in strength as the layer adhesion is good. Wondering if this could be the step loss issue with the 8255s. Might try Some of the newer more expensive drivers later but am building a MPCNC at the moment.

Re the heated bed. I bought a 220x220 Utrabase heated bed and glass bed for $40CAD from Amazon (even cheaper for those of you in the states) and it's a huge improvement. So long as I heat the bed a good 5-10mins before hand (depending on model size) to allow the whole bed to reach temp, adhesion is great and no more glue.

I originally bought 1 working and 1 blown motherboard Duos for $250. I converted the faulty one. I was going to sell the worker, but I am now considering converting that one too and going for 3 Bowdens and a triple Diamond Hotend..... More fun!

I picked up a Monoprice Select Mini V2 on Kijiji for $100 including a new spool of PLA. Guy couldn't get it to print, turns out he had bought a couple of chinese E3D hotends but they were too long so he had like 3/4 inch of heat break/throat between heater block and heatsink so was getting jams in the break.

I moved the z endstop and made it adjustable so the nozzle would reach the bed and now it prints great. Its small and fairly quiet so that one stays in my study.

|

Re: An alternative to buying a bad kit for $300-500 April 06, 2019 01:27PM |

Registered: 5 years ago Posts: 29 |

|

Re: An alternative to buying a bad kit for $300-500 April 18, 2019 12:48PM |

Registered: 5 years ago Posts: 29 |

I have a second Cubex Duo that is stock except mods to allow normal filament. I am considering reprap'ing that one too and this time go for a triple Bowden solution with a Diamond triple (3 into 1) hot end.

I have been thinking about further weight reduction on the center carriage. Anyone considered (or even done) removing the aluminum carriage completely and replace with a 3d printed carriage? Would cut weight down a lot I would imagine.

I have been thinking about further weight reduction on the center carriage. Anyone considered (or even done) removing the aluminum carriage completely and replace with a 3d printed carriage? Would cut weight down a lot I would imagine.

|

Re: An alternative to buying a bad kit for $300-500 April 28, 2019 04:22PM |

Registered: 5 years ago Posts: 9 |

Hi Guys,

New to this site and a some-what new to 3d printing! Just got through this thread! What a wealth of information here (with a few broken image links because the thread is so old, lol...) Many of you are way ahead of me with your diverse skills!

My Cubex Trio (bought locally without knowing enough!) is on the bench torn apart and waiting for parts to arrive.

I went the RumbaPlus motherboard because it had the right number of drivers for the Trio but after some reading wondered how the Smoothieboard would work as it says the drive interface is re-extendable for up to 265 subdivisions. Anyone know if there is a pre-configured board for extending a smoothie driver? So I'm not bread boarding I mean, not sure where to get the parts to breadboad...

I thought I'd start with the stock extrudes since I know they all work, previous owner had some crap cooked filament in one of them that I was able to clean out, I might be open to changing them later, looked at what DD said he used (even looked up on the web to see how close he might be to me in Nevada, lol, he comes across as be helpful to many and if he was close, I'd ask if it was of to visit...) Anyone of you guys who have done the conversion live around Southern Nevada or Bakersfield CA area, love to visit and talk about issues I might run into?

I've started printing small parts on my Monoprice Mini Select, it works well...

I want to thank anyone who has added information/pictures/knowledge here, Your input gave me the courage to do this conversion...

Thanks,

Bill

New to this site and a some-what new to 3d printing! Just got through this thread! What a wealth of information here (with a few broken image links because the thread is so old, lol...) Many of you are way ahead of me with your diverse skills!

My Cubex Trio (bought locally without knowing enough!) is on the bench torn apart and waiting for parts to arrive.

I went the RumbaPlus motherboard because it had the right number of drivers for the Trio but after some reading wondered how the Smoothieboard would work as it says the drive interface is re-extendable for up to 265 subdivisions. Anyone know if there is a pre-configured board for extending a smoothie driver? So I'm not bread boarding I mean, not sure where to get the parts to breadboad...

I thought I'd start with the stock extrudes since I know they all work, previous owner had some crap cooked filament in one of them that I was able to clean out, I might be open to changing them later, looked at what DD said he used (even looked up on the web to see how close he might be to me in Nevada, lol, he comes across as be helpful to many and if he was close, I'd ask if it was of to visit...) Anyone of you guys who have done the conversion live around Southern Nevada or Bakersfield CA area, love to visit and talk about issues I might run into?

I've started printing small parts on my Monoprice Mini Select, it works well...

I want to thank anyone who has added information/pictures/knowledge here, Your input gave me the courage to do this conversion...

Thanks,

Bill

|

Re: An alternative to buying a bad kit for $300-500 April 30, 2019 05:58PM |

Registered: 5 years ago Posts: 3 |

LINK TO PICTURES

Hey folks, got the printer and parts, started chewing through the old cables and platform and programming marlin of course.

So far we got all the motors harnessed, as well as XY sensors and added in a Z min switch.

Used a circular saw to make room for the e3d clone in the platform, we had to mix and match parts for Direct Drive with the BMG clone.

Either way the clone seems to protrude enough with the super long threaded adapter, don't know how well that'll print.

Printed the screen adapter, printed a raspberry pi enclosure for Octopi, printed a mount for the MKS 1.5/6.

We are trying to get a replacement board since X driver didn't work too well on our amazon sourced board.

We have a couple boards we could use at the shop, but I am confident a new board would be less thinking.

What do you guys think ?

Hey folks, got the printer and parts, started chewing through the old cables and platform and programming marlin of course.

So far we got all the motors harnessed, as well as XY sensors and added in a Z min switch.

Used a circular saw to make room for the e3d clone in the platform, we had to mix and match parts for Direct Drive with the BMG clone.

Either way the clone seems to protrude enough with the super long threaded adapter, don't know how well that'll print.

Printed the screen adapter, printed a raspberry pi enclosure for Octopi, printed a mount for the MKS 1.5/6.

We are trying to get a replacement board since X driver didn't work too well on our amazon sourced board.

We have a couple boards we could use at the shop, but I am confident a new board would be less thinking.

What do you guys think ?

|

Re: An alternative to buying a bad kit for $300-500 May 05, 2019 01:46PM |

Registered: 5 years ago Posts: 9 |

Monkey: Looking good, Nice Picts!

I'm in the middle of waiting for parts but have stripped out some items from my CubeX Trio like yourself.

I do have a question for people that have converted there Duo/Trio, I noticed the leads for the motors don't follow the standard(?) black-blue-green-red on the motor end. Is this because the motors travel away from the rear top-left to bottom-right in direction while progressing with a build and was done to make it work that way? Or just 3D Systems trying to engineer something different? Even on the extruder motors they flipped the blue-green placements. Did the people who have working units change the pinouts on the motor ends? As I said, I'm waiting on my power supply so I have not hooked up my RumbaPlus board yet to test this out... I was also thinking of creating an enclosure for the Rumba and extra modules (smoothers) with cooling fans. Noticed the fans that are installed in the base blow up so maybe start there and add a couple small fans at 90 degrees to blow across the drivers.

Thanks for any help!

Bill

I'm in the middle of waiting for parts but have stripped out some items from my CubeX Trio like yourself.

I do have a question for people that have converted there Duo/Trio, I noticed the leads for the motors don't follow the standard(?) black-blue-green-red on the motor end. Is this because the motors travel away from the rear top-left to bottom-right in direction while progressing with a build and was done to make it work that way? Or just 3D Systems trying to engineer something different? Even on the extruder motors they flipped the blue-green placements. Did the people who have working units change the pinouts on the motor ends? As I said, I'm waiting on my power supply so I have not hooked up my RumbaPlus board yet to test this out... I was also thinking of creating an enclosure for the Rumba and extra modules (smoothers) with cooling fans. Noticed the fans that are installed in the base blow up so maybe start there and add a couple small fans at 90 degrees to blow across the drivers.

Thanks for any help!

Bill

|

Re: An alternative to buying a bad kit for $300-500 May 05, 2019 02:37PM |

Registered: 5 years ago Posts: 29 |

Quote

monkey

Either way the clone seems to protrude enough with the super long threaded adapter, don't know how well that'll print.

Rather than increasing the size of the hole in the carriage to allow the the e3d heatsink to be fitted, I went the same way as others have and used a e3d with a bowden end and turned the bowden nut down on a lathe until it would fit inside the Cubex extruder. That way the extra length is at the top rather than the bottom (in order for the extruder to be long enough. Another option is to use the longer e3d V5.

Only problem I can see with what you have done is that the exposed length of throat/heat break will not be cooled and cause filament jams at that point.

I bought a monoprice select V2 off a guy who had all sorts of problems with jammed filament after changing the extruder to a e3d. As on the Cubex, the e3d was too short and because that printer comes with a fixed Z endstop and it was impossible to close the gap by raising the bed (without some drastic rebuild) he had done what you have done and only screw the heat break in so far (and he used a nut to lock it there. I tried it a number of times and got repeat jams. I modified the printer to include an adjustable z end stop and fitted a new e3d with the break all the way in (as per e3d's instructions) and have not had a jam since).

As for the stepper leads. I just looked up the spec for the steppers and got the pin description and just wired the controller board to match. If I remember rightly, they didn't even use the same colour coding on all 5 steppers??

I will be interested in how a trio conversion works. I converted a duo and went with a single extruder because I can't imagine the grief in trying to get two (let alone three) hot ends at exactly the right height so they are not bumping into the print. Especially at a .1mm layer height.

I have a second duo I might convert and I am thinking of trying a triple extruder/single hot end bowden setup using a Diamond 3 into 1 nozzle. Big reduction in weight on the carriage may allow for a higher print speed,

Edited 4 time(s). Last edit at 05/05/2019 02:41PM by jimboh3.

|

Re: An alternative to buying a bad kit for $300-500 May 05, 2019 02:53PM |

Registered: 5 years ago Posts: 29 |

Quote

GT500

Noticed the fans that are installed in the base blow up so maybe start there and add a couple small fans at 90 degrees to blow across the drivers.

I installed my Tango (mod of rumba) over the front of the two fans using a printed mount and pillars so that front fan is blowing on the underside of thePCB where the stepper drivers/ Mosfets are and I installed a new cover over the top with a raised lid for the hole over the rumba. so the back fan blows air onto the underside and is forced over the stepper heatsinks. I also added heatsinks to the large mosfets. I was going to print a air guid for the back fan that forces the air forward but have not gotten around to that yet.

Edited 1 time(s). Last edit at 05/05/2019 02:55PM by jimboh3.

|

Re: An alternative to buying a bad kit for $300-500 May 05, 2019 03:58PM |

Registered: 5 years ago Posts: 9 |

Quote

jimboh3

I installed my Tango (mod of rumba) over the front of the two fans using a printed mount and pillars so that front fan is blowing on the underside of thePCB where the stepper drivers/ Mosfets are and I installed a new cover over the top with a raised lid for the hole over the rumba. so the back fan blows air onto the underside and is forced over the stepper heatsinks. I also added heatsinks to the large mosfets. I was going to print a air guid for the back fan that forces the air forward but have not gotten around to that yet.

I like the way you did that with the standoffs and all, Might just try it myself! Thanks for the pictures of it.

-Bill

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 02:43PM |

Registered: 5 years ago Posts: 6 |

Hi,

Just wanted to say there are lots of impressive implementations here. I have mine almost completed, but I am having some issues with the extruders. I have the Cubex extruders but when trying to extrude material the motor just clicks and slightly moves then kicks back. Not sure why this is happening. It it just a straight run motor cable to an MKS Gen L with A4988 on the extruders. Both extruders (duo) do the same thing. Any advice on what I may have missed?

Thanks,

Just wanted to say there are lots of impressive implementations here. I have mine almost completed, but I am having some issues with the extruders. I have the Cubex extruders but when trying to extrude material the motor just clicks and slightly moves then kicks back. Not sure why this is happening. It it just a straight run motor cable to an MKS Gen L with A4988 on the extruders. Both extruders (duo) do the same thing. Any advice on what I may have missed?

Thanks,

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 03:09PM |

Registered: 8 years ago Posts: 105 |

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 06:26PM |

Registered: 5 years ago Posts: 6 |

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 06:35PM |

Registered: 5 years ago Posts: 29 |

Isn't that 2.3A? Also Isn't that a tad high for a A4988? Sorry I have not been thinking 3d printers for a month or two and am getting old so memory fades quickly.

I am surprised the extruder would need much current, it isn't doing much work is it?

Are you still using the original delivery system with the filament fed via the tubes?

Have you tried a length of filament fed straight into the top of the extruder to see if there is free flow. The extruder is only going to be working hard if it is difficult to pull the filament through the tubes or if it is trying to squeeze it past a blockage.

Have you made sure the hot ends are completely free of any blockages?

I am surprised the extruder would need much current, it isn't doing much work is it?

Are you still using the original delivery system with the filament fed via the tubes?

Have you tried a length of filament fed straight into the top of the extruder to see if there is free flow. The extruder is only going to be working hard if it is difficult to pull the filament through the tubes or if it is trying to squeeze it past a blockage.

Have you made sure the hot ends are completely free of any blockages?

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 06:46PM |

Registered: 5 years ago Posts: 6 |

Hi Jimboh3,

I gutted the filament system that was in the original system and plan on trialing loading the filament in directly through the top of the extruder (like I did when testing the original Cubex hardware and .bfb file printing). The issue i'm having is both extruders when you get the thermistor up to temp will not move; it's like they stutter in place. I try to extrude say; 10mm of filament and the gear just kicks back and forth. There isn't any filament or anything in the path yet I only noticed this issue when I was testing to make sure I didn't have to invert the motor directions in Marlin firmware. I tried a lower current; 0.85 volts and got the same thing.

I also checked the conductivity on the wire and I seem to have good connections from each side of the wire (board to motor).

I gutted the filament system that was in the original system and plan on trialing loading the filament in directly through the top of the extruder (like I did when testing the original Cubex hardware and .bfb file printing). The issue i'm having is both extruders when you get the thermistor up to temp will not move; it's like they stutter in place. I try to extrude say; 10mm of filament and the gear just kicks back and forth. There isn't any filament or anything in the path yet I only noticed this issue when I was testing to make sure I didn't have to invert the motor directions in Marlin firmware. I tried a lower current; 0.85 volts and got the same thing.

I also checked the conductivity on the wire and I seem to have good connections from each side of the wire (board to motor).

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 07:28PM |

Registered: 5 years ago Posts: 29 |

You could try removing the hot end from the extruder and check see if the filament feeds. But you would have to have marlin configured with no min temp for extrusion (can't recall the setting off the top of my head).

If the hotends are clear of obstruction it should not take any more torque to push through the stock end than a E3d I would have thought. I have 8255's but only set the current at 1.46 A and have no problems except when there is a blockage.

Have you double checked your wiring to the steppers?

If your x stepper is working correctly you could move the carriage to the left and use the x stepper driver cable to test drive the extruder....

Just some things I would try. I'm sure someone wil chip in with some better ideas.

If the hotends are clear of obstruction it should not take any more torque to push through the stock end than a E3d I would have thought. I have 8255's but only set the current at 1.46 A and have no problems except when there is a blockage.

Have you double checked your wiring to the steppers?

If your x stepper is working correctly you could move the carriage to the left and use the x stepper driver cable to test drive the extruder....

Just some things I would try. I'm sure someone wil chip in with some better ideas.

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 08:04PM |

Registered: 5 years ago Posts: 6 |

Thanks for the ideas. I tried heating up the extruder and I swapped the X cable. The X motor turned and moved the carriage (albeit slowly) so I do not think it is driver related. I did try the extruder in the X axis and that did not work. I also tried feeding trough some filament when it was cold and I could get into the hotend so I do not think it's a blockage. I'm beginning to think I have a bad solder job on the two wires I made for the extruder motors. I had bought 2 1m motor extensions for each extruder motor and just cut one type of end off each one and soldered each wire color together. Should I have cross something?

|

Re: An alternative to buying a bad kit for $300-500 June 08, 2019 11:00PM |

Registered: 5 years ago Posts: 29 |

|

Re: An alternative to buying a bad kit for $300-500 June 09, 2019 04:21AM |

Admin Registered: 11 years ago Posts: 3,096 |

Today I found an XYZprinting Davinci printer for 75 euros. It appears to be in new condition. I'm not sure how good it is, but I believe it has either 10 or 12mm guide rods and an enclosure. I'm really thinking of getting one and REPRAP-ifying it

Anyone knows anything about these printers?

It looks like it's this one:

[www.xyzprinting.com]

http://www.marinusdebeer.nl/

Anyone knows anything about these printers?

It looks like it's this one:

[www.xyzprinting.com]

http://www.marinusdebeer.nl/

|

Re: An alternative to buying a bad kit for $300-500 June 09, 2019 05:02PM |

Registered: 5 years ago Posts: 6 |

|

Re: An alternative to buying a bad kit for $300-500 June 09, 2019 08:07PM |

Registered: 5 years ago Posts: 29 |

|

Re: An alternative to buying a bad kit for $300-500 June 10, 2019 01:43AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Ohmarinus

Today I found an XYZprinting Davinci printer for 75 euros. It appears to be in new condition. I'm not sure how good it is, but I believe it has either 10 or 12mm guide rods and an enclosure. I'm really thinking of getting one and REPRAP-ifying it

Anyone knows anything about these printers?

It looks like it's this one:

[www.xyzprinting.com]

User @Whitewolf on the Duet3D forum (https://forum.duet3d.com/) has one, you could ask him/her.

Edited 1 time(s). Last edit at 06/10/2019 01:43AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2019 01:59AM |

Registered: 4 years ago Posts: 10 |

Hello, everyone.

I'm Wally, and I have a Cube Pro jettisoned as e-waste. My first 3D printer!

I've read through your entire multithread, all the stories of what you have made of them and (made for them and made with them).

I was encouraged. I bought the aluminum build plate with the garolite surface from that guy that's making replacement build plates, had a smoothieboard, got a V6 hotend, a CNC-machined titan extruder is on the way, my first kilo of nylonX was here when I got home today.

So I pulled it out of the case, started stripping it down and found that... I can't get the extruder plate off the X axis front linear bearing!

I've removed the single extruder (thanks for the help and pictures, btw). I've removed the PC from the other side, and can loosen the two brass stand-offs so the plate has let go of the back linear bearing.

The linear bearing on the front side has three torx screws that I can't budge and I think I'm starting to strip them.

Does anyone have:

I'm now on the lookout for a cube pro on eBay/craigslist for parts/repair and local pickup, I guess.

I'm Wally, and I have a Cube Pro jettisoned as e-waste. My first 3D printer!

I've read through your entire multithread, all the stories of what you have made of them and (made for them and made with them).

I was encouraged. I bought the aluminum build plate with the garolite surface from that guy that's making replacement build plates, had a smoothieboard, got a V6 hotend, a CNC-machined titan extruder is on the way, my first kilo of nylonX was here when I got home today.

So I pulled it out of the case, started stripping it down and found that... I can't get the extruder plate off the X axis front linear bearing!

I've removed the single extruder (thanks for the help and pictures, btw). I've removed the PC from the other side, and can loosen the two brass stand-offs so the plate has let go of the back linear bearing.

The linear bearing on the front side has three torx screws that I can't budge and I think I'm starting to strip them.

Does anyone have:

- a suggestion on how to loosen the screws (like, WD-40, torch heating the plate and canned air upside-down to chill the screw, drilling it out, throwing it away)

- an explanation re: why they won't loosen (like, are they actually left-hand-thread? Locktite applied? Bimetalic junction causing corrosion)

- an extra front linear bearing that has had the extruder plate removed

I'm now on the lookout for a cube pro on eBay/craigslist for parts/repair and local pickup, I guess.

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2019 02:46AM |

Registered: 8 years ago Posts: 105 |

The steel screws bind in the aluminium, they react with each other, think it's called galvanic corrosion.

WD-40 can help, and make sure you hex key/driver is the right size, by that I mean some are more accurately sized than others. I found one multi bit set would slip before it broke the bind in the metal, even with the right one T-bar type (good for applying torque) it still took some serious force to get one of them moving.

Worse case you can drill them out, or find a slightly oversize Torx bit that you can hammer in. Or get a screw removal kit, these might not work as they are pretty small.

Edited 1 time(s). Last edit at 11/07/2019 02:49AM by Firefox3D.

WD-40 can help, and make sure you hex key/driver is the right size, by that I mean some are more accurately sized than others. I found one multi bit set would slip before it broke the bind in the metal, even with the right one T-bar type (good for applying torque) it still took some serious force to get one of them moving.

Worse case you can drill them out, or find a slightly oversize Torx bit that you can hammer in. Or get a screw removal kit, these might not work as they are pretty small.

Edited 1 time(s). Last edit at 11/07/2019 02:49AM by Firefox3D.

Sorry, only registered users may post in this forum.