New adventures in 3d printing (aka so I designed a 3d printer)

Posted by plasticWrap

|

New adventures in 3d printing (aka so I designed a 3d printer) October 08, 2016 10:53AM |

Registered: 8 years ago Posts: 4 |

Hi all, I've been a member for a while but this is my first post.

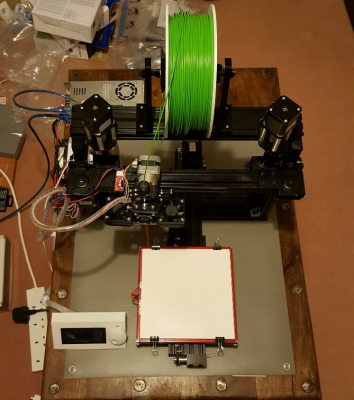

So after a little while with some kits I decided to design and build my own 3d printer. It was mostly just supposed to be a stop gap design so I could build decent parts for other printers and another design of my own later on. I couldn't find exactly what I wanted amongst existing designs but I knew there was some key elements I wanted to include. In the end it's basically just a mash-up of other peoples designs along with my own ideas & constraints etc.

Initially I wasn't sure that I had achieved much over what I had before and was a bit disappointed. I started to obsess over the design swapping out most of the remaining parts from the kit thinking they were to blame. I was regularly printing parts for the printer and they were mostly turning out OK. When I went to test something like Marvin however the results didn't seem as good as those on the internet. Well yes, of course! It's actually pretty hard to judge anything with a blurry photo and no details on print settings and post processing. Somehow though that wasn't a satisfactory answer and I indignantly insisted to myself that why should my prints be worse than those from a named brand printer infused to the brim with marketing hyperbole. Even though I knew what I had built wasn't necessarily meant to compete with those sorts of machines I was possessed of a nagging feeling that it should at least be close.

I had been trying to save my more expensive filament by keeping it sealed and waiting until I got the printer working really well before opening it. At various points I got curious, thinking maybe better filament will fix all my problems. I would then open one of the packs and try it, but if anything the more expensive filament was making the results worse. Eventually I crumbled and decided to open the most expensive one I had. Surely that would be the answer. Oh! Mighty ColorFabb save me from my crappy printing results! Just as surely as none of the other filaments had made much difference, the results with ColorFabb were actually the worst of all!

At this point I guess I had a few options open to me.

1. Throw printer, filament and all evidence of 3d printing out the window and insist that I had never heard of 3d printing much less attempted to do it.

2. Buy expensive marketing hyperbole infused 3d printer and see if that fixed the problem.

3. Try exhaustive and repetitive experimentation to assess whether or not I am a) Crazy b) Everyone else is c) Some small improvement in printing results can be achieved

For some reason I decided to try option 3 (probably because I'm crazy & self assessment for madness is somewhat unreliable). My focus was on Marvin as I felt if I could get that one working properly I could probably do it for other models too. The other reasons were due to practicality, it's a fairly small model which is relatively quick to print with numerous reference images to compare against. I had already read a wide range of suggestions on how to print Marvin and experimented accordingly. As many of these suggestions had done little to help or even made things worse I decided that it was time to just ignore everyone and do it my way (more evidence I'm crazy). In short using a systematic approach I went through every combination of setting and methodology that I was able to accommodate until I started seeing an improvement. Doing this eventually I did see a big improvement which was the ultimate pay off (also possibly proving my sanity although not conclusively).

I know some people will want to interpret this story as being about calibration or tuning of the machine. You're obviously entitled to do that although that's not what I'm saying at all. My experiments ultimately saw improvements based around the slicer settings and not the machine settings. I also did not re-tension my belts as I can't help thinking that beyond a sensible level of tension you will only risk doing damage. Besides I have no desire to see my machine fold up and implode like the house in Poltergeist.

I do wonder how well I could have got the original kit working with what I now know. I'm also curious to see just how well other printers work in reality. I do see plenty of questions on how to print Marvin which lead me to believe that generic slicer settings are far from perfect regardless of the brand of printer. Mostly I'm just happy to be able to say I designed my own printer and it actually seems to be working pretty well right now!

A few images of my prints, some are just test prints or have issues I know can be improved, but still pretty happy with the results overall

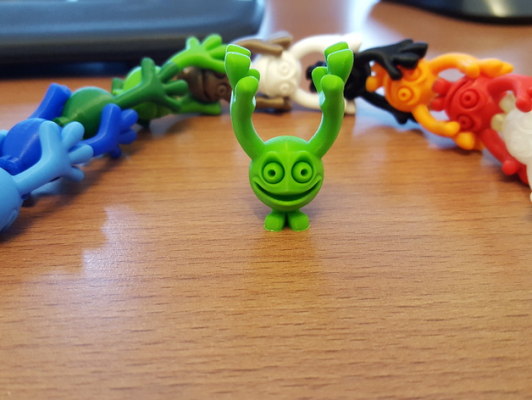

3D Hubs Marvin - Key Chain by 3DHubs

Aria the Dragon by loubie

The 3D Printed Marble Machine #3 by Tulio

Linklings by Davision3d

Folding DNA model kit. by mkuiper

3D printed mechanical Clock with Anchor Escapement by TheGoofy

Ball-joint articulated octopus by Ellindsey

Robot woman "Robotica" by Shira

It's been an interesting journey and I feel like I've learnt a lot on the way, although I'm not sure any of it was actually related to 3d printing

Edited 1 time(s). Last edit at 10/09/2016 03:37PM by plasticWrap.

If common sense is so common then why does no one actually seem to have it. Perhaps it should be renamed uncommon sense.

blog [plasticwrap3d.wordpress.com]

So after a little while with some kits I decided to design and build my own 3d printer. It was mostly just supposed to be a stop gap design so I could build decent parts for other printers and another design of my own later on. I couldn't find exactly what I wanted amongst existing designs but I knew there was some key elements I wanted to include. In the end it's basically just a mash-up of other peoples designs along with my own ideas & constraints etc.

Initially I wasn't sure that I had achieved much over what I had before and was a bit disappointed. I started to obsess over the design swapping out most of the remaining parts from the kit thinking they were to blame. I was regularly printing parts for the printer and they were mostly turning out OK. When I went to test something like Marvin however the results didn't seem as good as those on the internet. Well yes, of course! It's actually pretty hard to judge anything with a blurry photo and no details on print settings and post processing. Somehow though that wasn't a satisfactory answer and I indignantly insisted to myself that why should my prints be worse than those from a named brand printer infused to the brim with marketing hyperbole. Even though I knew what I had built wasn't necessarily meant to compete with those sorts of machines I was possessed of a nagging feeling that it should at least be close.

I had been trying to save my more expensive filament by keeping it sealed and waiting until I got the printer working really well before opening it. At various points I got curious, thinking maybe better filament will fix all my problems. I would then open one of the packs and try it, but if anything the more expensive filament was making the results worse. Eventually I crumbled and decided to open the most expensive one I had. Surely that would be the answer. Oh! Mighty ColorFabb save me from my crappy printing results! Just as surely as none of the other filaments had made much difference, the results with ColorFabb were actually the worst of all!

At this point I guess I had a few options open to me.

1. Throw printer, filament and all evidence of 3d printing out the window and insist that I had never heard of 3d printing much less attempted to do it.

2. Buy expensive marketing hyperbole infused 3d printer and see if that fixed the problem.

3. Try exhaustive and repetitive experimentation to assess whether or not I am a) Crazy b) Everyone else is c) Some small improvement in printing results can be achieved

For some reason I decided to try option 3 (probably because I'm crazy & self assessment for madness is somewhat unreliable). My focus was on Marvin as I felt if I could get that one working properly I could probably do it for other models too. The other reasons were due to practicality, it's a fairly small model which is relatively quick to print with numerous reference images to compare against. I had already read a wide range of suggestions on how to print Marvin and experimented accordingly. As many of these suggestions had done little to help or even made things worse I decided that it was time to just ignore everyone and do it my way (more evidence I'm crazy). In short using a systematic approach I went through every combination of setting and methodology that I was able to accommodate until I started seeing an improvement. Doing this eventually I did see a big improvement which was the ultimate pay off (also possibly proving my sanity although not conclusively).

I know some people will want to interpret this story as being about calibration or tuning of the machine. You're obviously entitled to do that although that's not what I'm saying at all. My experiments ultimately saw improvements based around the slicer settings and not the machine settings. I also did not re-tension my belts as I can't help thinking that beyond a sensible level of tension you will only risk doing damage. Besides I have no desire to see my machine fold up and implode like the house in Poltergeist.

I do wonder how well I could have got the original kit working with what I now know. I'm also curious to see just how well other printers work in reality. I do see plenty of questions on how to print Marvin which lead me to believe that generic slicer settings are far from perfect regardless of the brand of printer. Mostly I'm just happy to be able to say I designed my own printer and it actually seems to be working pretty well right now!

A few images of my prints, some are just test prints or have issues I know can be improved, but still pretty happy with the results overall

3D Hubs Marvin - Key Chain by 3DHubs

Aria the Dragon by loubie

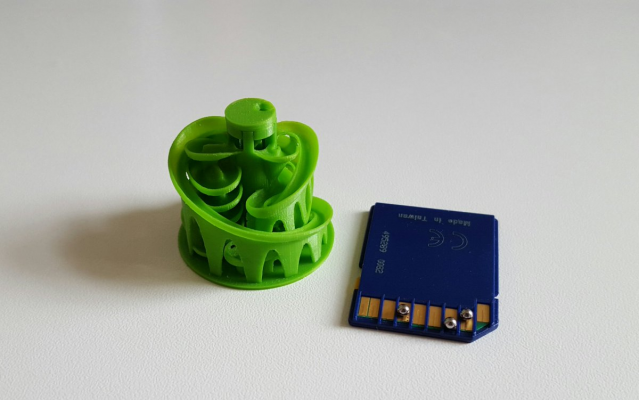

The 3D Printed Marble Machine #3 by Tulio

Linklings by Davision3d

Folding DNA model kit. by mkuiper

3D printed mechanical Clock with Anchor Escapement by TheGoofy

Ball-joint articulated octopus by Ellindsey

Robot woman "Robotica" by Shira

It's been an interesting journey and I feel like I've learnt a lot on the way, although I'm not sure any of it was actually related to 3d printing

Edited 1 time(s). Last edit at 10/09/2016 03:37PM by plasticWrap.

If common sense is so common then why does no one actually seem to have it. Perhaps it should be renamed uncommon sense.

blog [plasticwrap3d.wordpress.com]

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 08, 2016 11:08AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 08, 2016 11:12AM |

Registered: 11 years ago Posts: 5,780 |

Fantastic! Can it do this reliably, of is each print the result of 20 failed attempts? Are you going to provide any details of tuning procedures and of the printer itself?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 08, 2016 03:24PM |

Registered: 9 years ago Posts: 1,873 |

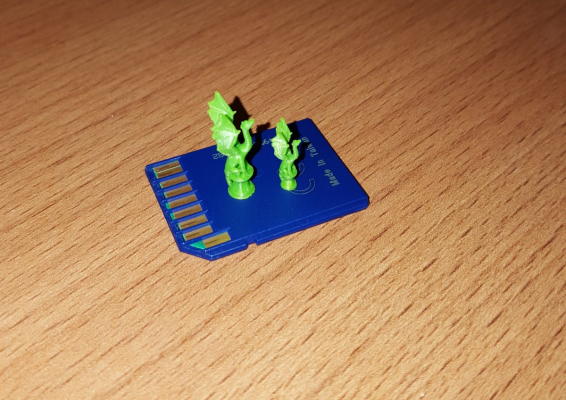

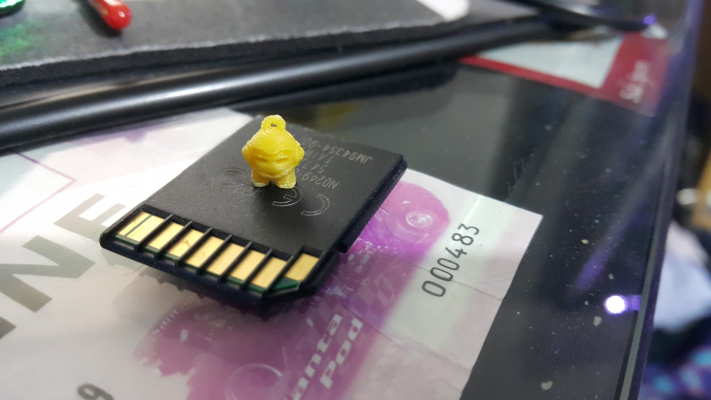

Um, remarkable. Or have we been trolled? I'd certainly like to know more about the filament, hardware and settings you are using! What on earth size nozzle did you use for those small prints?

And welcome to the forum. I think. I felt better about my prints before seeing yours

Edit: I don't suppose that's a really, really big model of an SD card?

Edited 1 time(s). Last edit at 10/08/2016 03:25PM by JamesK.

And welcome to the forum. I think. I felt better about my prints before seeing yours

Edit: I don't suppose that's a really, really big model of an SD card?

Edited 1 time(s). Last edit at 10/08/2016 03:25PM by JamesK.

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 08, 2016 10:10PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 09, 2016 03:16PM |

Registered: 8 years ago Posts: 4 |

@MechaBits Thanks, can never have too much filament

@the_digital_dentist

I remember your instructable, think I read it back when I was looking for my first kit / printer was an interesting read and print quality looked very good.

In terms of reliability / repeatability, on the basis of my testing I would say provided all the settings and preparations are the same then the results should be the same (including all the small models). For the smallest Aria & Marvin I did try numerous slicer settings looking to improve the small details or reduce stringing and blobs. Frankly for many of them it was hard to tell the difference. From the point of view of determining the best slicer settings I would not describe the process as being especially repeatable. That is for how long it would take to find the best settings as I suppose it was just a matter of my opinion in the end. The big and small Marvin (15%), the 2 small Arias (15%,10%) and the Linklings are not post processed in any way. I've tried to find an honest but flattering photo for them and have not done anything to deliberately manipulate the photos like focusing off the object (that I have seen in some photos). Marble machine #3 (approx 20%) was different as I wanted to see how close I could get to a sample print off the Autodesk Ember (SLA printer) also it needed to work to be of any value which it does. There are such a lot of retracts in a very small area and with a low aggregate print speed it is hard to avoid a small number of strings due to oozing. I did the print at 50 microns as it looks smoother although that makes it hard to maintain the quality of the overhangs and generates more oozing / retract problems. Mostly I just ran a tooth pick down the track after locating any point the ball stopped I think there were 2 or 3 of those. For the big Arias I used settings from Robotica and estimated temperature based on printing Marvin. It was to be a test to see what difference the filament made so they are all just one offs. There were some differences which were consistent with the comments on filament I made below. I did clean the wing tips up for all of them, personally I'm happy with them but I'm certain I could improve the print settings. The other models had supports that needed removing and generally required some assembly so almost anything could have happened there ...including making things worse

@JamesK Look, I only live under a bridge because someone told me the rent was cheap

Btw 3dhubs already asked the question about the SD card. I'll tell you what I told them, you should see the size of the printer!

The nozzle used for the small prints is a .25 I believe I could print smaller with a .1 nozzle. I think Jerrill used to make custom nozzles down to that size for the Ubis (Printrbot) hotend but not sure if anyone else produces 0.1mm nozzles commercially, got the impression they are hard to make. I also have a suspicion that reducing the size of the melt zone down proportionally would help (Prometheus customisable hotend may go a bit smaller than my e3d v6).

Filament notes

The filament is all PLA.

White and natural are left over from the first kit which I returned. Appears to be cheap and brittle filament but still seems to print ok.

Light blue from the 2nd kit and is probably very cheap filament but still seems to print ok. Also a brittle filament and some evidence of occasional colour inconsistencies. The end of the reel is very tightly wound and this did not feed properly via the original extruder drive. Amongst other things the new extruder has a large hobbed bolt and a geared NEMA 17.

Red and gold? (looks more brown or bronze to me) are rigid.ink filament. More flexible and print quality seems generally ok but overhangs sometimes a bit rough (more for the red than the gold). The gold is quite oozy filament which may help produce smooth results but also strings and blobs that are hard to get rid of. Colours are quite strong but as mentioned gold is quite dark and more brown than anything and also shows a fair amount of colour variation when printing.

Black (except for the clock) was from Nexus3d. This company seems to have gone out of business. Filament was fairly cheap and actually seemed to work well. The colour of the black seems very deep, would have bought more.

Light green, orange, black (clock parts) and dark blue are Verbatim. Quite flexible filament and seems a bit more forgiving than some. Light green and orange are pretty similar, both fairly bright and solid colours. Blue is quite a dark blue but slightly transparent. Black is also a bit transparent and more a dark grey as a result, bit disappointing colour wise.

Dark green is Leaf Green from ColorFabb. Colour is strong and solid. This does have PHA mixed in to help make it more flexible and less brittle and IMHO that is why the overhangs are rougher and print quality can be worse than the others / less forgiving with settings. As a result I typically used this to tune the more fiddly prints and get the best settings and then re-used them (bar temperature and flow rate) for the other filaments. I wasn't trying to put anyone off ColorFabb, after getting the setting right the prints come out ok and I would consider buying again just for the range of colours on offer.

I think if I had an overall comment it would be that the results are actually pretty similar for all the above filament brands / colours once the best settings for a specific stl are found in combination with correct temp / flow rate.

Took longer than I thought to write this post so I'm just going to leave it for now. If there's still some interest I can post a few more details some other time.

If common sense is so common then why does no one actually seem to have it. Perhaps it should be renamed uncommon sense.

blog [plasticwrap3d.wordpress.com]

@the_digital_dentist

I remember your instructable, think I read it back when I was looking for my first kit / printer was an interesting read and print quality looked very good.

In terms of reliability / repeatability, on the basis of my testing I would say provided all the settings and preparations are the same then the results should be the same (including all the small models). For the smallest Aria & Marvin I did try numerous slicer settings looking to improve the small details or reduce stringing and blobs. Frankly for many of them it was hard to tell the difference. From the point of view of determining the best slicer settings I would not describe the process as being especially repeatable. That is for how long it would take to find the best settings as I suppose it was just a matter of my opinion in the end. The big and small Marvin (15%), the 2 small Arias (15%,10%) and the Linklings are not post processed in any way. I've tried to find an honest but flattering photo for them and have not done anything to deliberately manipulate the photos like focusing off the object (that I have seen in some photos). Marble machine #3 (approx 20%) was different as I wanted to see how close I could get to a sample print off the Autodesk Ember (SLA printer) also it needed to work to be of any value which it does. There are such a lot of retracts in a very small area and with a low aggregate print speed it is hard to avoid a small number of strings due to oozing. I did the print at 50 microns as it looks smoother although that makes it hard to maintain the quality of the overhangs and generates more oozing / retract problems. Mostly I just ran a tooth pick down the track after locating any point the ball stopped I think there were 2 or 3 of those. For the big Arias I used settings from Robotica and estimated temperature based on printing Marvin. It was to be a test to see what difference the filament made so they are all just one offs. There were some differences which were consistent with the comments on filament I made below. I did clean the wing tips up for all of them, personally I'm happy with them but I'm certain I could improve the print settings. The other models had supports that needed removing and generally required some assembly so almost anything could have happened there ...including making things worse

@JamesK Look, I only live under a bridge because someone told me the rent was cheap

Btw 3dhubs already asked the question about the SD card. I'll tell you what I told them, you should see the size of the printer!

The nozzle used for the small prints is a .25 I believe I could print smaller with a .1 nozzle. I think Jerrill used to make custom nozzles down to that size for the Ubis (Printrbot) hotend but not sure if anyone else produces 0.1mm nozzles commercially, got the impression they are hard to make. I also have a suspicion that reducing the size of the melt zone down proportionally would help (Prometheus customisable hotend may go a bit smaller than my e3d v6).

Filament notes

The filament is all PLA.

White and natural are left over from the first kit which I returned. Appears to be cheap and brittle filament but still seems to print ok.

Light blue from the 2nd kit and is probably very cheap filament but still seems to print ok. Also a brittle filament and some evidence of occasional colour inconsistencies. The end of the reel is very tightly wound and this did not feed properly via the original extruder drive. Amongst other things the new extruder has a large hobbed bolt and a geared NEMA 17.

Red and gold? (looks more brown or bronze to me) are rigid.ink filament. More flexible and print quality seems generally ok but overhangs sometimes a bit rough (more for the red than the gold). The gold is quite oozy filament which may help produce smooth results but also strings and blobs that are hard to get rid of. Colours are quite strong but as mentioned gold is quite dark and more brown than anything and also shows a fair amount of colour variation when printing.

Black (except for the clock) was from Nexus3d. This company seems to have gone out of business. Filament was fairly cheap and actually seemed to work well. The colour of the black seems very deep, would have bought more.

Light green, orange, black (clock parts) and dark blue are Verbatim. Quite flexible filament and seems a bit more forgiving than some. Light green and orange are pretty similar, both fairly bright and solid colours. Blue is quite a dark blue but slightly transparent. Black is also a bit transparent and more a dark grey as a result, bit disappointing colour wise.

Dark green is Leaf Green from ColorFabb. Colour is strong and solid. This does have PHA mixed in to help make it more flexible and less brittle and IMHO that is why the overhangs are rougher and print quality can be worse than the others / less forgiving with settings. As a result I typically used this to tune the more fiddly prints and get the best settings and then re-used them (bar temperature and flow rate) for the other filaments. I wasn't trying to put anyone off ColorFabb, after getting the setting right the prints come out ok and I would consider buying again just for the range of colours on offer.

I think if I had an overall comment it would be that the results are actually pretty similar for all the above filament brands / colours once the best settings for a specific stl are found in combination with correct temp / flow rate.

Took longer than I thought to write this post so I'm just going to leave it for now. If there's still some interest I can post a few more details some other time.

If common sense is so common then why does no one actually seem to have it. Perhaps it should be renamed uncommon sense.

blog [plasticwrap3d.wordpress.com]

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 09, 2016 04:06PM |

Registered: 9 years ago Posts: 1,873 |

Very impressive, and many thanks for taking the time to write that follow-up. I tried a .2mm nozzle briefly, it worked but it took so long to print anything I didn't feel motivated enough to do much with it. I'll have to revisit that if I want to try improving my print quality at some stage!

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 10, 2016 01:06AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 10, 2016 02:08PM |

Registered: 9 years ago Posts: 1,873 |

Quote

The nozzle used for the small prints is a .25 I believe I could print smaller with a .1 nozzle. I think Jerrill used to make custom nozzles down to that size for the Ubis (Printrbot) hotend but not sure if anyone else produces 0.1mm nozzles commercially, got the impression they are hard to make.

So..., I just tried to make a nozzle. I need a larger diameter one to speed up some big prints I'm doing for my next printer, and I thought that a .8mm nozzle should be easy to drill as a first attempt. Not so much. The drill broke pretty much as soon as I started, and I only had the one. 10 more are now on their way courtesy of ebay, and in the meantime I bored out the new nozzle to 1.2 mm as that was the smallest 'normal' drill I had in the workshop. I can imagine that the 0.1mm nozzles might be a touch challenging!

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 10, 2016 02:14PM |

Registered: 9 years ago Posts: 483 |

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 10, 2016 02:15PM |

Registered: 12 years ago Posts: 2,470 |

I stopped trying to drilling anything below 0.4. The problems i had were one reason why i tried airbrush nozzles.Quote

JamesK

I can imagine that the 0.1mm nozzles might be a touch challenging!

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 10, 2016 04:47PM |

Registered: 10 years ago Posts: 580 |

Plasticwrap:

Thank you very much for taking the time to post the details that you provided!

I appreciate your observation that all the different filament brands you used could be made to print well (or at lest acceptably) given the right settings, with some minor exceptions due to defects.

I agree that experimentation and close observation are the only way to really improve.

I fully appreciate that your settings are very filament specific, and machine specific!

With that in mind: will you please provide some ballpark parameters for what you used for a given nozzle size?

This will help others understand some very basic things - as most people start out trying to print too fast, etc.

So, for a given nozzle diameter, what are your ballpark settings for:

- layer height

- perimeter width (inside, outside)

- perimeter speeds

- infill speeds and width

- nozzle temperature (using PLA)

And:

- Between different filaments, what settings do you adjust most?

- What do you look for when making the adjustments?

It's good for folks to understand that their prints will not come out the best (or even good at all) if they just use the auto settings in their slicer, unless they are exceptionally fortunate.

(Nor will your exact settings work perfectly for anyone else either, but they may be closer).

Thanks!

James:

I have purchased resharpened carbide bits from [drillcity.stores.yahoo.net] for drilling PCBs and also nozzles. (Not drillbitcity.com) These are extremely sharp.

I've been thinking of a better way to drill nozzles, as these bits are indeed very easy to break. Using in a drill press at high rpm, with the victim clamped very securely, and a very slow feed rate may help.

This looked cool, but the nozzle would need to be very securely and accurately fixed.

Alternately (for soft materials): something similar that would allow turning the bit carefully by hand, so you can feel the bite when it starts to break through. It does not take long to drill such short distances in soft materials.

For a mirror smooth finish you could drill slightly smaller, and use a micro reamer like one of these.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Thank you very much for taking the time to post the details that you provided!

I appreciate your observation that all the different filament brands you used could be made to print well (or at lest acceptably) given the right settings, with some minor exceptions due to defects.

I agree that experimentation and close observation are the only way to really improve.

I fully appreciate that your settings are very filament specific, and machine specific!

With that in mind: will you please provide some ballpark parameters for what you used for a given nozzle size?

This will help others understand some very basic things - as most people start out trying to print too fast, etc.

So, for a given nozzle diameter, what are your ballpark settings for:

- layer height

- perimeter width (inside, outside)

- perimeter speeds

- infill speeds and width

- nozzle temperature (using PLA)

And:

- Between different filaments, what settings do you adjust most?

- What do you look for when making the adjustments?

It's good for folks to understand that their prints will not come out the best (or even good at all) if they just use the auto settings in their slicer, unless they are exceptionally fortunate.

(Nor will your exact settings work perfectly for anyone else either, but they may be closer).

Thanks!

James:

I have purchased resharpened carbide bits from [drillcity.stores.yahoo.net] for drilling PCBs and also nozzles. (Not drillbitcity.com) These are extremely sharp.

I've been thinking of a better way to drill nozzles, as these bits are indeed very easy to break. Using in a drill press at high rpm, with the victim clamped very securely, and a very slow feed rate may help.

This looked cool, but the nozzle would need to be very securely and accurately fixed.

Alternately (for soft materials): something similar that would allow turning the bit carefully by hand, so you can feel the bite when it starts to break through. It does not take long to drill such short distances in soft materials.

For a mirror smooth finish you could drill slightly smaller, and use a micro reamer like one of these.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 10, 2016 06:33PM |

Registered: 9 years ago Posts: 1,873 |

Hi Paul, thanks for the suggestions. I usually do any precision drilling on the lathe and I wasn't really expecting any problems. I suspect that over-confidence was the main problem! I think the drill snapped as it broke through the face into the opposite bore, so next time I'll try drilling the nozzle first and then counter bore with the bigger drills. That might have it's own problems, but it seems worth a go.

Those micro-reamers look nice, but seem to be very expensive. I'm hoping I can get by without for now!

Srek, those airbrush nozzles are looking more appealing all the time. I really should listen to people with more experience, but I have a terrible curiosity and desire to try things out for myself!

Those micro-reamers look nice, but seem to be very expensive. I'm hoping I can get by without for now!

Srek, those airbrush nozzles are looking more appealing all the time. I really should listen to people with more experience, but I have a terrible curiosity and desire to try things out for myself!

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 11, 2016 04:17AM |

Registered: 8 years ago Posts: 3,525 |

These are amazing prints and in my opinion, the very small scale prints are a level above anything I've seen or experienced from FDM printing.

Any chance of a timelapse or something like that, I'd love to see your printer in action making such an amazingly tiny model. And I would love to try to replicate it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Any chance of a timelapse or something like that, I'd love to see your printer in action making such an amazingly tiny model. And I would love to try to replicate it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 11, 2016 06:26AM |

Registered: 12 years ago Posts: 2,470 |

I tried micro reamers as well. I got mine from a goldsmith supply and they weren't actually that expensive. Using them is something that requires more skill than i have though.Quote

JamesK

Those micro-reamers look nice, but seem to be very expensive. I'm hoping I can get by without for now!

Srek, those airbrush nozzles are looking more appealing all the time. I really should listen to people with more experience, but I have a terrible curiosity and desire to try things out for myself!

As for Airbrush, i only arrived at those after investing months in trying to drill and ream my own. Make your own experiences, regardless if it works or not, you will learn something usefull.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 11, 2016 04:27PM |

Registered: 8 years ago Posts: 3,525 |

Okay so micro-marvin is possible this one (first attempt) done with 0.3mm nozzle at 150micron layer height on the new large kossel. I suspect a 50 micron version with a 0.2mm nozzle would be comparable to yours PlasticWrap. That's next in the print queue.

My apologies if I was a little incredulous, I think that few, if any of us, have really tried printing objects this small let alone really optimised our machines for them.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

My apologies if I was a little incredulous, I think that few, if any of us, have really tried printing objects this small let alone really optimised our machines for them.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 11, 2016 09:32PM |

Registered: 8 years ago Posts: 916 |

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 16, 2016 08:02PM |

Registered: 8 years ago Posts: 4 |

@JamesK Thanks, mostly I find the time / hassle to swap nozzles is the problem. Printing the scaled down items doesn't take long as it's still a lot faster than printing a full size item with the 0.4, but I don't fancy changing the nozzle often so I just thought I'd get all the small ones I wanted to see done now. Hence why I tried to do a run of them, other hotends may have a more straightforward screw in method for the nozzles that incorporate the heat break seems like a messy change on the e3d.

@MechaBits I tried that already but the model vanished by the time I got back

@Paul Wanamaker Not sure I can really give ballpark figures as such because it varies wildly according to the model geometry. For example I seem to remember I printed the spool stands with around 80mm/s infill rate and a lower rate for the perimeters of course and with a 0.2mm layer height. With small models with lots of overhangs and complex geometries it's best to go slowly (under 30mm/s). Generally the speed needs to be balanced against the temperature and layer height, too slow or fast both cause problems. Minimum layer time can automatically adjust speeds so again best not confuse people with specifics (speed selected may not be the one used). There really is a lot of advice for new users so not sure I can add much in a few sentences. Be methodical and take notes. Don't expect great results with layer heights under 100 microns as the nozzle moves up (or at least relatively speaking) so little distance for each layer it will just melt whatever it catches as it passes back over. The flow can also get very low especially with small nozzles causing retraction issues that are hard to solve. Generally I adjust for a specific model until it comes out properly then I will reuse the settings for another filament. This is done primarily by adjusting the temperature and flow. I would monitor the retracts and overhangs until they come out properly to determine the new temperature. If you sliced with 100% flow (1.0 flow modifier) then you can just reuse the gcode and set the new temperature and flow in the gcode.

@DjDemonD Thanks, I'll have a look and see if I can upload a time lapse for you. Your little marvin looks good. The small one I did was with a 0.25 nozzle 15% scale 60 micron layer height. This was just arbitrarily decided by me because I saw the high end machines can produce marvin at 10% and under, also marvin would slice in Cura at that size without having to resort to under extrusion (closest I could get without messing about). I did see a previous thread on here with examples of printing small but I think it was after reading RichRap's blog about the DragonOff competition that I wanted to see how close I could get to the samples on that page as there were many small dragons and they looked hard to do. I think you are correct about few people trying, it looks to be the domain of high end machines and I think most people consider it too fiddly due to the number of issues that can crop up. An optimised hot end including a smaller nozzle would help greatly. The nozzle geometry i.e. size of the bore depth as well as the diameter and shoulders, melt zone size etc. will probably all have some effect on how easy it is to get a good result. You're concentrating heat in a very small area and probably spend relatively more time accelerating / decelerating, basically it seems inevitable that you will just get an indiscernible little blob of melted plastic at some point.

I didn't have any special agenda when I posted just seems like this was the best place to announce it. As I previously intimated there doesn't seem to be a very good way to benchmark machines so at least on a personal level trying to do some of those small models I got to test how well the machine was working. I may look at trying to make some resolution test objects and see if there is any discernible difference between machines assuming anyone else will print one.

@nebbian Thanks. I'll see what I can do.

Edited 1 time(s). Last edit at 10/16/2016 08:05PM by plasticWrap.

If common sense is so common then why does no one actually seem to have it. Perhaps it should be renamed uncommon sense.

blog [plasticwrap3d.wordpress.com]

@MechaBits I tried that already but the model vanished by the time I got back

@Paul Wanamaker Not sure I can really give ballpark figures as such because it varies wildly according to the model geometry. For example I seem to remember I printed the spool stands with around 80mm/s infill rate and a lower rate for the perimeters of course and with a 0.2mm layer height. With small models with lots of overhangs and complex geometries it's best to go slowly (under 30mm/s). Generally the speed needs to be balanced against the temperature and layer height, too slow or fast both cause problems. Minimum layer time can automatically adjust speeds so again best not confuse people with specifics (speed selected may not be the one used). There really is a lot of advice for new users so not sure I can add much in a few sentences. Be methodical and take notes. Don't expect great results with layer heights under 100 microns as the nozzle moves up (or at least relatively speaking) so little distance for each layer it will just melt whatever it catches as it passes back over. The flow can also get very low especially with small nozzles causing retraction issues that are hard to solve. Generally I adjust for a specific model until it comes out properly then I will reuse the settings for another filament. This is done primarily by adjusting the temperature and flow. I would monitor the retracts and overhangs until they come out properly to determine the new temperature. If you sliced with 100% flow (1.0 flow modifier) then you can just reuse the gcode and set the new temperature and flow in the gcode.

@DjDemonD Thanks, I'll have a look and see if I can upload a time lapse for you. Your little marvin looks good. The small one I did was with a 0.25 nozzle 15% scale 60 micron layer height. This was just arbitrarily decided by me because I saw the high end machines can produce marvin at 10% and under, also marvin would slice in Cura at that size without having to resort to under extrusion (closest I could get without messing about). I did see a previous thread on here with examples of printing small but I think it was after reading RichRap's blog about the DragonOff competition that I wanted to see how close I could get to the samples on that page as there were many small dragons and they looked hard to do. I think you are correct about few people trying, it looks to be the domain of high end machines and I think most people consider it too fiddly due to the number of issues that can crop up. An optimised hot end including a smaller nozzle would help greatly. The nozzle geometry i.e. size of the bore depth as well as the diameter and shoulders, melt zone size etc. will probably all have some effect on how easy it is to get a good result. You're concentrating heat in a very small area and probably spend relatively more time accelerating / decelerating, basically it seems inevitable that you will just get an indiscernible little blob of melted plastic at some point.

I didn't have any special agenda when I posted just seems like this was the best place to announce it. As I previously intimated there doesn't seem to be a very good way to benchmark machines so at least on a personal level trying to do some of those small models I got to test how well the machine was working. I may look at trying to make some resolution test objects and see if there is any discernible difference between machines assuming anyone else will print one.

@nebbian Thanks. I'll see what I can do.

Edited 1 time(s). Last edit at 10/16/2016 08:05PM by plasticWrap.

If common sense is so common then why does no one actually seem to have it. Perhaps it should be renamed uncommon sense.

blog [plasticwrap3d.wordpress.com]

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 17, 2016 06:04AM |

Registered: 7 years ago Posts: 1 |

UV LED Printer offers marketing services for UV LED technology based printing machines that can print on a variety of surfaces including 3D objects based in Singapore we provide Specially Printers and wide range of customers in South-East Asia.

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 17, 2016 07:06AM |

Registered: 8 years ago Posts: 3,525 |

PlasticWrap - don't start filming on my account, unless you want to anyway, it would look good. I was just questioning whether these really were FDM prints or whether they were resin prints and you were hoodwinking us. It is clear to me that they are not resin, you just have a very accurate printer. I think I also have a very accurate printer and I've ordered some 0.2mm nozzles to give it a try. It brings a whole new dimension to it. I agree that plenty of layer fan and slow printing will be required for these tiny objects, plus sacrificial towers to allow them time to cool. I printed the little marvin alongside another object I was printing anyway, just threw it onto slic3r to see what happened. I expected a nasty blobby mess but got a respectable micro-marvin.

Can I second Nebbian in saying thank you for opening our eyes to what these machines can do. I had just always presumed this level of accuracy is not possible, as often I (and I'm sure everyone else too) have struggled to get a nice print of a "normal" sized object let alone a micro-scale object.

I might try the marble run, I've been meaning to print one for ages, but the thought of the time/filament required to print a ""marble-sized" one has been putting me off.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Can I second Nebbian in saying thank you for opening our eyes to what these machines can do. I had just always presumed this level of accuracy is not possible, as often I (and I'm sure everyone else too) have struggled to get a nice print of a "normal" sized object let alone a micro-scale object.

I might try the marble run, I've been meaning to print one for ages, but the thought of the time/filament required to print a ""marble-sized" one has been putting me off.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 18, 2016 03:31AM |

Registered: 7 years ago Posts: 137 |

|

Re: New adventures in 3d printing (aka so I designed a 3d printer) October 18, 2016 03:51AM |

Registered: 7 years ago Posts: 137 |

I forgot to say Wow WOW! And lastly Sweet mother of God those are incredible.

Here I am thinking large scale and about my soon to be wonderful collection of helmets and masks that I've always wanted and now I'm thinking of building 2 printers one for micro prints and one for Macro prints.

You sir are an inspiration and I applaud your attention to detail.

Thanks for sharing Ryan.

Here I am thinking large scale and about my soon to be wonderful collection of helmets and masks that I've always wanted and now I'm thinking of building 2 printers one for micro prints and one for Macro prints.

You sir are an inspiration and I applaud your attention to detail.

Thanks for sharing Ryan.

Sorry, only registered users may post in this forum.