Joints/Arms for Delta

Posted by lincolnmroth

|

Joints/Arms for Delta October 09, 2016 09:37PM |

Registered: 7 years ago Posts: 2 |

|

Re: Joints/Arms for Delta October 09, 2016 09:39PM |

Registered: 9 years ago Posts: 483 |

|

Re: Joints/Arms for Delta October 10, 2016 12:43AM |

Registered: 8 years ago Posts: 916 |

Traxxas 5347 work well for me.

Buy 2 dozen, and pick the 12 that have the least slop once assembled.

Instructions on how to assemble, with pictures, are halfway down this page:

[forums.reprap.org]

Other options exist (magnetic balls, non-magnetic balls, bearings), but the Traxxas 6347 are the easiest to get working in my opinion.

Buy 2 dozen, and pick the 12 that have the least slop once assembled.

Instructions on how to assemble, with pictures, are halfway down this page:

[forums.reprap.org]

Other options exist (magnetic balls, non-magnetic balls, bearings), but the Traxxas 6347 are the easiest to get working in my opinion.

|

Re: Joints/Arms for Delta October 10, 2016 12:59AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Joints/Arms for Delta October 10, 2016 05:16AM |

Registered: 8 years ago Posts: 3,525 |

The magnetic balls that are on Aliexpress at the moment in large number do work and are zero backlash, but as I have found out the magnets on the effector need to be angled at 30-45 deg rather than lying flat. Plus you need to get your jerk values right or the sudden direction changes pull the balls away from the magnets.

I've got traxxas joints on my mini kossel and they've been pretty good.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I've got traxxas joints on my mini kossel and they've been pretty good.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Joints/Arms for Delta October 10, 2016 06:35AM |

Registered: 8 years ago Posts: 1,671 |

I've been wracking my brain on where magnets could be used and nothing yet seems to stand up to closer scrutiny, either sliding or effecting other parts, a metal part embedded in pla and a real magnet would probably be stonger... but a simple plastic rod end probably works much better.. has anyone seen a delta using metal rod ends?

Edited 1 time(s). Last edit at 10/10/2016 06:35AM by MechaBits.

Edited 1 time(s). Last edit at 10/10/2016 06:35AM by MechaBits.

|

Re: Joints/Arms for Delta October 10, 2016 08:34AM |

Registered: 10 years ago Posts: 14,672 |

A lot of people use magnets embedded in the plastic rod ends and mount the magnetic balls on the effector and carriages.You can buy ready-made rods with matching balls, see this thread on the Google deltabot group [groups.google.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Joints/Arms for Delta October 10, 2016 01:48PM |

Registered: 9 years ago Posts: 483 |

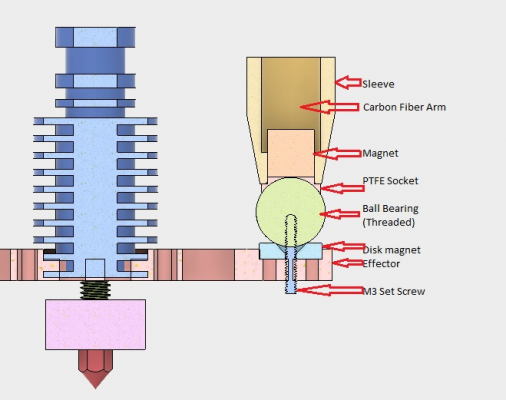

This is what I'm using now:

You'll probably need a lathe to fabricate it.

You'll probably need a lathe to fabricate it.

|

Re: Joints/Arms for Delta October 10, 2016 09:07PM |

Registered: 8 years ago Posts: 916 |

Quote

MechaBits

I've been wracking my brain on where magnets could be used and nothing yet seems to stand up to closer scrutiny, either sliding or effecting other parts, a metal part embedded in pla and a real magnet would probably be stonger... but a simple plastic rod end probably works much better.. has anyone seen a delta using metal rod ends?

Yes, I have one

One of my deltas uses metal rod ends, the other uses the plastic Traxxas rod ends.

One of my deltas uses metal rod ends, the other uses the plastic Traxxas rod ends.I'm not convinced that it's actually metal on metal, I think there might be a plastic sleeve between the two. However both parts (the ball, and the cup) are metal. One or two of these joints has developed a bit of slop over time. I don't think that metal rod ends have any advantage over plastic with the loads that we see.

Sorry, only registered users may post in this forum.