Custom CoreXY - -Linear Rail Vibration

Posted by makerparts

|

Re: Custom CoreXY - -Linear Rail Vibration October 16, 2016 01:26PM |

Registered: 7 years ago Posts: 321 |

What limits most printers is how heavy the X / Y carriages are (older Prusas, mendel 90 etc).

Microsteps just smooth things out. You could use a supercomputer to calculate the microsteps, but if the motor ain't got the torque to move the carriage, it won't budge past a certain point.

CoreXY machine with aluminium MGN12 rails rather than steel smooth rods? WHY????

I suspect the OPs rails are not as "smooth" as "smooth" rails should be, which would explain the behaviour, but using rails like like on a Corexy just strikes me as impractical.

Either get them repolished or replaced. Rails are not good on CoreXY, they flex way too easily for high accelerations and loads. They make sense on Deltas, because they don't move on Deltas.

Edited 2 time(s). Last edit at 10/16/2016 01:40PM by DragonFire.

Microsteps just smooth things out. You could use a supercomputer to calculate the microsteps, but if the motor ain't got the torque to move the carriage, it won't budge past a certain point.

CoreXY machine with aluminium MGN12 rails rather than steel smooth rods? WHY????

I suspect the OPs rails are not as "smooth" as "smooth" rails should be, which would explain the behaviour, but using rails like like on a Corexy just strikes me as impractical.

Either get them repolished or replaced. Rails are not good on CoreXY, they flex way too easily for high accelerations and loads. They make sense on Deltas, because they don't move on Deltas.

Edited 2 time(s). Last edit at 10/16/2016 01:40PM by DragonFire.

|

Re: Custom CoreXY - -Linear Rail Vibration October 16, 2016 05:34PM |

Registered: 7 years ago Posts: 28 |

@DragonFire

You'd need a very thick smooth rod to make a large machine. Alu extrusions are light and load bearing enough and a MGN12 allows for a single rail in stead of dual smooth rod for X axis.

Pretty much all larger printers use Aluminium support + MGN12 for that reason.. AFAIK.

edit: While one could use giant smooth rods, prints would take a long time for a large printer, hence the use of having a light moving part.

Edited 3 time(s). Last edit at 10/17/2016 10:56AM by orea.

You'd need a very thick smooth rod to make a large machine. Alu extrusions are light and load bearing enough and a MGN12 allows for a single rail in stead of dual smooth rod for X axis.

Pretty much all larger printers use Aluminium support + MGN12 for that reason.. AFAIK.

edit: While one could use giant smooth rods, prints would take a long time for a large printer, hence the use of having a light moving part.

Edited 3 time(s). Last edit at 10/17/2016 10:56AM by orea.

|

Re: Custom CoreXY - -Linear Rail Vibration October 16, 2016 07:55PM |

Registered: 7 years ago Posts: 321 |

Sorry, don't follow your logic at all.

If you mean a cheap aluminium MGN12 is easier to maneuver with tiny stepper motors, and a steel MGN12 or solid rod is going to stall a tiny stepper motor quicker, that's true.

If you mean a steel MGN12 or steel smooth rod cannot support the load stresses better than a moving, reasonating MGN12 made out of aluminium, then most "large machines" will self destruct with stepper motors equipped to punch them at big torque... because MGN12s made out of aluminium will not take as much load force as steel MGN12s or steel smooth rods.

I thought the aim was a moving rail at max acceleration without destroying it... especially on a large machine. Steel beets aluminium, carbon fibre beats steel... There are better materials for tensile strength than that, but it's not easy to get them smooth.

Edited 2 time(s). Last edit at 10/16/2016 08:10PM by DragonFire.

If you mean a cheap aluminium MGN12 is easier to maneuver with tiny stepper motors, and a steel MGN12 or solid rod is going to stall a tiny stepper motor quicker, that's true.

If you mean a steel MGN12 or steel smooth rod cannot support the load stresses better than a moving, reasonating MGN12 made out of aluminium, then most "large machines" will self destruct with stepper motors equipped to punch them at big torque... because MGN12s made out of aluminium will not take as much load force as steel MGN12s or steel smooth rods.

I thought the aim was a moving rail at max acceleration without destroying it... especially on a large machine. Steel beets aluminium, carbon fibre beats steel... There are better materials for tensile strength than that, but it's not easy to get them smooth.

Edited 2 time(s). Last edit at 10/16/2016 08:10PM by DragonFire.

|

Re: Custom CoreXY - -Linear Rail Vibration October 17, 2016 06:02AM |

Registered: 7 years ago Posts: 28 |

As you asked "CoreXY machine with aluminium MGN12 rails rather than steel smooth rods? WHY????" I replied as to why use MGN12+support rather than dual smooth rods. As for alu VS steel, OP didn't say anything about his MGN12 being aluminium, AFAIK they are all steel (a quick search gave your post as first result  ) Anyhow, OP can chime in on this..

) Anyhow, OP can chime in on this..

Edited 5 time(s). Last edit at 10/17/2016 07:50AM by orea.

) Anyhow, OP can chime in on this..

) Anyhow, OP can chime in on this..Edited 5 time(s). Last edit at 10/17/2016 07:50AM by orea.

|

Re: Custom CoreXY - -Linear Rail Vibration October 17, 2016 08:18AM |

Registered: 8 years ago Posts: 112 |

Never heard of alum mgn12 before. For my machine I run dual mgn12 stainless rails on x and y. It ads weight but for my setup it's much more convieient

Makerparts.ca

Your Canadian source for V-Slot Extrusion, CNC and 3D Printing Parts and Accessories.

we are proud to be an official Openbuilds distributor.

Makerparts.ca

Your Canadian source for V-Slot Extrusion, CNC and 3D Printing Parts and Accessories.

we are proud to be an official Openbuilds distributor.

|

Re: Custom CoreXY - -Linear Rail Vibration October 17, 2016 10:06AM |

Registered: 11 years ago Posts: 5,780 |

Wow! This is like watching people argue about whether fairies or unicorns have stronger magical powers. I'm just about 99.9% sure that there is no such thing as an aluminum MGN12, and no one mentioned them until DragonFire did. If anyone has seen them somewhere, please provide a link.

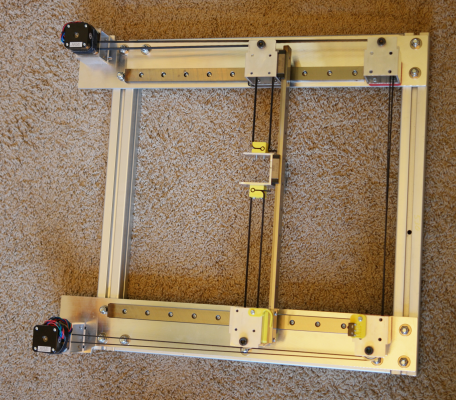

You can move almost any size of linear guide (steel or even the mythical aluminum type) with a small motor. You just have to adjust your expectations for speed and acceleration accordingly. I built a 300 mm square CoreXY mechanism using 24 mm wide linear guides (steel, not aluminum) for X and Y and it moves along just fine with two small, 64 oz-in, NEMA-17 motors:

First test

drawbot

Linear guides are used because they are almost perfect. You won't find better bearings for use in a 3D printer, and if the rest of the machine is built with the same sort of quality, your printer will be capable of producing very high quality prints. Yes, they cost more than end supported round rails, but there are ways to get them cheaply. I buy used Japanese made linear guides via ebay. If you search among the 20 pages of listings there are always a few deals. I don't go looking for any specific size, just minimum length. I can use any size guide and cut the rail to the length I need. I buy whatever I can get cheaply and then design around it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can move almost any size of linear guide (steel or even the mythical aluminum type) with a small motor. You just have to adjust your expectations for speed and acceleration accordingly. I built a 300 mm square CoreXY mechanism using 24 mm wide linear guides (steel, not aluminum) for X and Y and it moves along just fine with two small, 64 oz-in, NEMA-17 motors:

First test

drawbot

Linear guides are used because they are almost perfect. You won't find better bearings for use in a 3D printer, and if the rest of the machine is built with the same sort of quality, your printer will be capable of producing very high quality prints. Yes, they cost more than end supported round rails, but there are ways to get them cheaply. I buy used Japanese made linear guides via ebay. If you search among the 20 pages of listings there are always a few deals. I don't go looking for any specific size, just minimum length. I can use any size guide and cut the rail to the length I need. I buy whatever I can get cheaply and then design around it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Custom CoreXY - -Linear Rail Vibration October 18, 2016 04:34PM |

Registered: 10 years ago Posts: 756 |

Hi

I'm following your progresses and work since a while, and I learned a lot on core xy, thank you!.

One question: isn't it a little bit noisy? especially in terms of motor controls?

Are you evaluating silent step stick TMC2100 or similar? thank you for commenting on this!

Disclaimer: io ce la metto tutta a darti consigli sensati, sta a te non incendiare nulla :-)

CoreXY HyperCube. [www.thingiverse.com] | Cerchi test? Make: test set: [www.thingiverse.com]

I'm following your progresses and work since a while, and I learned a lot on core xy, thank you!.

One question: isn't it a little bit noisy? especially in terms of motor controls?

Are you evaluating silent step stick TMC2100 or similar? thank you for commenting on this!

Disclaimer: io ce la metto tutta a darti consigli sensati, sta a te non incendiare nulla :-)

CoreXY HyperCube. [www.thingiverse.com] | Cerchi test? Make: test set: [www.thingiverse.com]

|

Re: Custom CoreXY - -Linear Rail Vibration October 19, 2016 12:47PM |

Registered: 11 years ago Posts: 5,780 |

No, it's running with a smoothieboard at 16:1 ustepping. I don't like using modular drivers unless they are the DSP based pseudo-industrial type that can handle higher voltage and current. I think part of the sound is coming from the plastic cart top that the mechanism is sitting on, and I had the mic sensitivity up on the camera when I shot video. It really isn't very loud at all, especially when compared to my other printer, SoM, that uses a NEMA-23 motor to drive the Y axis with a ball screw.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Custom CoreXY - -Linear Rail Vibration October 19, 2016 12:56PM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

No, it's running with a smoothieboard at 16:1 ustepping. I don't like using modular drivers unless they are the DSP based pseudo-industrial type that can handle higher voltage and current. I think part of the sound is coming from the plastic cart top that the mechanism is sitting on, and I had the mic sensitivity up on the camera when I shot video. It really isn't very loud at all, especially when compared to my other printer, SoM, that uses a NEMA-23 motor to drive the Y axis with a ball screw.

Having listened to the video, I can tell you that it would be much quieter it it were controlled by a Duet WiFi with 256x microstepping!

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Custom CoreXY - -Linear Rail Vibration October 19, 2016 02:00PM |

Registered: 7 years ago Posts: 321 |

Quote

orea

AFAIK they are all steel (a quick search gave your post as first result) Anyhow, OP can chime in on this..

Let's put it this way - a lot of MGN12s are advertised as being made out of "metal".

What metal you get... is totally out of the buyer's control, in such cases.

Edited 1 time(s). Last edit at 10/19/2016 02:37PM by DragonFire.

Sorry, only registered users may post in this forum.