New technique for ABS adhesion!

Posted by ECJ

|

New technique for ABS adhesion! October 15, 2016 09:30PM |

Registered: 7 years ago Posts: 65 |

(The following was translated from Portuguese by Google Translator)

Among all experienced to date (no small feat), which I will now describe was what brought me the best result!

It is coated on the table (glass surface or aluminum) with a laser printer transparency! Let the procedure:

The first important point is to have the flat face, namely, the untreated part, not intended for toner printing, the transparency facing up. This face is that is in contact with the extruded material.

Second, you need to paste the other side on the table surface. It is important that there are no compliance failures. The whole area of transparency should be well adhered without bubbles. For this there are two methods. The simplest is to apply double-sided tape on the table and then apply transparency. The other way, I used, is spread acrylic adhesive (permanent glue Acrilex) on the table with the help of a brush, wait for the glue to dry completely and then apply transparency on the table. This glue is very resistant to high temperatures and provides a great result in terms of adhesion.

Finally, it is important that the surface of the transparency that will receive the extruded material is cleaned and degreased. To clean you can use a damp cloth. And to degrease recommend a small cotton ball soaked with a little acetone or isopropyl alcohol.

The result of the prints is amazing! I hope that experience and to post the results here.

I will be on hand to answer any questions.

Among all experienced to date (no small feat), which I will now describe was what brought me the best result!

It is coated on the table (glass surface or aluminum) with a laser printer transparency! Let the procedure:

The first important point is to have the flat face, namely, the untreated part, not intended for toner printing, the transparency facing up. This face is that is in contact with the extruded material.

Second, you need to paste the other side on the table surface. It is important that there are no compliance failures. The whole area of transparency should be well adhered without bubbles. For this there are two methods. The simplest is to apply double-sided tape on the table and then apply transparency. The other way, I used, is spread acrylic adhesive (permanent glue Acrilex) on the table with the help of a brush, wait for the glue to dry completely and then apply transparency on the table. This glue is very resistant to high temperatures and provides a great result in terms of adhesion.

Finally, it is important that the surface of the transparency that will receive the extruded material is cleaned and degreased. To clean you can use a damp cloth. And to degrease recommend a small cotton ball soaked with a little acetone or isopropyl alcohol.

The result of the prints is amazing! I hope that experience and to post the results here.

I will be on hand to answer any questions.

|

Re: New technique for ABS adhesion! October 16, 2016 03:57AM |

Registered: 8 years ago Posts: 5,232 |

If I understand the translation well, you are using laser printable transparent foil. It will not shrink, because it is heat resistant. Clever!

I'm wondering, how well it works when you've printed and removed a few ABS parts. Will it rip off partially or can you replace it when necessary?

I'm wondering, how well it works when you've printed and removed a few ABS parts. Will it rip off partially or can you replace it when necessary?

|

Re: New technique for ABS adhesion! October 16, 2016 06:56AM |

Registered: 7 years ago Posts: 65 |

Yes, laser printable transparent foil. I believe that is made of polyester, and not deform with heat. Already printed several pieces, but do not usually print very large pieces. The maximum until now was 50 x 40 x 30mm. No brim and adherence is excellent! Seems to be a good compatibility, as this material is precisely designed to provide good toner adhesion. Printed parts easily loosen when cold.

So far I did not notice any damage to the laser foil. But it is certainly easy to replace. The glue residue may be easily cleaned with acetone.

I wonder what would happen with large pieces. I do not want to waste materials making a piece that i does not need.

So far I did not notice any damage to the laser foil. But it is certainly easy to replace. The glue residue may be easily cleaned with acetone.

I wonder what would happen with large pieces. I do not want to waste materials making a piece that i does not need.

|

Re: New technique for ABS adhesion! October 17, 2016 06:18AM |

Registered: 7 years ago Posts: 65 |

|

Re: New technique for ABS adhesion! October 17, 2016 10:35AM |

Registered: 8 years ago Posts: 3,525 |

I think it is worth some consideration sure, but there are removable/replaceable printing surfaces on the market which are affordable i.e. kapton. However there are things like Printbite, which though it might cost £20-£40 it works, and is permanent and extremely durable, I have a piece now in its 2nd year of printing.

I personally, since I use printbite for all three printers, with great satisfaction, see no merit in a replacement for kapton tape which is also a sheet of adhesive backed polymer that can be applied, printed on, and then replaced when it gets damaged which it will. It's not how cheap a surface is that matters, its does it provide good but not too much adhesion and how much hassle and time is involved in replacing it (and how often). This is why gluestick/painters tape/kapton/hairspray are IMHO all ridiculous - they are messy and time consuming, so no matter how well they work unless you only print one object a year the time involved in replacing them is worth on aggregate much more to you than the cost of a sheet of printbite.

Full disclosure - I have no financial interest in Printbite, I just rate it highly, and wish to support Mutley 3D who makes and sells it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I personally, since I use printbite for all three printers, with great satisfaction, see no merit in a replacement for kapton tape which is also a sheet of adhesive backed polymer that can be applied, printed on, and then replaced when it gets damaged which it will. It's not how cheap a surface is that matters, its does it provide good but not too much adhesion and how much hassle and time is involved in replacing it (and how often). This is why gluestick/painters tape/kapton/hairspray are IMHO all ridiculous - they are messy and time consuming, so no matter how well they work unless you only print one object a year the time involved in replacing them is worth on aggregate much more to you than the cost of a sheet of printbite.

Full disclosure - I have no financial interest in Printbite, I just rate it highly, and wish to support Mutley 3D who makes and sells it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: New technique for ABS adhesion! October 17, 2016 10:47AM |

Registered: 11 years ago Posts: 5,780 |

I'll test it when I find a suitable adhesive...

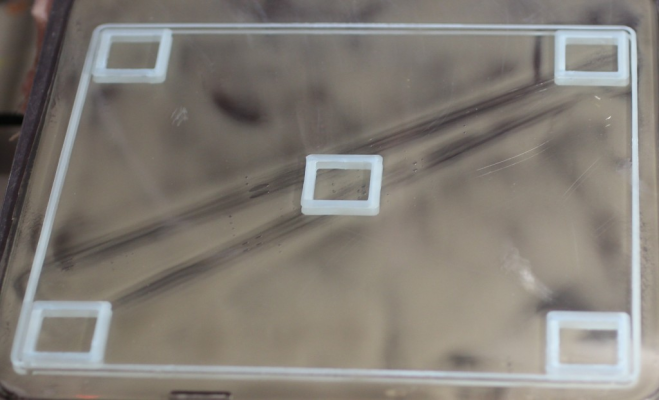

Since it is a plastic, it might be possible to use an electrostatic hold-down for it and eliminate the adhesive completely. I recently did an experiment with that for holding paper, but it should work fine for plastic, too. The electrostatic hold down is simple- I placed foil tape in an interdigitated finger pattern on one side of a piece of thin acrylic. I connected a HV DC supply to the two foil traces and paper stuck to the opposite side of the acrylic perfectly. For the next step I want to etch a single sided PCB. If you clamped such a hold-down on the print bed you could use it to hold the plastic film down while printing then release it when the print is finished. No scraping/prying. Just peel the plastic off the print and reuse or throw it away, depending on its condition when you remove it from the print.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Since it is a plastic, it might be possible to use an electrostatic hold-down for it and eliminate the adhesive completely. I recently did an experiment with that for holding paper, but it should work fine for plastic, too. The electrostatic hold down is simple- I placed foil tape in an interdigitated finger pattern on one side of a piece of thin acrylic. I connected a HV DC supply to the two foil traces and paper stuck to the opposite side of the acrylic perfectly. For the next step I want to etch a single sided PCB. If you clamped such a hold-down on the print bed you could use it to hold the plastic film down while printing then release it when the print is finished. No scraping/prying. Just peel the plastic off the print and reuse or throw it away, depending on its condition when you remove it from the print.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New technique for ABS adhesion! October 17, 2016 11:20AM |

Registered: 7 years ago Posts: 65 |

Quote

DjDemonD

I think it is worth some consideration sure, but there are removable/replaceable printing surfaces on the market which are affordable i.e. kapton. However there are things like Printbite, which though it might cost £20-£40 it works, and is permanent and extremely durable, I have a piece now in its 2nd year of printing.

I personally, since I use printbite for all three printers, with great satisfaction, see no merit in a replacement for kapton tape which is also a sheet of adhesive backed polymer that can be applied, printed on, and then replaced when it gets damaged which it will. It's not how cheap a surface is that matters, its does it provide good but not too much adhesion and how much hassle and time is involved in replacing it (and how often). This is why gluestick/painters tape/kapton/hairspray are IMHO all ridiculous - they are messy and time consuming, so no matter how well they work unless you only print one object a year the time involved in replacing them is worth on aggregate much more to you than the cost of a sheet of printbite.

Full disclosure - I have no financial interest in Printbite, I just rate it highly, and wish to support Mutley 3D who makes and sells it.

Here in Brazil an A4 sheet of transparency laser costs only $ 0.3. With it is possible to cover the entire table (200x200) "no divisions". And I believe that the durability is much larger than the kapton tape because I am using for eight days without any apparent damage. So I believe it is advantageous yes!

Quote

the_digital_dentist

I'll test it when I find a suitable adhesive...

Since it is a plastic, it might be possible to use an electrostatic hold-down for it and eliminate the adhesive completely. I recently did an experiment with that for holding paper, but it should work fine for plastic, too. The electrostatic hold down is simple- I placed foil tape in an interdigitated finger pattern on one side of a piece of thin acrylic. I connected a HV DC supply to the two foil traces and paper stuck to the opposite side of the acrylic perfectly. For the next step I want to etch a single sided PCB. If you clamped such a hold-down on the print bed you could use it to hold the plastic film down while printing then release it when the print is finished. No scraping/prying. Just peel the plastic off the print and reuse or throw it away, depending on its condition when you remove it from the print.

I am electronics technician and found it very interesting! You have created a topic to discuss this issue?

I believe that the best adhesive to attach the film on the table is "water based acrylic adhesive." Here it is very easy to find in hardware stores for sewing. Widely used for tissue fixation.

Edited 1 time(s). Last edit at 10/17/2016 11:21AM by ECJ.

|

Re: New technique for ABS adhesion! October 17, 2016 11:31AM |

Registered: 7 years ago Posts: 65 |

|

Re: New technique for ABS adhesion! November 11, 2016 12:43AM |

Registered: 9 years ago Posts: 53 |

|

Re: New technique for ABS adhesion! November 11, 2016 08:05AM |

Registered: 7 years ago Posts: 321 |

|

Re: New technique for ABS adhesion! November 11, 2016 08:31AM |

Registered: 7 years ago Posts: 65 |

Quote

to-the-nth

@ECJ can you post a link to the type of transparency you are using?

[www.lojafilipaper.com.br]

|

Re: New technique for ABS adhesion! November 11, 2016 10:20AM |

Registered: 9 years ago Posts: 1,873 |

I tried it, but the transparencies I had to hand were of unknown type and origin. The part stuck too well and I had difficulty getting it off, damaging the transparency in the process. I tried to get a box of transparencies from Staples but couldn't find any! Once I do track some down I'll give it another go. They are a lot thicker than the typical kapton tape, so I'm hopeful it will last longer. I need something for when I get the new printer going, and kapton, pei or printbrite would all be rather expensive for the roughly 650x300mm bed that I'm aiming for.

|

Re: New technique for ABS adhesion! November 11, 2016 10:34AM |

Registered: 7 years ago Posts: 65 |

Quote

JamesK

I tried it, but the transparencies I had to hand were of unknown type and origin. The part stuck too well and I had difficulty getting it off, damaging the transparency in the process. I tried to get a box of transparencies from Staples but couldn't find any! Once I do track some down I'll give it another go. They are a lot thicker than the typical kapton tape, so I'm hopeful it will last longer. I need something for when I get the new printer going, and kapton, pei or printbrite would all be rather expensive for the roughly 650x300mm bed that I'm aiming for.

Here in Brazil is very easy to find transparency of various brands in any stationary store. Beyond the laser transparency, there are also special for xerox (photocopiers) that should give good result.

As for durability, I'm still using the first to put on the table (about 40 days) without apparent damage!

Large pieces loose a little around the edges, so I spread ABS paste (ABS diluted in acetone 100%) and is perfect!

|

Re: New technique for ABS adhesion! November 11, 2016 10:37AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: New technique for ABS adhesion! November 11, 2016 10:43AM |

Registered: 7 years ago Posts: 65 |

|

Re: New technique for ABS adhesion! November 11, 2016 10:55AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: New technique for ABS adhesion! November 24, 2016 06:29AM |

Registered: 7 years ago Posts: 65 |

|

Re: New technique for ABS adhesion! November 24, 2016 07:24AM |

Registered: 9 years ago Posts: 1,873 |

Quote

ECJ

It did not arrive yet? Or were the tests a failure?

Hasn't arrived yet. Theoretically due in the next few days, but the seller has left ebay so there's the possibility that it's not actually coming and I'll have to go through the refund process once it's officially late

I've had a bit of a run of bad luck with ebay and alliexpress recently. So far I've had everything refunded that needed to be, but the delay of several weeks between ordering and being in a position to re-order is getting a bit stale. The down-side to cheap prices.

I've had a bit of a run of bad luck with ebay and alliexpress recently. So far I've had everything refunded that needed to be, but the delay of several weeks between ordering and being in a position to re-order is getting a bit stale. The down-side to cheap prices.

|

Re: New technique for ABS adhesion! November 28, 2016 01:52PM |

Registered: 7 years ago Posts: 2 |

I might have some of this stuff. I'll have to look.

Something I just hit on, quite by accident: I was smearing purple glue on my glass build plate, but was very unhappy with the slop. In washing it off, I realized that it was becoming slightly foamy. I completely washed it off and re-applied, then added a little bit of water and used a squeegee to push the resulting purple juice across the glass a couple of times. The result was a very thin, very fine sticky layer of glue. I'm sending an ABS print to it now and it adhered quite well. This is a very flat part of a case (occupies >70% of the bed), so it will be interesting to see what the result will be.

Something I just hit on, quite by accident: I was smearing purple glue on my glass build plate, but was very unhappy with the slop. In washing it off, I realized that it was becoming slightly foamy. I completely washed it off and re-applied, then added a little bit of water and used a squeegee to push the resulting purple juice across the glass a couple of times. The result was a very thin, very fine sticky layer of glue. I'm sending an ABS print to it now and it adhered quite well. This is a very flat part of a case (occupies >70% of the bed), so it will be interesting to see what the result will be.

|

Re: New technique for ABS adhesion! November 28, 2016 06:31PM |

Registered: 7 years ago Posts: 2 |

Update on purple glue stick + water + squeegee: The very large, flat case part I printed stuck perfectly to the glass bed. I tried placing the glass build plate and piece in to the freezer. This resulted in most of the part successfully separating - but the part took a large chunk of glass with it! So, this solution is, as far as I'm concerned, very effective. Whether or not I will continue to use this glass plate again, I'm not so sure. Heating would be uneven and that would result in stresses I won't see until it is too late.

|

Re: New technique for ABS adhesion! December 21, 2016 12:09PM |

Registered: 9 years ago Posts: 1,873 |

Finally got my hands on some transparencies, but sadly not the right glue. I'm working my way through the glues I have available to see if anything works. The first one definitely didn't, but held together long enough to do some experiments with pla. It seems quite promising:

I had to increase bed and first layer temperatures a little over what I normally use, 70 bed/230 hotend compared to 65/210, but adhesion seemed to kick in pretty well at that point. When I tried with abs I didn't get any adhesion at 70 bed, and the glue let go at 90, so I've prepped a second sheet with the next glue. The problem seems to be that many glues won't set once they are sealed between the glass and the transparency sheet.

I had to increase bed and first layer temperatures a little over what I normally use, 70 bed/230 hotend compared to 65/210, but adhesion seemed to kick in pretty well at that point. When I tried with abs I didn't get any adhesion at 70 bed, and the glue let go at 90, so I've prepped a second sheet with the next glue. The problem seems to be that many glues won't set once they are sealed between the glass and the transparency sheet.

|

Re: New technique for ABS adhesion! December 22, 2016 06:30AM |

Registered: 7 years ago Posts: 65 |

Sorry I have not updated before, but the only thing that really works is resin or epoxy glue! The epoxy supports the high temperature and has anaerobic cure.

You will need to do this over glass, as if applying the epoxy directly on the aluminum, you could not remove without damaging your bed!

Apply the epoxy over the glass and over the film. Attach the parts and remove all bubbles and excess epoxy with the help of a plastic spatula to avoid damaging the surface of the film. Instead, tape the edges of the bed so that excess epoxy does not fall into your printer.

The glue or resin should be slowly curing, which can then be accelerated by keeping the bed heated at 70 ° C for about 1 hour.

I fixed my film with resin and currently use ABS with 120ºC in the first layer. For slightly larger pieces, I also apply ABS paste (ABS dissolved in 100% pure acetone or methyl methacrylate).

http://www.ebay.com/sch/i.html?_odkw=epoxy+resin&_osacat=0&_from=R40&_trksid=p2045573.m570.l1313.TR9.TRC2.A0.H0.Xepoxy+glue.TRS0&_nkw=epoxy+glue&_sacat=0

You will need to do this over glass, as if applying the epoxy directly on the aluminum, you could not remove without damaging your bed!

Apply the epoxy over the glass and over the film. Attach the parts and remove all bubbles and excess epoxy with the help of a plastic spatula to avoid damaging the surface of the film. Instead, tape the edges of the bed so that excess epoxy does not fall into your printer.

The glue or resin should be slowly curing, which can then be accelerated by keeping the bed heated at 70 ° C for about 1 hour.

I fixed my film with resin and currently use ABS with 120ºC in the first layer. For slightly larger pieces, I also apply ABS paste (ABS dissolved in 100% pure acetone or methyl methacrylate).

http://www.ebay.com/sch/i.html?_odkw=epoxy+resin&_osacat=0&_from=R40&_trksid=p2045573.m570.l1313.TR9.TRC2.A0.H0.Xepoxy+glue.TRS0&_nkw=epoxy+glue&_sacat=0

|

Re: New technique for ABS adhesion! December 22, 2016 09:43AM |

Registered: 9 years ago Posts: 1,873 |

I was thinking the two part epoxies would be the glue of last resort  It's a conundrum - I don't really want to put glass over the aluminum bed of the next printer because of the weight, cost of getting custom size glass, poor thermal conductivity, risk of breakage and the fact that it would otherwise be unnecessary, but at the same time I need to be able to replace the printing surface when it wears out. Compared to glue stick, the surface finish of the first layer using transparencies is so much nicer I'm quite keen to find a way of using it if I can! I'll try a few more things and see where I get to.

It's a conundrum - I don't really want to put glass over the aluminum bed of the next printer because of the weight, cost of getting custom size glass, poor thermal conductivity, risk of breakage and the fact that it would otherwise be unnecessary, but at the same time I need to be able to replace the printing surface when it wears out. Compared to glue stick, the surface finish of the first layer using transparencies is so much nicer I'm quite keen to find a way of using it if I can! I'll try a few more things and see where I get to.

It's a conundrum - I don't really want to put glass over the aluminum bed of the next printer because of the weight, cost of getting custom size glass, poor thermal conductivity, risk of breakage and the fact that it would otherwise be unnecessary, but at the same time I need to be able to replace the printing surface when it wears out. Compared to glue stick, the surface finish of the first layer using transparencies is so much nicer I'm quite keen to find a way of using it if I can! I'll try a few more things and see where I get to.

It's a conundrum - I don't really want to put glass over the aluminum bed of the next printer because of the weight, cost of getting custom size glass, poor thermal conductivity, risk of breakage and the fact that it would otherwise be unnecessary, but at the same time I need to be able to replace the printing surface when it wears out. Compared to glue stick, the surface finish of the first layer using transparencies is so much nicer I'm quite keen to find a way of using it if I can! I'll try a few more things and see where I get to.

|

Re: New technique for ABS adhesion! December 22, 2016 10:54AM |

Registered: 8 years ago Posts: 916 |

|

Re: New technique for ABS adhesion! December 22, 2016 10:58AM |

Registered: 7 years ago Posts: 65 |

I partially solved the weight problem using a 1.5mm glass and put a more powerful stepper motor on the Y-axis.

Other types of glue do not give good results because the adhesion of the film must be rigid and firm. Otherwise the adhesion will not last long and you will have difficulty removing the printed part. That's what happened to me in relation to the acrylic glue, which lasted only 2 months and I had to replace the film, still good. The flexibility of the acrylic glue causes the film to follow the movement and the retraction of the parts, which makes it difficult to remove them. This is not the case with epoxy resin.

I do not see a glue option that can be as rigid, firm and temperature resistant as epoxy and is easier to remove. But epoxy can be removed with acetone. Maybe pour acetone over the residue of glue, put a plastic film on top and leave it for a few minutes to soften the epoxy, and thus be able to remove without scratching the aluminum. Soon I will test with piece of aluminum.

Other types of glue do not give good results because the adhesion of the film must be rigid and firm. Otherwise the adhesion will not last long and you will have difficulty removing the printed part. That's what happened to me in relation to the acrylic glue, which lasted only 2 months and I had to replace the film, still good. The flexibility of the acrylic glue causes the film to follow the movement and the retraction of the parts, which makes it difficult to remove them. This is not the case with epoxy resin.

I do not see a glue option that can be as rigid, firm and temperature resistant as epoxy and is easier to remove. But epoxy can be removed with acetone. Maybe pour acetone over the residue of glue, put a plastic film on top and leave it for a few minutes to soften the epoxy, and thus be able to remove without scratching the aluminum. Soon I will test with piece of aluminum.

|

Re: New technique for ABS adhesion! December 22, 2016 11:03AM |

Registered: 7 years ago Posts: 65 |

Quote

nebbian

Have you considered 3M 468MP tape?

It works well to stick PEI to aluminium. It really sticks well. You can remove it, although it takes a scraper, half an hour, and lots of acetone.

This adhesive is the base of acrylic glue. I've tested it and the result is well below epoxy. As I said, it makes it difficult to remove the parts, and the movement of removing the parts does not last long.

|

Re: New technique for ABS adhesion! December 22, 2016 06:02PM |

Registered: 9 years ago Posts: 1,873 |

Did a few more tests today. ABS adhered well enough to pull the transparency off the glass again, so on to another glue...

Petg seems to work really well on this surface, and since it doesn't shrink much it's less inclined to rip the sheet off the glass. On the other hand, I couldn't get enough adhesion with nylon to stop it from curling away from the bed. I suspect nylon will need an extra treatment on top of the transparency which is a shame.

Petg seems to work really well on this surface, and since it doesn't shrink much it's less inclined to rip the sheet off the glass. On the other hand, I couldn't get enough adhesion with nylon to stop it from curling away from the bed. I suspect nylon will need an extra treatment on top of the transparency which is a shame.

|

Re: New technique for ABS adhesion! December 22, 2016 08:23PM |

Registered: 10 years ago Posts: 564 |

Has anyone tried adhesive-backed polyester film from McMaster (https://www.mcmaster.com/#8689K42)?

|

Re: New technique for ABS adhesion! December 22, 2016 08:32PM |

Registered: 7 years ago Posts: 65 |

Quote

LoboCNC

Has anyone tried adhesive-backed polyester film from McMaster (https://www.mcmaster.com/#8689K42)?

In the description says it's PET. I already tested PET film and the result is not good. The adhesion of ABS to PET is worse than that of glass.

|

Re: New technique for ABS adhesion! December 22, 2016 10:45PM |

Registered: 10 years ago Posts: 564 |

Quote

ECJ

Quote

LoboCNC

Has anyone tried adhesive-backed polyester film from McMaster (https://www.mcmaster.com/#8689K42)?

In the description says it's PET. I already tested PET film and the result is not good. The adhesion of ABS to PET is worse than that of glass.

Do you know what type of polyester is in the transparency film you are using? 3M transparencies claim to be made of PET. Maybe a different formulation?

Sorry, only registered users may post in this forum.