Filament Monitor.

Posted by Rlewisrlou666

|

Filament Monitor. October 22, 2016 04:42PM |

Registered: 7 years ago Posts: 137 |

|

Re: Filament Monitor. October 22, 2016 06:56PM |

Registered: 11 years ago Posts: 5,780 |

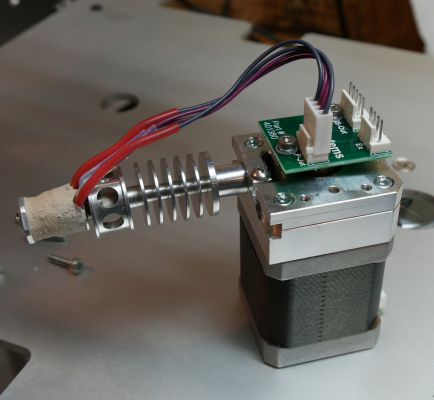

If you're willing to make your own, or modify your extruder, here's an example to learn from:

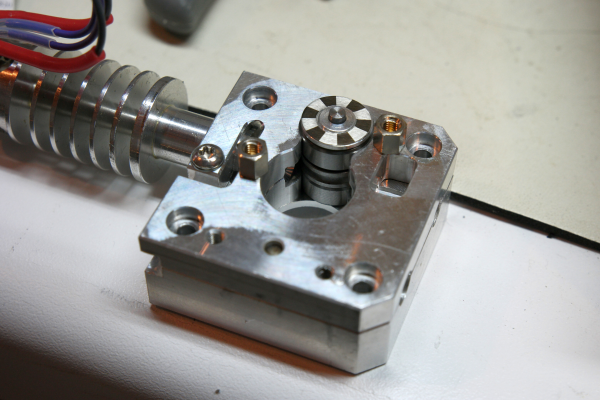

a disc on the pinch wheel:

another on the motor drive gear:

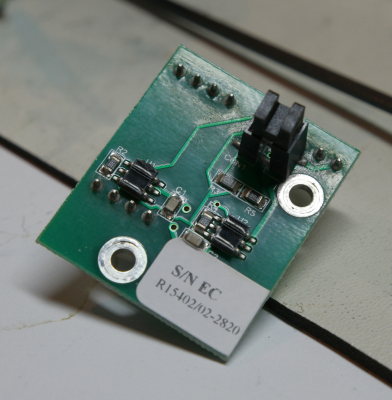

A circuit board that mounts on the extruder and has optical sensors (3 of them):

The tall sensor at the top of the board fits in a hole in the extruder body and monitors for presence of filament. The other two sensors monitor the discs on the drive gear and pinch roller (if the drive gear turns but the pinch wheel doesn't, the filament isn't feeding).

This extruder is from a CubeX Duo printer. Some people have been rehabbing these printers and some are replacing the stock extruders/hot-ends. You might be able to buy one cheaply.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

a disc on the pinch wheel:

another on the motor drive gear:

A circuit board that mounts on the extruder and has optical sensors (3 of them):

The tall sensor at the top of the board fits in a hole in the extruder body and monitors for presence of filament. The other two sensors monitor the discs on the drive gear and pinch roller (if the drive gear turns but the pinch wheel doesn't, the filament isn't feeding).

This extruder is from a CubeX Duo printer. Some people have been rehabbing these printers and some are replacing the stock extruders/hot-ends. You might be able to buy one cheaply.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Filament Monitor. October 22, 2016 08:09PM |

Registered: 7 years ago Posts: 137 |

|

Re: Filament Monitor. October 22, 2016 08:17PM |

Registered: 7 years ago Posts: 137 |

|

Re: Filament Monitor. October 22, 2016 09:44PM |

Registered: 11 years ago Posts: 5,780 |

You wouldn't have to monitor the filament at the extruder. You could feed the filament between two rollers and monitor motion anywhere along the path to the extruder.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Filament Monitor. October 22, 2016 10:33PM |

Registered: 7 years ago Posts: 137 |

|

Re: Filament Monitor. October 23, 2016 04:16AM |

Registered: 14 years ago Posts: 128 |

|

Re: Filament Monitor. October 23, 2016 04:49AM |

Registered: 8 years ago Posts: 312 |

If you want to measure correctly, you should measure the filament, not the rotation of the extruder.

That way you detect all issues there are, blockage, break or run out.

In order to make sure you register correctly, it makes the most sense to measure as close to the hot end as possible.

The most simple way would be to use rollers, as they are measured easily. I have seen various limit switches used, but they do not measure blockages only the absence of filament.

Pity though, this will add more weight to the hot end assembly.

Lykle

That way you detect all issues there are, blockage, break or run out.

In order to make sure you register correctly, it makes the most sense to measure as close to the hot end as possible.

The most simple way would be to use rollers, as they are measured easily. I have seen various limit switches used, but they do not measure blockages only the absence of filament.

Pity though, this will add more weight to the hot end assembly.

Lykle

|

Re: Filament Monitor. October 23, 2016 05:29AM |

Registered: 7 years ago Posts: 137 |

@RepRot - Thanks for sharing having some actual code will be very helpful.

@Lykle - My thinking behind having it close to the filament roll is that the motor drives from there and I didn't want to add drag at or near the hotend.

I suppose if it jams at the hotend and carries on feeding I won't know till all the fillament has run out and I have to rewind it on the spool. Argh! So many choices. lol

Out of the box thinking is easier when you never fitted in the box to begin with.

@Lykle - My thinking behind having it close to the filament roll is that the motor drives from there and I didn't want to add drag at or near the hotend.

I suppose if it jams at the hotend and carries on feeding I won't know till all the fillament has run out and I have to rewind it on the spool. Argh! So many choices. lol

Out of the box thinking is easier when you never fitted in the box to begin with.

|

Re: Filament Monitor. October 23, 2016 08:35AM |

Registered: 11 years ago Posts: 5,780 |

I think if you're monitoring filament motion in a machine with a direct extruder you're better off monitoring a least a few cm away from the extruder. In the case of the CubeX monitors, when it detects that the filament has stopped feeding, there's a piece of filament in the hot-end sitting just below the drive gear where it can't push. That means in order to feed more filament in there you'll probably have to take the extruder apart to get that filament out before you can feed new filament. Having to take apart the extruder is an annoyance.

In the event of a spool running out of filament, detecting it a few cm away from the extruder leaves you with something to grab to pull the filament out of the extruder without taking it apart.

In a Bowden set-up, if you detect filament out at the motor, the Bowden tube is full of filament, so you can just disconnect the tube at the exit of the motor and pull it out of the tube and hot-end.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In the event of a spool running out of filament, detecting it a few cm away from the extruder leaves you with something to grab to pull the filament out of the extruder without taking it apart.

In a Bowden set-up, if you detect filament out at the motor, the Bowden tube is full of filament, so you can just disconnect the tube at the exit of the motor and pull it out of the tube and hot-end.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Filament Monitor. October 27, 2016 07:59AM |

Registered: 8 years ago Posts: 312 |

We just announced that one of the add-on's we are developing for the Nimble is a filament sensor that will clip onto it, We are developing it together with David Crocker.

We had a discussion about the remaining filament and by positioning it where we do, the last end of the filament is still available to be pulled out. Another advantage of the breech system.

The design will be done in such a way that the sensor can be mounted in other ways. It will be a pretty little thing.

Lykle

We had a discussion about the remaining filament and by positioning it where we do, the last end of the filament is still available to be pulled out. Another advantage of the breech system.

The design will be done in such a way that the sensor can be mounted in other ways. It will be a pretty little thing.

Lykle

|

Re: Filament Monitor. October 27, 2016 09:35AM |

Registered: 7 years ago Posts: 137 |

|

Re: Filament Monitor. October 27, 2016 02:39PM |

Registered: 8 years ago Posts: 312 |

Sorry, only registered users may post in this forum.