Flexion vs Flexion for E3DRetrofit kit

Posted by PDBeal

|

Flexion vs Flexion for E3DRetrofit kit October 30, 2016 01:51PM |

Registered: 7 years ago Posts: 558 |

So, I've had some limited success printing Ninjaflex filament with a direct drive E3D Titan extruder on my CoreXY, but ran into an issue with it yesterday. So I've started looking at this Flexion extruder and I'm willing to pay for it if it'll work, but I noticed they offer it with an E3D Retrofit kit to use it with a V6 hot end. I've had some bad experiences with those Chinese clones and since then I won't use anything but the official E3D V6 hotend, but the distance between the drive gear on the Flexion extruder and the hotend on the V6 would be rather long compared to the Flexion hotend version. Has anyone had any experience with the Flexion extruded either with the E3D V6 Retrofit kit or with the Flexion extruder hotend?

Edited 2 time(s). Last edit at 10/30/2016 01:52PM by PDBeal.

Edited 2 time(s). Last edit at 10/30/2016 01:52PM by PDBeal.

|

Re: Flexion vs Flexion for E3DRetrofit kit October 30, 2016 05:39PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Flexion vs Flexion for E3DRetrofit kit October 30, 2016 08:30PM |

Registered: 7 years ago Posts: 558 |

I have come to the conclusion, the titan doesn't feed the flexible filaments consistently. I've calibrated the titan with PLA and that all works great. However, when I try to calibrate it with ninjaflex, it only extrudes 25% of what it was supposed to. Increasing the steps doesn't produce more filament either. Trying to increase the tension results in flexible filaments squeezing out of the captured path right under the teeth on the drive gear.

So my limited success seems to be it extrudes enough filament to make the part, but I now suspect the parts aren't what they should be. I've also looked at the titan design and the Flexion design, and beginning to wonder if the grooved idler plays an important role with flexible filaments not being squished along with the captured filament path. However, I'm not quite sold on he non-geared setup they're using.

So my limited success seems to be it extrudes enough filament to make the part, but I now suspect the parts aren't what they should be. I've also looked at the titan design and the Flexion design, and beginning to wonder if the grooved idler plays an important role with flexible filaments not being squished along with the captured filament path. However, I'm not quite sold on he non-geared setup they're using.

|

Re: Flexion vs Flexion for E3DRetrofit kit October 30, 2016 08:44PM |

Registered: 9 years ago Posts: 1,873 |

That's really interesting. I hadn't thought much about the idler profile. My original mk7 style extuders had grooved idlers and straight drive gears, but when I made my own I used a flat idler against a grooved mk8 style drive gear. That's been working ok with tpu, tpe and flex pla. I could imagine that the contour of the drive gear is critical, with some being more prone to pulling the filament around the radius and away from the feed path. All of my flex filaments are 3mm which I suspect makes life easier.

One area where I did have a lot of problems with printing flex is contamination from other filaments, particularly abs or nylon. I had to do a lot of purging to avoid clogs and jams. When I googled I found a suggestion to purge first with pla, and then with the flex as it seems to tolerate pla contamination better than anything else. They actually suggested a 1000mm purge of pla and the same again of flex!! It's also easier to print flex with larger nozzles than smaller (I used .4 or .5mm), and I have to print very slowly, 10 to 15mm/s max.

Edit: I just checked the wiki to make sure I had my terminology right for the drive gears, and it seems that what I thought was a mk7 gear doesn't appear in the list. The look like this:

Edited 2 time(s). Last edit at 10/30/2016 08:54PM by JamesK.

One area where I did have a lot of problems with printing flex is contamination from other filaments, particularly abs or nylon. I had to do a lot of purging to avoid clogs and jams. When I googled I found a suggestion to purge first with pla, and then with the flex as it seems to tolerate pla contamination better than anything else. They actually suggested a 1000mm purge of pla and the same again of flex!! It's also easier to print flex with larger nozzles than smaller (I used .4 or .5mm), and I have to print very slowly, 10 to 15mm/s max.

Edit: I just checked the wiki to make sure I had my terminology right for the drive gears, and it seems that what I thought was a mk7 gear doesn't appear in the list. The look like this:

Edited 2 time(s). Last edit at 10/30/2016 08:54PM by JamesK.

|

Re: Flexion vs Flexion for E3DRetrofit kit November 02, 2016 02:11PM |

Registered: 8 years ago Posts: 3,525 |

There was a good test on various drive gears [www.instructables.com]

And those came out very highly rated.

Don't view it on a phone the images aren't scaled for mobile browsing.

Edited 1 time(s). Last edit at 11/02/2016 02:13PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

And those came out very highly rated.

Don't view it on a phone the images aren't scaled for mobile browsing.

Edited 1 time(s). Last edit at 11/02/2016 02:13PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Flexion vs Flexion for E3DRetrofit kit November 24, 2016 03:11PM |

Registered: 7 years ago Posts: 558 |

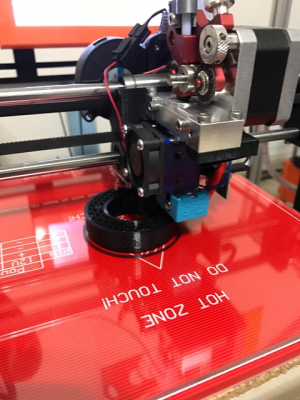

Just to close the loop on anyone reading this in the future, I ended up ordering and installing the Flexion E3D Retrofit Kit on my CoreXY (I actually built a new system, specifically for this extruder based on the Smartrapcore Alu build) After some initial setup issues, It's been working amazingly well. Using a standard genuine E3D V6 hotend with the Flexion Extruder, I've been able to print many parts with Ninjaflex at 60mm/s print speed.

I did have to find a slightly smaller motor (26Ncm torque) as the 45Ncm torque motors managed to kink the filament and stretch the PTFE tube, and getting the tension set with the cam and set screw setup was a pain. However, support from Diabase Engineering couldn't have been better with troubleshooting support from them on a Sunday afternoon and replacement parts sent the Monday morning.

Comparing what I managed to print with the Titan E3D and Ninjaflex vs the Flexion and Ninjaflex it's like night and day. The layers are fully connected and don't split when squished. At this point I thought I did pretty good with the Titan and Ninjaflex 1.75, but based on what I've gotten from the Flexion I was only about 20% there. For anyone seriously looking at Ninjaflex 1.75mm filament, you can't go wrong with the Flexion extruder. In my case, this machine will only print these flexible filaments, so I can't comment about how it runs ABS, PLA, or PETG.

Worst part in this is keeping myself from ordering all the different colors of Ninjaflex filament. This opens up a lot of different opportunities now for parts. And I'm looking forward to trying out the sample spool of Ninjaflex Jellyfish that they sent to try out with the Flexion extruder.

I did have to find a slightly smaller motor (26Ncm torque) as the 45Ncm torque motors managed to kink the filament and stretch the PTFE tube, and getting the tension set with the cam and set screw setup was a pain. However, support from Diabase Engineering couldn't have been better with troubleshooting support from them on a Sunday afternoon and replacement parts sent the Monday morning.

Comparing what I managed to print with the Titan E3D and Ninjaflex vs the Flexion and Ninjaflex it's like night and day. The layers are fully connected and don't split when squished. At this point I thought I did pretty good with the Titan and Ninjaflex 1.75, but based on what I've gotten from the Flexion I was only about 20% there. For anyone seriously looking at Ninjaflex 1.75mm filament, you can't go wrong with the Flexion extruder. In my case, this machine will only print these flexible filaments, so I can't comment about how it runs ABS, PLA, or PETG.

Worst part in this is keeping myself from ordering all the different colors of Ninjaflex filament. This opens up a lot of different opportunities now for parts. And I'm looking forward to trying out the sample spool of Ninjaflex Jellyfish that they sent to try out with the Flexion extruder.

|

Re: Flexion vs Flexion for E3DRetrofit kit November 24, 2016 03:17PM |

Registered: 8 years ago Posts: 3,525 |

Sounds great, never tried flexibles but its good to know the flexion does what it claims to be able to do.

Any prints to show us?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Any prints to show us?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Flexion vs Flexion for E3DRetrofit kit November 25, 2016 01:56AM |

Registered: 8 years ago Posts: 916 |

Quote

PDBeal

Using a standard genuine E3D V6 hotend with the Flexion Extruder, I've been able to print many parts with Ninjaflex at 60mm/s print speed.

That has to be a misprint. 60 mm/s?

The best I can manage with TPE is around 12... 15 if I'm really pushing it. I say again,

Far out that's impressive.

|

Re: Flexion vs Flexion for E3DRetrofit kit November 25, 2016 06:17AM |

Registered: 9 years ago Posts: 1,873 |

Quote

That has to be a misprint. 60 mm/s? The best I can manage with TPE is around 12... 15 if I'm really pushing it.

There's a lot of variation in flex filaments. The TPE I have is far softer than any of the others that I have used, it's the only one that produces prints with a soft rubbery feel. I think Ninjaflex is closer to TPU which is much easier to print. That said, I couldn't get to 60mm/s with TPU either. I go about 15 with TPE, 30 with TPU and 45 with soft pla, so 60 is still a very impressive result.

|

Re: Flexion vs Flexion for E3DRetrofit kit November 25, 2016 02:00PM |

Registered: 7 years ago Posts: 558 |

The 60mm/s isn't a misprint. I was skeptical at first and started at 30 and slowly worked my way to 60, but it held it without an issue. I'll try and get a video of it and post it up on YouTube with some other pictures after the holiday weekend. It does require a lot more retraction than a normal direct drive (5mm or so), but the prints don't need to be cleaned up either and I very rarely see the ooze boogers from a travel move. I get the occasional tiny hair, but I see those with standard PLA on my other CoreXY machines.

|

Re: Flexion vs Flexion for E3DRetrofit kit November 28, 2016 11:26PM |

Registered: 7 years ago Posts: 558 |

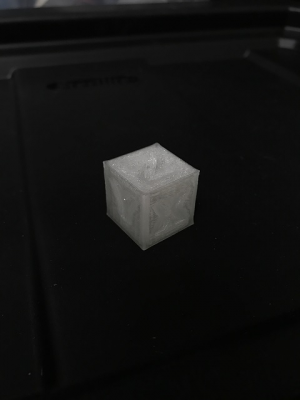

These were printed at 30 mm/s. I had to try out a Marvin keyring and it handled it just like it was PLA. The last two pictures are of it printing a tire for the Open F1 RC car, but I wanted to show how well its holding the thin infill at 30 mm/s.

These were printed at 45 mm/s (Still dialing in the retract settings for black seem to be a little different than the clear or blue.)

This was printed at 60 mm/s to see if it was possible, and it was.

Everything was sliced by Cura 2.3.1 with the exception of the blue fly wings which would not slice properly in Cura. The wings were sliced in Slic3r.

Edited 2 time(s). Last edit at 11/28/2016 11:28PM by PDBeal.

These were printed at 45 mm/s (Still dialing in the retract settings for black seem to be a little different than the clear or blue.)

This was printed at 60 mm/s to see if it was possible, and it was.

Everything was sliced by Cura 2.3.1 with the exception of the blue fly wings which would not slice properly in Cura. The wings were sliced in Slic3r.

Edited 2 time(s). Last edit at 11/28/2016 11:28PM by PDBeal.

|

Re: Flexion vs Flexion for E3DRetrofit kit November 29, 2016 07:19AM |

Registered: 9 years ago Posts: 1,873 |

Sorry, only registered users may post in this forum.