Print more parts, use less metal?

Posted by bacree

|

Print more parts, use less metal? January 29, 2011 06:56PM |

Registered: 13 years ago Posts: 9 |

|

Re: Print more parts, use less metal? January 29, 2011 07:24PM |

Registered: 13 years ago Posts: 9 |

|

Re: Print more parts, use less metal? January 29, 2011 07:47PM |

Registered: 16 years ago Posts: 438 |

Someone did plastic nuts recently. The prusa mendel uses many, many fewer parts in general.

I keep thinking that using plastic screws (self-threading type) is the way it's done in industry, why aren't we doing it that way? We could design most of the parts to clamp on (as opposed to being held in place with nuts & washers on both sides) and hold the clamp closed with a couple of screws. Plastic does creep, so maybe it wouldn't work to well with smooth rod, but clamping threaded rod should be very stable even if the plastic does creep.

Could even design the clamp's strap to come off entirely, and at the cost of two more screws per clamp you could take things apart in any order - no more shish kabobs, no more taking everything apart to redo the Y axis.

And the screws are cheap...

--

I'm building it with Baling Wire

I keep thinking that using plastic screws (self-threading type) is the way it's done in industry, why aren't we doing it that way? We could design most of the parts to clamp on (as opposed to being held in place with nuts & washers on both sides) and hold the clamp closed with a couple of screws. Plastic does creep, so maybe it wouldn't work to well with smooth rod, but clamping threaded rod should be very stable even if the plastic does creep.

Could even design the clamp's strap to come off entirely, and at the cost of two more screws per clamp you could take things apart in any order - no more shish kabobs, no more taking everything apart to redo the Y axis.

And the screws are cheap...

--

I'm building it with Baling Wire

|

Re: Print more parts, use less metal? January 29, 2011 11:47PM |

Registered: 13 years ago Posts: 9 |

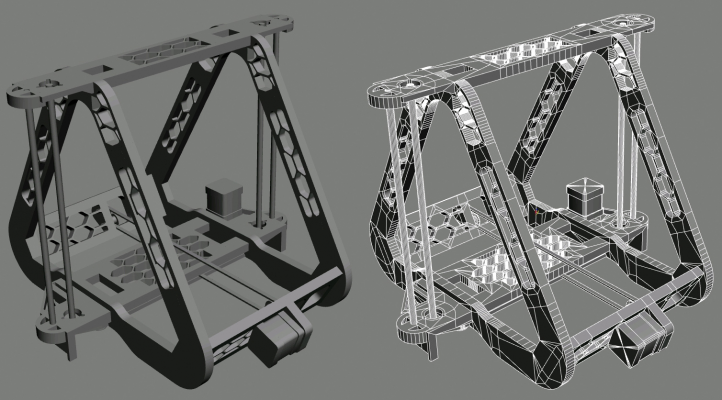

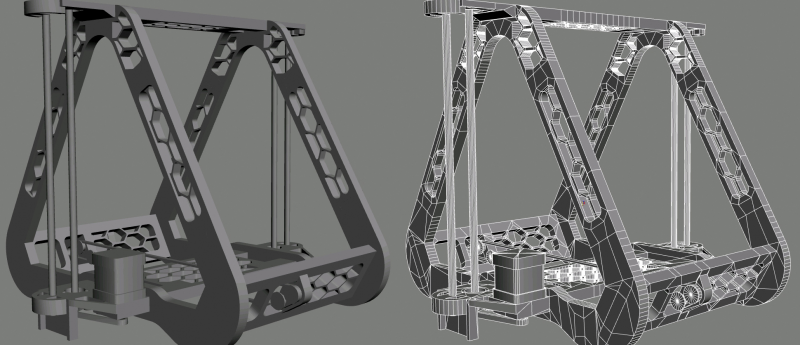

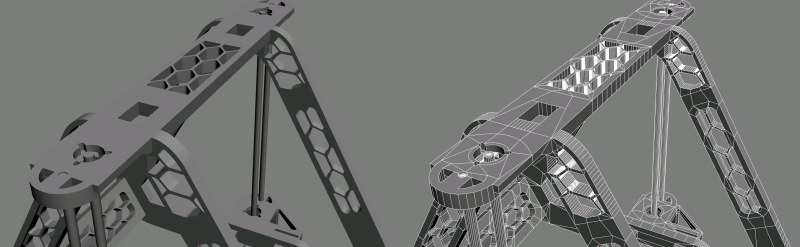

Hmm, well it sounds like I'm taking a bit of a different approach than that lol. The way I went at it was more like a jigsaw puzzle or making dovetails in woodworking. This way you can do away with bolts altogether, well, mostly. Now, depending on how sturdy the whole thing is, I might end up putting a screw through each of the joints to stiffen it up even more. But that would only cost $5 for a box of 100 screws and I don't think it will need even close to that count.

I'm hoping this will work fine as a straight replacement for all the frames plastic and lots of the additional metals parts too. I haven't the slightest idea how much it would cost in materials to print this, but I was more focused on really hitting home the whole, "Reprap can self replicate" thing. Of course I hope I can try to make it more efficient to print as well as stronger. But this is really my first go. If this works well, I'll have a go at doing the same for everything else, with the exception of all the thick and thin sheets and it goes without saying, the electronics.

Right now, all but two parts are sized to be printed on a standard Mendel. But I just need to find the time to figure that one out this weekend.

Brandon

|

Re: Print more parts, use less metal? January 30, 2011 12:33AM |

Registered: 13 years ago Posts: 188 |

Over at thingiverse, I occasionally see some things about a sarrus linkage. There were also some experiments with a design kind of like this. I don't remember where I saw it, but I think this particular developer was trying to use printed linkages in place of all the metal rods you see in that video.

Your design is much simpler than anything else I've seen. Good job. I'm curious to see what you have in mind for mounting the Y axis though.

Edited 2 time(s). Last edit at 01/30/2011 12:40AM by dazed.dnc.

Your design is much simpler than anything else I've seen. Good job. I'm curious to see what you have in mind for mounting the Y axis though.

Edited 2 time(s). Last edit at 01/30/2011 12:40AM by dazed.dnc.

|

Re: Print more parts, use less metal? January 30, 2011 12:40AM |

Registered: 13 years ago Posts: 9 |

Well, at this point I'm really just trying to scratch that itch lol. Once I build my more traditional Mendel and then print my design I can test it for all those things. Is there something in the way of a "crash test" or stress test procedure that I could run the design through to check for all of these potential faults?

At this point, I'm waiting on my Gen6 electronics and then Ill buy the full kit (minus electronics and printed parts) from mendel-parts.com....assuming those don't take a year to ship lol

At this point, I'm waiting on my Gen6 electronics and then Ill buy the full kit (minus electronics and printed parts) from mendel-parts.com....assuming those don't take a year to ship lol

|

Re: Print more parts, use less metal? January 30, 2011 01:35PM |

Registered: 13 years ago Posts: 167 |

|

Re: Print more parts, use less metal? January 31, 2011 01:18AM |

Admin Registered: 13 years ago Posts: 730 |

Hi bacree,

Your design reminds me a little of the Foton variant of Mendel.

Another concept design you might find interesting is the Rhombot.

There is also this well-known Makerbot variant which is made by gluing together printed pieces.

Some wiki entries that discuss related problems of printing motors, printing circuitry, and so on are:

Actuator Fabrication

Automated Circuitry Making

As for "crash testing" it sounds like Finite Element Analysis (FEA) might help identify weak points in the structure. FEA can be kind of difficult and time-consuming. There are a number of open source FEA software packages available. I don't know how well any of them work or how easy they are to use though...

Good luck with your design! Keep us posted on the results!

-Matt

Your design reminds me a little of the Foton variant of Mendel.

Another concept design you might find interesting is the Rhombot.

There is also this well-known Makerbot variant which is made by gluing together printed pieces.

Some wiki entries that discuss related problems of printing motors, printing circuitry, and so on are:

Actuator Fabrication

Automated Circuitry Making

As for "crash testing" it sounds like Finite Element Analysis (FEA) might help identify weak points in the structure. FEA can be kind of difficult and time-consuming. There are a number of open source FEA software packages available. I don't know how well any of them work or how easy they are to use though...

Good luck with your design! Keep us posted on the results!

-Matt

|

Re: Print more parts, use less metal? January 31, 2011 10:06AM |

Registered: 13 years ago Posts: 99 |

|

Re: Print more parts, use less metal? January 31, 2011 04:09PM |

Registered: 13 years ago Posts: 9 |

Well, its broken up in a way so that each part will fit on the print bed. Like I mentioned earlier, as far as what I have completed thus far, only two parts need to be made to fit on the bed.

As far as strength, I've done a test by printing out the outlines on regular paper, gluing them to 1/2in particle wood, and cutting them out and fitting them together. Leaving aside what is probably not the best craftsmanship, everything fits together very well and the joints don't seem to be an issue. Especially given the fact that most of the joints are simply dry fitted together. I was proposing that for the printed parts, as an extra measure of stability, I drill countersunk pilot holes and put reinforcing screws in each joint to solidify the whole thing and keep the joints from coming undone.

While I do realize that using the metal rods wont be the end of the world, using less metal and printing more of the actual structure is my goal. The only 4 that I'm content with leaving in are the 4 used for the Z axis, 2 threaded and 2 smooth. These seem pretty vital to a quality machine. All of the other metal rods seem to be more for structural purposes, which I would assert, can be done just as well without them.

As far as strength, I've done a test by printing out the outlines on regular paper, gluing them to 1/2in particle wood, and cutting them out and fitting them together. Leaving aside what is probably not the best craftsmanship, everything fits together very well and the joints don't seem to be an issue. Especially given the fact that most of the joints are simply dry fitted together. I was proposing that for the printed parts, as an extra measure of stability, I drill countersunk pilot holes and put reinforcing screws in each joint to solidify the whole thing and keep the joints from coming undone.

While I do realize that using the metal rods wont be the end of the world, using less metal and printing more of the actual structure is my goal. The only 4 that I'm content with leaving in are the 4 used for the Z axis, 2 threaded and 2 smooth. These seem pretty vital to a quality machine. All of the other metal rods seem to be more for structural purposes, which I would assert, can be done just as well without them.

Sorry, only registered users may post in this forum.