Motors - how bad are the regenerative current and the EMI relatated issues

Posted by icefire

|

Motors - how bad are the regenerative current and the EMI relatated issues November 08, 2016 04:12PM |

Registered: 8 years ago Posts: 168 |

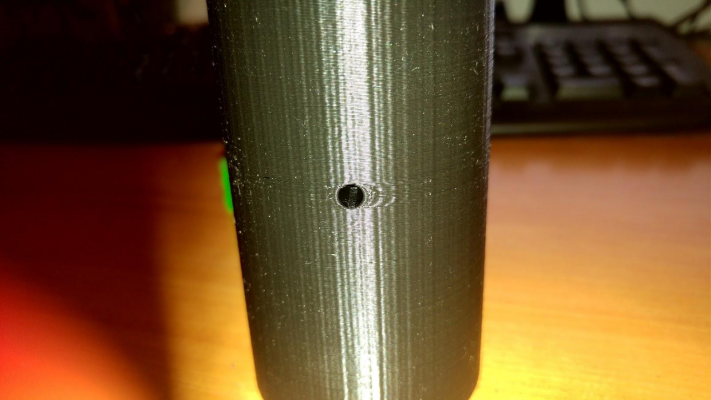

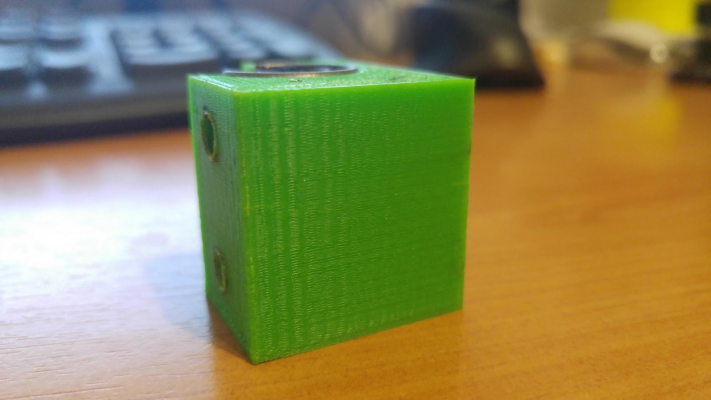

So I was wondering... I have some ringing effect on my prints which I can't seem to get rid of. I tried every "standard" solution one may think of (tightening/loosening belts, lowering speed, lowering acceleration, lowering jerk, etc.) but the ringing just doesn't go away. In addition to this I always get some strange vertical ripples across the prints.

Since I use my printer primarily for functional parts and not so much for Yoda heads etc. I would really like to solve this. Since I was experimenting a lot the last couple of weeks I cannot say when or why exactly the problem appeared. My current setup is:

- 24V 800W PSU

- Ramps/Arduino running at 12V via separate voltage regulator

- 350W heated bed running at 24V via a simple Mosfet switching circuit

- The voltage regulator of the Arduino (AMS1117) has been bypassed. The 5V rail is powered directly off the PSU through a separate (and much more powerful) 5V regulator.

- Chinese NEMA17 motors, 1,8°, phase inductance 3,2 mH

I have separate voltmeters for the 24V, 12V and 5V. I have noticed the following unpleasant side effects of the hardware setup:

- when the printer is off and I move the X or Y axis by hand I get up to 5V regenerative voltage which is shown on the voltmeters. The LCD backlight also lights up..

- during prints the LCD backlight and my LEDs which I use to always have light on the part being printed flicker. If I select "turn power off" from the LCD menu the flickering stops.

So this led me to the following questions:

- How bad is the regenerative voltage and current for the print quality? What can I go to prevent it (ex. use some diodes before connecting to the RAMPS board)?

- Should I switch over to 24V? The RAMPS can handle it (capacitors are rated for 35V), "all" I need is a new hot end heater, 4 new fans and a new resistance for the LEDs. I have read in multiple threads that there motors behave much better at 24V

- Should I be worried about EMI from the motor wires? Can this be the root cause for my print quality trouble?

Thanks for your help. Here are some pictures of the ringing and the ripples:

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Since I use my printer primarily for functional parts and not so much for Yoda heads etc. I would really like to solve this. Since I was experimenting a lot the last couple of weeks I cannot say when or why exactly the problem appeared. My current setup is:

- 24V 800W PSU

- Ramps/Arduino running at 12V via separate voltage regulator

- 350W heated bed running at 24V via a simple Mosfet switching circuit

- The voltage regulator of the Arduino (AMS1117) has been bypassed. The 5V rail is powered directly off the PSU through a separate (and much more powerful) 5V regulator.

- Chinese NEMA17 motors, 1,8°, phase inductance 3,2 mH

I have separate voltmeters for the 24V, 12V and 5V. I have noticed the following unpleasant side effects of the hardware setup:

- when the printer is off and I move the X or Y axis by hand I get up to 5V regenerative voltage which is shown on the voltmeters. The LCD backlight also lights up..

- during prints the LCD backlight and my LEDs which I use to always have light on the part being printed flicker. If I select "turn power off" from the LCD menu the flickering stops.

So this led me to the following questions:

- How bad is the regenerative voltage and current for the print quality? What can I go to prevent it (ex. use some diodes before connecting to the RAMPS board)?

- Should I switch over to 24V? The RAMPS can handle it (capacitors are rated for 35V), "all" I need is a new hot end heater, 4 new fans and a new resistance for the LEDs. I have read in multiple threads that there motors behave much better at 24V

- Should I be worried about EMI from the motor wires? Can this be the root cause for my print quality trouble?

Thanks for your help. Here are some pictures of the ringing and the ripples:

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 08, 2016 06:44PM |

Registered: 11 years ago Posts: 5,780 |

DRV8825sare known to have problems with low voltage and microstepping. See [cabristor.blogspot.se]

Can you try different drivers?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Can you try different drivers?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 08, 2016 07:07PM |

Registered: 7 years ago Posts: 45 |

I used to get that because my bearings weren't moving smoothly. I tweaked the rails to make sure they were smooth moving, cleaned and lightly oiled them with 3 in one oil, and made sure my belts line up with out rubbing on the sides of the pulleys and it went away at pretty much any speed.

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 09, 2016 05:18AM |

Registered: 8 years ago Posts: 168 |

There are no severe mechanical problems. The linear bearings are moving very smoothly, the issue is definitely not there.

My questions are specifically about the effects of the regenerative current, the EMI-related issues and the operating voltage.

@the_digital_dentist: If I understand the blog post correctly, changing the operating voltage to 24V would have a negative effect. It seems like a good idea to try out the suggested solution with the diodes...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

My questions are specifically about the effects of the regenerative current, the EMI-related issues and the operating voltage.

@the_digital_dentist: If I understand the blog post correctly, changing the operating voltage to 24V would have a negative effect. It seems like a good idea to try out the suggested solution with the diodes...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 11, 2016 12:25PM |

Registered: 8 years ago Posts: 168 |

So I just invested $3 for A4988 drivers to see what happens with other drivers. Since they are going to arrive in a month from china, in the meantime I am going to put the DRV8825 in fast decay mode and see if there is any improvement. If the high pitch noise is too bad I am going to solder the circuit according to the blog post.

So this may solve the ripples but.. what about the screen flickering? Can this have anything to do with the regenerated current?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

So this may solve the ripples but.. what about the screen flickering? Can this have anything to do with the regenerated current?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 11, 2016 05:20PM |

Registered: 9 years ago Posts: 1,873 |

The ripples in your photos look much more like a mechanical problem than a result of the drv8825 step irregularities. Back emf from the motors shouldn't cause flickering on your LCD during normal operation.

From your description it sounded like you had a single PSU supplying all the voltages, so if you turn it off where does the LCD get any power from? Or, if your PSU isn't actually switched by software, then what you're seeing is a side effect of turning off all the heaters and drivers. The most likely cause is the heat bed crow-barring the PSU and impacting the derived 5V supply. Do you have a scope you could check the 5V line with? A large amount of capacitance before (with a diode) and after the 5V regulator might help. Of course, if the 5V rail is struggling then likely the 12V is too (if I understood correctly and it is also derived from the 24V line), in which case any sag in the 12V line might get through the stepper drivers and show up in your motors.

When you said you were using regulators to derive the 12V and 5V lines did you actually mean DC-DC buck convertors? That would be a far better bet than a linear regulator.

Quote

If I select "turn power off" from the LCD menu the flickering stops

From your description it sounded like you had a single PSU supplying all the voltages, so if you turn it off where does the LCD get any power from? Or, if your PSU isn't actually switched by software, then what you're seeing is a side effect of turning off all the heaters and drivers. The most likely cause is the heat bed crow-barring the PSU and impacting the derived 5V supply. Do you have a scope you could check the 5V line with? A large amount of capacitance before (with a diode) and after the 5V regulator might help. Of course, if the 5V rail is struggling then likely the 12V is too (if I understood correctly and it is also derived from the 24V line), in which case any sag in the 12V line might get through the stepper drivers and show up in your motors.

When you said you were using regulators to derive the 12V and 5V lines did you actually mean DC-DC buck convertors? That would be a far better bet than a linear regulator.

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 11, 2016 06:45PM |

Registered: 8 years ago Posts: 168 |

Quote

JamesK

The ripples in your photos look much more like a mechanical problem than a result of the drv8825 step irregularities. Back emf from the motors shouldn't cause flickering on your LCD during normal operation.

Quote

If I select "turn power off" from the LCD menu the flickering stops

From your description it sounded like you had a single PSU supplying all the voltages, so if you turn it off where does the LCD get any power from? Or, if your PSU isn't actually switched by software, then what you're seeing is a side effect of turning off all the heaters and drivers. The most likely cause is the heat bed crow-barring the PSU and impacting the derived 5V supply. Do you have a scope you could check the 5V line with? A large amount of capacitance before (with a diode) and after the 5V regulator might help. Of course, if the 5V rail is struggling then likely the 12V is too (if I understood correctly and it is also derived from the 24V line), in which case any sag in the 12V line might get through the stepper drivers and show up in your motors.

When you said you were using regulators to derive the 12V and 5V lines did you actually mean DC-DC buck convertors? That would be a far better bet than a linear regulator.

I have a single PSU supplying all voltages which is not software-switched. "Turn power off" simply disables the steppers and heaters.

Unfortunately I don't have a scope.

The 5V regulator is a LM2596S which is supposed to have some capacitance before and after...

The 12V are provided by this buck converter.

For what it's worth, the voltmeters on the 24V, 12V and 5V line show pretty stable values.

Tomorrow I will investigate if the screen flickering occurs with no heaters on. I cannot do anything now because the printer is currently busy with a 40-hour-print (shouldn't've gone for 0,15mm layer height on a huge part

)

)Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 16, 2016 08:39PM |

Registered: 8 years ago Posts: 1,671 |

I wondered about the same, and how it looks in the print, got me thinking about moire...and how layer heights, combined with belt issues, or wobble from accel' or faceted models, 8bit, your issue(mech' or elec?), filament bulges,plus a number of other waveforms/frequencies...too numerouus to name, combine to produce moire, I just finished one of my cleanest prints, very smooth but I can see a moire, very feint diagonals in the x/y faces, plus differences of speed changes, also some vertical ribbing like your but on the micron scale...smooth faults can only be seen close in with light to emphasize.

Edited 1 time(s). Last edit at 11/17/2016 02:33AM by MechaBits.

Edited 1 time(s). Last edit at 11/17/2016 02:33AM by MechaBits.

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 17, 2016 04:10AM |

Registered: 8 years ago Posts: 168 |

To summarize, the screen flickering has nothing to do with the motors or the regenerated current. That was a problem with my 5V regulation which is already solved.

The ripples/vertical lines remain unsolved. I have ordered A4988 drivers. Until they come I am going to check the 4-diodes-per-phase solution.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

The ripples/vertical lines remain unsolved. I have ordered A4988 drivers. Until they come I am going to check the 4-diodes-per-phase solution.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 17, 2016 08:39AM |

Registered: 7 years ago Posts: 558 |

How much mass is flying around on top of your extruder nozzle? Are you running a direct drive or bowden setup? How big is your extruder drive? I'm making an assumption your probably running a direct drive extruder and if ringing is that big of a deal to you, I'd suggest you try a bowden setup. It would reduce how much weight is on your extruder carriage.

I've seen similar ringing on my CoreXY with the direct drive setup that uses the E3D Titan. I changed out my standard stepper for the little pancake one and it cut my ringing down by over 75%. On some parts there are no ringing marks visible, and on the other parts there are maybe 1 or 2 ghosted rings. On my CoreXY with the Bowden setup, there is no ringing on any speed.

I've seen similar ringing on my CoreXY with the direct drive setup that uses the E3D Titan. I changed out my standard stepper for the little pancake one and it cut my ringing down by over 75%. On some parts there are no ringing marks visible, and on the other parts there are maybe 1 or 2 ghosted rings. On my CoreXY with the Bowden setup, there is no ringing on any speed.

|

Re: Motors - how bad are the regenerative current and the EMI relatated issues November 17, 2016 03:44PM |

Registered: 8 years ago Posts: 168 |

Yes, you assumed correctly.

However, the X carriage is not heavy. A simple aluminum carrier plate, e3d v6 hot end, greg wade's geared extruder + one Nema 17 motor. That's it. I wouldn't go for bowden setup because this means trouble with stringing, etc. I have tried it as well but am overall happier with the direct setup. I have been thinking of using a smaller and lighter motor instead but I am pretty sure the problem is not mechanical.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

However, the X carriage is not heavy. A simple aluminum carrier plate, e3d v6 hot end, greg wade's geared extruder + one Nema 17 motor. That's it. I wouldn't go for bowden setup because this means trouble with stringing, etc. I have tried it as well but am overall happier with the direct setup. I have been thinking of using a smaller and lighter motor instead but I am pretty sure the problem is not mechanical.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Sorry, only registered users may post in this forum.