Vacuum hold-down for 3D build surface.

Posted by leadinglights

|

Re: Vacuum hold-down for 3D build surface. January 24, 2017 06:38AM |

Registered: 12 years ago Posts: 1,450 |

The foil used by ECJ in this thread [forums.reprap.org] is also laser foil. The foil that is rough on one side is for inkjet printers and also doesn't work. I suspect that the brief periods when all of my ABS prints held firmly and released as soon as wanted are a distant memory - but I will keep trying to find the arcane secret.

Mike

Mike

|

Re: Vacuum hold-down for 3D build surface. January 24, 2017 07:15AM |

Registered: 12 years ago Posts: 1,450 |

I have put a YouTube video showing the first successful print on the Vacuum Hold_Down stage [www.youtube.com]

I have edited the video as I had not set up Repetier to keep on the bed and hot-end heat but the time taken for a change over should be about right

Mike

I have edited the video as I had not set up Repetier to keep on the bed and hot-end heat but the time taken for a change over should be about right

Mike

|

Re: Vacuum hold-down for 3D build surface. January 24, 2017 07:16AM |

Registered: 9 years ago Posts: 1,873 |

I'm currently testing some polyester sheet from McMaster-Carr. It works well for pla and petg, but I wasn't getting enough adhesion with abs to resist warp. I worked my way up bed and nozzle temperatures until at 120/260 I got a print that stuck very well indeed. I'm hoping that I can find a point between the previous settings 115/250 and the last ones where the print releases a little more easily. I think each of these plastic printing surfaces requires a fair bit of experimentation to find working temperatures.

|

Re: Vacuum hold-down for 3D build surface. January 24, 2017 07:21AM |

Registered: 9 years ago Posts: 1,873 |

Quote

leadinglights

I have put a YouTube video showing the first successful print on the Vacuum Hold_Down stage [www.youtube.com]

I have edited the video as I had not set up Repetier to keep on the bed and hot-end heat but the time taken for a change over should be about right

Mike

With the vacuum bed and your highly engineered hot-end your printer looks like something out of CERN

|

Re: Vacuum hold-down for 3D build surface. January 24, 2017 07:23AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Vacuum hold-down for 3D build surface. January 24, 2017 10:11AM |

Registered: 8 years ago Posts: 312 |

|

Re: Vacuum hold-down for 3D build surface. January 24, 2017 10:31AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Vacuum hold-down for 3D build surface. January 26, 2017 02:57PM |

Registered: 12 years ago Posts: 1,450 |

The vacuum hold does seem to be able to hold the filament down against quite a strong force. I have been trying to see if ABS can be printed on the glue side of a document laminating pouch. I did this with a cold build stage and the hot end at 250C; the adhesion was very good though not enough to stop the print lifting off the foil although it never lifted the foil away from the aluminium plate. With a little bit of work I think that printing ABS on this kind of foil without a heated build stage should be practical.

Incidentally, the same film does work exceptionally well with PLA with a cold build stage even on a difficult print.

Mike

Incidentally, the same film does work exceptionally well with PLA with a cold build stage even on a difficult print.

Mike

|

Re: Vacuum hold-down for 3D build surface. September 24, 2019 12:58PM |

Registered: 12 years ago Posts: 1,450 |

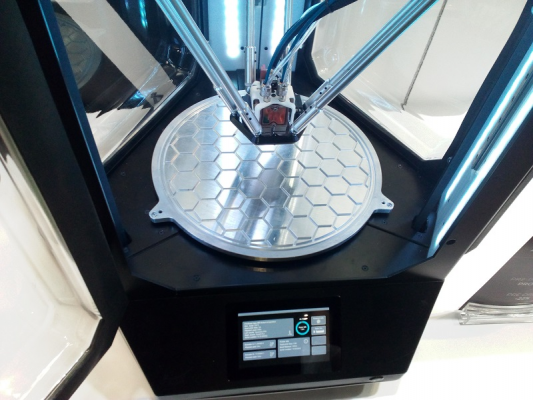

I saw this printer at the TCT show today. I don't claim that Innovatica copied my design, or even that their design was inspired by mine, but I do take pleasure in that the idea wasn't a crackpot one.

Innovatica Hydra on the left, my printer Miranda on the right.

I am still using vacuum hold down on my printers. The reason for the hexagonal cells is that there are no long lines to form creases and stress thin prints during removal.

Mike

Innovatica Hydra on the left, my printer Miranda on the right.

I am still using vacuum hold down on my printers. The reason for the hexagonal cells is that there are no long lines to form creases and stress thin prints during removal.

Mike

|

Re: Vacuum hold-down for 3D build surface. September 24, 2019 09:49PM |

Registered: 10 years ago Posts: 239 |

The Stratasys Fortus 900 uses a build plate with grooves and vacuum. Thin Ultem and PC sheets are used when printing their respective materials. I did some r&d on a similar design for a new machine I am building and had determined for abs, in a heated chamber, at least 750 mb of vacuum would be needed producing .77 kg/cm2 of holding force. PLA should need less (dah)

|

Re: Vacuum hold-down for 3D build surface. September 28, 2019 05:13PM |

Registered: 12 years ago Posts: 1,450 |

Quote

Bill Clark

.................................................................................. a similar design for a new machine I am building and had determined for abs, in a heated chamber, at least 750 mb of vacuum would be needed producing .77 kg/cm2 of holding force. PLA should need less (dah)

I found that the holding force is a lot more than you would get by only looking at the direct atmospheric pressure. I used a cheap vacuum pump giving 500mb max vacuum, a sheet of OH transparency film and a 2cm² aluminium block (square 14.4mm per side) glued to the transparency. With the film held to the vacuum plate, I pulled on it with a spring balance expecting it to lift at ca. 1kgf but (0.5bar and 2cm² taking 1 bar=1.033kgf/cm²) but there was no discernible lift until above 2kgf..

Mike

|

Re: Vacuum hold-down for 3D build surface. July 29, 2021 08:14AM |

Registered: 12 years ago Posts: 1,450 |

A recent comment on one of my YouTube videos asked if I still used the vacuum hold-down. In trying to find something to link to in answer, I found that I had hardly documented recent changes in this system on my newest printer. Since I usually document everything up to the wazoo, I am now doing the documents and putting this bit on the forum for anybody who wants to build their own vacuum system.

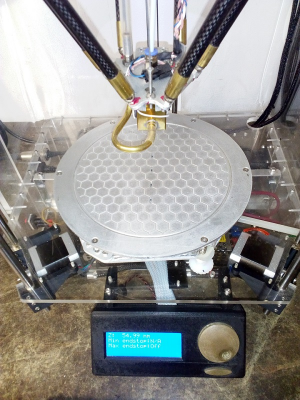

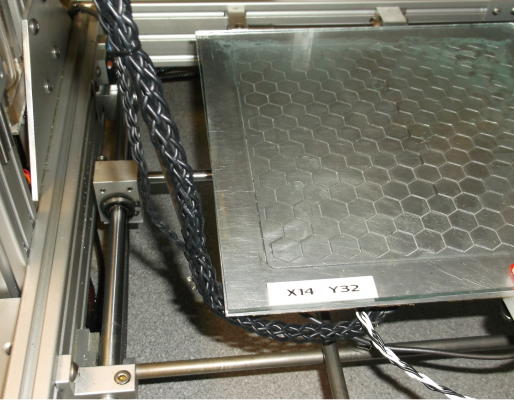

For this printer, I built a heated bed with vacuum channels milled in the same hexagonal pattern as on my Delta printer. In both cases, the milling for the vacuum channels and for the PTFE insulated Nichrome wire were cut 1mm deep with a 1mm end mill using the printer itself as a milling machine. The bed was made from 4mm thick anodised aluminium: Anodised aluminium is normally supplied dead flat, which is less often true of normal 6062 T6.

The bed is shown in the picture above. The glass plate is only there for some calibration runs I was doing. Vacuum is pulled through an 8mm diameter thin-walled stainless steel tube which is hidden in the plaited black cables – these are for bed heating, nozzle contact sensor, etc..

The first vacuum system used a 1/2HP vacuum pump but this was excessively noisy so was replaced with a small 24V vacuum pump which ran continuously. For the new printer, I built a vacuum reservoir with a diaphragm and microswitch to serve as a vacustat. When the pressure in the reservoir falls below ca 400mb, the motor is switched off and restarted when it rises above 500mb.

The reservoir is made of Perspex and has a capacity of 300ml. The vacuum pump is mounted on rubber mounts to avoid unwanted mechanical vibrations and if fitted with a silencer.

Although the frequency that the pump comes on obviously depends on the total leaks and out-gassing in the system, a typical figure is about 3 seconds of pumping every 3 minutes.

I have not used it sufficiently on the new printer to find any faults, but on the Delta printer, my conclusion remains the same: With PLA it is very very good, but with ABS it is pretty much unusable because of edge curl.

Mike

For this printer, I built a heated bed with vacuum channels milled in the same hexagonal pattern as on my Delta printer. In both cases, the milling for the vacuum channels and for the PTFE insulated Nichrome wire were cut 1mm deep with a 1mm end mill using the printer itself as a milling machine. The bed was made from 4mm thick anodised aluminium: Anodised aluminium is normally supplied dead flat, which is less often true of normal 6062 T6.

The bed is shown in the picture above. The glass plate is only there for some calibration runs I was doing. Vacuum is pulled through an 8mm diameter thin-walled stainless steel tube which is hidden in the plaited black cables – these are for bed heating, nozzle contact sensor, etc..

The first vacuum system used a 1/2HP vacuum pump but this was excessively noisy so was replaced with a small 24V vacuum pump which ran continuously. For the new printer, I built a vacuum reservoir with a diaphragm and microswitch to serve as a vacustat. When the pressure in the reservoir falls below ca 400mb, the motor is switched off and restarted when it rises above 500mb.

The reservoir is made of Perspex and has a capacity of 300ml. The vacuum pump is mounted on rubber mounts to avoid unwanted mechanical vibrations and if fitted with a silencer.

Although the frequency that the pump comes on obviously depends on the total leaks and out-gassing in the system, a typical figure is about 3 seconds of pumping every 3 minutes.

I have not used it sufficiently on the new printer to find any faults, but on the Delta printer, my conclusion remains the same: With PLA it is very very good, but with ABS it is pretty much unusable because of edge curl.

Mike

|

Re: Vacuum hold-down for 3D build surface. September 02, 2021 09:43AM |

Registered: 3 years ago Posts: 1 |

|

Re: Vacuum hold-down for 3D build surface. September 02, 2021 12:59PM |

Registered: 12 years ago Posts: 1,450 |

The bed is heated and in regular use at 60ºC and works well at 110ºC but as this temperature is used for ABS and ABS has too much edge curl for a vacuum hold down there has been no need for the higher temperature. The bottom of the bed with milled grooves for the heater wire can be seen on [reprap.org] (right-hand picture) and the assembled heater can be seen on [reprap.org].

Sealing works well with just a very thin smear of Vaseline or another grease around the outer periphery of the bed. Some materials like Tufnol or Garolite curl when first put on the bed and need to rest for a minute or so before the vacuum is switched on so that they will flatten.

Mike

Sealing works well with just a very thin smear of Vaseline or another grease around the outer periphery of the bed. Some materials like Tufnol or Garolite curl when first put on the bed and need to rest for a minute or so before the vacuum is switched on so that they will flatten.

Mike

Sorry, only registered users may post in this forum.