Delta printer

Posted by talha10com

|

Delta printer November 23, 2016 08:42AM |

Registered: 7 years ago Posts: 6 |

|

Re: Delta printer November 23, 2016 11:38AM |

Registered: 9 years ago Posts: 483 |

It will depend on the design. You can put the bed entirely inside the horizontals or it can extend outside. This will determine where the towers are placed and the length of the arms. It's pretty simple geometry to lay it out. Basic formula for arm length is 20 degrees to reach the edge of the print area and 60 degrees with the effector centered.

|

Re: Delta printer November 23, 2016 05:00PM |

Registered: 10 years ago Posts: 14,672 |

If you mean 300mm printable diameter, that happens to be the size of my 1m Kossel. Horizontals are 355mm and rods are 350mm between bearing centres. See the link to my blog in my signature for more build details. As etfrench says, the dimensions you need will depends on the design details of your printer, such as whether you mind the bed extending outside the horizontals (mine does) and how large the effector is.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta printer November 24, 2016 01:45AM |

Registered: 7 years ago Posts: 6 |

Quote

dc42

If you mean 300mm printable diameter, that happens to be the size of my 1m Kossel. Horizontals are 355mm and rods are 350mm between bearing centres. See the link to my blog in my signature for more build details. As etfrench says, the dimensions you need will depends on the design details of your printer, such as whether you mind the bed extending outside the horizontals (mine does) and how large the effector is.

can you please give the details for dimensioning? I'm a novice on this subject

|

Re: Delta printer November 24, 2016 01:45AM |

Registered: 7 years ago Posts: 6 |

Quote

etfrench

It will depend on the design. You can put the bed entirely inside the horizontals or it can extend outside. This will determine where the towers are placed and the length of the arms. It's pretty simple geometry to lay it out. Basic formula for arm length is 20 degrees to reach the edge of the print area and 60 degrees with the effector centered.

could you be more descriptive? I don't have too much experience.

|

Re: Delta printer December 03, 2016 10:08AM |

Registered: 7 years ago Posts: 6 |

|

Re: Delta printer December 03, 2016 02:39PM |

Registered: 9 years ago Posts: 483 |

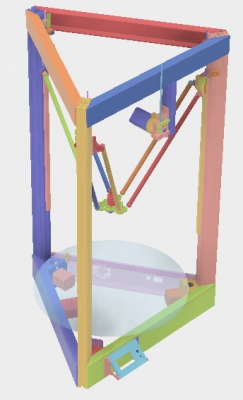

This drawing shows a delta with the print bed extending outside the horizontals:

If you make the horizontals longer in order to have the print bed inside the horizontals, then the towers will also be further away from each other and longer arms will be required for the same size print bed.

If you make the horizontals longer in order to have the print bed inside the horizontals, then the towers will also be further away from each other and longer arms will be required for the same size print bed.

|

Re: Delta printer December 03, 2016 02:49PM |

Registered: 12 years ago Posts: 1,450 |

The thing about scaling is that you often need to increase some parts much more than you may think. For example, many small printers have a working volume of about 200mm wide but 200mm deep by 200mm high and they use 8mm smooth rods - the individual errors over this size tend to be a bit less than 0.1mm and they add up to about 0.1mm or thereabouts with care. If however you wanted to double the size of everything then you would need to use shafts of 16mm and this is the bitter point -- the errors would also be twice as big at about 0.2mm. To get back to the 0.1mm figure you would need shafts and other load bearing bits about double as big again, that is 32mm shafts. The above applies to cartesian printers admittedly, but the forces are the same in delta printers. so you will be better off by squaring the increase so even 50% bigger will need 125% thicker bits.

Edited 1 time(s). Last edit at 12/03/2016 04:25PM by leadinglights.

Edited 1 time(s). Last edit at 12/03/2016 04:25PM by leadinglights.

|

Re: Delta printer December 06, 2016 06:40AM |

Registered: 8 years ago Posts: 356 |

Quote

leadinglights

The thing about scaling is that you often need to increase some parts much more than you may think. For example, many small printers have a working volume of about 200mm wide but 200mm deep by 200mm high and they use 8mm smooth rods - the individual errors over this size tend to be a bit less than 0.1mm and they add up to about 0.1mm or thereabouts with care. If however you wanted to double the size of everything then you would need to use shafts of 16mm and this is the bitter point -- the errors would also be twice as big at about 0.2mm. To get back to the 0.1mm figure you would need shafts and other load bearing bits about double as big again, that is 32mm shafts. The above applies to cartesian printers admittedly, but the forces are the same in delta printers. so you will be better off by squaring the increase so even 50% bigger will need 125% thicker bits.

This do not apply to delta, he want a bigger bed, he only need to scale the bottom and top extrusion in length. Even if he want to scale the height, you just use 20X40 tower for around 1 -1.5 meter tall and I say 40X40 for more than 1.5 meter, then no one use linear rod in delta anymore, you use MGN rail or if its really tall Vslot carrier might be better price/length. A larger delta do not throw more error than a small one, its all about the quality or part and build.

|

Re: Delta printer December 06, 2016 04:07PM |

Registered: 10 years ago Posts: 14,672 |

Quote

talha10com

Quote

dc42

If you mean 300mm printable diameter, that happens to be the size of my 1m Kossel. Horizontals are 355mm and rods are 350mm between bearing centres. See the link to my blog in my signature for more build details. As etfrench says, the dimensions you need will depends on the design details of your printer, such as whether you mind the bed extending outside the horizontals (mine does) and how large the effector is.

can you please give the details for dimensioning? I'm a novice on this subject

Like I said, follow the link in my signature to my blog for more details.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta printer December 07, 2016 04:52AM |

Registered: 7 years ago Posts: 6 |

|

Re: Delta printer December 07, 2016 07:03AM |

Registered: 10 years ago Posts: 14,672 |

Quote

talha10com

there are too many threads can you throw a link to access?

This one [miscsolutions.wordpress.com] contains the basic build details. The later ones describe upgrades.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta printer December 13, 2016 01:35PM |

Registered: 8 years ago Posts: 601 |

Quote

GroupB

Quote

leadinglights

The thing about scaling is that you often need to increase some parts much more than you may think. For example, many small printers have a working volume of about 200mm wide but 200mm deep by 200mm high and they use 8mm smooth rods - the individual errors over this size tend to be a bit less than 0.1mm and they add up to about 0.1mm or thereabouts with care. If however you wanted to double the size of everything then you would need to use shafts of 16mm and this is the bitter point -- the errors would also be twice as big at about 0.2mm. To get back to the 0.1mm figure you would need shafts and other load bearing bits about double as big again, that is 32mm shafts. The above applies to cartesian printers admittedly, but the forces are the same in delta printers. so you will be better off by squaring the increase so even 50% bigger will need 125% thicker bits.

This do not apply to delta, he want a bigger bed, he only need to scale the bottom and top extrusion in length. Even if he want to scale the height, you just use 20X40 tower for around 1 -1.5 meter tall and I say 40X40 for more than 1.5 meter, then no one use linear rod in delta anymore, you use MGN rail or if its really tall Vslot carrier might be better price/length. A larger delta do not throw more error than a small one, its all about the quality or part and build.

Actually, leadlinglights is correct but on a delta the main consideration when going big is the arms and effector as these can really show build errors.

Sorry, only registered users may post in this forum.