Tough X-axis?

Posted by ketil

|

Tough X-axis? February 06, 2011 06:45PM |

Registered: 13 years ago Posts: 43 |

Hi,

I'm building a TechZone Huxley, and I've just connected the motor and the belt to the X-axis. How much force should be required to move the carriage when the motors are off?

I'm concerned that there's a problem, because the carriage requires more force to move than I expected - I can barely move it with one finger, and I need to grip the frame with one hand and push the carriage pretty hard, hard enough that it's tough to do with just one finger. (Maybe I'm just really really weak ). If I just push on the carriage, I push the entire reprap around on the table without budging the carriage along its axis. If I unmount the belt, the carriage moves pretty freely again.

). If I just push on the carriage, I push the entire reprap around on the table without budging the carriage along its axis. If I unmount the belt, the carriage moves pretty freely again.

Cheers, Ketil

I'm building a TechZone Huxley, and I've just connected the motor and the belt to the X-axis. How much force should be required to move the carriage when the motors are off?

I'm concerned that there's a problem, because the carriage requires more force to move than I expected - I can barely move it with one finger, and I need to grip the frame with one hand and push the carriage pretty hard, hard enough that it's tough to do with just one finger. (Maybe I'm just really really weak

). If I just push on the carriage, I push the entire reprap around on the table without budging the carriage along its axis. If I unmount the belt, the carriage moves pretty freely again.

). If I just push on the carriage, I push the entire reprap around on the table without budging the carriage along its axis. If I unmount the belt, the carriage moves pretty freely again.Cheers, Ketil

|

Re: Tough X-axis? February 06, 2011 11:53PM |

Registered: 13 years ago Posts: 601 |

i don't know the huxley, but with a mendel, having the belts attached and tensioned makes the carriage a bit hard to move. it is mostly the magnets in motors that cause the resistance. I can move it one handed with the mendel, but it is probably quite a bit heavier than a huxley.

How well does it move with the belts unattached?

How well does it move with the belts unattached?

|

Re: Tough X-axis? February 06, 2011 11:56PM |

Registered: 13 years ago Posts: 188 |

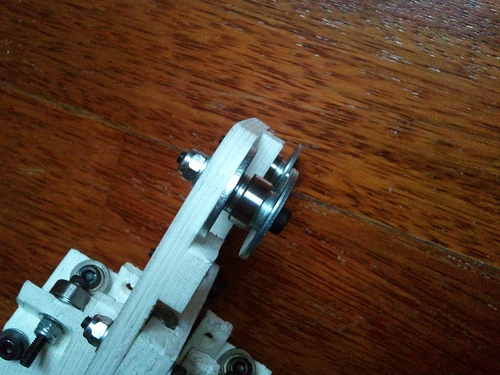

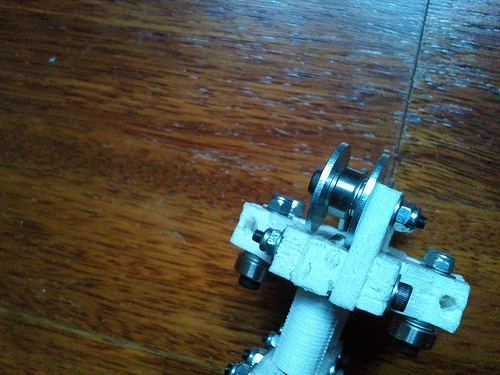

The X axis belt wraps around four bearings with fender washers serving as flanges. Did you use three washers or just two as spacers between the big fender washers and the bearing? If you only used two washers, the fender washers will be too close together and they will pinch down of the belt. Maybe this is the source of your friction?

Since you say it moves fine without the belt attached, the only other thing I would check is that the motor spins freely. If you glued the gear on, maybe some of it went into the motor and locked it up?

If the motor is truly not powered on, it should be just a bit harder to move than the X-carriage by itself. You will feel a bit of resistance from turning the motor, but it should be no where near as stiff as what you are describing until the motor is powered up.

Since you say it moves fine without the belt attached, the only other thing I would check is that the motor spins freely. If you glued the gear on, maybe some of it went into the motor and locked it up?

If the motor is truly not powered on, it should be just a bit harder to move than the X-carriage by itself. You will feel a bit of resistance from turning the motor, but it should be no where near as stiff as what you are describing until the motor is powered up.

|

Re: Tough X-axis? February 07, 2011 05:11AM |

Registered: 13 years ago Posts: 482 |

Also check that the motor wires are not shorted. That will cause the motor to fight back when you try turn it - even with no power supplied.

-induction and all that.

See "pair" wires to determine coils

for more details on this.

-induction and all that.

See "pair" wires to determine coils

for more details on this.

|

Re: Tough X-axis? February 07, 2011 05:39AM |

Registered: 13 years ago Posts: 43 |

Thanks for all the replies! I've not used glue, and I tested all the motors before mounting them on the frame, so everything should be fine with them. I've attached the gear with a screw, but I think the gear cracked, so I'll have to try and fix that to avoid any slipping.

Still, it seems there is some source of friction somewhere. I'll double check for friction between the belt and anything else, and hopefully that'll fix things. I actually happened to have some close up pictures already online:

RepRap Huxley X-axis detail by Ketil, on Flickr

RepRap Huxley X-axis detail by Ketil, on Flickr

and it looks like I've not used 3 washers on the Z180 side of the X-axis, only on the Z360 side. I'll try to add some more and hopefully things will move more smoothly.

Cheers, Ketil

Still, it seems there is some source of friction somewhere. I'll double check for friction between the belt and anything else, and hopefully that'll fix things. I actually happened to have some close up pictures already online:

RepRap Huxley X-axis detail by Ketil, on Flickr

RepRap Huxley X-axis detail by Ketil, on Flickr

and it looks like I've not used 3 washers on the Z180 side of the X-axis, only on the Z360 side. I'll try to add some more and hopefully things will move more smoothly.

Cheers, Ketil

|

Re: Tough X-axis? February 07, 2011 02:01PM |

Registered: 13 years ago Posts: 43 |

OK, I've added more washers and loosened the bolts holding the bearings. It may have helped a little, though I can't really say for sure. In a basic test, I didn't _see_ the X-axis slip, so it appears to be a bit better. It's still pretty tough to move the carriage, though. How can I quantise the power needed to do this? Maybe I ought to set up a pulley rig and see how much weight it takes to move the X-axis.

I really don't see what's causing the friction now, though. Without the belt, the carriage moves pretty freely. I can also check that the belt fits with room to spare between the large washers around the bearings, and that the belt seems to slide freely between each. After going through the exercises I've done, it actually seems it's just the force from the motor (even when it's off) that causes the friction. I can twist the gear pretty easily with 2 fingers, so hopefully it's light enough. I guess I'll just have to try.

I've also broken the gear. That is, I've screwn on the bolt too hard, so the bearing mounted inside the gear cracked the part and almost popped out. The gear itself is fine, but now I have some trouble fixing it. I'm considering glueing it onto the motor shaft, going easy on the glue and not using the toughest stuff around. Hopefully that will hold and allow for parts changing in the future. Any tips would be appreciated.

Cheers, Ketil

I really don't see what's causing the friction now, though. Without the belt, the carriage moves pretty freely. I can also check that the belt fits with room to spare between the large washers around the bearings, and that the belt seems to slide freely between each. After going through the exercises I've done, it actually seems it's just the force from the motor (even when it's off) that causes the friction. I can twist the gear pretty easily with 2 fingers, so hopefully it's light enough. I guess I'll just have to try.

I've also broken the gear. That is, I've screwn on the bolt too hard, so the bearing mounted inside the gear cracked the part and almost popped out. The gear itself is fine, but now I have some trouble fixing it. I'm considering glueing it onto the motor shaft, going easy on the glue and not using the toughest stuff around. Hopefully that will hold and allow for parts changing in the future. Any tips would be appreciated.

Cheers, Ketil

|

Re: Tough X-axis? February 07, 2011 02:14PM |

Registered: 14 years ago Posts: 3,742 |

I don't know about the Huxley but on the Mendel if you can't move the X & Y axis with your little finger (of course with the power off) then there is something WRONG!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Tough X-axis? February 07, 2011 02:36PM |

Registered: 13 years ago Posts: 43 |

I can move it... but it's pretty tough. Does everyone else's carriage slide really easily when the belt and the motor are mounted?

Perhaps my motor is just stiffer than other motors? It seems the motors I have are a new model, I think. None of the bolts that came with my techzone kit fit for the motors, the holes in the motor are just 4mm deep, and it seemed like that was more shallow than normal.

Or maybe I'm just clutching at straws... But I don't see what else it can be.

But I don't see what else it can be.

Perhaps my motor is just stiffer than other motors? It seems the motors I have are a new model, I think. None of the bolts that came with my techzone kit fit for the motors, the holes in the motor are just 4mm deep, and it seemed like that was more shallow than normal.

Or maybe I'm just clutching at straws...

But I don't see what else it can be.

But I don't see what else it can be.

|

Re: Tough X-axis? February 07, 2011 06:54PM |

Registered: 13 years ago Posts: 188 |

If I turn my mendel on its side, the carriage will move under its own weight - even with the belt and motor attached. With no belt on, if my table is not level, the carriage will naturally roll to one side.

I think my scales are only sensitive to 0.5lbs or more, but I didn't even get a reading out of it when I tried to test the force required.

Do you have any slack at all in the belt? Maybe you just have it so tight that it can't stretch enough for the timing teeth to ride over the bearings. You don't want it so loose that you see a lag between turning the gear and the carriage moving, but you should be able to displace it by 1mm or so easily with your finger. At least, this is how tight my belt is.

Edited 1 time(s). Last edit at 02/07/2011 06:56PM by dazed.dnc.

I think my scales are only sensitive to 0.5lbs or more, but I didn't even get a reading out of it when I tried to test the force required.

Do you have any slack at all in the belt? Maybe you just have it so tight that it can't stretch enough for the timing teeth to ride over the bearings. You don't want it so loose that you see a lag between turning the gear and the carriage moving, but you should be able to displace it by 1mm or so easily with your finger. At least, this is how tight my belt is.

Edited 1 time(s). Last edit at 02/07/2011 06:56PM by dazed.dnc.

|

Re: Tough X-axis? February 07, 2011 07:29PM |

Registered: 13 years ago Posts: 43 |

As it turns out, things do have an explanation, even though I don't see one.

I mailed with Lambert at TechZoneCom, and I got a pretty good description from him. The carriage has a bushing along one smooth bar on the X axis, and the belt is on the same side. Here's a picture showing the bushing being mounted:

http://reprap.org/wiki/File:HuxleyXCarriage180n360.jpg

Initial Huxley designs had the belt attached on the opposite side, but moving the belt to the same side creates much more linear pressure. I can verify this by gripping the bushing side of my carriage, and I can push it back and forth (still not easy, but it's not too hard I guess). If I grip the opposite side of the carriage, near the other smooth bar, the carriage won't budge.

So since I can manually turn the motor, and that doesn't require a lot of force, it's pretty easy with two fingers, I guess (hope) I'm ok.

Also, I didn't seat the bushings as well as the manual described, so this could be caused by that, at least in part. Maybe it'll smoothen out over time. If I miss steps during use, I'll try to disassemble the X-axis again and do that properly, but I hope that won't be necessary...

Thanks for the help, everyone!

I mailed with Lambert at TechZoneCom, and I got a pretty good description from him. The carriage has a bushing along one smooth bar on the X axis, and the belt is on the same side. Here's a picture showing the bushing being mounted:

http://reprap.org/wiki/File:HuxleyXCarriage180n360.jpg

Initial Huxley designs had the belt attached on the opposite side, but moving the belt to the same side creates much more linear pressure. I can verify this by gripping the bushing side of my carriage, and I can push it back and forth (still not easy, but it's not too hard I guess). If I grip the opposite side of the carriage, near the other smooth bar, the carriage won't budge.

So since I can manually turn the motor, and that doesn't require a lot of force, it's pretty easy with two fingers, I guess (hope) I'm ok.

Also, I didn't seat the bushings as well as the manual described, so this could be caused by that, at least in part. Maybe it'll smoothen out over time. If I miss steps during use, I'll try to disassemble the X-axis again and do that properly, but I hope that won't be necessary...

Thanks for the help, everyone!

|

Re: Tough X-axis? February 07, 2011 08:24PM |

Registered: 13 years ago Posts: 601 |

|

Re: Tough X-axis? April 20, 2011 11:19PM |

Registered: 13 years ago Posts: 248 |

Hi Ketil

I am in a similar position as you, but I have the motors powered now. I tried to jog it using the repsnapper to see if it will move by command and it inches by 1mm but does not do the 10mm, it makes a humming motor noise as if the motor is stuck. I don't know what the problem is.

Im going to try the following (unless I see others have already done it on the forum)

-Readjust the belt tension (even though I can displace it 1mm, its not soo tight)

-Readjust the height of one side of the Z axis (i measured it and the left side is 1mm shorter than the right side)

-I might add one more washer as Dazed.Dnc said:

ANy help would be greatly appreciated. I have this week off so I want to get it running and into my middle school so the students can check it out! Excited and appreciating the community's help!

Thanks all

I am in a similar position as you, but I have the motors powered now. I tried to jog it using the repsnapper to see if it will move by command and it inches by 1mm but does not do the 10mm, it makes a humming motor noise as if the motor is stuck. I don't know what the problem is.

Im going to try the following (unless I see others have already done it on the forum)

-Readjust the belt tension (even though I can displace it 1mm, its not soo tight)

-Readjust the height of one side of the Z axis (i measured it and the left side is 1mm shorter than the right side)

-I might add one more washer as Dazed.Dnc said:

Quote

Dazed.DNC

The X axis belt wraps around four bearings with fender washers serving as flanges. Did you use three washers or just two as spacers between the big fender washers and the bearing? If you only used two washers, the fender washers will be too close together and they will pinch down of the belt. Maybe this is the source of your friction?

ANy help would be greatly appreciated. I have this week off so I want to get it running and into my middle school so the students can check it out! Excited and appreciating the community's help!

Thanks all

|

Re: Tough X-axis? April 21, 2011 03:04AM |

Admin Registered: 16 years ago Posts: 13,884 |

... if your motors drive 1mm steps and stall for longer distances, then you have acceleration on and the max. speed is to fast for your motors ... or the driving current and/or voltage isn't enough for this speed ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Tough X-axis? April 21, 2011 07:03AM |

Registered: 13 years ago Posts: 248 |

Thank you Viktor. That's exactly what Kurt from Techzonecom said:

Quote

Kurt Bidstrup from Techzonecom.com

If the belts seem loose enough then the potentiometer most likely needs adjusted up. Just adjust in small increments and make sure the motor doesn't get too hot. It should be able to move the axis without heating up above 50-55 degrees Celsius. I have had one time when the axis was tight enough despite my best efforts that i needed to turn the motor up above that, but i put a heat sink on it to keep it down in that range of temperature. Once it had been running for a while and loosened everything up i was able to turn the motor back down and remove the heat sink. Same thing happens with the speed you can print at. When the machine is new it is still tight enough that it is hard to print at full speed without losing steps. Once it has worn itself in a bit then it can be sped up.

|

Re: Tough X-axis? April 21, 2011 07:35AM |

Registered: 13 years ago Posts: 248 |

Ok, I tried to adjust the pot's, but this is what happened

1) I adjusted the pot to the highest (before it turns to the red light?) I dunno what the red light means?

2) I stepped it and the light turned red. I reduced the pot until the red light dimmed enough, then stepped it and the light turned green.

How Do you decrease the acceleration Viktor? I increased the pot but Im afraid of the red light..

Interpretation of red light would be helpful... ill go search for that

1) I adjusted the pot to the highest (before it turns to the red light?) I dunno what the red light means?

2) I stepped it and the light turned red. I reduced the pot until the red light dimmed enough, then stepped it and the light turned green.

How Do you decrease the acceleration Viktor? I increased the pot but Im afraid of the red light..

Interpretation of red light would be helpful... ill go search for that

|

Re: Tough X-axis? April 21, 2011 07:56AM |

Registered: 13 years ago Posts: 248 |

Just an update.

MY Y axis is moving great in 1 direction, the X axis is still not moving at all now. The Extruder is doing great.

The Z axis is also doing great.

How do I make the X pot same as the y? It keeps turning, so is the Red LED there for a flag? Or it means somthing else?

Thanks!

Edited 1 time(s). Last edit at 04/21/2011 07:58AM by owism8.

MY Y axis is moving great in 1 direction, the X axis is still not moving at all now. The Extruder is doing great.

The Z axis is also doing great.

How do I make the X pot same as the y? It keeps turning, so is the Red LED there for a flag? Or it means somthing else?

Thanks!

Edited 1 time(s). Last edit at 04/21/2011 07:58AM by owism8.

|

Re: Tough X-axis? April 21, 2011 08:54AM |

Admin Registered: 17 years ago Posts: 7,879 |

The red and green lights just indicate the polarity of the voltage applied to each coil, so just indicate the board is working if they alternate while moving slowly. They don't mean anything much when it is stationary as it can stop on any combination of red and green.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Tough X-axis? April 21, 2011 08:59AM |

Registered: 13 years ago Posts: 248 |

Thanks a bunch nophead. Great documentation by-the-way on your blog.

I am going to jog the axis 10 mm at a time and adjust the pot at the same time.

Is that the method Everyone does?

Thanks for your help!

***Update - I did the adjust while moving the axis 10mm at a time and its working, but the problem wasnt the pot, the problem was the Gear.

The gear on the x axis was slipping (I guess out of heat expansion) after I shoved it back it, it started working again.

How did you make sure your gear doesnt slip off your motor? Just a screw? Hot glue?

Also: Y axis - moving forward +10mm but not -10mm, wahts the problem? I adjusted all my pots. The Opto-end is connected... whats the issue?

Edited 1 time(s). Last edit at 04/21/2011 09:37AM by owism8.

I am going to jog the axis 10 mm at a time and adjust the pot at the same time.

Is that the method Everyone does?

Thanks for your help!

***Update - I did the adjust while moving the axis 10mm at a time and its working, but the problem wasnt the pot, the problem was the Gear.

The gear on the x axis was slipping (I guess out of heat expansion) after I shoved it back it, it started working again.

How did you make sure your gear doesnt slip off your motor? Just a screw? Hot glue?

Also: Y axis - moving forward +10mm but not -10mm, wahts the problem? I adjusted all my pots. The Opto-end is connected... whats the issue?

Edited 1 time(s). Last edit at 04/21/2011 09:37AM by owism8.

|

Re: Tough X-axis? April 22, 2011 12:30PM |

Registered: 16 years ago Posts: 824 |

Bronze bushings need perfect alignment in order to work well. The two smooth rods need to be equally distant along the full length. Take a caliper, and check that this is in fact the case.

If you find that this is a little off at one end or the other, you can file the rod clapm holes a bit side to side to give extra wiggle room, and then tighten your screws while the X Carriage is butt up against the part.

If your gear is slipping because your X motor is running hot, turn your pots down. The motors should never be hot. Only a little warm. The best way to adjust the pots is to turn it all the way down, issue a long move command, and turn the pots until the motor begins moving without making much vibration. This should only be about 1/8 of a turn from full off (assuming that you are using POLOLU drivers).

If you can't get the X axis going, consider using PLA bushings. They are very forgiving, and in fact quite adequate.

Good luck!

If you find that this is a little off at one end or the other, you can file the rod clapm holes a bit side to side to give extra wiggle room, and then tighten your screws while the X Carriage is butt up against the part.

If your gear is slipping because your X motor is running hot, turn your pots down. The motors should never be hot. Only a little warm. The best way to adjust the pots is to turn it all the way down, issue a long move command, and turn the pots until the motor begins moving without making much vibration. This should only be about 1/8 of a turn from full off (assuming that you are using POLOLU drivers).

If you can't get the X axis going, consider using PLA bushings. They are very forgiving, and in fact quite adequate.

Good luck!

|

Re: Tough X-axis? April 22, 2011 12:39PM |

Registered: 13 years ago Posts: 248 |

Thanks for the help.

I got advice to glue the cogs on and that should help.

I got a nice test video here showing the X and Z working: Success video

One thing the Z is causing issues now. When it goes down to the Opto, it wont go back up but will still go down (which is against the law of opto-end!) When I remove the opto, it goes back up. so its seeing the world upside-down.

Anywho I got some advice on that from someone saying that the motor is reversed, I gotta test that after the glue is cured on the cogs.

Enjoy the video!

I got advice to glue the cogs on and that should help.

I got a nice test video here showing the X and Z working: Success video

One thing the Z is causing issues now. When it goes down to the Opto, it wont go back up but will still go down (which is against the law of opto-end!) When I remove the opto, it goes back up. so its seeing the world upside-down.

Anywho I got some advice on that from someone saying that the motor is reversed, I gotta test that after the glue is cured on the cogs.

Enjoy the video!

Sorry, only registered users may post in this forum.