Cooling with an air pump?

Posted by icefire

|

Re: Cooling with an air pump? March 24, 2017 09:40AM |

Registered: 12 years ago Posts: 799 |

Quote

dc42

Quote

leadinglights

Now that is a heater worth having. Somebody please make those and put them on the market - I will pay real money

Mike

It is on the market, but sadly it's not available in 24V, otherwise I would have bought one to try.

Activating PWM for the hotend will allow you to use 12V heater on higher voltages

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: Cooling with an air pump? March 24, 2017 02:54PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Chri

Quote

dc42

Quote

leadinglights

Now that is a heater worth having. Somebody please make those and put them on the market - I will pay real money

Mike

It is on the market, but sadly it's not available in 24V, otherwise I would have bought one to try.

Activating PWM for the hotend will allow you to use 12V heater on higher voltages

Chri

That has the potential to run the heater at 4x its usual power if anything goes wrong. Too dangerous for me.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cooling with an air pump? March 27, 2017 02:07AM |

Registered: 8 years ago Posts: 312 |

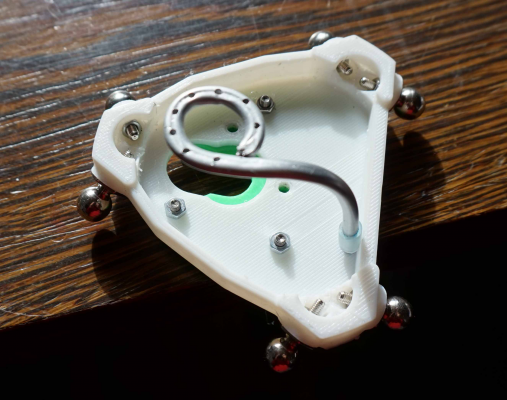

This is the air ring I made.

It uses a 4 mm alu tube that I simply bent into shape with my hands. Every now and then I had to squeeze the tube with some pliers when there was a little kink starting. Then I squashed the whole ring in a vice to lower the profile (3.15 mm) and simply drilled the 1.5 mm holes. It now fits under my V6 heatblock around the nozzle. It will also still fit with the sock installed, but then there is next to no free space between it and the part. About 0.5 mm and that is a bit too close for comfort.

I have printed with it and it does work. As long as I have my first layer right.

I think I will try and squash it a little more before I go do some real testing with it. Also, I still need to connect the air pump to the control board, I am now simply using a wall wart.

Edited 1 time(s). Last edit at 03/27/2017 02:08AM by Lykle.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

It uses a 4 mm alu tube that I simply bent into shape with my hands. Every now and then I had to squeeze the tube with some pliers when there was a little kink starting. Then I squashed the whole ring in a vice to lower the profile (3.15 mm) and simply drilled the 1.5 mm holes. It now fits under my V6 heatblock around the nozzle. It will also still fit with the sock installed, but then there is next to no free space between it and the part. About 0.5 mm and that is a bit too close for comfort.

I have printed with it and it does work. As long as I have my first layer right.

I think I will try and squash it a little more before I go do some real testing with it. Also, I still need to connect the air pump to the control board, I am now simply using a wall wart.

Edited 1 time(s). Last edit at 03/27/2017 02:08AM by Lykle.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Cooling with an air pump? April 10, 2017 10:32PM |

Registered: 9 years ago Posts: 71 |

Has anyone thought about running two fans in series (no, not wiring) to create more pressure? I figure it ought to work similar to series vs parallel in electronics, with series keeping the same current, or airflow, and parallel keeping the same voltage, or air pressure.

I have a 50mm centrifugal fan connected to some 3d printed locline duct currently, and the back pressure is still lacking. I may try whipping up a modular centrifugal fan combiner to play with if anyone can confirm I'm not just stupid lol.

I normally have the centrifugal fan at 100% PWM to compensate for poor pressure, but if this concept applies, multiple near-silent fans run at lower speeds in series should still give the required airflow.

I have a 50mm centrifugal fan connected to some 3d printed locline duct currently, and the back pressure is still lacking. I may try whipping up a modular centrifugal fan combiner to play with if anyone can confirm I'm not just stupid lol.

I normally have the centrifugal fan at 100% PWM to compensate for poor pressure, but if this concept applies, multiple near-silent fans run at lower speeds in series should still give the required airflow.

|

Re: Cooling with an air pump? April 11, 2017 03:38AM |

Registered: 12 years ago Posts: 2,470 |

Stacking fans does not realy help to increase pressure. Fans in principle are very limited in the pressure they can achieve. The more backpressure you get the more turbulences are produced in the fan and at some point you are not moving air anymore but mixing it in place. Radial fans (blowers) will work a bit better than axial fans, but not nearly as much as even a small pump. Pumps on the other hand will not move as much volume as fans.

This is why i redesigned my extruders to work with the small amount of air a small membrane pump can produce. You have to rethink your approach on cooling if you want to use pressure instead of volume.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

This is why i redesigned my extruders to work with the small amount of air a small membrane pump can produce. You have to rethink your approach on cooling if you want to use pressure instead of volume.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Cooling with an air pump? April 11, 2017 03:48AM |

Registered: 12 years ago Posts: 1,450 |

I think that two centrifugal blowers in series would not be enough but this would depend on the design of the vanes on the fan wheel. Very deep vanes curving forward on the air inlet and either straight or backwards on the exit gives a much higher pressure - this is similar to the shape on a turbocharger compressor or possibly a vacuum cleaner. I have never seen such a fan although that does not mean they don't exist.

As far as aquarium pumps go, very few are noisy when they have some back pressure - as you would expect for something used in a domestic environment. If they become noisy this indicates that a air line has fallen off.

Mike

As far as aquarium pumps go, very few are noisy when they have some back pressure - as you would expect for something used in a domestic environment. If they become noisy this indicates that a air line has fallen off.

Mike

|

Re: Cooling with an air pump? April 11, 2017 01:51PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Cooling with an air pump? May 14, 2017 06:05AM |

Registered: 7 years ago Posts: 10 |

Hi

I converted to an air pump supply some 18months ago.The air exits in a fan shape just under the nozzle about 3mm away from the tip .I have printed lots of things since

with no problems.The only fan i use is for cooling the hotend also by removing the fans and ducting you save a lot of weight on the moving printhead.

Rod.

I converted to an air pump supply some 18months ago.The air exits in a fan shape just under the nozzle about 3mm away from the tip .I have printed lots of things since

with no problems.The only fan i use is for cooling the hotend also by removing the fans and ducting you save a lot of weight on the moving printhead.

Rod.

|

Re: Cooling with an air pump? May 19, 2017 04:53AM |

Registered: 10 years ago Posts: 169 |

I just assembled the cyclops hot end mount I designed for the air pump system. It took about an hour to clear the Alumide power from all the openings but it seems to flow pretty good under pressure. Started putting the machine back together with new linear Delrin ball slides I designed for the XY & Z axis. They feel really smooth and run really quite. We'll soon see if this was worthwhile or not...

|

Re: Cooling with an air pump? May 20, 2017 09:35AM |

Registered: 8 years ago Posts: 312 |

|

Re: Cooling with an air pump? May 20, 2017 04:17PM |

Registered: 10 years ago Posts: 169 |

Thanks Lykle. I hope to be printing this summer, but that's what I said last year about this same time. I have a lot of irons in the fire so this printer isn't my first priority. I do however, finally have all the components at hand after several design iterations that were just too ambitious given my limited experience and dead end alleys with local print hubs. I ended up using Shapeways to print the motion parts I needed in Alumide. I'm very satisfied with the work they produced even though they were somewhat expensive. In the end, the time and expense I wasted on hub printers was a near total loss, so what Shapeways cost me was money well spent. Given the quality of these parts, I'd love to have a SLS printer to work with but that's simply out of the question. I'll post reassembly pictures as I put the machine back together for this final design version. Thanks....

|

Re: Cooling with an air pump? May 21, 2017 01:47AM |

Registered: 8 years ago Posts: 312 |

|

Re: Cooling with an air pump? May 23, 2017 11:15PM |

Registered: 10 years ago Posts: 169 |

Sorry, only registered users may post in this forum.