is there any difference in layer accuracy between m5 and m8 threaded rods ??

Posted by Nikki81

|

is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 18, 2017 01:58PM |

Registered: 9 years ago Posts: 198 |

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 18, 2017 02:27PM |

Registered: 11 years ago Posts: 5,780 |

There shouldn't be any difference in accuracy. The pitch may be different, requiring different steps/mm setting.

If you're trying to fix z wobble, swapping M8 for M5 rods may not improve anything. There's no guarantee that the M8 rods are any straighter than the M5 rods, and if they aren't any straighter, the stiffer M8 rods will apply more lateral force to the printer's frame, so things may actually get worse.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you're trying to fix z wobble, swapping M8 for M5 rods may not improve anything. There's no guarantee that the M8 rods are any straighter than the M5 rods, and if they aren't any straighter, the stiffer M8 rods will apply more lateral force to the printer's frame, so things may actually get worse.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 18, 2017 02:54PM |

Registered: 9 years ago Posts: 198 |

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 18, 2017 03:34PM |

Registered: 11 years ago Posts: 98 |

Correct me if I'm wrong but M6 will give you more better accuracies as it is a 1mm pitch. It allows you to adjust layer height to two decimal places and still have even steps. M5 and M8 will both be limited to certain heights at 2 decimal places. Not sure how important this would be to anybody. For instance a 0.25mm layer height is even steps on m6 and m8 but not on m5. All three are good to any one decimal place. Haven't heard of any printers with 6mm lead screws though.

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 18, 2017 04:08PM |

Registered: 9 years ago Posts: 198 |

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 18, 2017 09:24PM |

Registered: 9 years ago Posts: 483 |

Leadscrews can have any thread form, so your M5, 6, or 8 threaded rods will properly be called leadscrews. A leadscrew should not be expected to add any rigidity to a frame. A larger diameter leadscrew will have less whipping at higher rpms and less droop over a long expanse. I don't think it's possible for anyone to tell you what diameter leadscrew you need without knowing more specifics about the length, the support system (ball bearings, bushings, etc.), stepper motor size, rpm, etc.

You can make hardware store threaded rod into quite respectable leadscrews by lapping.

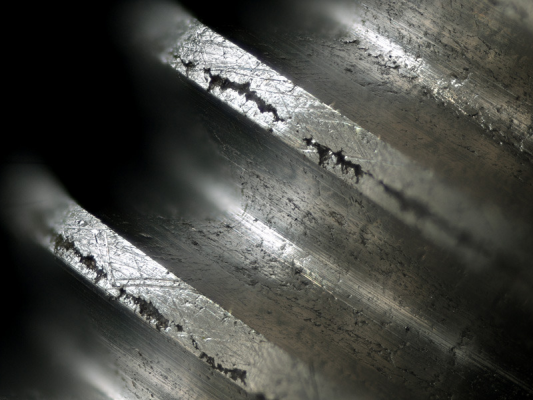

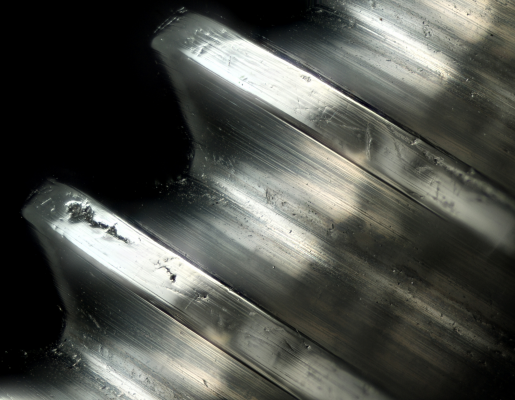

Here's before and after photos of an M6 threaded rod that I lapped:

p.s. The threaded rod looked really good until I took the macro photos of it

Edited 1 time(s). Last edit at 02/18/2017 09:25PM by etfrench.

You can make hardware store threaded rod into quite respectable leadscrews by lapping.

Here's before and after photos of an M6 threaded rod that I lapped:

p.s. The threaded rod looked really good until I took the macro photos of it

Edited 1 time(s). Last edit at 02/18/2017 09:25PM by etfrench.

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 06:45AM |

Registered: 8 years ago Posts: 622 |

You can buy 8mm x 1mm lead screws (I did). Note that I use the term "lead" rather than pitch. Lead is the linear distance a nut would travel in 1 revolution, pitch is the distance between threads. With a single start screws, they happen to amount to the same thing but on multi start screws, they are completely different.

IMO it's important that layer height should be a function of full steps and not rely on micro steps for positional accuracy. As an example, there are 4 start screws with 2mm pitch but 8mm lead which, for reasons that make no sense at all, people like to use on their Z axes. So with normal 1.8 degree stepper and 1:1 gearing, I revolution is 200 steps which is 8mm. That comes down to 25 (full) steps per mm or 2.5 steps per 0.1mm. i.e. at 0.1mm layer height, you'd be relying on micro stepping to give one half of a full step for positional accuracy which is not good. 0.2mm layer height would be fine as it would be 5 full steps but 0.3mm layer height, you'd be using 7.5 full steps (not good). Choosing layer heights that are divisible by 4 would work - i.e 0.4, 0.8, 1.2, 1.6, 2.0, 2.4, 2.8 etc. but a missed step would have a significant impact on accuracy so using a finer "lead" is IMO more desirable (unless of course you want a really fast Z axis which also requires more torque to turn the screws and hence possible bigger motors, and the possibility that once power to the motors is disconnected the steeper helix angle of an 8mm pitch screws may not hold the bed in position ).

IMO it's important that layer height should be a function of full steps and not rely on micro steps for positional accuracy. As an example, there are 4 start screws with 2mm pitch but 8mm lead which, for reasons that make no sense at all, people like to use on their Z axes. So with normal 1.8 degree stepper and 1:1 gearing, I revolution is 200 steps which is 8mm. That comes down to 25 (full) steps per mm or 2.5 steps per 0.1mm. i.e. at 0.1mm layer height, you'd be relying on micro stepping to give one half of a full step for positional accuracy which is not good. 0.2mm layer height would be fine as it would be 5 full steps but 0.3mm layer height, you'd be using 7.5 full steps (not good). Choosing layer heights that are divisible by 4 would work - i.e 0.4, 0.8, 1.2, 1.6, 2.0, 2.4, 2.8 etc. but a missed step would have a significant impact on accuracy so using a finer "lead" is IMO more desirable (unless of course you want a really fast Z axis which also requires more torque to turn the screws and hence possible bigger motors, and the possibility that once power to the motors is disconnected the steeper helix angle of an 8mm pitch screws may not hold the bed in position ).

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 08:00AM |

Registered: 8 years ago Posts: 5,232 |

Most people here call 1/4 steps " safe". Anything above is just for noise reduction.

My personal gut feeling tells me, that once the initial inertia problems are overcome, the position accuracy is pretty good. ( With reasonable low acceleration and deceleration ).

So I don't see a problem with 2.5 full steps. As long as you don't try to lift the bed by 0.5 steps only, it should work.

Just my 2 cents

My personal gut feeling tells me, that once the initial inertia problems are overcome, the position accuracy is pretty good. ( With reasonable low acceleration and deceleration ).

So I don't see a problem with 2.5 full steps. As long as you don't try to lift the bed by 0.5 steps only, it should work.

Just my 2 cents

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 08:18AM |

Registered: 11 years ago Posts: 5,780 |

Lapping the threaded rods makes them look pretty up close, but it doesn't straighten the rod which is the main problem with using threaded rods instead of lead screws. It's like my grandmother in Tennessee used to say: "you can't make a silk purse out of a sow's ear". Threaded rods are the sow's ears of 3D printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 09:05AM |

Registered: 8 years ago Posts: 622 |

Quote

o_lampe

Most people here call 1/4 steps " safe". Anything above is just for noise reduction.

My personal gut feeling tells me, that once the initial inertia problems are overcome, the position accuracy is pretty good. ( With reasonable low acceleration and deceleration ).

So I don't see a problem with 2.5 full steps. As long as you don't try to lift the bed by 0.5 steps only, it should work.

Just my 2 cents

Most steppers have a quoted positional accuracy of 5% non- accumulative. So 1 full step could be out by 5% and micro-stepping won't improve that - it just chops the step into segments. In the example of the 8mm pitch lead screw, 1 full step is 0.4mm so a 5% error will equate to a positional accuracy of +/- 0.02mm which I'd call fairly significant. With 4mm lead, the error comes down to 0.01mm, with 2mm it's 0.005 and of course, 1mm lead gives you 0.0025mm positional accuracy. Of course, gearing or using 0.9 degree steppers can improve things. My twopence worth.

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 11:29AM |

Registered: 8 years ago Posts: 3,525 |

I'm with you Deckingman on using multiples of full steps with leadscrews but one slight correction 1 full step is 0.04mm with 8mm pitch. I used to only print 0.12, 0.16, 0.20, etc.. when I had them. Now I've got 2 deltas and a corexy with belt driven z axis I print any layer height I want, within reason.

As for the op's question if you can get nice straight m8 rods use them. Chinese leadscrews beat hardware store threaded rods and are $10 each so is the threaded rod really saving you money or ruining your print to save you $15?

Even on an i3 style printer why not consider a belt driven axis like this one [www.thingiverse.com] but upside down, running up the frame and across the top then down, then you've got 1 motor not 2 and good precision especially with 0.9 degree motor.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

As for the op's question if you can get nice straight m8 rods use them. Chinese leadscrews beat hardware store threaded rods and are $10 each so is the threaded rod really saving you money or ruining your print to save you $15?

Even on an i3 style printer why not consider a belt driven axis like this one [www.thingiverse.com] but upside down, running up the frame and across the top then down, then you've got 1 motor not 2 and good precision especially with 0.9 degree motor.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 12:01PM |

Registered: 8 years ago Posts: 622 |

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 02:43PM |

Registered: 11 years ago Posts: 5,780 |

Quote

DjDemonD

Even on an i3 style printer why not consider a belt driven axis like this one [www.thingiverse.com] but upside down, running up the frame and across the top then down, then you've got 1 motor not 2 and good precision especially with 0.9 degree motor.

I have acquired some experience with belt driven Z axes lately. In that design, there's nothing to stop the bed from dropping like a rock when power to the motor is lost. With a small printer and a relatively light bed assembly it may not matter much, just pointing it out so there are no surprises. The paths from the belt clamps back to the motor (which is the anchor for the bed) has different length of belt on each side. The side that is further from the motor can stretch more than the side that is closer, potentially tilting the bed. A more symmetrical arrangement using two belts prevents that, as well as reducing total stretch. Also in this design, the motor has to have adequate torque to lift the bed assembly and the mass of the print. A gear reduced motor will have plenty of speed and torque for Z axis use. If the gear ratio is high enough you won't have any bed drop problems either.

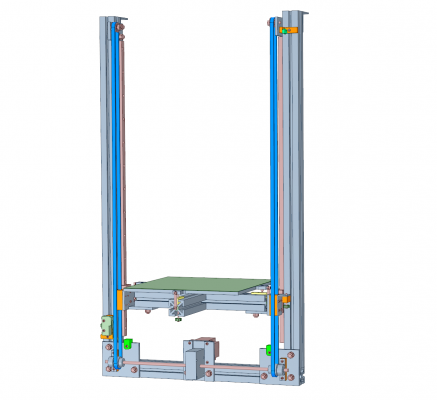

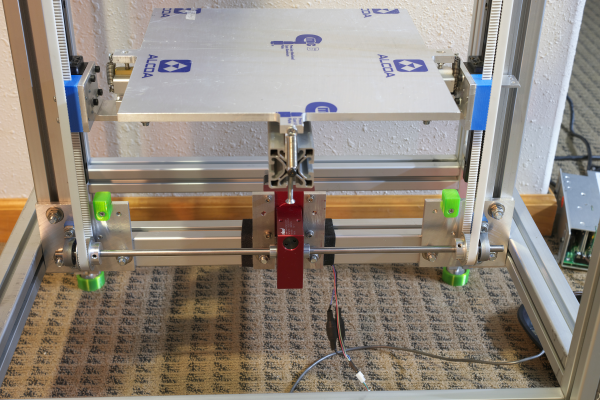

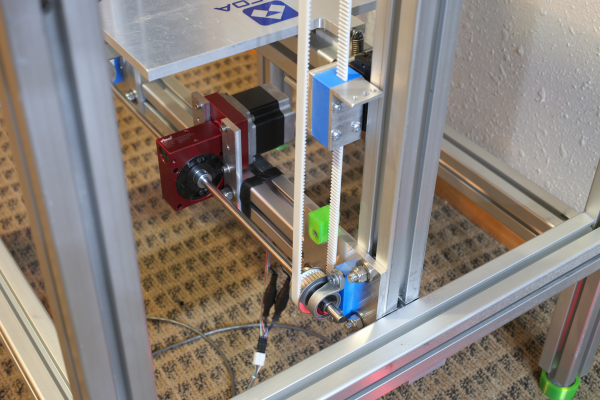

Here's my Z axis design for my latest CoreXY printer:

Here's what the base of it looks like:

Motive power is supplied by a 164 oz-in NEMA-23 size motor mounted on a 30:1 worm gear reducer. Maximum speed with this setup is about 20mm/sec (more than adequate for Z axis). Belts are 10mm wide steel core HTD-3M. The belts stretch under load, of course:

The bed does not drop when power to the Z motor is cut.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 02:46PM |

Registered: 8 years ago Posts: 3,525 |

The worm drive is a nice touch I went with a counterweight which works pretty well. Haven't seen the issue with the belts stretching more on one side, but I'll keep an eye out for it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 03:41PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: is there any difference in layer accuracy between m5 and m8 threaded rods ?? February 19, 2017 07:13PM |

Registered: 9 years ago Posts: 483 |

Quote

the_digital_dentist

Lapping the threaded rods makes them look pretty up close, but it doesn't straighten the rod which is the main problem with using threaded rods instead of lead screws. It's like my grandmother in Tennessee used to say: "you can't make a silk purse out of a sow's ear". Threaded rods are the sow's ears of 3D printing.

Not only does it make them pretty, but it decreases stiction and friction as well as making them more accurate. A 6mm leadscrew of any significant length is going to behave like a wet noodle so worrying about how straight they are is rather pointless. When you can't afford the rump roast, the sow's ear will work just fine.

Sorry, only registered users may post in this forum.