Starting a new 3D printer project. Would really appreciate any input.

Posted by flydeprutten

Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 02:08PM |

Registered: 7 years ago Posts: 63 |

I have long wanted to build my own 3D printer, as the concept intrigue me, and I really want to learn it from scratch.

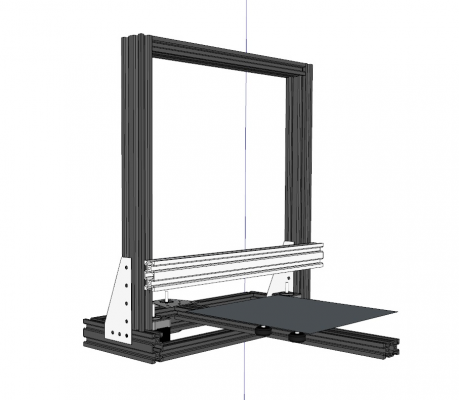

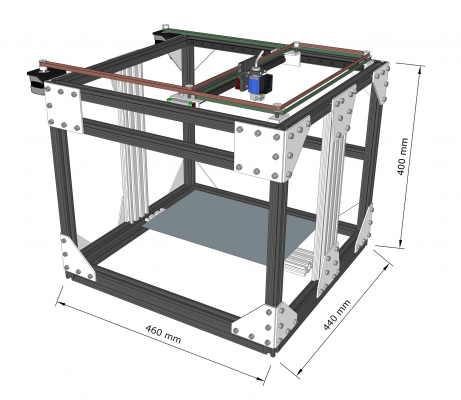

I have planned to use the V slot wheels for both x, y and z axis, and I will use belts for both y and x. For the z axis I will use a lead screw on both sides.

I will use a E3D v6 hotend and a arduino / RAMPS as controller. I will use 5 nema 17, 17HS8401 stepper engines with a holding torque of 0.52 Nm. The rest I have not quite made up my mind on. I have attached a picture of my design (the drawing officially is not finished, and I haven't decided on the height yet). For size comparison, the bed is 214x214.

I have an engineering degree, but not a mechanical engineer. Therefore, I would really like to hear your input on my choices, and my design. Are there problems with it, that I should be aware of, or is it complete nonsense? :-)

I have planned to use the V slot wheels for both x, y and z axis, and I will use belts for both y and x. For the z axis I will use a lead screw on both sides.

I will use a E3D v6 hotend and a arduino / RAMPS as controller. I will use 5 nema 17, 17HS8401 stepper engines with a holding torque of 0.52 Nm. The rest I have not quite made up my mind on. I have attached a picture of my design (the drawing officially is not finished, and I haven't decided on the height yet). For size comparison, the bed is 214x214.

I have an engineering degree, but not a mechanical engineer. Therefore, I would really like to hear your input on my choices, and my design. Are there problems with it, that I should be aware of, or is it complete nonsense? :-)

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 02:40PM |

Registered: 8 years ago Posts: 1,671 |

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 03:32PM |

Registered: 8 years ago Posts: 3,525 |

That design looks like it will do the job, consider beefing up the bracing on the sides, there is no such thing as a frame that's too stiff. Also have you thought about linear rails such as MGN-12H type? They are better than roller wheels and not that expensive now. The chinese ones work fine.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 04:47PM |

Registered: 7 years ago Posts: 63 |

Quote

MechaBits

So far so good...now tell us a little bit more about the Degree, did you get your monies worth?

Year I think I got my monies worth. I am a chemical engineer specialized in environmental chemistry. But right now, I work with occupational health in the health care system. I love that job, and right now cannot imagine doing anything else, but it is mostly consulting, and therefore I really miss building something. :-)

Quote

DjDemonD

That design looks like it will do the job, consider beefing up the bracing on the sides, there is no such thing as a frame that's too stiff. Also have you thought about linear rails such as MGN-12H type? They are better than roller wheels and not that expensive now. The chinese ones work fine.

I have considered linear rails, but when I selected aluminum profiles for the frame, to create a more solid framework, it just seemed natural. Do the linear rails perform better than the wheels, or is it a matter of resistance?

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 04:50PM |

Registered: 8 years ago Posts: 3,525 |

I have only used one machine with wheels a delta, its not the wheels that are the issue its the printed carriage they are often attached to. If you are going to use metal carriages then the wheels should compete with the rails. To be fair I've 3 machines all using rails and am totally happy with them - zero play.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 05:09PM |

Registered: 8 years ago Posts: 1,671 |

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 05:22PM |

Registered: 7 years ago Posts: 63 |

Quote

DjDemonD

I have only used one machine with wheels a delta, its not the wheels that are the issue its the printed carriage they are often attached to. If you are going to use metal carriages then the wheels should compete with the rails. To be fair I've 3 machines all using rails and am totally happy with them - zero play.

I had actually imagined that I would make the carriage in aluminum. But maybe I should consider MGN-12s. Should I use two on the z-axis, or is that over doing it.

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 05:45PM |

Registered: 8 years ago Posts: 1,671 |

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 06:05PM |

Registered: 8 years ago Posts: 3,525 |

*reaches for 3-in-1 oil*

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Re: Starting a new 3D printer project. Would really appreciate any input.  March 05, 2017 06:46PM |

Registered: 8 years ago Posts: 1,671 |

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 05:48AM |

Registered: 8 years ago Posts: 601 |

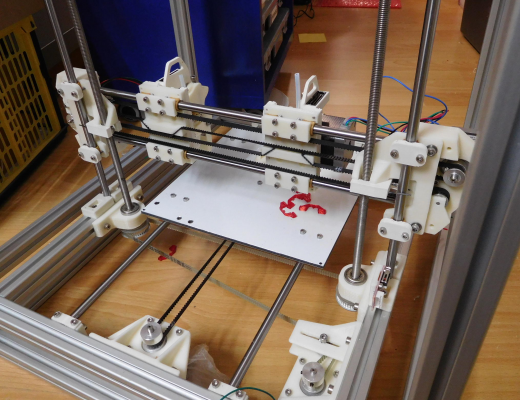

I use a machine very similar in design to this, and It looks absolutely fine. The Z axis doesn't need beefing up at all, mainly because you will never get fast enough to need it. The 214mm bed will limit your print speeds to 50mm/s maximum. I print at 30mm/s to minimize ringing.

Things to consider -

1 -- Where will your electronics and wiring go? Design this in so you don't have a birds nest. I placed mine under the bed but It meant I needed about 60mm more height to stuff everything under. Wire can route through the extrusion.

2 -- Consider a single motor Z axis run by a belt. Its cheap to make and it honestly makes more sense.

3 -- Your Y axis is a bit cantilevered. Not a huge problem as the extrusion can handle it, but if you push down on the front your machine will fall over.

4 -- On the topic of bed, consider how heavy its going to be. I use 5mm tooling plate topped with printbite and it weighs 1kg. I used 5mm glass before this with a pcb heater and alu heat spreader and it weighed even more then. I use heavy duty nema 17's and they still struggle to move the bed at decent speeds. If you want speed, get a nema 23 or don't use a moving bed.

5 -- The wheels work as well as any linear rail in my opinion (with metal plates, not printed). This is because they use eccentric nuts to place pre-load onto the rail so you have zero slop or backlash. Cheap rails like to bind or have missing bearings.... I doubt you would see print quality go up with linear rail, although it is lighter. I'm designing a CoreXY at the moment and I've tried moving away from wheels to linear rail but they are the most compact form of linear movement and are extremely modular. I've opted to use both. (linear on X, wheels on Y).

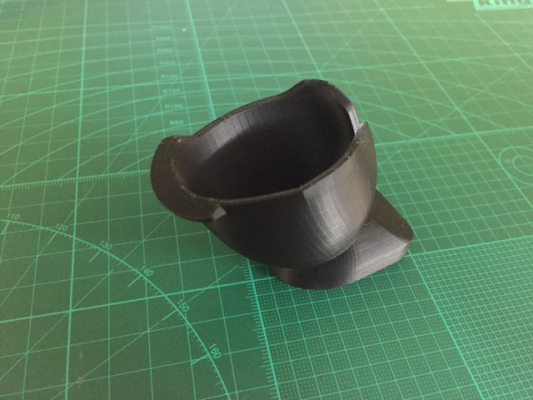

Proof that wheels work, layer alignment at 300 microns -

Things to consider -

1 -- Where will your electronics and wiring go? Design this in so you don't have a birds nest. I placed mine under the bed but It meant I needed about 60mm more height to stuff everything under. Wire can route through the extrusion.

2 -- Consider a single motor Z axis run by a belt. Its cheap to make and it honestly makes more sense.

3 -- Your Y axis is a bit cantilevered. Not a huge problem as the extrusion can handle it, but if you push down on the front your machine will fall over.

4 -- On the topic of bed, consider how heavy its going to be. I use 5mm tooling plate topped with printbite and it weighs 1kg. I used 5mm glass before this with a pcb heater and alu heat spreader and it weighed even more then. I use heavy duty nema 17's and they still struggle to move the bed at decent speeds. If you want speed, get a nema 23 or don't use a moving bed.

5 -- The wheels work as well as any linear rail in my opinion (with metal plates, not printed). This is because they use eccentric nuts to place pre-load onto the rail so you have zero slop or backlash. Cheap rails like to bind or have missing bearings.... I doubt you would see print quality go up with linear rail, although it is lighter. I'm designing a CoreXY at the moment and I've tried moving away from wheels to linear rail but they are the most compact form of linear movement and are extremely modular. I've opted to use both. (linear on X, wheels on Y).

Proof that wheels work, layer alignment at 300 microns -

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 07:46AM |

Registered: 11 years ago Posts: 5,780 |

Look at the available off the shelf heaters when deciding bed size. It's cheaper and faster to use one of them than to make some bed size that requires a custom heater. At 214 x 214 you're asking for problems.

It looks like you're planning on using two motors for the Z axis. Though many manage to get that to work, the alignment of the X axis relative to the Z axis is critically dependent on the two motors/screws staying synchronized. It is very difficult to keep to motors synchronized and you'll be realigning the thing over and over. Use two lead screws connected to a single motor with a belt and you'll never have to align it after the initial set-up. I know you see a lot of printers- especially cheap ones- set up with two motors, but that's done because a second motor is cheaper than a loop belt and pulleys, not because it's better.

If you ever intend to print ABS you will need to enclose the printer and keep it warm inside. It's best to plan for that now. That means use a frame design that makes enclosure easy and plan for the electronics to be away from the warm print chamber.

I'm a big fan of linear guides. HiWin makes good ones at reasonable prices, but the cheap Chinese knock-offs are crap. Make sure you get genuine HiWin guides, which can very very difficult to be sure of, or buy used Japanese/German/'murican guides via ebay.

Unless the bed is going to be small, get a line powered heater and an SSR to control it. Glue it to a piece of cast aluminum tooling plate and put a layer of PEI on the top surface. Mount the plate on a 3 point leveling system. You will not need any glass, glue, hairspray, or other crap, and once leveled the bed will stay that way, so you won't need autoleveling.

Look for a 24V MeanWell, PowerOne, or similar industrial brand power supply on ebay. Don't buy a "LED strip" power supply. They are cheap junk.

Get a 32 bit controller. It will save you many hours of frustration setting it up and down the road when you want to make changes. Recompiling firmware for an 8 bit board gets old, fast. Keeping copies of an obsolete, compatible IDE working on your computer for the next several years is a PITA. The 32 bit printer OSes keep variables in a single text file making updates as easy and editing the file and rebooting the controller board.

I suggest approaching the design from the opposite direction. You're working from the frame down to the details of the stuff that will fit (you hope) into the frame. That's going to be much harder than working the other way- start at the extruder carriage, include all the stuff you intend to have on it (one, two three extruders?, fans, hot-ends, LEDs, circuit bards, etc.) then work your way outward. The size of the extruder carriage will determine how long the guide rails need to be, which will in turn determine how big the frame needs to be. Accumulate the parts first and work your design around them instead of trying to shoehorn them into your frame design that was done without considering those specific parts. Not sure about how long the guide rails need to be? By them in a length you know is long enough and cut them to length, once you know what the exact length needs to be.

If you care about print quality, minimize the number of printed parts in your printer.

Click the link in my sig, below, to see my second printer design/build. You might find some useful ideas there.

Edited 2 time(s). Last edit at 03/06/2017 07:58AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It looks like you're planning on using two motors for the Z axis. Though many manage to get that to work, the alignment of the X axis relative to the Z axis is critically dependent on the two motors/screws staying synchronized. It is very difficult to keep to motors synchronized and you'll be realigning the thing over and over. Use two lead screws connected to a single motor with a belt and you'll never have to align it after the initial set-up. I know you see a lot of printers- especially cheap ones- set up with two motors, but that's done because a second motor is cheaper than a loop belt and pulleys, not because it's better.

If you ever intend to print ABS you will need to enclose the printer and keep it warm inside. It's best to plan for that now. That means use a frame design that makes enclosure easy and plan for the electronics to be away from the warm print chamber.

I'm a big fan of linear guides. HiWin makes good ones at reasonable prices, but the cheap Chinese knock-offs are crap. Make sure you get genuine HiWin guides, which can very very difficult to be sure of, or buy used Japanese/German/'murican guides via ebay.

Unless the bed is going to be small, get a line powered heater and an SSR to control it. Glue it to a piece of cast aluminum tooling plate and put a layer of PEI on the top surface. Mount the plate on a 3 point leveling system. You will not need any glass, glue, hairspray, or other crap, and once leveled the bed will stay that way, so you won't need autoleveling.

Look for a 24V MeanWell, PowerOne, or similar industrial brand power supply on ebay. Don't buy a "LED strip" power supply. They are cheap junk.

Get a 32 bit controller. It will save you many hours of frustration setting it up and down the road when you want to make changes. Recompiling firmware for an 8 bit board gets old, fast. Keeping copies of an obsolete, compatible IDE working on your computer for the next several years is a PITA. The 32 bit printer OSes keep variables in a single text file making updates as easy and editing the file and rebooting the controller board.

I suggest approaching the design from the opposite direction. You're working from the frame down to the details of the stuff that will fit (you hope) into the frame. That's going to be much harder than working the other way- start at the extruder carriage, include all the stuff you intend to have on it (one, two three extruders?, fans, hot-ends, LEDs, circuit bards, etc.) then work your way outward. The size of the extruder carriage will determine how long the guide rails need to be, which will in turn determine how big the frame needs to be. Accumulate the parts first and work your design around them instead of trying to shoehorn them into your frame design that was done without considering those specific parts. Not sure about how long the guide rails need to be? By them in a length you know is long enough and cut them to length, once you know what the exact length needs to be.

If you care about print quality, minimize the number of printed parts in your printer.

Click the link in my sig, below, to see my second printer design/build. You might find some useful ideas there.

Edited 2 time(s). Last edit at 03/06/2017 07:58AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 11:41AM |

Registered: 7 years ago Posts: 63 |

Quote

the_digital_dentist

If you ever intend to print ABS you will need to enclose the printer and keep it warm inside. It's best to plan for that now. That means use a frame design that makes enclosure easy and plan for the electronics to be away from the warm print chamber.

Do I really need to enclose the entire print area to print in ABS? I had the understanding that it was just the print bed which should be heated?

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 11:55AM |

Registered: 12 years ago Posts: 2,470 |

Just a heated bed is sufficient for small ABS parts (few cm³), but anything with edges that are a few cm long will only print reliably in a heated chamber.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 12:11PM |

Registered: 7 years ago Posts: 41 |

I see a few recommendations for using a single motor and belt on the Z axis. Do you guys have any list of parts to make this happen while still using a flex coupler to account for any bends in the lead screws? I've found Pillow block bearings, but the bore on those only seems to go down to 8mm. I wouldn't want to connect those directly to my leadscrews because I feel any imperfections in the leadscrews will go right into the print.

It seems like with perfect leadscrews, it would be really easy to set that up. But with imperfect lead screws, I can't seem to find the parts to fit it all together.

It seems like with perfect leadscrews, it would be really easy to set that up. But with imperfect lead screws, I can't seem to find the parts to fit it all together.

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 12:30PM |

Registered: 12 years ago Posts: 2,470 |

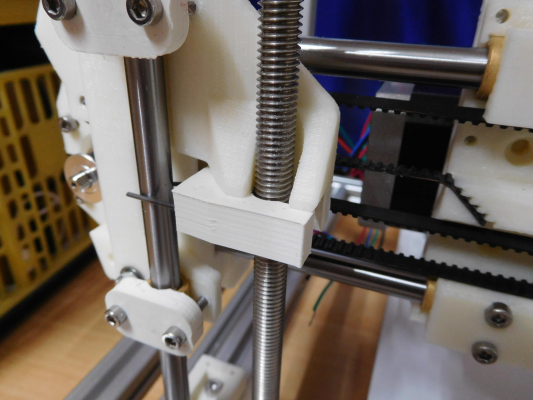

I went the other direction and mechanically decoupled the X/Y plane from the Z axis. This way any movement of the nut in the X/Y plane is not transfered to the print. The Z nutholder provides a small planar platform for the X assembly on which it loosely rests. Only gravity pushes it down on the platform. The platform can move in X/Y under the X assembly without influencing it, but Z movement is transfered. The X assembly is only held in place by the Z rails, not by the Z lead screws.

Here you can see the belt for Z

Edited 1 time(s). Last edit at 03/06/2017 12:32PM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Here you can see the belt for Z

Edited 1 time(s). Last edit at 03/06/2017 12:32PM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 01:02PM |

Registered: 11 years ago Posts: 1,049 |

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 01:17PM |

Registered: 11 years ago Posts: 1,049 |

Once again the good Dentist speaks truth.

Find existing hardware -- use it to develop design

Crap in the components will result in printed crap cubed!

Do you really NEED ABS?

214 x 214mm 8.42 x 8.42 in nice custom $$$$$ bed?

I suppose a 200 x 200 heater would work?

perhaps cut down a 300 x 300 on a table saw (just kidding)

Find existing hardware -- use it to develop design

Crap in the components will result in printed crap cubed!

Do you really NEED ABS?

214 x 214mm 8.42 x 8.42 in nice custom $$$$$ bed?

I suppose a 200 x 200 heater would work?

perhaps cut down a 300 x 300 on a table saw (just kidding)

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 02:14PM |

Registered: 8 years ago Posts: 3,525 |

You have had some good advice and if you follow it you'll have a really good printer (and spend quite a lot) but then quality isn't cheap.

It's a case of differing points of view in term of what is money well spent on components.

These Chinese rails really are ruining my prints.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

It's a case of differing points of view in term of what is money well spent on components.

These Chinese rails really are ruining my prints.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 02:30PM |

Registered: 7 years ago Posts: 63 |

The design was actually heavily influenced by this printer: Openbuilds v-slot z axis for Lulzbot Taz 4/5 Printers

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 02:31PM |

Registered: 7 years ago Posts: 63 |

Thank you all for your good advice. I'm going back to the design and rethink things. I'm leaning a little to make a box design and certainly change the beds size of the machine (can hear that this was a big mistake  ). I do not expect that this project will be cheap, easy or anything I finish in the next several months. But I will continue.

). I do not expect that this project will be cheap, easy or anything I finish in the next several months. But I will continue.

). I do not expect that this project will be cheap, easy or anything I finish in the next several months. But I will continue.

). I do not expect that this project will be cheap, easy or anything I finish in the next several months. But I will continue.

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 03:33PM |

Registered: 11 years ago Posts: 5,780 |

Quote

flydeprutten

Quote

the_digital_dentist

If you ever intend to print ABS you will need to enclose the printer and keep it warm inside. It's best to plan for that now. That means use a frame design that makes enclosure easy and plan for the electronics to be away from the warm print chamber.

Do I really need to enclose the entire print area to print in ABS? I had the understanding that it was just the print bed which should be heated?

You can print very small objects and even large single walled vases in ABS on an unenclosed 3D printer, but if the objects are long and narrow or have any bulk they will tend to pull themselves apart at the layer boundaries. Designing the machine to print ABS is much easier than adding the capability later. Designing for ABS includes easy enclosure, moving electronics away from heat, having no PLA printed parts (and minimal ABS parts, too) in the machine, adequate heating for the bed -look for a 0.4-0.5W/cm^2 (or more) heater, and preferably, an all-metal hot-end that won't mind high temperatures. The bed heater will determine the required power supply (use 24V instead of 12V), and that may affect the choice of controller. For a 400 cm^2 bed you'll want about 200W or more bed heater or you'll be waiting forever for it to heat up. You need the bed to get to 105C or so for ABS, even higher for polycarbonate. You can save some money and improve reliability by using a line powered bed heater and SSR to switch it on and off, but you have to be comfortable with wiring line powered electronics. That means you can use a lower power, lower cost, physically smaller, maybe even fanless, supply for the rest of the printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 04:28PM |

Registered: 7 years ago Posts: 63 |

Thanks for the clarification. I had missed that in my research, which I do see now is a little sloppy. I would in no way start by making a printer that can work with ABS, but it's nice not to close any doors, and when I have mastered the basics, I would like to move forward with, for example ABS.Quote

the_digital_dentist

You can print very small objects and even large single walled vases in ABS on an unenclosed 3D printer, but if the objects are long and narrow or have any bulk they will tend to pull themselves apart at the layer boundaries. Designing the machine to print ABS is much easier than adding the capability later. Designing for ABS includes easy enclosure, moving electronics away from heat, having no PLA printed parts (and minimal ABS parts, too) in the machine, adequate heating for the bed -look for a 0.4-0.5W/cm^2 (or more) heater, and preferably, an all-metal hot-end that won't mind high temperatures. The bed heater will determine the required power supply (use 24V instead of 12V), and that may affect the choice of controller. For a 400 cm^2 bed you'll want about 200W or more bed heater or you'll be waiting forever for it to heat up. You need the bed to get to 105C or so for ABS, even higher for polycarbonate. You can save some money and improve reliability by using a line powered bed heater and SSR to switch it on and off, but you have to be comfortable with wiring line powered electronics. That means you can use a lower power, lower cost, physically smaller, maybe even fanless, supply for the rest of the printer.

So far, I will just continue with the design on my computer. :-)

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 07:16PM |

Registered: 8 years ago Posts: 916 |

Quote

DjDemonD

You have had some good advice and if you follow it you'll have a really good printer (and spend quite a lot) but then quality isn't cheap.

It's a case of differing points of view in term of what is money well spent on components.

[attachment 91545 IMG_20170306_19041801.jpg]

These Chinese rails really are ruining my prints.

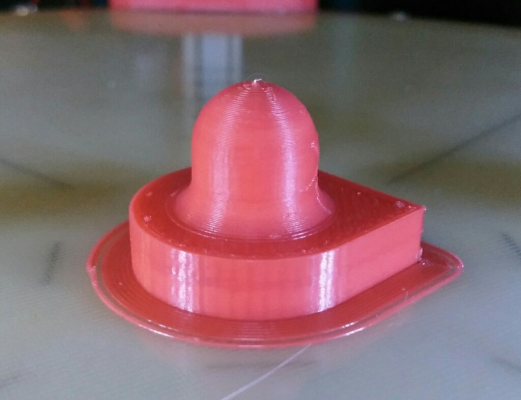

+1 on DJDemon's slightly veiled assertion that cheap linear rails are better than no linear rails.

Here's a print I did recently using cheap linear rails as well:

Note the facets in this print... they have come straight through from the model. I can see the facets in DJDemon's print as well. If you can see the facets in your print, and the model is saved as a high poly model, then I think you're doing pretty well.

I can't imagine how more expensive linear rails will help with the quality.

Re: Starting a new 3D printer project. Would really appreciate any input.  March 06, 2017 09:04PM |

Registered: 11 years ago Posts: 5,780 |

Those are some fine prints.

Quality is just a myth promulgated by people trying to sell you more expensive stuff. Always buy the cheapest of everything because that's how you get the very best of everything.

Good luck with your project.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Quality is just a myth promulgated by people trying to sell you more expensive stuff. Always buy the cheapest of everything because that's how you get the very best of everything.

Good luck with your project.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Starting a new 3D printer project. Would really appreciate any input.  March 07, 2017 12:17AM |

Registered: 8 years ago Posts: 3,525 |

I think it's more a case of talking about value. Price and quality alone are meaningless unless your budget is very small or almost unlimited, and whilst a lot of people's budget is small, few are operating at the unlimited end of the scale, and if they are why would they bother with reprap, why not just buy a turnkey, pro 3D printer?

I understand the exasperation of constantly seeing the problems that corner cutting creates, but isn't there a little risk in going too far the other way? I agree with almost everything you said, I only chimed in with my sarcastic comment because you can't just make a sweeping generalisation and say all Chinese rails are crap without being taken to task. Maybe they aren't going to give the longevity of their german/Japanese equivalents, but they can match them in term of smooth linear motion, and at 1/4 of the cost can be replaced if necessary.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I understand the exasperation of constantly seeing the problems that corner cutting creates, but isn't there a little risk in going too far the other way? I agree with almost everything you said, I only chimed in with my sarcastic comment because you can't just make a sweeping generalisation and say all Chinese rails are crap without being taken to task. Maybe they aren't going to give the longevity of their german/Japanese equivalents, but they can match them in term of smooth linear motion, and at 1/4 of the cost can be replaced if necessary.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Re: Starting a new 3D printer project. Would really appreciate any input.  March 07, 2017 03:27PM |

Registered: 7 years ago Posts: 63 |

As a new user on this forum, I feel a little bad about starting this discussion about rails. It really was not my intention.

Just one more question. Will a coreXY design, where the bed moves in the z-axis be a better idea? This will give me a box design that might not be as beautiful (I think), but it will give me much more space, and I have the ability to isolate the printer area. I also theorize that this will minimize the risk that the items will topple, because the z-axis do not move as much as the y-axis, and only moves in one direction.

Just one more question. Will a coreXY design, where the bed moves in the z-axis be a better idea? This will give me a box design that might not be as beautiful (I think), but it will give me much more space, and I have the ability to isolate the printer area. I also theorize that this will minimize the risk that the items will topple, because the z-axis do not move as much as the y-axis, and only moves in one direction.

Re: Starting a new 3D printer project. Would really appreciate any input.  March 07, 2017 03:47PM |

Registered: 8 years ago Posts: 3,525 |

Don't worry flydeprutten, its normal around here, 3D printing is populated by people with strong opinions (guilty as charged) which are not always in agreement. That's what a forum is for though isn't it?

One of my machines is a corexy with box frame, fully enclosed and heated by the bed, and as Digital Dentist says (we do often agree) for any large parts or particularly long thin parts (its about contact area to length ratio) a heated/enclosed chamber especially for ABS is the difference between success and failure. I agree again with DD that designing for it in the first place is much more sensible, but this is from the point of view of the experienced 3D printer designer/builder. However it is a whole other layer of stuff to worry about (position of motors/electronics/will it be hot enough/too hot/need heaters/fans) and so what many people do is build a open machine, get going with 3D printing enjoy making small parts in ABS and larger parts in PLA/PETG then rebuild it enclosed or move on to a new machine, possibly using the parts from the old one (although having two 3D printers is quite handy when you need a part as one machine is out of action).

Keeping the bed stationary (might be controversial) completely is best i.e. a delta. However since they are slightly more to wrap your head around when your starting out, the next best thing is moving the bed in Z as the movements are small and slow. There are many ways to do this leadscrews, ballscrews, cantilevered or fully supported, belts. Each system has its ups and downs, its proponents and its detractors.

Moving the bed in Y is a configuration which enables relatively low cost production i.e. the I3 which until the release of the I3 Mk2 was seen by many here as a bit of a flawed design, and widely cloned badly. That being said Mr Prusa is apparently selling 3000 a month so we are obviously wrong!

Edited 2 time(s). Last edit at 03/07/2017 03:50PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

One of my machines is a corexy with box frame, fully enclosed and heated by the bed, and as Digital Dentist says (we do often agree) for any large parts or particularly long thin parts (its about contact area to length ratio) a heated/enclosed chamber especially for ABS is the difference between success and failure. I agree again with DD that designing for it in the first place is much more sensible, but this is from the point of view of the experienced 3D printer designer/builder. However it is a whole other layer of stuff to worry about (position of motors/electronics/will it be hot enough/too hot/need heaters/fans) and so what many people do is build a open machine, get going with 3D printing enjoy making small parts in ABS and larger parts in PLA/PETG then rebuild it enclosed or move on to a new machine, possibly using the parts from the old one (although having two 3D printers is quite handy when you need a part as one machine is out of action).

Keeping the bed stationary (might be controversial) completely is best i.e. a delta. However since they are slightly more to wrap your head around when your starting out, the next best thing is moving the bed in Z as the movements are small and slow. There are many ways to do this leadscrews, ballscrews, cantilevered or fully supported, belts. Each system has its ups and downs, its proponents and its detractors.

Moving the bed in Y is a configuration which enables relatively low cost production i.e. the I3 which until the release of the I3 Mk2 was seen by many here as a bit of a flawed design, and widely cloned badly. That being said Mr Prusa is apparently selling 3000 a month so we are obviously wrong!

Edited 2 time(s). Last edit at 03/07/2017 03:50PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Re: Starting a new 3D printer project. Would really appreciate any input.  March 08, 2017 04:46AM |

Registered: 10 years ago Posts: 14,672 |

Each configuration has its pros and cons:

- Traditional Cartesian (bed moving in the Y direction): simple and cheap to build. IMO entirely adequate if a 200x200mm build area is sufficient for you. If you are on a tight budget, go for this. My Ormerod is of this basic construction, and it has been doing a sterling job printing parts for my delta printer, which is out of action for a major upgrade.

- Linear delta (fixed bed, 3 carriages moving vertically): mechanically the simplest design. Compact in its horizontal dimensions, but taller than most other designs. Demands more precision in its construction and needs better (more expensive) electronics unless you want to spend an age calibrating and tuning it. So less suitable for those on a right budget. My favourite configuration for small and medium size printers. My delta has a printable area of 300mm diameter and I would happily build a printer with 450mm printable diameter. Some people go much larger.

- Cartesian or CoreXY with bed moving in the Z direction: I haven't built one yet, but CoreXY would probably be my choice if I wanted a large square or rectangular print area. CoreXY has the advantage over Cartesian that the print head is lighter which in theory should allow higher printing speeds (though perhaps not as fast as a delta).

My suggestion to you is that you buy a low-cost Prusa i3 kit and use it to learn about 3D printing. Bear in mind that it will be way behind state-of-the-art in mechanical construction and especially in electronics. When you have gained experience with that, consider building a printer from scratch using good mechanical parts and good 32-bit electronics - perhaps a delta based on my Kossel variant (see link in my signature) or a CoreXY machine. It's useful to have two 3D printers anyway, so one can print parts for the other.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- Traditional Cartesian (bed moving in the Y direction): simple and cheap to build. IMO entirely adequate if a 200x200mm build area is sufficient for you. If you are on a tight budget, go for this. My Ormerod is of this basic construction, and it has been doing a sterling job printing parts for my delta printer, which is out of action for a major upgrade.

- Linear delta (fixed bed, 3 carriages moving vertically): mechanically the simplest design. Compact in its horizontal dimensions, but taller than most other designs. Demands more precision in its construction and needs better (more expensive) electronics unless you want to spend an age calibrating and tuning it. So less suitable for those on a right budget. My favourite configuration for small and medium size printers. My delta has a printable area of 300mm diameter and I would happily build a printer with 450mm printable diameter. Some people go much larger.

- Cartesian or CoreXY with bed moving in the Z direction: I haven't built one yet, but CoreXY would probably be my choice if I wanted a large square or rectangular print area. CoreXY has the advantage over Cartesian that the print head is lighter which in theory should allow higher printing speeds (though perhaps not as fast as a delta).

My suggestion to you is that you buy a low-cost Prusa i3 kit and use it to learn about 3D printing. Bear in mind that it will be way behind state-of-the-art in mechanical construction and especially in electronics. When you have gained experience with that, consider building a printer from scratch using good mechanical parts and good 32-bit electronics - perhaps a delta based on my Kossel variant (see link in my signature) or a CoreXY machine. It's useful to have two 3D printers anyway, so one can print parts for the other.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Starting a new 3D printer project. Would really appreciate any input.  March 14, 2017 05:19PM |

Registered: 7 years ago Posts: 63 |

Ok, I have restarted my project, and tried to incorporate your excellent advice.

I have gone for a corexy design with the idea that it will later be easier to wrap in the machine to print ABS. I have also placed all stepper motors outside the frame and all the parts within the frame is made of aluminum or steel (except the cooler and the belts). All custom parts and mounts are designed in aluminum, and in a way so that I can make them myself.

I will use mgn12 tracks for x and y, but I'll stick with v-slot wheel for the z-axis. I have already order a mgn12 track to see the quality, but I will not begin to buy anything else before I am completely finished with the design. I am not good at building as I go. I would much rather be able to tweak everything before I start to build in real life.

I have not finished with the bed and z-axis, but as I said, I will use v-slot wheels. I'll make a bed of 300x200x6mm aluminum, and I will use two leadscrews on each side of the bed, driven by one stepper motor.

I have not planned anything regarding electronics yet. But that does not worry me as much, because I will place it outside the frame.

What do you all think. Is this a good approach?

I have gone for a corexy design with the idea that it will later be easier to wrap in the machine to print ABS. I have also placed all stepper motors outside the frame and all the parts within the frame is made of aluminum or steel (except the cooler and the belts). All custom parts and mounts are designed in aluminum, and in a way so that I can make them myself.

I will use mgn12 tracks for x and y, but I'll stick with v-slot wheel for the z-axis. I have already order a mgn12 track to see the quality, but I will not begin to buy anything else before I am completely finished with the design. I am not good at building as I go. I would much rather be able to tweak everything before I start to build in real life.

I have not finished with the bed and z-axis, but as I said, I will use v-slot wheels. I'll make a bed of 300x200x6mm aluminum, and I will use two leadscrews on each side of the bed, driven by one stepper motor.

I have not planned anything regarding electronics yet. But that does not worry me as much, because I will place it outside the frame.

What do you all think. Is this a good approach?

Sorry, only registered users may post in this forum.