DIY 400x400x200 printer, choice question / doubt

Posted by HugoW

|

Re: DIY 400x400x200 printer, choice question / doubt April 27, 2017 02:33PM |

Registered: 7 years ago Posts: 162 |

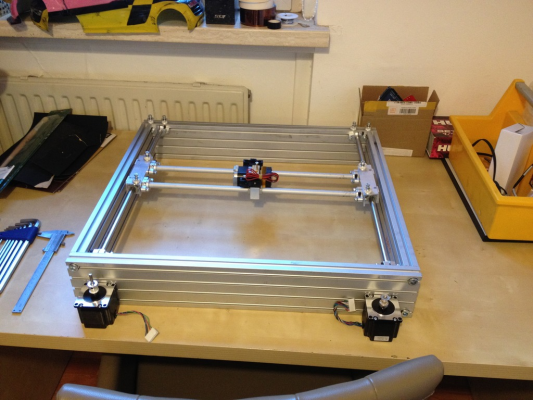

Well, did I mention this would be a slow build? It is... I did some dumpster diving last week at the factory I work at and retrieved some rather large but usefull alloy. So, I can now start assembling the lot.

See you again in a month or two!

Cheers,

Hugo

See you again in a month or two!

Cheers,

Hugo

|

Re: DIY 400x400x200 printer, choice question / doubt April 27, 2017 03:43PM |

Registered: 11 years ago Posts: 5,780 |

It seems a shame to waste such rigid frame stock on flexible guide rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY 400x400x200 printer, choice question / doubt April 27, 2017 03:44PM |

Registered: 7 years ago Posts: 162 |

|

Re: DIY 400x400x200 printer, choice question / doubt April 27, 2017 04:00PM |

Registered: 11 years ago Posts: 5,780 |

End supported rails always flex. The Y axis will be the worst because of the mass of the X axis rails and extruder carriage are riding on them, but the X axis rails are going to flex, too.

My first printer had 12 mm end supported rails and I eventually replaced them with linear guides because they were flexing. Of course, in that machine, the massive bed was riding on the Y axis rails, and your printer's mass on the Y axis rails is going to be much smaller, so maybe it will be OK.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

My first printer had 12 mm end supported rails and I eventually replaced them with linear guides because they were flexing. Of course, in that machine, the massive bed was riding on the Y axis rails, and your printer's mass on the Y axis rails is going to be much smaller, so maybe it will be OK.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY 400x400x200 printer, choice question / doubt April 27, 2017 04:13PM |

Registered: 7 years ago Posts: 34 |

Quote

deckingman

For info, my Core XY has a build area a tad under 400 x 400 and 740 in Z. The main frame is 600 x 600 x 1,000. I can print stuff like this [www.youtube.com] and this [www.youtube.com] and there are some other things on my Youtube channel. The bed weighs in at around 7kg (10mm thick aluminium topped with 6mm thick float glass) and is lifted by 3 screws driven by a single Nema 17 via a continuous belt. As configured in the videos, the Y axis including the X axis weighed in at 1,900 gms and I regularly print at 90mm/sec. All belts are 6mm gt2 - never a problem.

What diameter screws? just curious.

One thing I like about the CoreXY idea is that you have two motors controlling both x and y axes, so you can keep it stronger or go with cheaper motors theoretically.

|

Re: DIY 400x400x200 printer, choice question / doubt April 27, 2017 04:29PM |

Registered: 11 years ago Posts: 5,780 |

Each motor needs to be able to drive the total X+Y moving mass at the target speed/acceleration because when the machine is laying down infill at 45 or 135 degrees, only one motor is providing all the force. If you cheap-out and use low torque motors you'll be able to print cubes all day until you get to 45/135 degree infill, then it will start shifting. If you look at the posts from people who have print layer shifting in coreXY machines, the print is usually (always?) shifted at 45 or 135 degrees.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY 400x400x200 printer, choice question / doubt April 28, 2017 06:37AM |

Registered: 7 years ago Posts: 270 |

|

Re: DIY 400x400x200 printer, choice question / doubt April 28, 2017 08:29AM |

Registered: 7 years ago Posts: 270 |

Quote

HugoW

Well, did I mention this would be a slow build? It is... I did some dumpster diving last week at the factory I work at and retrieved some rather large but usefull alloy. So, I can now start assembling the lot.

See you again in a month or two!

Cheers,

Hugo

Nice frame. I would expect for carriage riding on single, normal length, bearing will be wobbly as it's pulled left and right due to bearing tolerances. Looking forward to be proven wrong

Edited 1 time(s). Last edit at 04/28/2017 08:32AM by newbob.

|

Re: DIY 400x400x200 printer, choice question / doubt August 02, 2017 05:28AM |

Registered: 7 years ago Posts: 162 |

|

Re: DIY 400x400x200 printer, choice question / doubt August 09, 2017 04:00PM |

Registered: 7 years ago Posts: 162 |

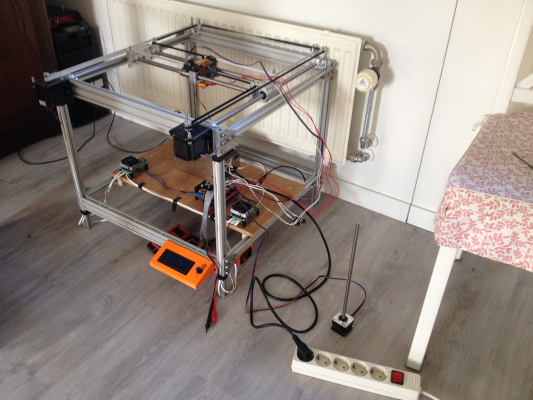

Well, things change over time. Photobucket screws up, so I cannot show the pic, but I think I can link it:

Click for pic

So I hope you can click it and see my progress. I bought the frame bits second hand from someone who gave up, it's nice stuff and fits well. It limits the motion to 340 x 290 x 300mm, but that is OK for now. The bits for the table and Z-movement are on the slow boat from China. The sliding bearings are replaced with Chinese cheap ball bearings. I think the sliding ones will return on a version I can set the tension on, tune them to the rail.

Cheers,

Hugo

Click for pic

So I hope you can click it and see my progress. I bought the frame bits second hand from someone who gave up, it's nice stuff and fits well. It limits the motion to 340 x 290 x 300mm, but that is OK for now. The bits for the table and Z-movement are on the slow boat from China. The sliding bearings are replaced with Chinese cheap ball bearings. I think the sliding ones will return on a version I can set the tension on, tune them to the rail.

Cheers,

Hugo

|

Re: DIY 400x400x200 printer, choice question / doubt August 12, 2017 12:55PM |

Registered: 7 years ago Posts: 162 |

Sorry, only registered users may post in this forum.