War against ripples

Posted by icefire

|

War against ripples March 19, 2017 02:24PM |

Registered: 8 years ago Posts: 168 |

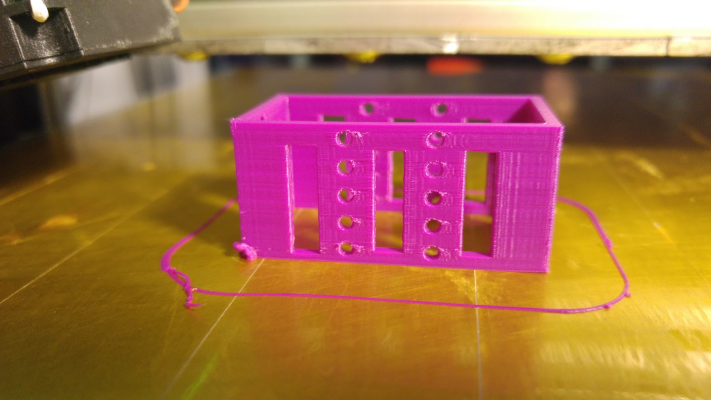

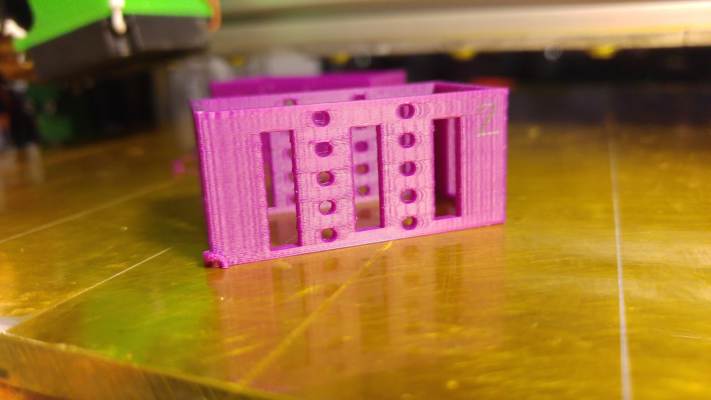

So I have ben trying to get rid of this terrible rippling effect on my prints:

It is not very bad but I want to eliminate it.

When I declared war against the ripples I was using DRV8825. So I have tried the following thus far:

1. Putting the DRV8825 in fast decay mode. Result: Small improvement

2. Changing DRV8825 with A4988. Result: Same as DRV8825 in fast decay mode, overall better than the original state

3. Changing the A4988 with another set if A4988 - just to be sure that the ones I got are not defective. Result: No difference.

4. Increasing the Vref of the stepper drivers. Tried different values for the motor current between 0,7A and 2A. Result: No difference.

So I left the A4988 and started troubleshooting the speed, acceleration and jerk settings. After spending days trying out different combinations of settings (XY jerk between 1 and 15, acceleration between 100 and 3000 mm/s^2, print speed between 40 and 80 mm/s) I found very little difference between different print settings. Acceleration above 900 mm/s^2 and XY jerk above 15 result in small visible increase of the rippling effect but everything below that makes even less difference. Layer height doesn't considerably influence the rippling as well.. Both pictures above are printed at 0,1mm layer height. It does get a bit better at 0,2mm but the effect remains clearly visible, especially when printing larger models.

In total desperation I tried swapping one of the stepper motors (had one spare) but this didn't help at all.

What else is there to try? Other than that I do not have any print quality issues. Can the rippling effect be a result of backlash in the system? Even if it could, the GT2 belts I am using for the X and Y axis are supposed to be practically "backlash free". Maybe a hardware issue with the printer mechanics? If necessary I could post pictures of my setup. It is a mendel-style printer based on Mendelmax 2.0

Please give me any ideas. Am I expecting too much of FDM in general? Maybe someone who has perfected his machine could print the model I created to test the ripples and post some pictures.. it uses just about 2g of filament. I have attached the model, please don't forget to scale it at 200% to get the dimensions I have been using (approx. 44x24mm)

Many thanks to anyone willing to help!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

It is not very bad but I want to eliminate it.

When I declared war against the ripples I was using DRV8825. So I have tried the following thus far:

1. Putting the DRV8825 in fast decay mode. Result: Small improvement

2. Changing DRV8825 with A4988. Result: Same as DRV8825 in fast decay mode, overall better than the original state

3. Changing the A4988 with another set if A4988 - just to be sure that the ones I got are not defective. Result: No difference.

4. Increasing the Vref of the stepper drivers. Tried different values for the motor current between 0,7A and 2A. Result: No difference.

So I left the A4988 and started troubleshooting the speed, acceleration and jerk settings. After spending days trying out different combinations of settings (XY jerk between 1 and 15, acceleration between 100 and 3000 mm/s^2, print speed between 40 and 80 mm/s) I found very little difference between different print settings. Acceleration above 900 mm/s^2 and XY jerk above 15 result in small visible increase of the rippling effect but everything below that makes even less difference. Layer height doesn't considerably influence the rippling as well.. Both pictures above are printed at 0,1mm layer height. It does get a bit better at 0,2mm but the effect remains clearly visible, especially when printing larger models.

In total desperation I tried swapping one of the stepper motors (had one spare) but this didn't help at all.

What else is there to try? Other than that I do not have any print quality issues. Can the rippling effect be a result of backlash in the system? Even if it could, the GT2 belts I am using for the X and Y axis are supposed to be practically "backlash free". Maybe a hardware issue with the printer mechanics? If necessary I could post pictures of my setup. It is a mendel-style printer based on Mendelmax 2.0

Please give me any ideas. Am I expecting too much of FDM in general? Maybe someone who has perfected his machine could print the model I created to test the ripples and post some pictures.. it uses just about 2g of filament. I have attached the model, please don't forget to scale it at 200% to get the dimensions I have been using (approx. 44x24mm)

Many thanks to anyone willing to help!

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: War against ripples March 19, 2017 02:57PM |

Registered: 7 years ago Posts: 558 |

|

Re: War against ripples March 19, 2017 03:14PM |

Registered: 8 years ago Posts: 601 |

I have recently had a similar war. I substantially reduced the mass of my X gantry to about 400grams by using a titan and a pancake stepper. My Y axis bed is still very heavy at around 1kg, but I did shave off about 200grams switching from glass+alu heat spreader to just 5mm aluminium tooling plate.

My accel is set to around 1000mm/s (I think, or thereabouts) and I only print at 35mm/s. I use heavy duty Nema 17's set to their maximum vref in duetwifi and GT2 belt. I don't use toothed idlers. To go faster I'd have to get some Nema 23's but it just isn't worth it. I've nearly eliminated all ringing, but instead I get corners with a bit more 'bulge' in them. Going faster now starts to give noticeable ringing.

I don't think I can make this better in a standard prusa style cartesian with a 218mm^2 bed. Any weight savings now would be small.... I'm currently designing a CoreXY to solve the bed weight issue.

My accel is set to around 1000mm/s (I think, or thereabouts) and I only print at 35mm/s. I use heavy duty Nema 17's set to their maximum vref in duetwifi and GT2 belt. I don't use toothed idlers. To go faster I'd have to get some Nema 23's but it just isn't worth it. I've nearly eliminated all ringing, but instead I get corners with a bit more 'bulge' in them. Going faster now starts to give noticeable ringing.

I don't think I can make this better in a standard prusa style cartesian with a 218mm^2 bed. Any weight savings now would be small.... I'm currently designing a CoreXY to solve the bed weight issue.

|

Re: War against ripples March 19, 2017 03:33PM |

Registered: 7 years ago Posts: 94 |

Hi!

I did change my belts (GT2) to prosper quality that is soft and fiber reinforced.

Also swapped my bearings to, toothed pulleys. That did bring ringing and distortion quite a bit.

A Bowden setup, also improved the prints. Still not perfect. But I will try to change some 8 mm rods to better ones.

+ quality bearings.

Improved frame rigidity. Small improvement there too..

Think there is many small steps to get to the goal..

But, core xy is the best option..

I did change my belts (GT2) to prosper quality that is soft and fiber reinforced.

Also swapped my bearings to, toothed pulleys. That did bring ringing and distortion quite a bit.

A Bowden setup, also improved the prints. Still not perfect. But I will try to change some 8 mm rods to better ones.

+ quality bearings.

Improved frame rigidity. Small improvement there too..

Think there is many small steps to get to the goal..

But, core xy is the best option..

|

Re: War against ripples March 19, 2017 03:36PM |

Registered: 8 years ago Posts: 601 |

Quote

SatorCodex

Hi!

I did change my belts (GT2) to prosper quality that is soft and fiber reinforced.

Also swapped my bearings to, toothed pulleys. That did bring ringing and distortion quite a bit.

A Bowden setup, also improved the prints. Still not perfect. But I will try to change some 8 mm rods to better ones.

+ quality bearings.

Improved frame rigidity. Small improvement there too..

Think there is many small steps to get to the goal..

But, core xy is the best option..

Toothed idlers can be a good option, but be wary of cheap stuff on ebay. They use really inferior bearings that bind as soon as you tighten them up. It's for this reason I haven't switched from smooth yet.

|

Re: War against ripples March 19, 2017 05:39PM |

Registered: 7 years ago Posts: 94 |

Toothed idlers, was what I did mean!

I got a couple real cheap from ali.. They work ok.

But I agree.. bearings is probably not good. The alu extrution they are made of. Is one of the lowest quality

Iever seen. (defy not Swedish quality anyway.)

Though. Im trying to spend as little as possible on the Anet. Its a cheap printer. Im trying to keep it that way.

Still, I have plans for new bearings and rods.. bearings on the Anet is not bearings.. sloppy as (ugly word)

Binds ect.. grease makes them not grind the rods to much..

Hm.. start to feel that it is soon time to kick up a core xy build. seriously

Edited 1 time(s). Last edit at 03/19/2017 05:41PM by SatorCodex.

I got a couple real cheap from ali.. They work ok.

But I agree.. bearings is probably not good. The alu extrution they are made of. Is one of the lowest quality

Iever seen. (defy not Swedish quality anyway.)

Though. Im trying to spend as little as possible on the Anet. Its a cheap printer. Im trying to keep it that way.

Still, I have plans for new bearings and rods.. bearings on the Anet is not bearings.. sloppy as (ugly word)

Binds ect.. grease makes them not grind the rods to much..

Hm.. start to feel that it is soon time to kick up a core xy build. seriously

Edited 1 time(s). Last edit at 03/19/2017 05:41PM by SatorCodex.

|

Re: War against ripples March 19, 2017 06:03PM |

Registered: 8 years ago Posts: 168 |

I am thinking of a CoreXY Build myself... But that was just a small footnote

Back on the topic, I would almost conclude that the weight on the Y carriage has little to no effect. I used to have a small 200x200 PCB heatbed and had the same issue nonetheless. Now I am utilizing a 250x320mm silicone heater glued to a 6mm machined cast aluminum plate. I even used to have a glass on top of it which is a total weight gain of 3kg. But this didn't make the rippling any worse than it already was. I got rid of the glass (1.3 kg) but there was no effect.

I suspect that the key contributer to our ripple problem is the X axis.

I switched from a greg wade's extruder with a huge Nema 17 motor to e3d titan with the small motor they supply with it. Maybe I could use a pancake motor instead but shy of that I have one inductive sensor, two 40mm fans and the classic e3d hot end attached to the X carriage. No extreme weight.

I guess I should try geared idlers. I would furthermore think how to stabilize the X carriage. It is not the weight itself that causes the ripples but the freedom the nozzle has to vibrate. So a more rigid construction should be able to take that freedom away...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Back on the topic, I would almost conclude that the weight on the Y carriage has little to no effect. I used to have a small 200x200 PCB heatbed and had the same issue nonetheless. Now I am utilizing a 250x320mm silicone heater glued to a 6mm machined cast aluminum plate. I even used to have a glass on top of it which is a total weight gain of 3kg. But this didn't make the rippling any worse than it already was. I got rid of the glass (1.3 kg) but there was no effect.

I suspect that the key contributer to our ripple problem is the X axis.

I switched from a greg wade's extruder with a huge Nema 17 motor to e3d titan with the small motor they supply with it. Maybe I could use a pancake motor instead but shy of that I have one inductive sensor, two 40mm fans and the classic e3d hot end attached to the X carriage. No extreme weight.

I guess I should try geared idlers. I would furthermore think how to stabilize the X carriage. It is not the weight itself that causes the ripples but the freedom the nozzle has to vibrate. So a more rigid construction should be able to take that freedom away...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: War against ripples March 19, 2017 06:27PM |

Registered: 8 years ago Posts: 601 |

Quote

icefire

I am thinking of a CoreXY Build myself... But that was just a small footnote

Back on the topic, I would almost conclude that the weight on the Y carriage has little to no effect. I used to have a small 200x200 PCB heatbed and had the same issue nonetheless. Now I am utilizing a 250x320mm silicone heater glued to a 6mm machined cast aluminum plate. I even used to have a glass on top of it which is a total weight gain of 3kg. But this didn't make the rippling any worse than it already was. I got rid of the glass (1.3 kg) but there was no effect.

I suspect that the key contributer to our ripple problem is the X axis.

I switched from a greg wade's extruder with a huge Nema 17 motor to e3d titan with the small motor they supply with it. Maybe I could use a pancake motor instead but shy of that I have one inductive sensor, two 40mm fans and the classic e3d hot end attached to the X carriage. No extreme weight.

I guess I should try geared idlers. I would furthermore think how to stabilize the X carriage. It is not the weight itself that causes the ripples but the freedom the nozzle has to vibrate. So a more rigid construction should be able to take that freedom away...

My comment above is based on a good machine construction that doesn't wobble and add noise to the print in its own right! If it does, lowering Jerk and Accel will certainly help. Assuming good construction, I don't see how your X gantry can add more rippling then Y, unless it weighs more? It is very hard to quantify rippling, and so it can be hard to know if changing settings has an effect. The ripple often ends further out then you think and I've found a decent camera will actually show this better as the ripple will catch the light under the camera. you can then measure the distance of the ripple to know if you are on the right path, as well as the distance between each individual ripple. if the spacing is similar between each ripple, it is likely something with a pattern causing it such as drivers, motors, pulleys and idlers. Ripples with greater distances are more likely to be acceleration based.

Also, your test is flawed as not only does it show rippling but it also shows the effects of under and over extrusion caused by retracts. I suggest making a solid cube with holes in, as well as raised surfaces.

Edited 2 time(s). Last edit at 03/19/2017 06:28PM by Origamib.

|

Re: War against ripples March 19, 2017 08:03PM |

Registered: 8 years ago Posts: 46 |

|

Re: War against ripples March 20, 2017 08:29AM |

Registered: 8 years ago Posts: 916 |

First way to improve:

Get 0.9 degree steppers, instead of 1.8 degree steppers.

Second way:

Get some Panucatt SD6128 drivers. They are amazing.

Third way: Get a Duet board that does segment less movements.

The explanation for the ripples involves the way that RAMPS firmware segment travel moves into discrete segments, and the way that those segments don't often line up with whole microsteps. It's tricky. I'm seeing the light after going down the same rabbit hole.

Get 0.9 degree steppers, instead of 1.8 degree steppers.

Second way:

Get some Panucatt SD6128 drivers. They are amazing.

Third way: Get a Duet board that does segment less movements.

The explanation for the ripples involves the way that RAMPS firmware segment travel moves into discrete segments, and the way that those segments don't often line up with whole microsteps. It's tricky. I'm seeing the light after going down the same rabbit hole.

|

Re: War against ripples March 20, 2017 09:12AM |

Registered: 8 years ago Posts: 168 |

The model may be less than perfect but it illustrates the effect pretty well. However, I forgot to mention that the ripples are the biggest immediately after a geometry chaneg (corner, hole, etc.) and then become immer smaller and with larger spacing until they disappear.

@ Origamib could you please print the model I attached in my first post @200% scale and post some pictures? It will cost you just 2g of filamment and 20 min time. I just want to see how far I can go.

@ nebbian: Thank you for your suggestions! Just one question: Are the 0,9° steppers going to bring any improvement over my current 1,8° steppers with the DRV8825 in fast decay mode with 1/32 microstepping? Theoretically this should be the same as the 0,9° steppers at 1/16 microstepping. I guess that the hardware resolution of the motor ist much more reliable than the theoretical microstepping rate of the driver but still...

Apart from that, I wanted to get 0,9° steppers anyway because of the noise reduction. I didn't know about the SD6128 drivers, I'll check them out.

I would start with geared idlers and while I wait for them to get delivered I would think the next step through. Will keep you posted about the progress. In the meantime, any other suggestions are very welcome.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

@ Origamib could you please print the model I attached in my first post @200% scale and post some pictures? It will cost you just 2g of filamment and 20 min time. I just want to see how far I can go.

@ nebbian: Thank you for your suggestions! Just one question: Are the 0,9° steppers going to bring any improvement over my current 1,8° steppers with the DRV8825 in fast decay mode with 1/32 microstepping? Theoretically this should be the same as the 0,9° steppers at 1/16 microstepping. I guess that the hardware resolution of the motor ist much more reliable than the theoretical microstepping rate of the driver but still...

Apart from that, I wanted to get 0,9° steppers anyway because of the noise reduction. I didn't know about the SD6128 drivers, I'll check them out.

I would start with geared idlers and while I wait for them to get delivered I would think the next step through. Will keep you posted about the progress. In the meantime, any other suggestions are very welcome.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: War against ripples March 20, 2017 10:51AM |

Registered: 8 years ago Posts: 601 |

Quote

nebbian

First way to improve:

Get 0.9 degree steppers, instead of 1.8 degree steppers.

Second way:

Get some Panucatt SD6128 drivers. They are amazing.

Third way: Get a Duet board that does segment less movements.

The explanation for the ripples involves the way that RAMPS firmware segment travel moves into discrete segments, and the way that those segments don't often line up with whole microsteps. It's tricky. I'm seeing the light after going down the same rabbit hole.

Do you believe 0.9 degree motors are necessary on a Cartesian machine? I wonder if it's possible to stop ringing entirely. On my machine I can see ringing for nearly 10mm after a feature, although the worst of the ringing exists around 2-3mm away and after that it is acceptable.

|

Re: War against ripples March 20, 2017 02:47PM |

Registered: 8 years ago Posts: 3,525 |

I've moved two machines over to 0.9 degree steppers (and whilst they are now also 32 bit boards) the amount of these artefacts I now see is very small.

Kossel XL - Duetwifi, TMC 2660' drivers, 0.9 deg motors - no ripple artefacts unless I print fast, and then these are probably true ringing from the frame resonating.

Smartrapcore Alu (corexy), Re-Arm, 0.9 deg steppers, with a4988. Only very slight ripple, and again when printing fast.

The 0.9 degree steppers are physically more accurate, even without microstepping, at 1 full step its 80 microns (+/- 5% error non cumulative) its 160 microns per full step assuming gt2 belt and 16t pulleys for 1.8 degree motors. With 1/16 microstepping, and we all know not every microstep results in actual movement its in theory 5 microns accuracy for the 0.9 deg steppers. Plus they're quieter and they cost barely any more to buy than 1.8 degree units, even if there's slightly less choice of motors.

The issue is with 8bit electronics, its a push generating 0.9 deg steppers enough steps/second to get great quality prints. With a delta with 3 motors all running 200 steps/mm (1/16th) moving at 50mm/s you need 30,000 step pulses per second, without extruders, LCD's and everything else gobbling up processor cycles. At 100mm/s thats 60khz step pulses, way beyond 8 bit boards. Duetwifi now claims to be able to get 350Khz+ step pulses with the latest firmware. Hello true 1/64 microstepping

Try this, pull your arduino off your ramps board and shove a re-arm on there - instant improvement in print quality, I'd say maybe 50% better in some areas.

Nebbian - how are the raps drivers working out compared to the tmc2100's?

Edited 1 time(s). Last edit at 03/20/2017 02:52PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Kossel XL - Duetwifi, TMC 2660' drivers, 0.9 deg motors - no ripple artefacts unless I print fast, and then these are probably true ringing from the frame resonating.

Smartrapcore Alu (corexy), Re-Arm, 0.9 deg steppers, with a4988. Only very slight ripple, and again when printing fast.

The 0.9 degree steppers are physically more accurate, even without microstepping, at 1 full step its 80 microns (+/- 5% error non cumulative) its 160 microns per full step assuming gt2 belt and 16t pulleys for 1.8 degree motors. With 1/16 microstepping, and we all know not every microstep results in actual movement its in theory 5 microns accuracy for the 0.9 deg steppers. Plus they're quieter and they cost barely any more to buy than 1.8 degree units, even if there's slightly less choice of motors.

The issue is with 8bit electronics, its a push generating 0.9 deg steppers enough steps/second to get great quality prints. With a delta with 3 motors all running 200 steps/mm (1/16th) moving at 50mm/s you need 30,000 step pulses per second, without extruders, LCD's and everything else gobbling up processor cycles. At 100mm/s thats 60khz step pulses, way beyond 8 bit boards. Duetwifi now claims to be able to get 350Khz+ step pulses with the latest firmware. Hello true 1/64 microstepping

Try this, pull your arduino off your ramps board and shove a re-arm on there - instant improvement in print quality, I'd say maybe 50% better in some areas.

Nebbian - how are the raps drivers working out compared to the tmc2100's?

Edited 1 time(s). Last edit at 03/20/2017 02:52PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: War against ripples March 21, 2017 03:59AM |

Registered: 8 years ago Posts: 916 |

DJD,

Your numbers are a bit off. I measured about 125 mm/s actual speed on a delta moving down 100mm, using 200 steps/mm on Repetier and RAMPS.

Moving up/down is the worst case for a delta, as all motors are maxed out.

Using 20 tooth pulleys, 0.9 degree steppers, and 1/16 microsteps is the sweet spot, it gives you 160 steps/mm, top speed of around 150 mm/s, and my print quality is pretty good.

I find the Panucatt SD6128 drivers to be excellent, way less ripple than A4988 or DRV8825, even if the 8825's are modded.

Your numbers are a bit off. I measured about 125 mm/s actual speed on a delta moving down 100mm, using 200 steps/mm on Repetier and RAMPS.

Moving up/down is the worst case for a delta, as all motors are maxed out.

Using 20 tooth pulleys, 0.9 degree steppers, and 1/16 microsteps is the sweet spot, it gives you 160 steps/mm, top speed of around 150 mm/s, and my print quality is pretty good.

I find the Panucatt SD6128 drivers to be excellent, way less ripple than A4988 or DRV8825, even if the 8825's are modded.

|

Re: War against ripples March 21, 2017 04:58AM |

Registered: 8 years ago Posts: 3,525 |

Okay maybe I'm being slightly pessimistic but Marlin is frequently quoted as only being able to generate 40khz step pulses from a mega/ramps board. So you're using repetier? I've little experience with it, but to do the moves you quoted that's 75khz step pulses, so that seems reasonable from what I'm told it's code is more efficient.

But on a delta is a pure z move really a good test? Whilst moving up/down is the worst case in terms of maximum step pulses to be generated, the processing requirements to calculate the movement are very little, all motors move by the same amount to achieve pure z movement. Any other movements require a lot of square root calculations which load the processor . How fast can that same machine (on a dry run) do a circular spiral vase, this is a more useful test, given that you almost never do a large pure z move when printing?

Is the choice of 20t pulleys just to lower the steps/mm to give the 8bit controller a chance? Surely mechanically improving your resolution 25% by just using smaller pulleys is a no-brainer. Would you run 20t pulleys on a 32bit controller? If so, why?

Glad you're liking the SD6128 drivers, might buy some, but can you comment on how they compare to TMC2100's?

Edited 2 time(s). Last edit at 03/21/2017 05:38AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

But on a delta is a pure z move really a good test? Whilst moving up/down is the worst case in terms of maximum step pulses to be generated, the processing requirements to calculate the movement are very little, all motors move by the same amount to achieve pure z movement. Any other movements require a lot of square root calculations which load the processor . How fast can that same machine (on a dry run) do a circular spiral vase, this is a more useful test, given that you almost never do a large pure z move when printing?

Is the choice of 20t pulleys just to lower the steps/mm to give the 8bit controller a chance? Surely mechanically improving your resolution 25% by just using smaller pulleys is a no-brainer. Would you run 20t pulleys on a 32bit controller? If so, why?

Glad you're liking the SD6128 drivers, might buy some, but can you comment on how they compare to TMC2100's?

Edited 2 time(s). Last edit at 03/21/2017 05:38AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: War against ripples March 21, 2017 11:48AM |

Registered: 8 years ago Posts: 356 |

Quote

DjDemonD

Okay maybe I'm being slightly pessimistic but Marlin is frequently quoted as only being able to generate 40khz step pulses from a mega/ramps board. So you're using repetier? I've little experience with it, but to do the moves you quoted that's 75khz step pulses, so that seems reasonable from what I'm told it's code is more efficient.

But on a delta is a pure z move really a good test? Whilst moving up/down is the worst case in terms of maximum step pulses to be generated, the processing requirements to calculate the movement are very little, all motors move by the same amount to achieve pure z movement. Any other movements require a lot of square root calculations which load the processor . How fast can that same machine (on a dry run) do a circular spiral vase, this is a more useful test, given that you almost never do a large pure z move when printing?

Is the choice of 20t pulleys just to lower the steps/mm to give the 8bit controller a chance? Surely mechanically improving your resolution 25% by just using smaller pulleys is a no-brainer. Would you run 20t pulleys on a 32bit controller? If so, why?

Glad you're liking the SD6128 drivers, might buy some, but can you comment on how they compare to TMC2100's?

Remember the SD6128 are not the raps 128, the raps 128 are the THB2168. There some difference between them I don't know what exactly but some say the raps are little better than the SD6128 but they cost around 4-5$ more.

In anycase sd or thb both driver are the best driver you can get so far in plug in socket, they require no special pulse like 8825 and are compatible without solder anything on all socket board.

I can only compare them to what I use before say 4988 and 8825 both on radds and rrf firmware with 1.8 degree 1.8A stepper set to 1.4 ish Amp on all 3 drivers, I use 1/64 right now, but I test 1/32 when I switch from my 8825 to stick to the same setup to see if I gain quality and I did, they are cooler to the touch too (those 6128's are the only one with top cooling too.

What I would like to know is the quality difference between them and say a duet wifi tmc drivers both setting on the same machine and using RRF and the same micro stepping say 1/64.

Im looking for my next printer electronic and I am not sure if a wifi duet is really an upgrade to a radds with raps128 specially if you already have a couple raps 128 as replacement and you dont care much about the wifi part cause you have octoprint anyway.

|

Re: War against ripples March 21, 2017 12:10PM |

Registered: 8 years ago Posts: 3,525 |

So far I have not used RAPs or SD6128's but I cannot fault the TMC 2660's as implemented on duetwifi. I've used 4988's, TMC2100's, 8825's and the 2660's win hands down every day and twice on Sunday. This is why I'm interested in these two further products.

Don't hesitate if you're thinking about getting a duet wifi they are worth every penny.

I'll make you a deal, if you don't like it I'll buy it from you for the price you paid. I'm that confident.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Don't hesitate if you're thinking about getting a duet wifi they are worth every penny.

I'll make you a deal, if you don't like it I'll buy it from you for the price you paid. I'm that confident.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: War against ripples March 21, 2017 04:24PM |

Registered: 8 years ago Posts: 33 |

|

Re: War against ripples March 21, 2017 05:57PM |

Registered: 7 years ago Posts: 62 |

If your looking to reduce the mass of your print head you can't beat the Nimble extruder, Though we've been stating less than 27grams in marketing materials I weighed production parts last week and we're pretty much at 25grams for the nimble extruder including the weight of longer than you will need mounting screws.

Michael Hackney will have a Nimble on display at MRRF and had the following to say after playing with it for a few days:

"I've only had the Zesty Nimble for a few days but so far I'm very impressed with it. It is well designed and built. And it is SMALL, much smaller than photos can show. The breech loading system is very nicely done and a great way to "feel" the extrusion path through the hot end in addition to making filament changes dead simple. The remote direct drive concept has a lot of potential and so far the Nimble has been living up to that. Low mass on the effector (delta) or carriage (Cartesian) is highly desirable and Zesty deliver that. The remote drive shaft and stepper are precise, I have not observed or measured any hysteresis so extrusion moves are precise and snappy. My next task is to evaluate the long term reliability and that, of course, takes time. But experience tells me that the Nimble will continue to perform reliably over the long haul.”

Check it out at: https://zesty.tech/

Edited 3 time(s). Last edit at 03/21/2017 06:13PM by briangilbert.

Co-creator of the Zesty Nimble, worlds lightest direct drive extruder.

[zesty.tech]

Michael Hackney will have a Nimble on display at MRRF and had the following to say after playing with it for a few days:

"I've only had the Zesty Nimble for a few days but so far I'm very impressed with it. It is well designed and built. And it is SMALL, much smaller than photos can show. The breech loading system is very nicely done and a great way to "feel" the extrusion path through the hot end in addition to making filament changes dead simple. The remote direct drive concept has a lot of potential and so far the Nimble has been living up to that. Low mass on the effector (delta) or carriage (Cartesian) is highly desirable and Zesty deliver that. The remote drive shaft and stepper are precise, I have not observed or measured any hysteresis so extrusion moves are precise and snappy. My next task is to evaluate the long term reliability and that, of course, takes time. But experience tells me that the Nimble will continue to perform reliably over the long haul.”

Check it out at: https://zesty.tech/

Edited 3 time(s). Last edit at 03/21/2017 06:13PM by briangilbert.

Co-creator of the Zesty Nimble, worlds lightest direct drive extruder.

[zesty.tech]

|

Re: War against ripples March 21, 2017 06:23PM |

Registered: 12 years ago Posts: 116 |

I've had the Nimble for a few more days and starting to push it a bit with faster print speeds and troublesome filaments like NinjaFlex. Lots new to learn to optimize and extract the best results out of the Nimble but so far it has performed quite well. I'd estimate I have 40+ hours of print time on it. No jams and several 12+ hour prints came out great.

Edited 1 time(s). Last edit at 03/21/2017 06:31PM by mhackney.

[sublimelayers.blogspot.com]

A strategy for Successful (and Great) Prints [forum.seemecnc.com]

Strategies for Resolving Print Artifacts [forum.seemecnc.com]

[www.EclecticAngler.com]

Edited 1 time(s). Last edit at 03/21/2017 06:31PM by mhackney.

[sublimelayers.blogspot.com]

A strategy for Successful (and Great) Prints [forum.seemecnc.com]

Strategies for Resolving Print Artifacts [forum.seemecnc.com]

[www.EclecticAngler.com]

|

Re: War against ripples March 23, 2017 04:05PM |

Registered: 8 years ago Posts: 312 |

So nice to see this thing in customer hands.

And a happy customer as well. Nice!

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

And a happy customer as well. Nice!

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: War against ripples March 23, 2017 06:47PM |

Registered: 8 years ago Posts: 601 |

|

Re: War against ripples March 24, 2017 09:43AM |

Registered: 8 years ago Posts: 168 |

So layer height definitely has impact on the ripples. I have a 0.4mm nozzle and a layer height of 0.2mm shows visible improvement compared to 0.1mm, whereas 0.3mm is not better that 0.2mm...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: War against ripples March 24, 2017 11:47AM |

Registered: 9 years ago Posts: 425 |

Origamib - I totally agree with you as do quite a few others that have contacted me expressing the very same. The spamvertising and hijacking of threads all around the various 3d print forums is rediculous and a lot of people are quite sick of it. Either shows they are desperate for sales, or greedy for sales.

icefire - What do you think your findings are telling you regarding layer height and ripples?

Edited 1 time(s). Last edit at 03/24/2017 01:54PM by Mutley3D.

Flex3Drive.com

icefire - What do you think your findings are telling you regarding layer height and ripples?

Edited 1 time(s). Last edit at 03/24/2017 01:54PM by Mutley3D.

Flex3Drive.com

|

Re: War against ripples March 24, 2017 12:04PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: War against ripples March 24, 2017 02:01PM |

Registered: 9 years ago Posts: 425 |

Quote

MechaBits

There is no real 3D Printing news, it's all Fake.

When was the last time a reporter came to you for the Real Story.

Ok Maybe Mutley & Pursa get a few inquiries?

LOL, the spamvertising on any unrelated thread where the tiniest excuse to "plug" exists, is plain to see.

Flex3Drive.com

|

Re: War against ripples March 24, 2017 02:38PM |

Registered: 8 years ago Posts: 1,671 |

Exactly same with Fake News, spot it a mile away, though you have to talk about your babies some times, hopefully without creating ripples or war's, though it is fun to create some shockwaves every now & then. On subject of Ripples when I dropped speed they where totally invisible, though if I left things at that speed and then dropped layer height from .2 to .1 I think I probably would have seen ripples introduced (visualizes squirty cream from a can, just guessing not done .1 yet) that I might have to reduce flow a tad more, as with a slight under extrude your chances of a finer surface is probably higher. Wish there was some deceleration parameters to play with.

Edited 1 time(s). Last edit at 03/24/2017 03:53PM by MechaBits.

Edited 1 time(s). Last edit at 03/24/2017 03:53PM by MechaBits.

|

Re: War against ripples March 24, 2017 04:34PM |

Registered: 9 years ago Posts: 425 |

@Mechabits - My comment was in part a subtle hint to the party concerned in case they cared, just as someone else had hinted prior. Nothing "fake" about it so I honestly dont know where that comment comes from.

If every 3d seller took every smallest opportunity to pimp their product on every possible thread, where would this forum be? full of spammy posts with no informative or helpful content.

Edited 1 time(s). Last edit at 03/24/2017 04:40PM by Mutley3D.

Flex3Drive.com

If every 3d seller took every smallest opportunity to pimp their product on every possible thread, where would this forum be? full of spammy posts with no informative or helpful content.

Edited 1 time(s). Last edit at 03/24/2017 04:40PM by Mutley3D.

Flex3Drive.com

|

Re: War against ripples March 24, 2017 05:11PM |

Registered: 9 years ago Posts: 425 |

Ripples are caused by several factors, each to varying degree and at different points along a motion path. They can have distinctly different visual characteristic. Identifying type of ripple identifies the path to solution. The subject is too expansive for a single post.

Causes include but not limited to (in no particular order):

Poor calibration of E axis or incorrect extrusion widths

Bad linear bearings or rods

Belt issues

Motion control settings that are not in synch

Poor quality filament

Material group

Non ideal hotend temps

Bad nozzles

Moving mass (note a moving bed is much more stable than a moving carriage on a cartesian)

Extruder gear profiles and ratio's

Filament hobb profiles

Controller brand

Stepper driver type

Decay mode

vref settings

...and more

Edited 1 time(s). Last edit at 03/24/2017 05:13PM by Mutley3D.

Flex3Drive.com

Causes include but not limited to (in no particular order):

Poor calibration of E axis or incorrect extrusion widths

Bad linear bearings or rods

Belt issues

Motion control settings that are not in synch

Poor quality filament

Material group

Non ideal hotend temps

Bad nozzles

Moving mass (note a moving bed is much more stable than a moving carriage on a cartesian)

Extruder gear profiles and ratio's

Filament hobb profiles

Controller brand

Stepper driver type

Decay mode

vref settings

...and more

Edited 1 time(s). Last edit at 03/24/2017 05:13PM by Mutley3D.

Flex3Drive.com

|

Re: War against ripples March 24, 2017 05:18PM |

Registered: 8 years ago Posts: 1,671 |

No dont get me wrong mutley I'm not arguing with you "Call it when you see it" im all for that, that comments been in my head for some time, I didnt mean to imply anything against you or pursa, and I'm sure I missed a few more people famous enough to have the press rummaging through your bins trying to find out whats next in the world of 3D printing Most stories are submitted, lots of it interesting stuff out there, I can easy over look things I'm not interested in. On the above nimble plug, I am more interested in seeing pictures at 0.1

Yeah having built a 3D Printer(cough plug) you become familiar with all those points, some I have still to address but I'm not going to adjust my vref's or implement decay modes, to see if there's an improvement till I'm forced too.

Edited 3 time(s). Last edit at 03/24/2017 05:34PM by MechaBits.

Yeah having built a 3D Printer(cough plug) you become familiar with all those points, some I have still to address but I'm not going to adjust my vref's or implement decay modes, to see if there's an improvement till I'm forced too.

Edited 3 time(s). Last edit at 03/24/2017 05:34PM by MechaBits.

Sorry, only registered users may post in this forum.