|

Stuck March 21, 2017 07:22PM |

Registered: 11 years ago Posts: 1,277 |

I have an extrusion frame and everything was fitting together nicely when I stumbled into Hades trying to find a 5mm smooth rod (~600mm long) that was dead straight. After a lot of attempts I have given up on ever finding this so my entire printer build is dead just because of this.

Here is the issue and that is I have X that moves from side to side using 500mm extrusion. One side has the motor and gt2 belt and the other side has a simple loop that was driven by the motor on the opposite side so that each side was moved by a single motor using that m5 smooth rod. They seem to do this on the Flash Forge Creator for Y but where they found a supply of dead straight 5mm rod is beyond me.

Since I can't find a smooth rod to buy (even McMaster Carr was a horrible 4 attempts) that is dead straight how do I move X on both sides using a single motor?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Here is the issue and that is I have X that moves from side to side using 500mm extrusion. One side has the motor and gt2 belt and the other side has a simple loop that was driven by the motor on the opposite side so that each side was moved by a single motor using that m5 smooth rod. They seem to do this on the Flash Forge Creator for Y but where they found a supply of dead straight 5mm rod is beyond me.

Since I can't find a smooth rod to buy (even McMaster Carr was a horrible 4 attempts) that is dead straight how do I move X on both sides using a single motor?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck March 21, 2017 07:59PM |

Registered: 11 years ago Posts: 1,277 |

Ahhh, the piece I forgot to mention is that I cannot find an 8mm 16t pulley. Besides, that would be 21 dollars a piece per smooth rod but they would be dead straight as Mitsumi doesn't play around so they can conform to g6/h5 tolerances.Quote

MechaBits

Dual shaft motor, in the middle of 2 300mm rods...go for 8mm thicker/shorter less chance of bends in the post but still possible, or join two pieces with a coupler, or step back down to 5mm up to you.

You know out of 4 rods from McMaster not a single one had a straight bit to them. 1m rods and not a single piece was usable for anything over say 100mm. smh.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck March 21, 2017 09:07PM |

Registered: 11 years ago Posts: 1,277 |

Interesting on the 12mm being crappier than 8mm but I haven't had luck with eBay or even worse Aliexpress or even worse yet Banggood. As far as the 16t I have been using them since I got into 3d printing 4 years ago as there are no round off errors with them and they offer finer resolutions. At 16 micro stepping 16t is 10 micron and 20t is 12.5 micron resolution so finer and no rounding errors thanks to that .5. It does matter ever so slightly the smaller the nozzle diameter gets.Quote

MechaBits

I got quite a few 8mm's from cheap ebay listings...not had one reject...but I have with 12mm rods,

why you wanting 16t?

Edited 1 time(s). Last edit at 03/21/2017 09:11PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

If you only need it to be 5mm so the pulley will fit on the end why not get a bigger diameter and turn down the ends? I know not easy with a long rod but can be done.

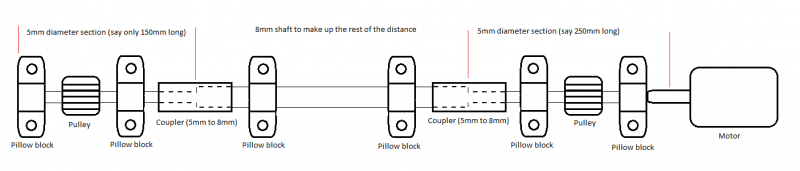

Or use small bits of 5mm for the pulley and then use a coupler to step up to the diameter of the straightest rod you can find, a pillow block each side of the coupler should keep it aligned

Or use small bits of 5mm for the pulley and then use a coupler to step up to the diameter of the straightest rod you can find, a pillow block each side of the coupler should keep it aligned

|

Re: Stuck March 21, 2017 09:36PM |

Registered: 11 years ago Posts: 1,277 |

If I had a lathe you bet I would have turned down 8mm rod but I don't and I am not sure what you mean on your second bit there? This is why I started this thread for suggestions because right now I can reprint all of my parts and make a big Core X/Y (not something I really want to do) because it doesn't demand a rod like that or find some way I can pull that extrusion beam from both sides using just one motor that doesn't involve a rod that always seems to be bent.Quote

scottybfg

If you only need it to be 5mm so the pulley will fit on the end why not get a bigger diameter and turn down the ends? I know not easy with a long rod but can be done.

Or use small bits of 5mm for the pulley and then use a coupler to step up to the diameter of the straightest rod you can find, a pillow block each side of the coupler should keep it aligned

I am not even sure a lathe that I could afford (think seig type) would allow me to shove a 600mm rod at it so only the 30mm at each end could be turned down to 5mm (well, 4.9mm to allow it to fit into a 5mm bore bearing or pulley).

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

So my thinking is you only need 5mm where the pulleys are needed, and what you are trying to make is just one big drive axial, so use 5mm for where the pulleys need to be placed and then use a coupler to join it to a rod of another diameter that is straight. Using pillow blocks ( bearings) to help align the shaft.

See bad paint drawing for reference

See bad paint drawing for reference

|

Re: Stuck March 21, 2017 10:29PM |

Registered: 11 years ago Posts: 1,277 |

Yep, I was thinking the same but trying to get anything that is straight is a nightmare if less than 8mm. If I had a lathe I would easily turn it down to 7.9mm for 100mm and the last 30mm would be 4.9mm but I just don't have it. The X moves so smoothly by itself and even with an idler pulley but attach the rod and it feels like I am on the old Chisholm trail in a wagon with a broke axle.Quote

scottybfg

So my thinking is you only need 5mm where the pulleys are needed, and what you are trying to make is just one big drive axial, so use 5mm for where the pulleys need to be placed and then use a coupler to join it to a rod of another diameter that is straight. Using pillow blocks ( bearings) to help align the shaft.

See bad paint drawing for reference

Pillow blocks are easy to print and just use a 608 bearing but that last piece of 5mm is where the pain is. You know I have some 5mmx35mm screws and all of them are not true either (alright as a screw doesn't need to be true but I was hoping to use one of those for this purpose). You would think finding a 5mm ANYTHING round would be straight, and true, but it is surprising just how much isn't truly straight.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

I also find it hard to believe that you can t find 2 sections of 30mm to 40mm 5mm straight rod, or maybe I have been blessed with my suppliers of smooth rod (usually use 8mm or 10mm)

The only other thing i can suggest is to use flex couplers to take some of the miss alignment of the shaft. Or as there is only radial load, use a flexable shaft that is constrained by the pillow blocks. you might have to use more bearings but you you cant find straight shaft this might be the way to go.

The only other thing i can suggest is to use flex couplers to take some of the miss alignment of the shaft. Or as there is only radial load, use a flexable shaft that is constrained by the pillow blocks. you might have to use more bearings but you you cant find straight shaft this might be the way to go.

|

Re: Stuck March 21, 2017 11:06PM |

Registered: 11 years ago Posts: 1,277 |

Yeah, 8mm from mitsumi was dead straight and true but anyway I am intrigued at what you said. Could you go more indepth and possibly show a picture, or two, as I am not fully grasping how it would be done.Quote

scottybfg

I also find it hard to believe that you can t find 2 sections of 30mm to 40mm 5mm straight rod, or maybe I have been blessed with my suppliers of smooth rod (usually use 8mm or 10mm)

The only other thing i can suggest is to use flex couplers to take some of the miss alignment of the shaft. Or as there is only radial load, use a flexable shaft that is constrained by the pillow blocks. you might have to use more bearings but you you cant find straight shaft this might be the way to go.

Edited 1 time(s). Last edit at 03/21/2017 11:07PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

This was the first idea I was talking about, or did you want info on a flex system? (EDIT: My numbers for the length of the 5mm rod might be a bit off, you could almost half them)

Also have you looked at carbon fibber rod? It has a bit of play so as long as your pillow blocks where aligned correctly you could force it to be straight

Edited 1 time(s). Last edit at 03/21/2017 11:57PM by scottybfg.

|

Re: Stuck March 22, 2017 12:01AM |

Registered: 11 years ago Posts: 1,277 |

Info on a flex system would be nice as well and since all of these will be printed and on the extrusion they will be as aligned as I will ever be able to get them.Quote

scottybfg

[attachment 92248 Untitled1.png]

This was the first idea I was talking about, or did you want info on a flex system? (EDIT: My numbers for the length of the 5mm rod might be a bit off, you could almost half them)

Also have you looked at carbon fibber rod? It has a bit of play so as long as your pillow blocks where aligned correctly you could force it to be straight

So, more info on the flex system since it is going to have flex. Oh, and where on ebay do you get such straight 8mm smooth rods from?

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck March 22, 2017 12:09AM |

Registered: 11 years ago Posts: 1,277 |

88625K64 and twice it came with rust on it to the point it was pitted over a 1/3 of it. First order from them and not all that happy with them.Quote

LoboCNC

What McMaster part number were you ordering for 5mm rods? Did you look at the linear shafting (6112K13) which has a 0.03mm/300mm straightness tolerance?

I would be afraid to pay about 40 dollars (that is with the shipping) to them for another rod.

Edited 1 time(s). Last edit at 03/22/2017 12:12AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

The flex couplers are everywhere, most people use them on the z axis

As for the flex shaft, do a bit of reading and see if its what you want, hard to explain that one on a forum. or use a soft shaft (something that can bend a bit) if you are worried about getting perfect alignment with the pillow blocks

I get all my rods from a local guy in Australia so cant be much help there

Edited 1 time(s). Last edit at 03/22/2017 12:12AM by scottybfg.

As for the flex shaft, do a bit of reading and see if its what you want, hard to explain that one on a forum. or use a soft shaft (something that can bend a bit) if you are worried about getting perfect alignment with the pillow blocks

I get all my rods from a local guy in Australia so cant be much help there

Edited 1 time(s). Last edit at 03/22/2017 12:12AM by scottybfg.

|

Re: Stuck March 22, 2017 12:13AM |

Registered: 11 years ago Posts: 1,277 |

Yeah, flex couplers is what I use for Z on my Prusa and this has some merit only I can't figure out how I would implement it.

Edited 1 time(s). Last edit at 03/22/2017 12:16AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Edited 1 time(s). Last edit at 03/22/2017 12:16AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck March 22, 2017 12:18AM |

Registered: 11 years ago Posts: 1,277 |

If I only had an 800 dollar metal lathe, lol. I could buy anything, even from HD/Lowes, and turn a bigger down to what I needed I think and turning it down yourself it would be a lot truer than what you could buy.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck March 22, 2017 12:32AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Stuck March 22, 2017 12:40AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Stuck March 22, 2017 12:43AM |

Registered: 11 years ago Posts: 1,277 |

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

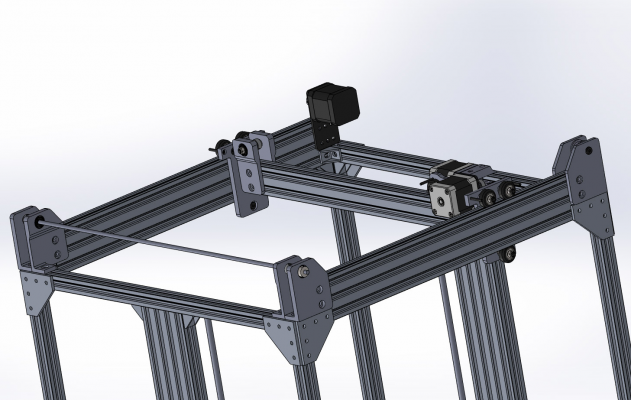

Yep I see, all you need to do is mount a section of 2020 (or even a plate) along the back that the assembly can bolt into

Also disregard my motor placement in my sketch, I thought this shaft was coupled directly to the motor

Edited 1 time(s). Last edit at 03/22/2017 12:55AM by scottybfg.

Also disregard my motor placement in my sketch, I thought this shaft was coupled directly to the motor

Edited 1 time(s). Last edit at 03/22/2017 12:55AM by scottybfg.

|

Re: Stuck March 22, 2017 12:57AM |

Registered: 11 years ago Posts: 1,277 |

Well, not even that as everything in that picture can be printed including the pillow block 608zz holders so everything would line up precisely but I wish there was some other way to do this that didn't need that axle or the use of smooth rods.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Stuck March 22, 2017 01:03AM |

Registered: 11 years ago Posts: 1,277 |

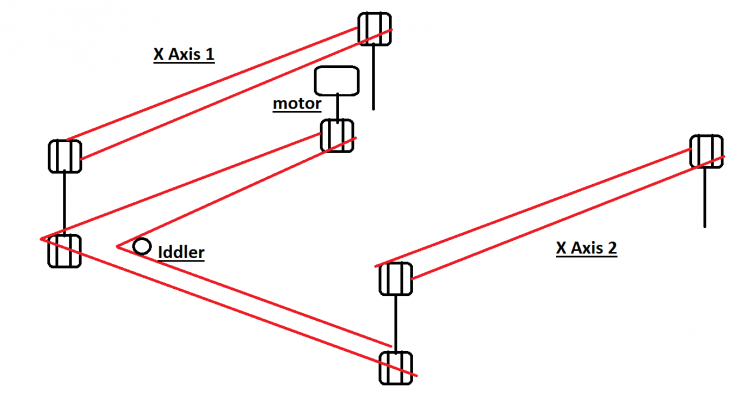

The only thing I could find doing anything like that was a Core XY though not closed belts. I really don't care if closed is required as long as something could be done that would eliminate the smooth rod axle.Quote

scottybfg

well, it could be done with one closed loop belt to drive the 2 pulleys

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Time for another one of my awesome quick paint jobs,

motor drives a closed loop belt underneath, two belts on top drive the X axis

motor drives a closed loop belt underneath, two belts on top drive the X axis

Sorry, only registered users may post in this forum.