leaking nozzzle head

Posted by AgeingHippy

|

leaking nozzzle head March 07, 2011 05:11AM |

Registered: 13 years ago Posts: 482 |

NO MAKERGEAR PRODUCTS INVOLVED HERE (don't want to start that pointless argument again )

Hi guys

I have a bighead style nozzle which is leaking out the threads up the barrel. I have seen references to plumbers tape, but wonder if anyone has had success with such an approach. Alternatively, if anyone has used any other means to block the leakage that would be usefull to know.

I initially had my heater block and nozzle wrapped in loft insulation which absorbed the leaking plastic for the first few days that I was extruding. My extruder then croaked and now having fixed the thermal break I found while testing without the insulation the leak is noticeable.

I guess I will go for a one piece barrel/nozzle eventually which will bring the heater block closer to the tip, but a fix in the meantime would be usefull.

I am thinking of maybe cutting a thin slice of 10mm PTFE, drilling a hole in it and squeezing it between my heater block and the nozzle head which will hopefully deform slightly under the pressure and seal off the nozzle leak, but that may slow down the heat transfer between the heater block and nozzle head to only work via the barrel itself. I don't know if that would be detrimental or not.

Cheers guys.

(and no arguments about who is responsible and who's products are good or rubbish please)

Hi guys

I have a bighead style nozzle which is leaking out the threads up the barrel. I have seen references to plumbers tape, but wonder if anyone has had success with such an approach. Alternatively, if anyone has used any other means to block the leakage that would be usefull to know.

I initially had my heater block and nozzle wrapped in loft insulation which absorbed the leaking plastic for the first few days that I was extruding. My extruder then croaked and now having fixed the thermal break I found while testing without the insulation the leak is noticeable.

I guess I will go for a one piece barrel/nozzle eventually which will bring the heater block closer to the tip, but a fix in the meantime would be usefull.

I am thinking of maybe cutting a thin slice of 10mm PTFE, drilling a hole in it and squeezing it between my heater block and the nozzle head which will hopefully deform slightly under the pressure and seal off the nozzle leak, but that may slow down the heat transfer between the heater block and nozzle head to only work via the barrel itself. I don't know if that would be detrimental or not.

Cheers guys.

(and no arguments about who is responsible and who's products are good or rubbish please)

|

Re: leaking nozzzle head March 07, 2011 05:40AM |

Registered: 14 years ago Posts: 3,742 |

PFTE plumbers tape should seal the leak but I have gone to a single piece design where this problem can not occur.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: leaking nozzzle head March 07, 2011 06:04AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes PTFE plumber's tape works to seal the thread, but as mentioned before the thread is not where the seal should be formed. The end of the barrel and the inside of the nozzle should be shaped so that they seal when forced together by the screw.

I haven't tried it but I guess Fernox LSX joint compound would work. I have had a lot of success bodging plumbing jobs with it and it appears to be silicone, so it should handle the temperature.

[www.hydraraptor.blogspot.com]

I haven't tried it but I guess Fernox LSX joint compound would work. I have had a lot of success bodging plumbing jobs with it and it appears to be silicone, so it should handle the temperature.

[www.hydraraptor.blogspot.com]

|

Re: leaking nozzzle head March 07, 2011 06:32AM |

Registered: 13 years ago Posts: 482 |

cool - did not realise plumbers tape was PTFE

I guess I should decide whether to source a 1-piece nozzle or plumbers tape.

Anyone capable of supplying me with a 1 piece brass M6 barrel and nozzle combo bored to 3.1mm with a 0.5mm orifice in the UK? Price?

I could always try with my cheap drill press... but not sure how well that will work though, and then I need to source an M6 brass bolt. Anyone know where I can find one of these?

Edited 1 time(s). Last edit at 03/09/2011 04:50AM by AgeingHippy.

I guess I should decide whether to source a 1-piece nozzle or plumbers tape.

Anyone capable of supplying me with a 1 piece brass M6 barrel and nozzle combo bored to 3.1mm with a 0.5mm orifice in the UK? Price?

I could always try with my cheap drill press... but not sure how well that will work though, and then I need to source an M6 brass bolt. Anyone know where I can find one of these?

Edited 1 time(s). Last edit at 03/09/2011 04:50AM by AgeingHippy.

|

Re: leaking nozzzle head March 08, 2011 06:26PM |

Registered: 13 years ago Posts: 818 |

|

Re: leaking nozzzle head March 13, 2011 06:13PM |

Registered: 13 years ago Posts: 197 |

I know the plumbers tape can fix the leak... hope everything else hold the pressure well after the leak is fixed. My experiences in this area are that you simply don't ever want to rely on ptfe or peek threads for structural integrity. If you can keep that in mind you should be able to avoid the many issues me and friends had.

|

Re: leaking nozzzle head May 11, 2011 01:19AM |

Registered: 13 years ago Posts: 91 |

I am having the same issue with my nozzle leaking up the threads.... i thought about using PTFE plumbers tape, but thought that it might insulate the nozzle too much from the barrel. Does anyone think that would be a problem?

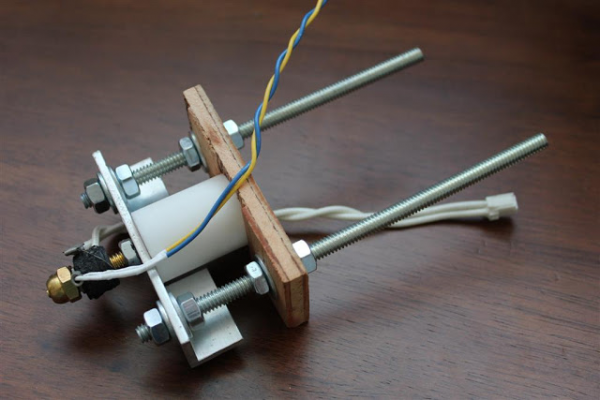

Here are a few pics of my hot end...

Thanks,

-Drew

Here are a few pics of my hot end...

Thanks,

-Drew

|

Re: leaking nozzzle head May 11, 2011 05:33AM |

Registered: 13 years ago Posts: 197 |

wow, you went all oldschool with the nichrome wire and acorn nut

the plumbers tape might actually insulate a bit as you say but it wont be enough to keep the nozzle from heating. I think the important thing is that you put your thermistor on your nozzle so that you know what the nozzle temp is regardless.

the plumbers tape might actually insulate a bit as you say but it wont be enough to keep the nozzle from heating. I think the important thing is that you put your thermistor on your nozzle so that you know what the nozzle temp is regardless.

|

Re: leaking nozzzle head May 11, 2011 05:53AM |

Registered: 13 years ago Posts: 1,780 |

I think the big problem with this design with nichrome wire is not having a good place to mount the thermistor. In my last hot end with nichrome wire, I used a 15 mm long round rod, tapped it along the axis for the nozzle and drilled a hole also along the axis for the thermistor as close to the nozzle as possible. I wound the nichrome wire around the rod and then I just used kapton tape wound several times to hold it in place. It worked really well until the PTFE insulater started leaking.

The thread in the PTFE would not last long unless you put a nut between it and the nozzle. Then you need something to function like the PEEK block to support the nozzle on the nut instead of the PTFE insulator.

The thread in the PTFE would not last long unless you put a nut between it and the nozzle. Then you need something to function like the PEEK block to support the nozzle on the nut instead of the PTFE insulator.

|

Re: leaking nozzzle head May 11, 2011 12:41PM |

Registered: 13 years ago Posts: 91 |

Haha, yeah Anthong, I did go old school! I forgot to mention im building a "JunkStrap" mendel and trying to make it for as cheep or free as possible. I also don't have a lathe or drill press to make a proper up to date extruder barrel/nozzle, so i went with the hardware store version.

Brnrd, thanks for the tips, i forgot to mention that was just part of my extruder... below are some pics of the whole thing (minus the "Wade" like geared feeding system).... I am using a piece of aluminum angle in place of the PEEK support block... It's tapped so it takes all the preasure from the extruder rather than the threads in the PTFE thermal break.

Right now i just have the thermistor mounted inside a little spade crimp connector, but i plan to grind a small notch in the side of the nut part of the acorn nut and glue it in with the same black fire cement i used for my heater element.

You can also see that i made the heater modular by wrapping it around a threaded insert so that it could screw onto the barrel... this also leaves me the ability to upgrade to a heater block when i can find some free aluminum stock and a vitrious enamel wirewound resistor. But for now im sticking with the nichrome wire because i got it free from a broken hair dryer! (there is TONS of it in those things!)

Thanks,

-Drew

Brnrd, thanks for the tips, i forgot to mention that was just part of my extruder... below are some pics of the whole thing (minus the "Wade" like geared feeding system).... I am using a piece of aluminum angle in place of the PEEK support block... It's tapped so it takes all the preasure from the extruder rather than the threads in the PTFE thermal break.

Right now i just have the thermistor mounted inside a little spade crimp connector, but i plan to grind a small notch in the side of the nut part of the acorn nut and glue it in with the same black fire cement i used for my heater element.

You can also see that i made the heater modular by wrapping it around a threaded insert so that it could screw onto the barrel... this also leaves me the ability to upgrade to a heater block when i can find some free aluminum stock and a vitrious enamel wirewound resistor. But for now im sticking with the nichrome wire because i got it free from a broken hair dryer! (there is TONS of it in those things!)

Thanks,

-Drew

Sorry, only registered users may post in this forum.