Does using bigger aluminium extrusions prevent ringing?

Posted by drmaestro

|

Does using bigger aluminium extrusions prevent ringing? April 18, 2017 02:23AM |

Registered: 9 years ago Posts: 330 |

As far as I know, ringing artefacts due to the acceleration and jerk settings happen because sudden changes create vibrations. So, could using larger extrusions (4040 instead of 2020) prevent these artefacts becasue the frame is more rigid or is it still related to the relationship between the belts and the carriages?

Thanks..

Thanks..

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 05:06AM |

Registered: 8 years ago Posts: 3,525 |

Interesting question to which sadly I do not know the answer definitively, but it stands to reason that the greater the mass (and hopefully stiffness) of the frame, relative to the moving mass of the axes/carriages, the less it should impart vibration to the prints. I have heard people talking about filling frames with heavy materials - sand/resin/cement etc.. to achieve this. You could go to extremes but there has to be a sensible cut off somewhere.

So a larger heavier frame i.e. 4040 increases the frame stiffness and mass compared to a lighter frame. But it also increases the cost quite substantially. The other way is to ensure your moving mass is very light and therefore needs a less substantial frame to achieve high print quality.

Edited 1 time(s). Last edit at 04/18/2017 05:08AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So a larger heavier frame i.e. 4040 increases the frame stiffness and mass compared to a lighter frame. But it also increases the cost quite substantially. The other way is to ensure your moving mass is very light and therefore needs a less substantial frame to achieve high print quality.

Edited 1 time(s). Last edit at 04/18/2017 05:08AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 06:26AM |

Registered: 8 years ago Posts: 601 |

It depends what your definition of ringing is.... Ringing tends to be repetitive banding on the print, mostly caused by an element of the printer that is repeating. For example, drivers, belt, pulleys, motors etc can all cause ringing by some form of repetitive action.

The frame will add rigidity and help with layer alignment, but will not specifically help with ringing. There are lower hanging fruits to tackle ringing.

Edited 1 time(s). Last edit at 04/18/2017 06:26AM by Origamib.

The frame will add rigidity and help with layer alignment, but will not specifically help with ringing. There are lower hanging fruits to tackle ringing.

Edited 1 time(s). Last edit at 04/18/2017 06:26AM by Origamib.

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 07:58AM |

Registered: 11 years ago Posts: 5,780 |

Ringing isn't caused by the frame, it's caused by the moving mass interacting with the acceleration, belt stretch and motor springiness. Motor steps are defined by magnetic fields. They aren't hard mechanical stops, they behave like springs. When the motor is accelerating, the inertia of the moving mass causes it to respond late to what the motor is doing. If it's speeding up, as the motor tries to step, the magnetic spring loads, the belt stretches a little, then the mass starts to move. When the step has finished, the mass overshoots the final step position a little, then springs back. It wobbles back and forth a little and takes some finite time to settle.

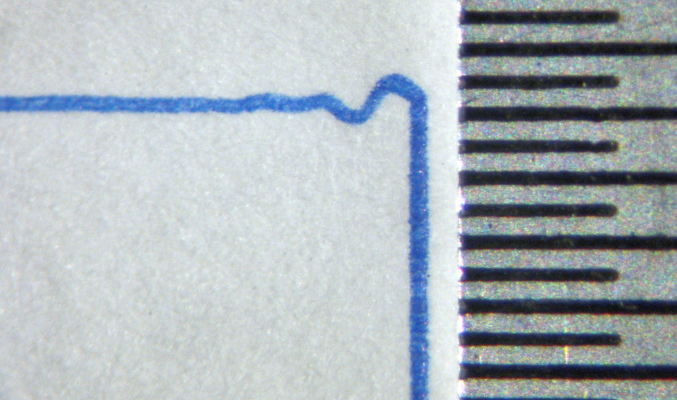

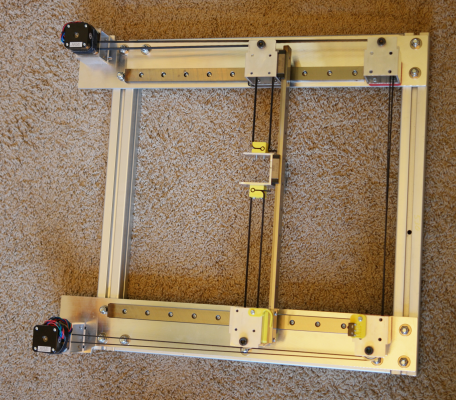

This is a drawing made by my coreXY stage hooked up as a plotter when I was playing with it a little to check the acceleration and junction deviation settings.

The X axis is horizontal, but you can think of it as time, with t=0 at the far right. The Y axis vertical. The pen mounted in the extruder carriage moved up along Y then turned left to move along X. You can see that when it got to the corner, the high moving mass of the Y axis overshot the stopping point and sprung back the other way and wobbled a little until it settled onto the X line. That is ringing. It isn't because the pen was loose in the holder- it was mounted in a linear guide and there was zero wiggle in the bearing. If you stack it layer upon layer in a print, you get ripples in the walls of the print.

The printer has 40x40mm t-slot with 1/4" MIC6 plate. It is rock solid.

Edited 1 time(s). Last edit at 04/18/2017 08:02AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This is a drawing made by my coreXY stage hooked up as a plotter when I was playing with it a little to check the acceleration and junction deviation settings.

The X axis is horizontal, but you can think of it as time, with t=0 at the far right. The Y axis vertical. The pen mounted in the extruder carriage moved up along Y then turned left to move along X. You can see that when it got to the corner, the high moving mass of the Y axis overshot the stopping point and sprung back the other way and wobbled a little until it settled onto the X line. That is ringing. It isn't because the pen was loose in the holder- it was mounted in a linear guide and there was zero wiggle in the bearing. If you stack it layer upon layer in a print, you get ripples in the walls of the print.

The printer has 40x40mm t-slot with 1/4" MIC6 plate. It is rock solid.

Edited 1 time(s). Last edit at 04/18/2017 08:02AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 08:01AM |

Registered: 8 years ago Posts: 3,525 |

There's also segmentation to account for in terms of ripples in the walls of prints, depending on controller/stepper driver. But that's not caused by the frame either.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 11:18AM |

Registered: 9 years ago Posts: 330 |

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 12:08PM |

Registered: 7 years ago Posts: 270 |

Quote

the_digital_dentist

Ringing isn't caused by the frame, it's caused by the moving mass interacting with the acceleration, belt stretch and motor springiness. Motor steps are defined by magnetic fields. They aren't hard mechanical stops, they behave like springs. When the motor is accelerating, the inertia of the moving mass causes it to respond late to what the motor is doing. If it's speeding up, as the motor tries to step, the magnetic spring loads, the belt stretches a little, then the mass starts to move. When the step has finished, the mass overshoots the final step position a little, then springs back. It wobbles back and forth a little and takes some finite time to settle.

This is a drawing made by my coreXY stage hooked up as a plotter when I was playing with it a little to check the acceleration and junction deviation settings.

The X axis is horizontal, but you can think of it as time, with t=0 at the far right. The Y axis vertical. The pen mounted in the extruder carriage moved up along Y then turned left to move along X. You can see that when it got to the corner, the high moving mass of the Y axis overshot the stopping point and sprung back the other way and wobbled a little until it settled onto the X line. That is ringing. It isn't because the pen was loose in the holder- it was mounted in a linear guide and there was zero wiggle in the bearing. If you stack it layer upon layer in a print, you get ripples in the walls of the print.

The printer has 40x40mm t-slot with 1/4" MIC6 plate. It is rock solid.

This is a good example of how one should consider size and type of all components together. Frame maybe strong, slope near zero but using long 6mm wide belt with heavier gantry will cause 'ringing' sooner than lighter setup. Also, one thing about current corexy designs is highly unequal belt length at corners where motors are - one very short and one very long.

Edited 2 time(s). Last edit at 04/18/2017 04:57PM by newbob.

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 04:00PM |

Registered: 9 years ago Posts: 330 |

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 04:55PM |

Registered: 10 years ago Posts: 770 |

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 05:21PM |

Registered: 9 years ago Posts: 330 |

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 06:19PM |

Registered: 11 years ago Posts: 5,780 |

Yes, wider belts will stretch less than narrower belts. I use 9mm wide GT2 belts in the coreXY stage pictured above. Reducing jerk or junction deviation and acceleration reduces ringing, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Does using bigger aluminium extrusions prevent ringing? April 18, 2017 09:20PM |

Registered: 10 years ago Posts: 564 |

A lot of the reason for ringing is that many printers use really high acceleration and "jerk" parameters which excite the ringing. Setting high accel and "jerk" values creates something closer to a constant velocity, which in turn minimizes the over/under-extrusion when you go around sharp corners due to the hysteresis in extrusion process. Essentially, there is a trade-off between over/under-extrusion at corners and ringing.

I believe DC42's reprap firmware has extruder pressure advance compensation to reduce the over/under-extrusion, which in turn should allow you to use lower accel values (more appropriate for most printers) to reduce the ringing. I haven't tried it myself, but it is a much better approach than trying to make a hyper-rigid printer.

I believe DC42's reprap firmware has extruder pressure advance compensation to reduce the over/under-extrusion, which in turn should allow you to use lower accel values (more appropriate for most printers) to reduce the ringing. I haven't tried it myself, but it is a much better approach than trying to make a hyper-rigid printer.

|

Re: Does using bigger aluminium extrusions prevent ringing? April 19, 2017 07:42AM |

Registered: 7 years ago Posts: 558 |

|

Re: Does using bigger aluminium extrusions prevent ringing? April 19, 2017 09:52AM |

Registered: 8 years ago Posts: 3,525 |

A chain drive corexy would be quite a sight even if I suspect not necessarily a better printer. If belts cause ringing then surely it can be eliminated or reduced to the point where it is imperceptible by tensioning them well, and using geared idlers rather than toothed or twisting the belts, where possible to run the smooth side over the idlers, interestingly I don't do this on my kossel XL and I don't get any ringing, but going back to earlier comments it has a 2040 frame with metal corners, so very stiff and heavy and uses RRF so segmentation free firmware.

Edited 3 time(s). Last edit at 04/19/2017 10:08AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 3 time(s). Last edit at 04/19/2017 10:08AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Does using bigger aluminium extrusions prevent ringing? April 19, 2017 10:02AM |

Registered: 10 years ago Posts: 770 |

|

Re: Does using bigger aluminium extrusions prevent ringing? April 19, 2017 11:21AM |

Registered: 11 years ago Posts: 5,780 |

It isn't just belts causing ringing- the motors themselves also contribute, possibly more than the belts.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Does using bigger aluminium extrusions prevent ringing? April 19, 2017 12:05PM |

Registered: 10 years ago Posts: 564 |

Quote

the_digital_dentist

It isn't just belts causing ringing- the motors themselves also contribute, possibly more than the belts.

You can test the effects of motor stiffness on ringing by adjusting the motor current - higher current will increase the stiffness and should decrease the magnitude of the ringing and increase the frequency. I tried this on my largish (350x350mm) H-drive printer and didn't see much effect on the ringing, leading me to the conclusions that is was mostly due to the flexibility of my really long belts. In a more typical sized (200x200mm) printer, though, motor stiffness could be a major contributor to the ringing.

In addition to the belts, frame extrusions and motors, you also have to look hard at the motor mounts, idler pulley mounts, frame connections etc. which can easily be overlooked as a source of unwanted flexibility.

|

Re: Does using bigger aluminium extrusions prevent ringing? April 21, 2017 02:19AM |

Registered: 9 years ago Posts: 330 |

|

Re: Does using bigger aluminium extrusions prevent ringing? April 21, 2017 04:06AM |

Registered: 10 years ago Posts: 150 |

In addition to what has been said about the belts and motors, which is true, I think that the structure also participates in ringing, insofar as it is exposed to a deformation of the rectangles that compose it in parallelograms (both coreXY and delta).

You can easily test the stiffness of your structure: approach the nozzle a few mm above the bed, and touch with one finger at the same time the bed, and the nozzle.

The pulp of your finger is very sensitive to the shear induced by the relative movement. If you can feel the movement in your finger, when you hit the structure diagonally, it is that it is likely prone to participate to ringing.

For CoreXY machines, the test could be more sensitive by interposing some high object between the nozzle and the bed.

You can easily test the stiffness of your structure: approach the nozzle a few mm above the bed, and touch with one finger at the same time the bed, and the nozzle.

The pulp of your finger is very sensitive to the shear induced by the relative movement. If you can feel the movement in your finger, when you hit the structure diagonally, it is that it is likely prone to participate to ringing.

For CoreXY machines, the test could be more sensitive by interposing some high object between the nozzle and the bed.

|

Re: Does using bigger aluminium extrusions prevent ringing? April 21, 2017 04:52AM |

Registered: 12 years ago Posts: 1,450 |

Quote

drmaestro

So probably, with anything in plastic in this setup, we'll have ringing, as the plastic will invariably flex.

Sort of, but only a partial truth. The thing that rings most is a bell - try printing one in PLA and you will find it clunks but does not ring. Plastic does flex, but it also damps vibration.

Proper structure is more important than what material. You have only to look at an ordinary printer (ink on paper, not 3D) to see how accurate and reproducible good engineering can make something. Take it apart so it is no longer a structure and all of the bits are downright floppy.

Mike

|

Re: Does using bigger aluminium extrusions prevent ringing? April 21, 2017 11:49AM |

Registered: 8 years ago Posts: 601 |

Quote

leadinglights

Quote

drmaestro

So probably, with anything in plastic in this setup, we'll have ringing, as the plastic will invariably flex.

Sort of, but only a partial truth. The thing that rings most is a bell - try printing one in PLA and you will find it clunks but does not ring. Plastic does flex, but it also damps vibration.

Proper structure is more important than what material. You have only to look at an ordinary printer (ink on paper, not 3D) to see how accurate and reproducible good engineering can make something. Take it apart so it is no longer a structure and all of the bits are downright floppy.

Mike

Considerably lighter gantries then what 3D printers typically deal with and made with injection moulded plastic parts that are dynamically stronger.... Cheap 3D printer have tried to emulate this and failed, so I feel like it's not a great comparison

|

Re: Does using bigger aluminium extrusions prevent ringing? April 21, 2017 02:08PM |

Registered: 12 years ago Posts: 1,450 |

Quote

Origamib

.........................

Considerably lighter gantries then what 3D printers typically deal with and made with injection moulded plastic parts that are dynamically stronger.... Cheap 3D printer have tried to emulate this and failed, so I feel like it's not a great comparison

It was not intended as a comparison but simply to make the point that good engineering can eliminate a lot of mass and a lot of cost. Just as cheap 3D printers have too little rigidity, some heavily built 3D printers have perceived rigidity which is really just more mass to shake about and give artifacts.

Mike

|

Re: Does using bigger aluminium extrusions prevent ringing? May 08, 2017 03:09PM |

Registered: 9 years ago Posts: 330 |

|

Re: Does using bigger aluminium extrusions prevent ringing? May 08, 2017 03:35PM |

Registered: 8 years ago Posts: 3,525 |

It's a shame that motors are not often mounted in such a way so they can slide to tension the belts. I have this on my corexy it makes a and B belt relative tensioning easy.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Does using bigger aluminium extrusions prevent ringing? May 09, 2017 02:02AM |

Registered: 9 years ago Posts: 330 |

The mounting part can be arranged by using grooves instead of holes for bolts. The real problem is to have a mechanism, which works like a ratchet, to keep things in place and tension them. so that you can keep things in tension. I am surprised to see that there is no such a mechanism for GT2 belts.

|

Re: Does using bigger aluminium extrusions prevent ringing? May 09, 2017 05:28PM |

Registered: 11 years ago Posts: 335 |

Rigidity is limited by the weakest component in your build, so its hard to find a single change that will eliminate ringing.

Major contributors of compliance will be the frame, belt, pulley mounts, and stepper motors. Timing belts are sufficient for this application, but you need proper width and tension (I suspect some of the chinese belts act like rubber bands as well).

People also give stepper motors way too much credit, they are very compliant at the step level. Magnets are springy by nature; you need a servo (encoder+feedback) to make the motor shaft rigid.

Major contributors of compliance will be the frame, belt, pulley mounts, and stepper motors. Timing belts are sufficient for this application, but you need proper width and tension (I suspect some of the chinese belts act like rubber bands as well).

People also give stepper motors way too much credit, they are very compliant at the step level. Magnets are springy by nature; you need a servo (encoder+feedback) to make the motor shaft rigid.

Sorry, only registered users may post in this forum.