Induction heater

Posted by newbob

|

Re: Induction heater May 28, 2017 12:00PM |

Registered: 12 years ago Posts: 1,450 |

At the moment it is not clear that an induction heated hotend will be much more complex or expensive than a resistively heated one. It may be as simple as a two transistor oscillator with some capacitors and a self supporting coil powered by the same MOSFET (on the RAMPS board or whatever) as the heater cartridge is. The main problems are:

It does seem a bit strange to me that a community of makers, geeks and others who DO know which end of a soldering iron to hold seems so adverse to any new or novel ideas.

Mike

- Can the oscillator be relied to start each time the MOSFET is switched on. If it cannot, can the design be made safe against thermal runaway and all of the heartbreak, homelessness and fire brigade involvement that goes with a bad failure

- Can the part of the hotend that is heated by the high frequency induction be made in such a way as to allow a short transition zone in the filament path.

- Can the design be simple enough to be made by greengrocers, lawyers, midwives and others who start from a position of not knowing which end of a soldering iron to hold.

It does seem a bit strange to me that a community of makers, geeks and others who DO know which end of a soldering iron to hold seems so adverse to any new or novel ideas.

Mike

|

Re: Induction heater May 28, 2017 03:53PM |

Registered: 15 years ago Posts: 537 |

Hello,

Please feel free to try developing and selling hot-ends and let me know how it works out for you.

I've made hot-ends since around 2008 or 2009 and literally been told to create new designs so that people can buy chinese knock-offs. The J-Head Mk 9 is only a prototype because of this reason and the fact that china can sell hot-ends for around the price of the raw materials and include free shipping. The majority buy on price alone.

Personally, I could envision a proper hot-end with induction heating and a thermocouple. Throw in a quick-change mount (another design I haven't marketed because of my above reasons.) and a bowden configuration and it would be fantastic. But, once china would sell it, all of the sales of the original developer would dry up quickly.

I have no way of knowing the numbers. However, I suspect that E3d has lost millions of dollars in sales to chinese knock-offs. I have no way of knowing how much business I have lost due to the same issue.

Best Regards,

Brian

Please feel free to try developing and selling hot-ends and let me know how it works out for you.

I've made hot-ends since around 2008 or 2009 and literally been told to create new designs so that people can buy chinese knock-offs. The J-Head Mk 9 is only a prototype because of this reason and the fact that china can sell hot-ends for around the price of the raw materials and include free shipping. The majority buy on price alone.

Personally, I could envision a proper hot-end with induction heating and a thermocouple. Throw in a quick-change mount (another design I haven't marketed because of my above reasons.) and a bowden configuration and it would be fantastic. But, once china would sell it, all of the sales of the original developer would dry up quickly.

I have no way of knowing the numbers. However, I suspect that E3d has lost millions of dollars in sales to chinese knock-offs. I have no way of knowing how much business I have lost due to the same issue.

Best Regards,

Brian

Quote

Lykle

Quote

reifsnyderb

Given that the induction heater requires more electronics, people aren't going to want to pay for it, either.

If there is a clear benefit sure they will. And the costs can come down by quite a bit after the initial experimentation.

As to the clones, that should not be a reason to stop developing. E3D do it very successfully. Yes they are cloned, but I will still buy original.

Until we develop a better one.

I like the idea of induction heating. Makes sense. Put the energy where you need it, heat only that part you want hot. It is not a magical cure all, for sure, but it does need investigating.

|

Re: Induction heater June 13, 2017 11:53AM |

Registered: 12 years ago Posts: 1,450 |

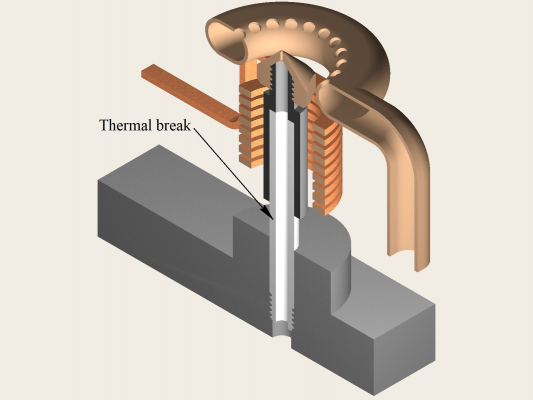

I am still playing with induction heating although not on the front burner. My first trials were delayed a bit buy the first board from ebay not working then I found that the 5mm diameter non-magnetic stainless steel drilled bolt that I was trying for the heat break was heating up somewhat too much to be much use. In the sectioned view below the light grey part is the heat break tube and the big dark grey block is the heatsink

Some trials that I have just made with 4mm diameter 316 stainless steel tube look a lot more promising as it heats up very little. Also the aluminium of the heatsink neither heats up nor seems to steal any power.

Mike

Some trials that I have just made with 4mm diameter 316 stainless steel tube look a lot more promising as it heats up very little. Also the aluminium of the heatsink neither heats up nor seems to steal any power.

Mike

|

Re: Induction heater June 29, 2017 06:11AM |

Registered: 12 years ago Posts: 1,450 |

I have managed to confirm that it is possible to get a short thermal break . This required a HF "soft" ferrite washer to localize the magnetic field and prevent induction into the thermal break area. Having said than, I can now see no good engineering reason to use induction heating as it is unlikely to be lighter or cheaper or less complex than the resistive options. Geek factor  and general coolness

and general coolness  are good but must always give way to good engineering.

are good but must always give way to good engineering.

I can now use the time saved on several other projects

Mike

and general coolness

and general coolness  are good but must always give way to good engineering.

are good but must always give way to good engineering.

I can now use the time saved on several other projects

Mike

|

Re: Induction heater June 29, 2017 07:07AM |

Registered: 7 years ago Posts: 5 |

|

Re: Induction heater June 29, 2017 10:07AM |

Registered: 7 years ago Posts: 270 |

Quote

leadinglights

I have managed to confirm that it is possible to get a short thermal break . This required a HF "soft" ferrite washer to localize the magnetic field and prevent induction into the thermal break area. Having said than, I can now see no good engineering reason to use induction heating as it is unlikely to be lighter or cheaper or less complex than the resistive options. Geek factorand general coolness

are good but must always give way to good engineering.

I can now use the time saved on several other projects

Mike

How wide was your coil and what was the distance between thermal break and the nozzle? I'm looking into localizing the induction heating in the nozzle, far away from the heat break...

Edited 1 time(s). Last edit at 06/29/2017 10:11AM by newbob.

|

Re: Induction heater June 29, 2017 10:17AM |

Registered: 12 years ago Posts: 1,450 |

After a few attempts I have found a number of problems and I think it unlikely that the complexity and cost would make it something that appeals to the Makers or the Open Source movement at large. If a credible user base of a few thousand existed and if I were still in product development I would be furiously trying to sell this as a worthwhile investment (if HP, Polaroid etc are listening then PM me), otherwise nah!!

A hotend idea that may still be feasible is sensing the temperature with the same wire as the heater is made of [forums.reprap.org] Running the numbers for thermal resistance of the parts and the electrical characteristics of pure nickel wire seem to indicate this may work - not one of my priorities at the moment though.

Mike

A hotend idea that may still be feasible is sensing the temperature with the same wire as the heater is made of [forums.reprap.org] Running the numbers for thermal resistance of the parts and the electrical characteristics of pure nickel wire seem to indicate this may work - not one of my priorities at the moment though.

Mike

|

Re: Induction heater June 29, 2017 10:30AM |

Registered: 12 years ago Posts: 1,450 |

Quote

newbob

..........................

How wide was your coil and what was the distance between thermal break and the nozzle? I'm looking into localizing the induction heating in the nozzle, far away from the heat break...

The length of the ferromagnetic part between the 316 stainless steel (non-magnetic) heatbreak and the brass nozzle was 16mm, the diameter of the coil was 14mm od made of 10 turns of flat 0.95mm x 2mm silver plated copper wire. The ferrite flux concentrator to keep the HF files away from the heatbreak was 15mm od, 8mm id and 2mm thick placed at the beginning of the ferromagnetic part. The concentrator worked, but not great. The other significant problem was self heating of the capacitors at about 40 degrees above ambient. If there was some way of getting a flexible hotend without having a very short transition zone I might still explore, but at the moment I have other fish to fry

Mike

|

Re: Induction heater June 29, 2017 11:59AM |

Registered: 7 years ago Posts: 249 |

Sorry, only registered users may post in this forum.