Precision Piezo Z-probe Now available.

Posted by DjDemonD

|

Re: Precision Piezo Z-probe Now available. June 02, 2017 10:25AM |

Registered: 8 years ago Posts: 3,525 |

This is my simplified start code for slic3r

Which works fine. It heats the bed, and waits for temp to stabilise, then heats the hotend, then probes, then goes to first layer temp, then prints. You can drop the t0 unless you have duet/RRF.

Substitute G29 for G32 depending on machine/firmware.

Edited 3 time(s). Last edit at 06/02/2017 10:32AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

G28 ;home M190 S[first_layer_bed_temperature] ;heat bed M109 S130 T0 ; set extruder temp G32 ;autocalibration - set grid on/off in bed.g M109 S[first_layer_temperature] T0 ; set extruder temp

Which works fine. It heats the bed, and waits for temp to stabilise, then heats the hotend, then probes, then goes to first layer temp, then prints. You can drop the t0 unless you have duet/RRF.

Substitute G29 for G32 depending on machine/firmware.

Edited 3 time(s). Last edit at 06/02/2017 10:32AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 02, 2017 05:02PM |

Registered: 7 years ago Posts: 8 |

Received mine a few days ago. I was going to install it and a Prometheus hotend, but sure enough the Prometheus doesn't fit. The Prometheus bills itself as a drop in solution, but it has a different sized mount than E3D making it very difficult to install.

So instead I'll give this a go with my existing $15 E3D clone

So instead I'll give this a go with my existing $15 E3D clone

|

Re: Precision Piezo Z-probe Now available. June 02, 2017 05:47PM |

Registered: 8 years ago Posts: 3,525 |

Shame it doesn't fit I don't have one to test. What dimension/s are tight?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 02, 2017 09:06PM |

Registered: 9 years ago Posts: 517 |

I think I broke something on mine. When I was making the mount and all, I would test it out and make sure it was still working. When I had finished and tried testing it out with the final assembly, the trigger light was on when I powered it up. A slight tweak to the left pot caused it to go out, but it didn't seem like it was a sensitive as it had been. I have been able to probe with it, but I have been getting some false triggers so I thought I would return it. I started by measuring the resistance from the top piezo connector to the middle of the right pot. I was seeing about 0.32M so try adjusting to 0.4M. But no matter how much I turn the right pot, the resistance is always staying the same. Now I'm not sure what I need to do.

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 04:46AM |

Registered: 8 years ago Posts: 3,525 |

These small pots can wear out. So just to see if that's the issue put a drop of wd40 or something similar on the right pot and then see if you can adjust it. That being said 0.4 is the value most have been set to when I built them. If you can adjust it go to 0.3 for less sensitive and 0.5 for more.

If it really won't work at all you can send it back to me or perhaps remove the pcb and I'll swap one for you.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

If it really won't work at all you can send it back to me or perhaps remove the pcb and I'll swap one for you.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 09:39AM |

Registered: 8 years ago Posts: 487 |

Hi Elmo,

The easiest way to measure the setting of the right hand pot is to measure the resistance between the two piezo poles. The right hand pot really shouldn't need any adjustment, if you set it with the tab pointing straight down you should then see a resistance of roughly 400k. These sub miniature pots have a pretty wide deadband and it can be quite easy to lose track of where the tab is.

Please could you try measuring the resistance between the piezo connectors and tell me whether that changes with (gentle!) rotation of the right hand pot.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

The easiest way to measure the setting of the right hand pot is to measure the resistance between the two piezo poles. The right hand pot really shouldn't need any adjustment, if you set it with the tab pointing straight down you should then see a resistance of roughly 400k. These sub miniature pots have a pretty wide deadband and it can be quite easy to lose track of where the tab is.

Please could you try measuring the resistance between the piezo connectors and tell me whether that changes with (gentle!) rotation of the right hand pot.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 02:45PM |

Registered: 9 years ago Posts: 517 |

Turning which way increases sensitivity? Clockwise or Counter-Clockwise?

Quote

DjDemonD

These small pots can wear out. So just to see if that's the issue put a drop of wd40 or something similar on the right pot and then see if you can adjust it. That being said 0.4 is the value most have been set to when I built them. If you can adjust it go to 0.3 for less sensitive and 0.5 for more.

If it really won't work at all you can send it back to me or perhaps remove the pcb and I'll swap one for you.

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 02:51PM |

Registered: 9 years ago Posts: 517 |

Right now it is looking like I have it pretty close. Still getting a few false triggers and seeing the effector tilt on a few probes. Will try measuring across the poles later. It could just be my old multi-meter. It's at least 40 years old, but is a top of the line HP unit. (HP34702A if anyone is curious)

Quote

Moriquendi

Hi Elmo,

The easiest way to measure the setting of the right hand pot is to measure the resistance between the two piezo poles. The right hand pot really shouldn't need any adjustment, if you set it with the tab pointing straight down you should then see a resistance of roughly 400k. These sub miniature pots have a pretty wide deadband and it can be quite easy to lose track of where the tab is.

Please could you try measuring the resistance between the piezo connectors and tell me whether that changes with (gentle!) rotation of the right hand pot.

Idris

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 02:52PM |

Registered: 8 years ago Posts: 3,525 |

Clockwise. Glad you're getting there something around 0.6M OHM will probably give you better sensitivity.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 03:02PM |

Registered: 9 years ago Posts: 517 |

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 03:58PM |

Registered: 8 years ago Posts: 487 |

The right hand pot (VR1 as we call it) is primarily there for accommodating variability in the piezo disks themselves, they're tuned during assembly and that should really be all that's needed. The only situations I can think of that would require retuning VR1 would be if you were going to be probing inside a hot heated chamber, if you were going to be using multiple piezo disks or if you were going to be using a different sized disk. I have a piezo endstop handling board that has a fixed value of VR1 and it works without any difficulty.

The left hand pot (VR2) is the one that should be used to tune the probe to your specific machine. DjDemonD sets VR2 to a baseline position that has been found to work for most people in most machines, however we know that every machine is different so that's where tuning should be done. If you find that you're getting false triggers during probing try turning VR2 slightly counterclockwise, if you feel like it's not sensitive enough turn VR2 slightly clockwise, somewhere in there should be a sweetspot.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

The left hand pot (VR2) is the one that should be used to tune the probe to your specific machine. DjDemonD sets VR2 to a baseline position that has been found to work for most people in most machines, however we know that every machine is different so that's where tuning should be done. If you find that you're getting false triggers during probing try turning VR2 slightly counterclockwise, if you feel like it's not sensitive enough turn VR2 slightly clockwise, somewhere in there should be a sweetspot.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. June 03, 2017 06:43PM |

Registered: 8 years ago Posts: 3,525 |

Yes I have it running on two duetwifi powered machines. I use:

M201 X250 Y250 Z250 ; Accelerations (mm/s^2)

M566 X100 Y100 Z100 ; Maximum instant speed changes mm/minute

just before probing and then return to normal accel/jerk afterwards.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

M201 X250 Y250 Z250 ; Accelerations (mm/s^2)

M566 X100 Y100 Z100 ; Maximum instant speed changes mm/minute

just before probing and then return to normal accel/jerk afterwards.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 06:49AM |

Registered: 10 years ago Posts: 14,672 |

You may find it helpful to use the R parameter in the M558 command to add a short delay after the travel move before the probing move. We use R0.1 with our prototype delta effectors, in case the probe is triggered by the deceleration at the end of the travel move.

The jerk setting shouldn't matter, because RRF doesn't use jerk during bed probing.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The jerk setting shouldn't matter, because RRF doesn't use jerk during bed probing.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 06:52AM |

Registered: 8 years ago Posts: 3,525 |

Yes I'm using it on one machine

M558 P5 I1 R0.2 F500 X0 Y0 Z0 ;digital piezo sensor, output falls on contact, probing speed, not used to home axes

G31 X0 Y0 Z-0.2 P10 ;sensor is nozzle and debounce value.

Thats one possible config.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

M558 P5 I1 R0.2 F500 X0 Y0 Z0 ;digital piezo sensor, output falls on contact, probing speed, not used to home axes

G31 X0 Y0 Z-0.2 P10 ;sensor is nozzle and debounce value.

Thats one possible config.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 08:36AM |

Registered: 9 years ago Posts: 517 |

Quote

dc42

You may find it helpful to use the R parameter in the M558 command to add a short delay after the travel move before the probing move. We use R0.1 with our prototype delta effectors, in case the probe is triggered by the deceleration at the end of the travel move.

The jerk setting shouldn't matter, because RRF doesn't use jerk during bed probing.

THANK YOU! Perfect timing on that. I was going to ask if there was a way to delay the probing.

Now. Is there a way to run a macro before and after the G29 command? I keep forgetting to change the speeds before doing that. I already have two macros to do that and would be nice to be able to run them. The macros could also be used for deploying/retracting a probe if needed (something else I kept forgetting to do).

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 09:04AM |

Registered: 8 years ago Posts: 3,525 |

Yes why not make a macro called run_g29 and add:

Your slow down m codes

G29

Back to normal speed mcodes

Then in your start gcode call the macro using

M98 Prun_g29.g

You might need to add folder structure to the m98 command if it can't find your macro.

I do this on my delta, have the slow down and speed up built in to my bed.g file. You have to remember that's where you need to change your speed/accel/jerk if you decide to run your machine on different settings,not config.g as it will be overridden.

Edited 1 time(s). Last edit at 06/04/2017 09:05AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Your slow down m codes

G29

Back to normal speed mcodes

Then in your start gcode call the macro using

M98 Prun_g29.g

You might need to add folder structure to the m98 command if it can't find your macro.

I do this on my delta, have the slow down and speed up built in to my bed.g file. You have to remember that's where you need to change your speed/accel/jerk if you decide to run your machine on different settings,not config.g as it will be overridden.

Edited 1 time(s). Last edit at 06/04/2017 09:05AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 09:18AM |

Registered: 9 years ago Posts: 517 |

Quote

DjDemonD

Yes why not make a macro called run_g29 and add:

Your slow down m codes

G29

Back to normal speed mcodes

Then in your start gcode call the macro using

M98 Prun_g29.g

You might need to add folder structure to the m98 command if it can't find your macro.

I do this on my delta, have the slow down and speed up built in to my bed.g file. You have to remember that's where you need to change your speed/accel/jerk if you decide to run your machine on different settings,not config.g as it will be overridden.

I have the macros in the bed.g file too. For G29, since I normally just enter it manually, it is easier to type than the M98 line. Okay. I'm lazy!

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 09:38AM |

Registered: 9 years ago Posts: 517 |

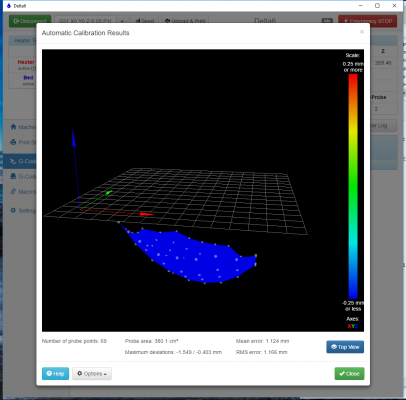

Okay. So yesterday, I was getting a nice fairly flat picture of my bed after doing the mesh leveling. Now this morning, I am getting this...

Shouldn't at least one point be on the grid as a reference for all the other points? Where is it getting the zero reference from to indicate all the probe points are below zero?

Shouldn't at least one point be on the grid as a reference for all the other points? Where is it getting the zero reference from to indicate all the probe points are below zero?

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 09:41AM |

Registered: 8 years ago Posts: 3,525 |

I had this the other day, not sure why it happens but it can be solved by doing G30 at bed centre then G29. The G30 at bed centre resets the z level and is the reference level.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 09:41AM |

Registered: 9 years ago Posts: 517 |

Quote

DjDemonD

I had this the other day, not sure why it happens but it can be solved by doing G30 at bed centre then G29. The G30 at bed centre resets the z level and is the reference level.

Thanks. Will give that a try.

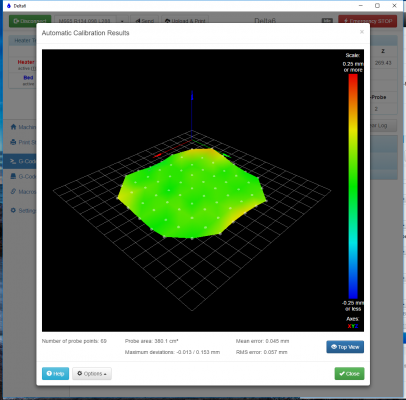

That helped. Ended up doing a G32 first, then G30, and finally the G29

Edited 1 time(s). Last edit at 06/04/2017 09:58AM by ElmoC.

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 10:00AM |

Registered: 8 years ago Posts: 3,525 |

Looking great

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 10:12AM |

Registered: 9 years ago Posts: 517 |

So, my test benchy is now printing. Just for completeness of the past few messages, here are my files that I am currently using.

SlowSpeed.g

NormalSpeed.g

bed.g

Mesh Level (in the Macro Folder)

My start script for S3D

Any other files that might be of help? I know some of the comments are out of data, like the one referencing the inductive probe.

SlowSpeed.g

;slow down movement to improve accuracy, improve probing and lmit damage in case of head crash M906 X500 Y500 Z500 E800 I60 M201 X250 Y250 Z250 E1000 M203 X15000 Y15000 Z15000 E3600 M566 X100 Y100 Z100 E1200

NormalSpeed.g

;restore speed settings to normal printing speeds M906 X1100 Y1100 Z1100 E500 I60 ; Set normal motor currents (mA) and increase idle current to 60% M201 X3000 Y3000 Z3000 E120 ; Accelerations (mm/s^2) M203 X15000 Y15000 Z15000 E3600 ; Maximum speeds (mm/min) M566 X1200 Y1200 Z1200 E60 ; Maximum instant speed changes mm/minute

bed.g

; Auto calibration routine for delta printers ; Before running this, you should have set up your zprobe Z offset to suit your build, in the G31 ; command in config.g. M561 ; clear any bed transform, otherwise homing may be at the wrong height G31 X0 Y0 ; don't want any probe offset for this G28 ; Home the printer G0 Z2 F2000 ; Get ready for first probe. ;slow down movement to improve accuracy, improve probing and lmit damage in case of head crash M98 PSlowSpeed.g G30 P0 X0 Y0 Z-99999 ; Dummy probe. Just to be safe. Probably not needed with the inductive probe. ; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 16 points, 6 factors, probing radius: 90, probe offset (0, 0) ;restore speed settings to normal printing speeds M98 PNormalSpeed.g G1 X0 Y0 Z250 F15000 ; get the head out of the way of the bed

Mesh Level (in the Macro Folder)

M190 S60 M109 S130 T0 G32 G0 X0 Y0 Z1 M98 PSlowSpeed.g G30 G29 M98 PNormalSpeed.g G28 M140 S0 M104 S0

My start script for S3D

G28 M190 S[bed0_temperature] M109 S130 T0 G32 G29 S1 M109 S[extruder0_temperature]

Any other files that might be of help? I know some of the comments are out of data, like the one referencing the inductive probe.

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 12:10PM |

Registered: 9 years ago Posts: 517 |

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 12:51PM |

Registered: 7 years ago Posts: 8 |

|

Re: Precision Piezo Z-probe Now available. June 04, 2017 12:53PM |

Registered: 8 years ago Posts: 3,525 |

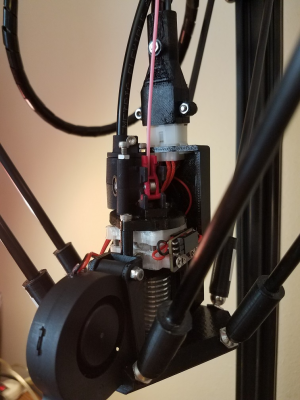

ElmoC effector looks great.

Jonathank please post up some measurements of the prometheus hotend groovemount it won't take much to knock up a version that will fit might be useful for future customers. The fine fitting between e3d v6/v5 and clones are all marginally different. We hoped the clamp had enough tolerance to accommodate most variants.

Edited 1 time(s). Last edit at 06/04/2017 12:56PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Jonathank please post up some measurements of the prometheus hotend groovemount it won't take much to knock up a version that will fit might be useful for future customers. The fine fitting between e3d v6/v5 and clones are all marginally different. We hoped the clamp had enough tolerance to accommodate most variants.

Edited 1 time(s). Last edit at 06/04/2017 12:56PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 05, 2017 06:48PM |

Registered: 9 years ago Posts: 978 |

On a different tack entirely.... Have you thought about using the piezo as a pressure sensor for regulating filament extrusion and/or nozzle height?

It seems to me that, during extrusion, the amount of pressure sensed by the piezo would be related to the pressure that the molten filament is under. So measuring the piezo voltage as an analogue signal whilst extruding would tell you if you were over/under-extruding. Assuming that the over/under-extrusion was due to nozzle height (e.g. due to an uneven/unlevel bed), that could be used to decrease/increase the extruder flow rate and/or the Z height to compensate. At a later point in the print, when you know the previous layer was actually level and flat, you might assume that variations in the flow rate were due to variations in filament diameter, and decrease/increase the extruder flow rate to compensate.

It seems to me that, during extrusion, the amount of pressure sensed by the piezo would be related to the pressure that the molten filament is under. So measuring the piezo voltage as an analogue signal whilst extruding would tell you if you were over/under-extruding. Assuming that the over/under-extrusion was due to nozzle height (e.g. due to an uneven/unlevel bed), that could be used to decrease/increase the extruder flow rate and/or the Z height to compensate. At a later point in the print, when you know the previous layer was actually level and flat, you might assume that variations in the flow rate were due to variations in filament diameter, and decrease/increase the extruder flow rate to compensate.

|

Re: Precision Piezo Z-probe Now available. June 05, 2017 07:42PM |

Registered: 7 years ago Posts: 8 |

It would be trivial to implement a crude system for this. Ideally the piezo controller would communicate not just yes/no if the endstop is triggered, but also serial communication of the magnitude of force on the print head at all times. This could also give a failsafe against printers physically falling apart mid print (the z-stop triggered, was it a small force? Or did the effector smash into the build plate?).

It could also report not just the magnitude, but the time the triggering force was first observed (obviously there's a delay until a force is declared and a trigger is sent). This would give even more precision, and make tuning easier since probing would use the point the contact first occured.

At the very minimum, the printer board should be logging when the z-stop is triggered while printing! Just monitoring that alone is the first start, as it'll give some extra information when printing benchmark objects using various extrusion multipliers. Later some crude logic could be added to adjust extruder multiplier mid print.

Edited 1 time(s). Last edit at 06/05/2017 07:53PM by jonathank.

It could also report not just the magnitude, but the time the triggering force was first observed (obviously there's a delay until a force is declared and a trigger is sent). This would give even more precision, and make tuning easier since probing would use the point the contact first occured.

At the very minimum, the printer board should be logging when the z-stop is triggered while printing! Just monitoring that alone is the first start, as it'll give some extra information when printing benchmark objects using various extrusion multipliers. Later some crude logic could be added to adjust extruder multiplier mid print.

Edited 1 time(s). Last edit at 06/05/2017 07:53PM by jonathank.

|

Re: Precision Piezo Z-probe Now available. June 06, 2017 01:21AM |

Registered: 8 years ago Posts: 3,525 |

It's certainly possible to measure analogue voltage from the piezo. Translating that into some meaningful data to fine tune filament flow would be amazing.

I can see that provided you are extruding into free air, the analogue value should represent the pressure being applied by the extruder. Once the nozzle is in contact with anything you aren't measuring filament pressure anymore.

My concern is that you'd only be using the very low part of the range of the piezo as this force would be way below a nozzle tap on the bed, it's whether it would be fine grained enough to really tune filament flow which is a very fine grained adjustment especially when you get to adjusting by 0.5% etc..

But it's worth some experimentation, any volunteers?

We have discussed using piezo data to slow down printing if the nozzle is travelling over rough patches, or even pause or emergency stop if a big impact if detected.

This really represents phase 2 and I haven't put much time towards it yet. If we can develop some logging code maybe we can crowd source enough data to start to make sense of how piezo analogue values relate to extrusion or nozzle contact with the print rather than the bed.

Edited 1 time(s). Last edit at 06/06/2017 01:27AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I can see that provided you are extruding into free air, the analogue value should represent the pressure being applied by the extruder. Once the nozzle is in contact with anything you aren't measuring filament pressure anymore.

My concern is that you'd only be using the very low part of the range of the piezo as this force would be way below a nozzle tap on the bed, it's whether it would be fine grained enough to really tune filament flow which is a very fine grained adjustment especially when you get to adjusting by 0.5% etc..

But it's worth some experimentation, any volunteers?

We have discussed using piezo data to slow down printing if the nozzle is travelling over rough patches, or even pause or emergency stop if a big impact if detected.

This really represents phase 2 and I haven't put much time towards it yet. If we can develop some logging code maybe we can crowd source enough data to start to make sense of how piezo analogue values relate to extrusion or nozzle contact with the print rather than the bed.

Edited 1 time(s). Last edit at 06/06/2017 01:27AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. June 06, 2017 03:28AM |

Registered: 8 years ago Posts: 487 |

One thing to remember about piezo sensors is that they only respond to changes in pressure, not to pressure itself. What that means is that once an equilibrium is reached in the nozzle only the fluctuations are going to produce changes in pressure and they're going to be very small. To measure the pressure at the nozzle you would need to integrate very small fluctuations from the piezo, this type of measurement is susceptible to drift.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. June 06, 2017 06:07AM |

Registered: 8 years ago Posts: 3,525 |

Good point . Although I do wonder if some type of loadcell/force gauge of some sort used in a similar mechanism might yield this information. Interesting offshoot if it does, as measuring filament pressure has been a bit of a holy grail so far, and would enable essentially closed loop extrusion, which is a big step towards a truly user friendly 3d printer, but I fear its a bit outside the scope of what we're doing right now (and I haven't the time).

So seriously if someone wants to try this with an actual force measuring device I will gladly help and support them in whatever way I can.

As I see it you'd build the rig, measure a baseline force being applied during perfectly tuned extrusion, then feedback flow increases/decease depending on subsequent measurements. But what if force decreases so you speed up the extruder, should fix it yes? Not if the problem is filament slipping on the drive gear. A blockage will increase the force being measured, but slowing down the extruder won't improve the print. Its definitely not an easy task, but some way of quantifying extrusion pressure is a good place to start experimenting.

Edited 1 time(s). Last edit at 06/06/2017 06:49AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So seriously if someone wants to try this with an actual force measuring device I will gladly help and support them in whatever way I can.

As I see it you'd build the rig, measure a baseline force being applied during perfectly tuned extrusion, then feedback flow increases/decease depending on subsequent measurements. But what if force decreases so you speed up the extruder, should fix it yes? Not if the problem is filament slipping on the drive gear. A blockage will increase the force being measured, but slowing down the extruder won't improve the print. Its definitely not an easy task, but some way of quantifying extrusion pressure is a good place to start experimenting.

Edited 1 time(s). Last edit at 06/06/2017 06:49AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.