Precision Piezo Z-probe Now available.

Posted by DjDemonD

|

Re: Precision Piezo Z-probe Now available. October 15, 2017 04:41AM |

Registered: 6 years ago Posts: 30 |

Well I guess I will start investigating the under the bed way then

Can I connect 3 or 4 piezos to a piezo20 board or do I need the one with multiple inputs?

EDIT: oh dear lord ignore my last two messages, I totally misunderstood that bracket mount. Now I got it and can probably adapt it for my mount.

I blame sleep deprivation!

Edited 1 time(s). Last edit at 10/15/2017 05:12AM by coredump.

Can I connect 3 or 4 piezos to a piezo20 board or do I need the one with multiple inputs?

EDIT: oh dear lord ignore my last two messages, I totally misunderstood that bracket mount. Now I got it and can probably adapt it for my mount.

I blame sleep deprivation!

Edited 1 time(s). Last edit at 10/15/2017 05:12AM by coredump.

|

Re: Precision Piezo Z-probe Now available. October 15, 2017 05:32AM |

Registered: 8 years ago Posts: 487 |

It's not clear from the pictures exactly how you're mounting that assembly to your printer but it looks like you're mounting it via four holes on the second plate. If that's the case, unless you're doing something clever where the motor screws to the mount, you're unlikely to get the best signal as there's nothing to bend the piezo.

I wouldn't worry about the sensitivity of the piezo, they can be so sensitive that breathing on the disk triggers the circuit. The main purpose of the mount is to maximise the signal from the piezo while minimising the movement of the nozzle in the z-axis and eliminating any other movement. Using silicone as an adhesive may well reduce the signal from the piezo as it adds some flexibility, cyanoacrylate (super glue) is very rigid and better for this application I think. Piezo disks are very cheap on ebay, if you're developing a new mount it might well be worth buying some to try in lots of different situations.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

I wouldn't worry about the sensitivity of the piezo, they can be so sensitive that breathing on the disk triggers the circuit. The main purpose of the mount is to maximise the signal from the piezo while minimising the movement of the nozzle in the z-axis and eliminating any other movement. Using silicone as an adhesive may well reduce the signal from the piezo as it adds some flexibility, cyanoacrylate (super glue) is very rigid and better for this application I think. Piezo disks are very cheap on ebay, if you're developing a new mount it might well be worth buying some to try in lots of different situations.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. October 15, 2017 05:48AM |

Registered: 8 years ago Posts: 487 |

Yes you can connect multiple piezo disks to a PP20 PCB, wire the disks in parallel and connect as normal. It will require re-tuning however.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. October 15, 2017 06:55AM |

Registered: 8 years ago Posts: 3,525 |

Just to say I still have this module in fetching bright green. Surplus demo unit (never used) from TCT.

£30 plus shipping (free UK - £7.99 international 9.99 international with tracking). Normally £39.99 plus shipping.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

£30 plus shipping (free UK - £7.99 international 9.99 international with tracking). Normally £39.99 plus shipping.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 15, 2017 10:00AM |

Registered: 6 years ago Posts: 30 |

Quote

Moriquendi

It's not clear from the pictures exactly how you're mounting that assembly to your printer but it looks like you're mounting it via four holes on the second plate. If that's the case, unless you're doing something clever where the motor screws to the mount, you're unlikely to get the best signal as there's nothing to bend the piezo.

Yeah when I looked at the Titan adapter on thingiverse (from DJ) I totally misunderstood the position it was, and I replicated it inverted on my mount. After re-reading the docmentation I noticed that the extruder continues to go through the piezo that needs to be drilled and etc. After that I noticed that there was no way mine was going to work.

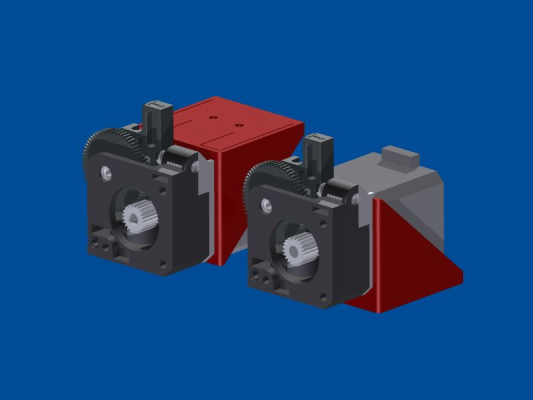

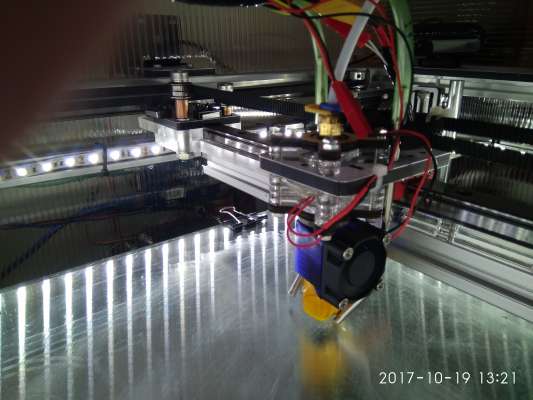

I also realized that the titan mount won't work for the titan aero. The Titan has a long exposed/dangling heatsink where youse add the piezo mount, while the titan aero has the heatsink combined with the 'gear area'. This shows it better:

so the only thing I have outside the square is already the heat block, and I kinda don't want anything touching there.

BUT I think now I have a better grasp of what must happen. If BENDING is the best way to get signal, I think I have a way to make a little lever system for that. I will sketch something later today after I get some hours of sleep.

Edited 1 time(s). Last edit at 10/15/2017 10:00AM by coredump.

|

Re: Precision Piezo Z-probe Now available. October 15, 2017 02:41PM |

Registered: 8 years ago Posts: 3,525 |

The titan piezo bracket works for the aero, as its the bracket which holds the piezo. But to mount the bracket requires that the mounting surface be at 90 degrees to the bracket. You could achieve this possibly with your carriage but not perhaps in a neat way.

You can if you're using a regular titan place a Piezo20 module under the extruder, and to be honest E3d's gif with the wobbly hotend is rather exaggerating the effect. But if using titan or aero I'd advise using the bracket, its just working out how to mount it parallel as in your setup.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

You can if you're using a regular titan place a Piezo20 module under the extruder, and to be honest E3d's gif with the wobbly hotend is rather exaggerating the effect. But if using titan or aero I'd advise using the bracket, its just working out how to mount it parallel as in your setup.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 15, 2017 05:34PM |

Registered: 6 years ago Posts: 30 |

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 05:06AM |

Registered: 10 years ago Posts: 23 |

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 06:26AM |

Registered: 8 years ago Posts: 487 |

Quote

coredump

Do you have better pictures with the detailing on how you assemble that brackeT? I may be missing something.

The Titan bracket was designed to work like this, bolted to a carriage by the two bolt holes you can see at the top of the left hand model. If you use it in the inverted manner as shown on the left you'll need a spacer to allow the mount to flex as designed, I think that's posted on thingverse too. The piezo disk is glued into the pocket below the motor. I think this should work for the Titan Aero just as well as the Titan but I don't actually own either, or a cartesian printer for that matter, Simon has tested the Titan mount however.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 06:32AM |

Registered: 6 years ago Posts: 43 |

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 08:18AM |

Registered: 8 years ago Posts: 3,525 |

Consider printing one it's more obvious in real life. The upwards force on the nozzle, via the hotend, and titan extruder bends the bracket (just 0.1mm), Idris clever design on the bracket ensures the force gets transmitted through the piezo which bends (imperceptibly) but enough to generate a rising voltage which the pcb detects.

Correct me if this is an incorrect assumption, but I think people struggle with it as they don't realise until they play with them how sensitive these things are. I can trigger my micro delta by walking past it. Or blowing on the printbed.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Correct me if this is an incorrect assumption, but I think people struggle with it as they don't realise until they play with them how sensitive these things are. I can trigger my micro delta by walking past it. Or blowing on the printbed.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 08:36AM |

Registered: 8 years ago Posts: 487 |

As Simon says, printing one is the best way to see how it works but I'll try to explain.

Looking at the left hand unit you'll see a slot cut out of the flat top part. At the rearmost edge the plastic left by the slot acts as a pivot allowing the front face with the motor/extruder to move up or when force is applied to the nozzle. In the centre of the front face is a tongue that holds the piezo, when the motor/extruder and front face move up that tongue is forced to bend where it's thinnest, which is where the piezo is glued so the piezo has to bend too which produces the signal.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Looking at the left hand unit you'll see a slot cut out of the flat top part. At the rearmost edge the plastic left by the slot acts as a pivot allowing the front face with the motor/extruder to move up or when force is applied to the nozzle. In the centre of the front face is a tongue that holds the piezo, when the motor/extruder and front face move up that tongue is forced to bend where it's thinnest, which is where the piezo is glued so the piezo has to bend too which produces the signal.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 12:21PM |

Registered: 6 years ago Posts: 36 |

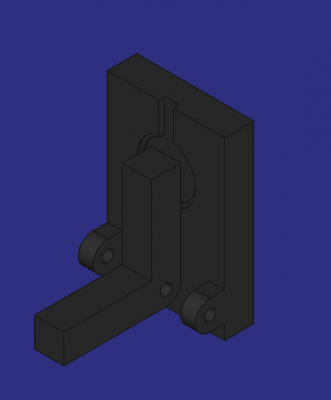

so, here is my basic idea for the mount on my set up. pardon the crudeness of the design as this is just a concept i drew up in about 5 min to get the idea viewable. The piezo would be mounted the same distance from the pivot point as the center of the hotends shaft, so a 1/1 ratio of force being transfered by the lever.

Edited 1 time(s). Last edit at 10/16/2017 12:21PM by OutcastZeroOne.

Edited 1 time(s). Last edit at 10/16/2017 12:21PM by OutcastZeroOne.

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 01:36PM |

Registered: 6 years ago Posts: 36 |

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 02:02PM |

Registered: 8 years ago Posts: 3,525 |

Hi that looks doable, my suggestion would be to make the pivoting bracket the full width of the hinge for stability with just a small bump on it aligned with the centre of the piezo, which is supported on its perimeter. You could even put screws through the pivoting part to screw it to the upright part, which would stabilise it and enable you to preload the piezo. I like that deisgn.

20mm murata 7bb piezos are exactly 20mm in diameter and around 0.6mm thick (but Ill measure on with calipers later), excluding the solder pads which are usually around 1.0-1.5mm high, and variably positioned so allow space for them. I used to allow a 20.5mm recess for the 20mm piezos but have recently changed the design to 21mm as even precisely printed this doesn't allow enough tolerance. If you take the piezo20 module as a guide for supporting and mounting the piezo, its tried and tested, but less optimal designs will work, they are very sensitive.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

20mm murata 7bb piezos are exactly 20mm in diameter and around 0.6mm thick (but Ill measure on with calipers later), excluding the solder pads which are usually around 1.0-1.5mm high, and variably positioned so allow space for them. I used to allow a 20.5mm recess for the 20mm piezos but have recently changed the design to 21mm as even precisely printed this doesn't allow enough tolerance. If you take the piezo20 module as a guide for supporting and mounting the piezo, its tried and tested, but less optimal designs will work, they are very sensitive.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 02:12PM |

Registered: 6 years ago Posts: 30 |

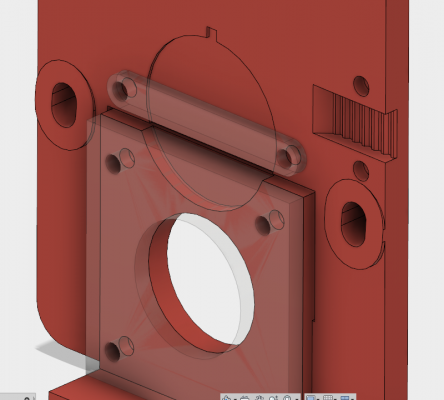

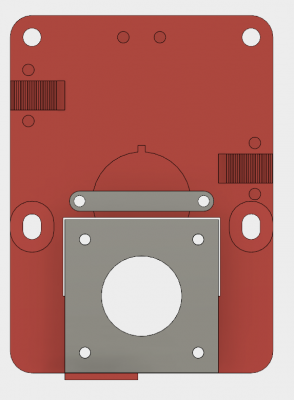

This is my new try. My hope/idea is that the split plate will bend the piezo at the middle enough. I am printing those things now to do some testing.

1 more pics here: [imgur.com]

Where would you mount the titan in this casE?

Edited 1 time(s). Last edit at 10/16/2017 02:13PM by coredump.

1 more pics here: [imgur.com]

Quote

OutcastZeroOne

so, here is my basic idea for the mount on my set up. pardon the crudeness of the design as this is just a concept i drew up in about 5 min to get the idea viewable. The piezo would be mounted the same distance from the pivot point as the center of the hotends shaft, so a 1/1 ratio of force being transfered by the lever.

Where would you mount the titan in this casE?

Edited 1 time(s). Last edit at 10/16/2017 02:13PM by coredump.

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 02:50PM |

Registered: 6 years ago Posts: 36 |

im not using a titan, I'm using a Zesty Nimble Sidewinder (working title)

thanks DjDemon, i was planning to do those sugestions, just wanted to get eh basic concept down to help explain what i was thinking. Any idea when the DIY kits will be back in stock? are they the 7bb-20-3 or 7bb-20-6? i found spec sheets listing the sizes but there are a few variations with different thicknesses

Edited 1 time(s). Last edit at 10/16/2017 02:54PM by OutcastZeroOne.

thanks DjDemon, i was planning to do those sugestions, just wanted to get eh basic concept down to help explain what i was thinking. Any idea when the DIY kits will be back in stock? are they the 7bb-20-3 or 7bb-20-6? i found spec sheets listing the sizes but there are a few variations with different thicknesses

Edited 1 time(s). Last edit at 10/16/2017 02:54PM by OutcastZeroOne.

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 03:03PM |

Registered: 8 years ago Posts: 3,525 |

Outcastzeroone 7bb 20 6

Coredump that's similar to the piezo plate design I tried with the motor as the mount. The issue with placing a sensor plate between titan and motor was for me the raised area around the motor shaft and needing longer screws, and possibly having issue with the metal gear on the motor shaft in the titan, that's why I focused on mounting the motor.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Coredump that's similar to the piezo plate design I tried with the motor as the mount. The issue with placing a sensor plate between titan and motor was for me the raised area around the motor shaft and needing longer screws, and possibly having issue with the metal gear on the motor shaft in the titan, that's why I focused on mounting the motor.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 06:12PM |

Registered: 8 years ago Posts: 3,525 |

Quote

OutcastZeroOne

also, can anyone give me accurate dimensions of the 20mm piezo disk's so that i can make a propper sized recess in my design?

Murata 7BB-20-6

diameter 20.00mm

thickness 0.41mm (excluding solder)

thickness 0.95mm with solder

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 16, 2017 06:34PM |

Registered: 6 years ago Posts: 36 |

Quote

DjDemonD

Quote

OutcastZeroOne

also, can anyone give me accurate dimensions of the 20mm piezo disk's so that i can make a propper sized recess in my design?

Murata 7BB-20-6

diameter 20.00mm

thickness 0.41mm (excluding solder)

thickness 0.95mm with solder

interesting.... the spec sheet lists it as much thinner... good thing i asked

|

Re: Precision Piezo Z-probe Now available. October 17, 2017 04:04AM |

Registered: 6 years ago Posts: 36 |

ive got my parts printing, now i just need some of your gear to make it all work. just ordered 2 universal kits from your site. Will need to add your logo to teh placard i plan to make for my machine to show all the fancy new tech it has on it

Edited 1 time(s). Last edit at 10/17/2017 04:11AM by OutcastZeroOne.

Edited 1 time(s). Last edit at 10/17/2017 04:11AM by OutcastZeroOne.

|

Re: Precision Piezo Z-probe Now available. October 17, 2017 04:37AM |

Registered: 8 years ago Posts: 3,525 |

We can probably rustle up some stickers if you want? Or consider printing this precisionpiezologo.stl

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 17, 2017 03:35PM |

Registered: 6 years ago Posts: 36 |

|

Re: Precision Piezo Z-probe Now available. October 17, 2017 03:42PM |

Registered: 10 years ago Posts: 14,672 |

If you send an email to info at Duet3D dot com I am sure they will send you the logo image, perhaps even some stickers in the post.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Precision Piezo Z-probe Now available. October 18, 2017 03:56PM |

Registered: 6 years ago Posts: 36 |

Is it possible to have the sensor work in reverse? As in, activate when pressure is released? I'm sure there was a firmware setting but just seeing if anyone has tried this. Earlier I cam to realize a design flaw in my mount where the drive cable of my Zesty Nimble Sidewinder (working title) may give false readings when it nears the stepper driver and the cable tries to push out.

Edited 1 time(s). Last edit at 10/18/2017 03:57PM by OutcastZeroOne.

Edited 1 time(s). Last edit at 10/18/2017 03:57PM by OutcastZeroOne.

|

Re: Precision Piezo Z-probe Now available. October 18, 2017 04:49PM |

Registered: 8 years ago Posts: 487 |

Yep, just plug the piezo in the other way round. When you're testing check that it triggers as pressure is removed.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. October 18, 2017 08:31PM |

Registered: 6 years ago Posts: 36 |

|

Re: Precision Piezo Z-probe Now available. October 19, 2017 06:26AM |

Registered: 6 years ago Posts: 20 |

Thank you guys for this awesome probing system. I've bought from you the boards, used some 30mm large piezo discs and some lasercut acrylic hotend holders.

Results are impressive: 3 micron resolution

Results are impressive: 3 micron resolution

Send: M48 Recv: M48 Z-Probe Repeatability Test Recv: Finished! Recv: Mean: -0.015469 Min: -0.017 Max: -0.014 Range: 0.003 Recv: Standard Deviation: 0.001298 Recv: Recv: X:200.00 Y:200.00 Z:1.00 E:50.00 Count A:32000 B:0 Z:640 Recv: ok

|

Re: Precision Piezo Z-probe Now available. October 19, 2017 06:34AM |

Registered: 8 years ago Posts: 3,525 |

Fantastic result, please if you are not already, consider sharing your design, it obviously works very well.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. October 19, 2017 08:12AM |

Registered: 6 years ago Posts: 20 |

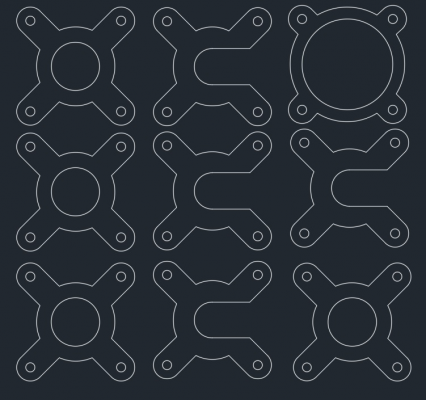

Here are the plans as dxf (attached and also here).

They are meant to be laser cut from 3mm thick acrylic.

From bottom up you need:

1)Hotend is held by a sandwich made of: smaller circle piece, U shape, another U shape (rotated 180 degrees), and another smaller circle piece

2)Put the piezo on top

3)The larger circle piece

4)Put 4 M3x 35/40/45mm and 4 nuts. Pretension the piezo a little like in the youtube guide. Glue the piezo with a litte CA glue on the margin.

The screws are 30mm apart. If you can, use a flat hotend holder with appropriate sized and spaced holes and make the whole assembly easier to fix.

The bowden holder is just an e3dv6 clone heatsink threaded throat cut from the rest of the heatsink and held in pace by a similar sandwich as the lower part.

They are meant to be laser cut from 3mm thick acrylic.

From bottom up you need:

1)Hotend is held by a sandwich made of: smaller circle piece, U shape, another U shape (rotated 180 degrees), and another smaller circle piece

2)Put the piezo on top

3)The larger circle piece

4)Put 4 M3x 35/40/45mm and 4 nuts. Pretension the piezo a little like in the youtube guide. Glue the piezo with a litte CA glue on the margin.

The screws are 30mm apart. If you can, use a flat hotend holder with appropriate sized and spaced holes and make the whole assembly easier to fix.

The bowden holder is just an e3dv6 clone heatsink threaded throat cut from the rest of the heatsink and held in pace by a similar sandwich as the lower part.

Sorry, only registered users may post in this forum.