Precision Piezo Z-probe Now available.

Posted by DjDemonD

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 11:00AM |

Registered: 8 years ago Posts: 36 |

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 11:15AM |

Registered: 8 years ago Posts: 487 |

We're aware of it, there's really not much we can do apart from putting notices on our documentation and videos and keeping people aware of the damage cloning does to innovation in the open source hardware world.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 11:18AM |

Registered: 8 years ago Posts: 3,525 |

I'd say let's give them as little publicity as possible. I do not know if their product works, but linking to our documentation and files is not going to be entirely to their advantage. Its open source and anyone can make one, its the use of our name that I object to, but it is not a protected trademark.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 12:14PM |

Registered: 6 years ago Posts: 207 |

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 01:04PM |

Registered: 8 years ago Posts: 3,525 |

Thanks for doing that it is appreciated. People are going to find it, but I'd like to think they might find us first.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 04:12PM |

Registered: 6 years ago Posts: 30 |

So. Youse.

¯\_(ツ)_/¯

removed all the cables and moved my duet/duex to another mount, then re-connected all the cables and used a flexible tubing to organize everything, put some zip ties to hold everything in place including the precision piezo board... and now it doesn't work anymore?

I had it very well tuned yesterday, even got some prints out and etc. Then now the bed will just flex the shit of my mount without working.

I even used a new board that I received today, tried increasing sensibility, tried inverting the piezo connection and etc. Those are the behaviors I am getting:

- When I touch the nozzle and etc, the trigger blue light goes out

- Using the analog mode on duet (as described by DJ on the duet forum) I read VERY low values (like 40s-100s), I have to really bang it to get to over 600. Just for reference, yesterday I had it triggering at 750 with 0.001 std dev.

- Using the digital mode I can get it too sensitive to even move, or not sensitive enough to stop on touch, there's no middle ground there.

I tried a different board, different calibrations, inverted the piezo entry, tried to make my mount (the part that presses the piezo) tighter or more loose to see if that had something to do. I also tried reducing the R parameter, recovery time, on M558.

I can't think how adding tubing and organizing the cables would change that. I even tried to disconnect my Duex to see if there was some weird electronics interaction happening there, but nothing changed. Maybe the zipties made the mount stiffer? Or the cables bunched up inside the conduit are attenuating the signal to the z-probe?

- Would a broken cable between the piezo and the z-probe connector on the Duet make it not work at all or do what it is doing now?

- Is it possible to 'break' the piezo disk? I suppose that as long the blue light on the board is going on and off, the disk is fine (and I can't think on something to break on that except for the cables and those are ok afaict)

- Why would the Duet be reading such low values?

That's a headscratcher :|

Edited 1 time(s). Last edit at 11/06/2017 04:13PM by coredump.

¯\_(ツ)_/¯

removed all the cables and moved my duet/duex to another mount, then re-connected all the cables and used a flexible tubing to organize everything, put some zip ties to hold everything in place including the precision piezo board... and now it doesn't work anymore?

I had it very well tuned yesterday, even got some prints out and etc. Then now the bed will just flex the shit of my mount without working.

I even used a new board that I received today, tried increasing sensibility, tried inverting the piezo connection and etc. Those are the behaviors I am getting:

- When I touch the nozzle and etc, the trigger blue light goes out

- Using the analog mode on duet (as described by DJ on the duet forum) I read VERY low values (like 40s-100s), I have to really bang it to get to over 600. Just for reference, yesterday I had it triggering at 750 with 0.001 std dev.

- Using the digital mode I can get it too sensitive to even move, or not sensitive enough to stop on touch, there's no middle ground there.

I tried a different board, different calibrations, inverted the piezo entry, tried to make my mount (the part that presses the piezo) tighter or more loose to see if that had something to do. I also tried reducing the R parameter, recovery time, on M558.

I can't think how adding tubing and organizing the cables would change that. I even tried to disconnect my Duex to see if there was some weird electronics interaction happening there, but nothing changed. Maybe the zipties made the mount stiffer? Or the cables bunched up inside the conduit are attenuating the signal to the z-probe?

- Would a broken cable between the piezo and the z-probe connector on the Duet make it not work at all or do what it is doing now?

- Is it possible to 'break' the piezo disk? I suppose that as long the blue light on the board is going on and off, the disk is fine (and I can't think on something to break on that except for the cables and those are ok afaict)

- Why would the Duet be reading such low values?

That's a headscratcher :|

Edited 1 time(s). Last edit at 11/06/2017 04:13PM by coredump.

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 04:22PM |

Registered: 8 years ago Posts: 3,525 |

The most common failure is the piezo disc leads desoldering.

If this is not the case then how long is the lead between the piezo and the piezo PCB and does it run in a cable bundle with other cables such as hotend heaters which have high frquency PWM signals? Interference can cause issues, try to keep piezo board on the head if possible to keep cables short.

- Would a broken cable between the piezo and the z-probe connector on the Duet make it not work at all or do what it is doing now?

A broken cable between the piezo PCB and the Duet would mean either the duet registering triggered permanently or open permanently with no change when the blue light comes on/off on the piezo board registering on the duet

- Is it possible to 'break' the piezo disk? I suppose that as long the blue light on the board is going on and off, the disk is fine (and I can't think on something to break on that except for the cables and those are ok afaict)

Maybe but Mike has subjected some to 130,000 compressions at 500g force, which is 2 orders of magnitude above what were using. So the disc themselves no, the wires/solder yes.

- Why would the Duet be reading such low values?

Not sure at all.

Edited 1 time(s). Last edit at 11/06/2017 04:25PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

If this is not the case then how long is the lead between the piezo and the piezo PCB and does it run in a cable bundle with other cables such as hotend heaters which have high frquency PWM signals? Interference can cause issues, try to keep piezo board on the head if possible to keep cables short.

- Would a broken cable between the piezo and the z-probe connector on the Duet make it not work at all or do what it is doing now?

A broken cable between the piezo PCB and the Duet would mean either the duet registering triggered permanently or open permanently with no change when the blue light comes on/off on the piezo board registering on the duet

- Is it possible to 'break' the piezo disk? I suppose that as long the blue light on the board is going on and off, the disk is fine (and I can't think on something to break on that except for the cables and those are ok afaict)

Maybe but Mike has subjected some to 130,000 compressions at 500g force, which is 2 orders of magnitude above what were using. So the disc themselves no, the wires/solder yes.

- Why would the Duet be reading such low values?

Not sure at all.

Edited 1 time(s). Last edit at 11/06/2017 04:25PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 04:35PM |

Registered: 6 years ago Posts: 30 |

Quote

DjDemonD

The most common failure is the piezo disc leads desoldering.

If this is not the case then how long is the lead between the piezo and the piezo PCB and does it run in a cable bundle with other cables such as hotend heaters which have high frquency PWM signals? Interference can cause issues, try to keep piezo board on the head if possible to keep cables short.

Only the cable going from the PCB to the Duet, the lead from piezo to the PP20 is jst the default one (5/10 cm maybe).

wth

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 04:44PM |

Registered: 8 years ago Posts: 3,525 |

Might be worth taking a multimeter to the VR1 pot and reading the value relative to piezo +. And the VR2 pot relative to piezo pcb GND.

Also measure GND to SIG voltage both open and triggering (more difficult without a storage scope).

Replace the cable between piezo PCB and Duet just to see if it makes a difference.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Also measure GND to SIG voltage both open and triggering (more difficult without a storage scope).

Replace the cable between piezo PCB and Duet just to see if it makes a difference.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 06, 2017 04:55PM |

Registered: 6 years ago Posts: 30 |

Quote

DjDemonD

Might be worth taking a multimeter to the VR1 pot and reading the value relative to piezo +. And the VR2 pot relative to piezo pcb GND.

Also measure GND to SIG voltage both open and triggering (more difficult without a storage scope).

So about that measurement. I saw on the video you doing it, but I may have a too thick of a lead or something, becase no matter how I measure, I only get something like 0.009 on the 2kohm scale, what is like 9 ohms? OR I am measuring the wrong place or touching soemthing I shouldnt.

I will try another cable. I just removed the cable from the conduit/flexible cable and back to what was yesterday so I can check

|

Re: Precision Piezo Z-probe Now available. November 07, 2017 03:43AM |

Registered: 8 years ago Posts: 487 |

First things first, you cannot use a PP20 board in active low mode, with the BLUE led normally on and turning off when triggered.

It is possible to fracture the ceramic on the piezo disk which can cause strange behaviour, however, I don't think that's the case here.

What you're describing suggests an issue with VR1. VR1 should measure somewhere around 400-600k when measured between PZ- and the metal top of VR1. Turn VR1 so that the flat part of the "knob" is closest to to the edge of the board.

Be gentle with the variable resistors, they are delicate.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

It is possible to fracture the ceramic on the piezo disk which can cause strange behaviour, however, I don't think that's the case here.

What you're describing suggests an issue with VR1. VR1 should measure somewhere around 400-600k when measured between PZ- and the metal top of VR1. Turn VR1 so that the flat part of the "knob" is closest to to the edge of the board.

Be gentle with the variable resistors, they are delicate.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. November 07, 2017 04:15AM |

Registered: 8 years ago Posts: 3,525 |

Sorry my bad, VR1 is to piezo -, piezo + should always read around 10kohm.

Edited 1 time(s). Last edit at 11/07/2017 04:16AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 11/07/2017 04:16AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 08, 2017 12:33AM |

Registered: 6 years ago Posts: 30 |

|

Re: Precision Piezo Z-probe Now available. November 10, 2017 12:39AM |

Registered: 6 years ago Posts: 17 |

Finally at a stage where this is ready for testing in anger now (I changed to just a mount rather than a whole carriage, as all that was doing was making things more complex).

[cad.onshape.com]

Unfortunately I'm using Smoothieware to control the machine, not RepRapFirmware. I can see how to set it up to probe (and have done some tests with a microswitch & finger combo whilst I wait for my final draft to print) but I can't see how to get the bed map/standard deviation output.

Anyone have any guesses?

[cad.onshape.com]

Unfortunately I'm using Smoothieware to control the machine, not RepRapFirmware. I can see how to set it up to probe (and have done some tests with a microswitch & finger combo whilst I wait for my final draft to print) but I can't see how to get the bed map/standard deviation output.

Anyone have any guesses?

|

Re: Precision Piezo Z-probe Now available. November 10, 2017 01:55AM |

Registered: 8 years ago Posts: 3,525 |

I know basically how to get a probe working in Smoothieware, but I didn't get as far as grid levelling. I'm not sure there is a built in probe accuracy test, but you can send G30 and just record 10-20 values and stick them in a spreadsheet.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 10, 2017 04:53PM |

Registered: 6 years ago Posts: 17 |

Thanks, these are my first set of tests:Quote

DjDemonD

I know basically how to get a probe working in Smoothieware, but I didn't get as far as grid levelling. I'm not sure there is a built in probe accuracy test, but you can send G30 and just record 10-20 values and stick them in a spreadsheet.

0.0375 0.5225 0.7913 0.9713 1.2288 1.5050 0.0738

0.6175 0.7388 0.8750 1.0588 1.2800 1.5150 -0.8737

0.6975 0.8763 1.0200 1.2413 1.3913 1.6113 1.7350

0.8350 0.9563 1.1425 1.3213 1.4650 1.5700 1.7225

2.7263 1.1025 1.2438 1.3825 1.5425 1.7063 1.7525

1.0888 1.1925 1.3200 1.4575 1.6113 1.8050 1.8850

2.7263 1.3975 1.4938 1.6488 1.8488 1.9313 0.1038

Some of the edges are a bit weird as the buildplate was slightly off centred and I probed with the side of the nozzle. If you're interested/want to link it for others I've been documenting my progress setting this up with Smoothie on my blog @ jebk.wordpress.com

What are your reccomendations in terms of testing for repeatability? Just run the same probe strategy multiple times and look for differences?

Edited 1 time(s). Last edit at 11/10/2017 04:56PM by jebk.

|

Re: Precision Piezo Z-probe Now available. November 10, 2017 05:05PM |

Registered: 8 years ago Posts: 3,525 |

Good work. In terms of testing probe accuracy I'd just run G30 S-1 (not sure the equivlanent in Smoothie but this reports the distance travelled) and repeat it 20 times, then put values into a spreadsheet and get range and deviation.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 11, 2017 04:27AM |

Registered: 6 years ago Posts: 17 |

Quote

DjDemonD

Good work. In terms of testing probe accuracy I'd just run G30 S-1 (not sure the equivlanent in Smoothie but this reports the distance travelled) and repeat it 20 times, then put values into a spreadsheet and get range and deviation.

So, in terms of accuracy (this is from z=10):

10.415 10.4187 10.42 10.4213 10.4187 10.4175 10.4225 10.425 10.425 10.4362 10.425 10.4263 10.4237 10.43 Std Deviation = 0.005274mm

I have to say I'm pretty impressed. The only other ABL system I've used is one of the big 14mm capacitative (sp?) sensors and it was nowhere near close to that. This test is on FR4 if it makes a difference. I'll run it again on glass later.

Now it's (somewhat) tested the parts are publicly available at https://www.thingiverse.com/thing:2638792 Onshape link to the CAD files is in the description there. I'm still likely to change the mount a bit more - at the moment it's deeper than I'd like, which makes a 5015 fan more of a hassle than needed.

I'd suggest you also need a tester with a CR10, the tronxy printers are probably a bit niche. I now need to hurry up and convert my Wanhao i3 to RAMPS so I can use it there. Have you tried something constrained between the rails on an i3 type printer? I reckon with a 27mm sensor theres enough deflection in them to trigger it.

|

Re: Precision Piezo Z-probe Now available. November 12, 2017 05:48PM |

Registered: 8 years ago Posts: 7 |

Hi, the piezo system looks cool for a hotend swapper like me  .

.

I have to admit i know nothing about piezo but would it be possible to just shove them under these for measuring on the bed of a prusa style machine? (with some kapton between the extrusion and the piezo) Or would the pre-load be to much?

.

. I have to admit i know nothing about piezo but would it be possible to just shove them under these for measuring on the bed of a prusa style machine? (with some kapton between the extrusion and the piezo) Or would the pre-load be to much?

|

Re: Precision Piezo Z-probe Now available. November 12, 2017 06:31PM |

Registered: 8 years ago Posts: 3,525 |

Hi yes its certainly possible. If you redesign those parts to allow space for a piezo to sit in the bracket, so that any downward force will squeeze it, then it should work. Its easy enough to experiment on the bench if you have our PCB, or have made your own amplifier circuit. Just tap the part with the piezo in it lightly and see if you get triggers. Generally with underbed its very sensitive as there are 3 or 4 piezos contributing to the signal.

For probing with a moving bed in y axis, youll need to use the "pause before probing" setting in your firmware, 0.4sec is usually enough just to allow the bed to come to rest, before each probing dive takes place, the lateral movement of the bed will trigger the z-probe, but so long as you pause briefly before each probe it doesnt matter.

Interested to see how you get on/help, since we don't currently have a solution for i3 style machines, especially the original prusa, maybe it can be adapted under the bed there too.

Edited 1 time(s). Last edit at 11/12/2017 06:33PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

For probing with a moving bed in y axis, youll need to use the "pause before probing" setting in your firmware, 0.4sec is usually enough just to allow the bed to come to rest, before each probing dive takes place, the lateral movement of the bed will trigger the z-probe, but so long as you pause briefly before each probe it doesnt matter.

Interested to see how you get on/help, since we don't currently have a solution for i3 style machines, especially the original prusa, maybe it can be adapted under the bed there too.

Edited 1 time(s). Last edit at 11/12/2017 06:33PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 12:12PM |

Registered: 8 years ago Posts: 3,525 |

Hi all. So Idris and I have been thinking about designing a version 2 of the Piezo20 module, or something similar.

We'd like to ask what features would people like to see in an improved version?

We are currently working on an idea of having the piezo disc/s embedded into a PCB which sits in the middle of the unit. This way there are no leads to pull/snag, and the total size is smaller.

Feel free to brainstorm and let us know what you think.

I do have some specific questions also:

1) how useful is it to be able to get your hotend out of the module without unmounting the module or dismantling it? Do you do this/need to do it?

2) Is the unit the right size? Would you like it to be smaller? Would you have any issues if it were bigger?

3) How many people are using these with cloned v6's which do not have the tiny bowden fittings like the genuine v6, but the larger screw in ones? and is this a problem? Do you just mount your Bowden coupler above the unit and run the PTFE from below it into the heatsink or do you drill out your Bowden coupler to enable the ptfe tube to pass all the way through. Would a piezo20 with built in bowden coupler be useful?

4) since custom colours are always going to be more expensive and time-consuming to provide, I am thinking of making them all one colour, possibly using the new ColorFabb Ngen Lux, once it's available unless it's insanely expensive.

Grateful for your input in advance.

Edited 1 time(s). Last edit at 11/13/2017 12:13PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

We'd like to ask what features would people like to see in an improved version?

We are currently working on an idea of having the piezo disc/s embedded into a PCB which sits in the middle of the unit. This way there are no leads to pull/snag, and the total size is smaller.

Feel free to brainstorm and let us know what you think.

I do have some specific questions also:

1) how useful is it to be able to get your hotend out of the module without unmounting the module or dismantling it? Do you do this/need to do it?

2) Is the unit the right size? Would you like it to be smaller? Would you have any issues if it were bigger?

3) How many people are using these with cloned v6's which do not have the tiny bowden fittings like the genuine v6, but the larger screw in ones? and is this a problem? Do you just mount your Bowden coupler above the unit and run the PTFE from below it into the heatsink or do you drill out your Bowden coupler to enable the ptfe tube to pass all the way through. Would a piezo20 with built in bowden coupler be useful?

4) since custom colours are always going to be more expensive and time-consuming to provide, I am thinking of making them all one colour, possibly using the new ColorFabb Ngen Lux, once it's available unless it's insanely expensive.

Grateful for your input in advance.

Edited 1 time(s). Last edit at 11/13/2017 12:13PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 03:42PM |

Registered: 6 years ago Posts: 17 |

I can't speak to direct use, but in principle my answers below:

1 probably not hugely. Certainly functionality would be higher on the list.

2 as far as possible I'd suggest you don't exceed the heatsink diameter in at least one direction. Most mounts (for non deltas) would let you go as far as you like 'forward' but not very far back.

3 I'd say this depends on the market you're aiming at. The bulk of the market (seems to me to be) is interested in cheap over quality. I'm not sure how many people are running £100 hotends on Anet A8s etc. I'd say either PC4-M6 (still quite small but you can run a tube through them) or 1/4" NAP would be the ones to go for.

1 probably not hugely. Certainly functionality would be higher on the list.

2 as far as possible I'd suggest you don't exceed the heatsink diameter in at least one direction. Most mounts (for non deltas) would let you go as far as you like 'forward' but not very far back.

3 I'd say this depends on the market you're aiming at. The bulk of the market (seems to me to be) is interested in cheap over quality. I'm not sure how many people are running £100 hotends on Anet A8s etc. I'd say either PC4-M6 (still quite small but you can run a tube through them) or 1/4" NAP would be the ones to go for.

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 03:44PM |

Registered: 8 years ago Posts: 3,525 |

Thank you those are good points.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 04:14PM |

Registered: 6 years ago Posts: 19 |

Hi,

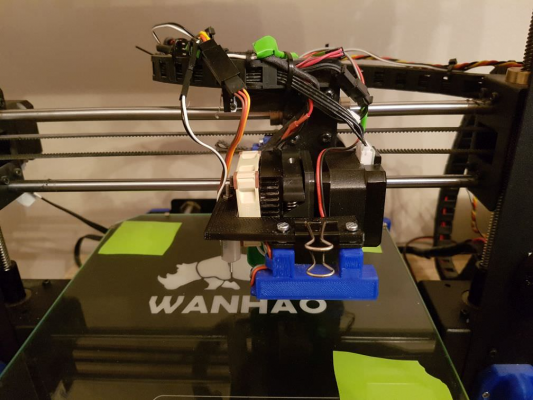

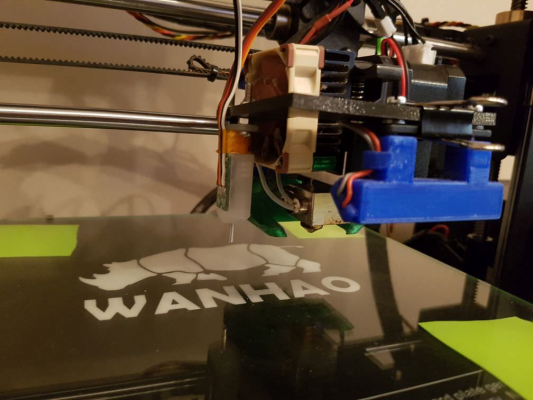

I am interested in trying this out and I was wondering if this probe can also be used with non E3D V6 hotends specifically i would like to use this with the stock hotend of the Wanhao i3. Is this possible? If so what sort of modifications would i need to do to make it work (for the hotend placement and not under the heated bed)? Is there any special place the Piezo needs to be placed for it to work properly?

Appriciate the help.

I am interested in trying this out and I was wondering if this probe can also be used with non E3D V6 hotends specifically i would like to use this with the stock hotend of the Wanhao i3. Is this possible? If so what sort of modifications would i need to do to make it work (for the hotend placement and not under the heated bed)? Is there any special place the Piezo needs to be placed for it to work properly?

Appriciate the help.

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 04:28PM |

Registered: 8 years ago Posts: 3,525 |

Hi it's specifically designed for genuine e3d v6 but I don't know the x carriage design of the wanhao i3 well enough to know how well it will fit. Please post an image of the hotend and x carriage.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 04:35PM |

Registered: 6 years ago Posts: 19 |

Sure. Here you go. Let me know if anything is unclear based on the pictures.

The blue thing in front is a LED light mount. The black L shaped piece held there with a clip is only a temporary mount for my BL touch atm. The rest is the hotend, extruder gear etc.

Edited 1 time(s). Last edit at 11/13/2017 04:36PM by CaptainHero.

The blue thing in front is a LED light mount. The black L shaped piece held there with a clip is only a temporary mount for my BL touch atm. The rest is the hotend, extruder gear etc.

Edited 1 time(s). Last edit at 11/13/2017 04:36PM by CaptainHero.

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 04:51PM |

Registered: 8 years ago Posts: 3,525 |

Hmm that isnt an e3d v6 hotend it's a mk8 extruder so this will take some work. The best plan may be to incorporate a piezo between extruder and x carriage. A bit like this [www.thingiverse.com]

There are so many printers we can't design mounts for all of them but we will help you if you want to give it a try.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

There are so many printers we can't design mounts for all of them but we will help you if you want to give it a try.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 04:58PM |

Registered: 6 years ago Posts: 19 |

Yeah i forgot to mention that the Wanhao uses actually a MK10 extruder and not the E3D V6. I didn't read through the whole thread and maybe thats why i am missing the info but i want to first understand how this Piezo actually works as a zprobe in order to give it a crack to try to fit it on my wanhao.

I guess it works sort of like a vibration sensor detecting the impact of the nozzle towards the surface? Or what is the logic here? I just want to understand to be able to guess what sort of placement for such a sensor on my printer would make it work. Do i only need to have it make contact with the area of my hotend? I.e.: the cooling block or somewhere else?

Or am i completely wrong and it works completly different way. I am using a Ramps board btw so wiring this up should be very easy as soon as i know where the Piezo disc actually needs to be placed on my printer for it to register the hotends height.

I guess it works sort of like a vibration sensor detecting the impact of the nozzle towards the surface? Or what is the logic here? I just want to understand to be able to guess what sort of placement for such a sensor on my printer would make it work. Do i only need to have it make contact with the area of my hotend? I.e.: the cooling block or somewhere else?

Or am i completely wrong and it works completly different way. I am using a Ramps board btw so wiring this up should be very easy as soon as i know where the Piezo disc actually needs to be placed on my printer for it to register the hotends height.

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 05:08PM |

Registered: 8 years ago Posts: 3,525 |

It works by generating a voltage when compressed or bent. It's a long story so please check out [reprap.org] if you really want to understand it read the other long thread in the general forum.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 05:09PM |

Registered: 6 years ago Posts: 19 |

Sorry, only registered users may post in this forum.