Precision Piezo Z-probe Now available.

Posted by DjDemonD

|

Re: Precision Piezo Z-probe Now available. November 13, 2017 05:21PM |

Registered: 6 years ago Posts: 19 |

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 05:43AM |

Registered: 8 years ago Posts: 3,525 |

Its not too bad, take a little getting used to, and having a play with the piezo and PCB without integrating them into anything first will give you a sound understanding of how it works.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 09:09AM |

Registered: 6 years ago Posts: 19 |

So while i await the arrival of the kit i have been doing some reading on how exactly the piezo sensor works. I understand it requires some squeeze pressure or bend for it to send a signal. Now looking at the Wanhao I3 extruder setup i am pondering where ideally i would need to find a place for the sensor / design some sort of mount for this effect to be achieved.

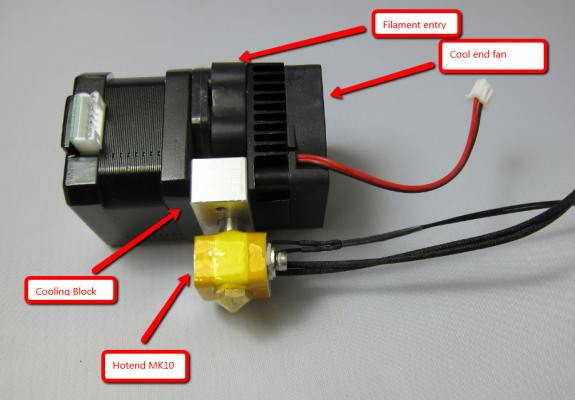

Attached below i have a pic of the general setup of the normal Wanhao I3 extruder setup (stepper motor, hotend, cooling block, fan, feeder part).

Not sure where logically it would make sense to try to find a place for this sensor with this setup. I really don't want to use under bed sensors because a) its a heated bed b) its a moving bed c) would want to have readings based off the nozzle mainly.

Anyone have a good idea where it would make sense to try to squeeze in the sensor in the above setup for it to work?

Attached below i have a pic of the general setup of the normal Wanhao I3 extruder setup (stepper motor, hotend, cooling block, fan, feeder part).

Not sure where logically it would make sense to try to find a place for this sensor with this setup. I really don't want to use under bed sensors because a) its a heated bed b) its a moving bed c) would want to have readings based off the nozzle mainly.

Anyone have a good idea where it would make sense to try to squeeze in the sensor in the above setup for it to work?

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 11:55AM |

Registered: 8 years ago Posts: 3,525 |

Well it needs to be somewhere where the force of nozzle contact will be transmitted, And where it won't interfere with the functionality of the extruder. I can't really see anywhere on the Mk8/10 where you can do this. However you could place the piezo possibly between the mk10 and the x carriage.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 12:26PM |

Registered: 6 years ago Posts: 19 |

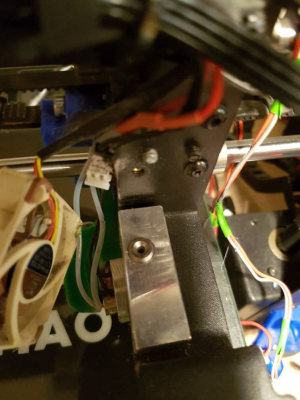

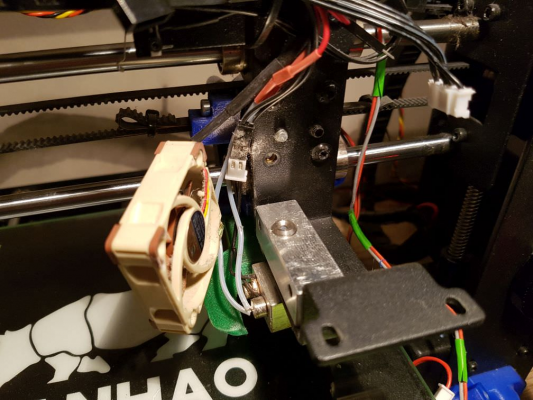

Took off the motor and the filament guide part and this is how it looks. I guess technically i may be able to put the sensor somewhere at the black backplate that holds the extruder setup to the x carriage but its quite sturdy setup so i am not sure what good that would do since i don't think the motor would press against the sensor at all when the nozzle touches the plate. I could be mistaken tough but that is my initial reaction looking at this.

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 12:40PM |

Registered: 8 years ago Posts: 3,525 |

Unless someone can come up with a new and clever way of doing this I can't see any other way to do this other than to make a plate containing the piezo disc and sandwich it between the extruder and the X carriage apologies for the lack of punctuation I'm dictating this as I'm driving

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 01:29PM |

Registered: 6 years ago Posts: 19 |

I guess i can give that a shot i just don't know how that would work in reality as the setup is quite sturdy and i doubt that there is any sort of movement of the components on the black carriage plate that would push against the sandwitched sensor. However at this point i also don't have a better idea so i will give that a go first when it arrives.

Worst case when push comes to shove i may alternatively have to go for a under bed setup but i really hope i can get it to work somehow around the hotend first.

Worst case when push comes to shove i may alternatively have to go for a under bed setup but i really hope i can get it to work somehow around the hotend first.

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 01:31PM |

Registered: 6 years ago Posts: 43 |

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 01:34PM |

Registered: 6 years ago Posts: 19 |

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 01:37PM |

Registered: 6 years ago Posts: 43 |

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 01:39PM |

Registered: 6 years ago Posts: 19 |

What do you mean only axis that moves is the Z? If i do an auto bed leveling mesh before a print it will probe my bed at various points therefore the x, y and z axis will all be moving constantly for the duration. How can i make sure that no false triggers are registered because of the movements between probe points? Also since the piezo acts basically as the Z endstop as well if it is triggered by motion during print will it not stop the print?

Edited 1 time(s). Last edit at 11/14/2017 01:40PM by CaptainHero.

Edited 1 time(s). Last edit at 11/14/2017 01:40PM by CaptainHero.

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 01:45PM |

Registered: 6 years ago Posts: 43 |

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 01:47PM |

Registered: 6 years ago Posts: 19 |

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 02:14PM |

Registered: 8 years ago Posts: 3,525 |

You can and should also set pause before probing, all the main firmwares now have this, it was a feature request we made to a few of them, others had it already. This ensures any mechanical ringing in the frame ceases before the probing dive takes place. Set Jerk to 1 for z and accel to 200. You dont need to move your z axis fast. Probing speed to between 4-7mm/s, pause at 0.4sec.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 02:24PM |

Registered: 6 years ago Posts: 19 |

Thanks for the tips.

In Marlin this would be the following setting right (value in miliseconds)?

#define DELAY_BEFORE_PROBING 400

Pause for how long? I assume this would be a gcode command in the startup script right? If so which one?

Edited 1 time(s). Last edit at 11/14/2017 02:25PM by CaptainHero.

Quote

pause at 0.4sec

In Marlin this would be the following setting right (value in miliseconds)?

#define DELAY_BEFORE_PROBING 400

Quote

You can and should also set pause before probing

Pause for how long? I assume this would be a gcode command in the startup script right? If so which one?

Edited 1 time(s). Last edit at 11/14/2017 02:25PM by CaptainHero.

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 04:03PM |

Registered: 8 years ago Posts: 3,525 |

No its defined in configuration.h and is not adjustable on the fly, you'd have to recompile and flash the firmware each time you wanted to change it. This is the issue with 8 bit arduino based systems, not time-saving for tinkers.

400 ms should be enough some get by with 100.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

400 ms should be enough some get by with 100.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 04:35PM |

Registered: 8 years ago Posts: 7 |

Quote

DjDemonD

Hi yes its certainly possible. If you redesign those parts to allow space for a piezo to sit in the bracket, so that any downward force will squeeze it, then it should work. Its easy enough to experiment on the bench if you have our PCB, or have made your own amplifier circuit. Just tap the part with the piezo in it lightly and see if you get triggers. Generally with underbed its very sensitive as there are 3 or 4 piezos contributing to the signal.

For probing with a moving bed in y axis, youll need to use the "pause before probing" setting in your firmware, 0.4sec is usually enough just to allow the bed to come to rest, before each probing dive takes place, the lateral movement of the bed will trigger the z-probe, but so long as you pause briefly before each probe it doesnt matter.

Interested to see how you get on/help, since we don't currently have a solution for i3 style machines, especially the original prusa, maybe it can be adapted under the bed there too.

I just ordered a pack of 20mm piezos so i dont have anything to measure thickness of the probes jet, but i did make a (quick and dirty) bracket model of how i would try to mount it.

I guess gluing one or two washers in the middle of the piezos upper side and a layer of tape between the two printed parts (for adding a sliiiight squishe room) should increase the output current as the piezo will be bent and not pressed?

[www.thingiverse.com]

That "channel" is for the wires.

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 04:41PM |

Registered: 8 years ago Posts: 3,525 |

Yes using washers or similar to create bending will improve sensitivity. Try it without first, you might not need them. What it also does is widen the tuning "window" on the piezo PCB so that you are not balanced on a knife edge between not triggering and triggering if you sneeze somewhere nearby.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 14, 2017 05:06PM |

Registered: 8 years ago Posts: 7 |

|

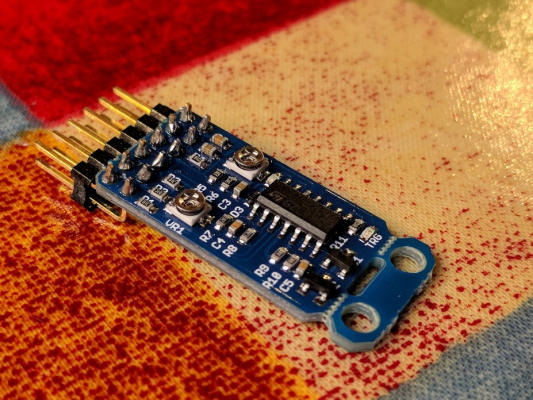

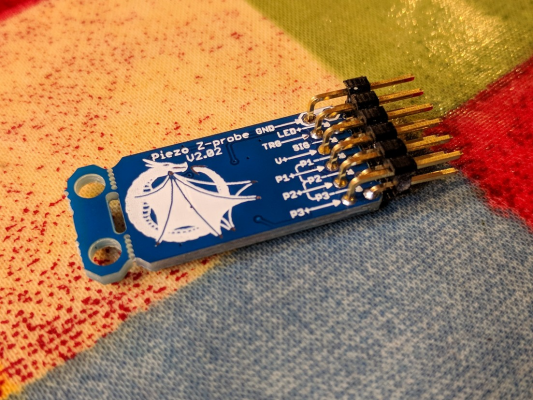

Version 2.02 now available! November 15, 2017 10:01AM |

Registered: 8 years ago Posts: 487 |

Based on user feedback I have made some updates to the v1.22 piezo controller.

Many people asked for mounting holes so I've added two 3mm holes but if you don't need them or you're trying to save space they can be cut or snapped off easily.

A number of people pointed out that and active LOW signal is safer in the event of a broken wire. The new TRG output is an active low signal meaning that the printer should stop rather than crash the bed if you have a loose connection*.

I've added a short delay to the TRG output making it easier to see when the board is triggering.

The new TRG led is normally on and only goes off when triggered meaning you can tell at a glance whether the board has power.

For anybody who doesn't want to use the new features or who cannot use an active LOW signal for any reason, backwards compatibility is available by using the SIG output which behaves in exactly the same way as the output of the old (v1.22) boards.

Let us know what you think.

Idris

* This will fail safe if there is a loose connection between the piezo PCB and the printer controller, it is not yet possible to detect a failure between the piezo disk and the PCB

Edited 1 time(s). Last edit at 11/15/2017 10:08AM by Moriquendi.

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Many people asked for mounting holes so I've added two 3mm holes but if you don't need them or you're trying to save space they can be cut or snapped off easily.

A number of people pointed out that and active LOW signal is safer in the event of a broken wire. The new TRG output is an active low signal meaning that the printer should stop rather than crash the bed if you have a loose connection*.

I've added a short delay to the TRG output making it easier to see when the board is triggering.

The new TRG led is normally on and only goes off when triggered meaning you can tell at a glance whether the board has power.

For anybody who doesn't want to use the new features or who cannot use an active LOW signal for any reason, backwards compatibility is available by using the SIG output which behaves in exactly the same way as the output of the old (v1.22) boards.

Let us know what you think.

Idris

* This will fail safe if there is a loose connection between the piezo PCB and the printer controller, it is not yet possible to detect a failure between the piezo disk and the PCB

Edited 1 time(s). Last edit at 11/15/2017 10:08AM by Moriquendi.

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Version 2.02 now available! November 15, 2017 03:45PM |

Registered: 6 years ago Posts: 21 |

I think the new design makes more sense, I had a bit of trouble to find a place to put mine and ensure is fixed and stable.

Regarding suggestions, I think I read before that you were thinking about replacing the pots with some kind of digital version, so it will be easier to just "program" it instead of playing around with the pots... I think that would be a really amazing improvement... although I'm not sure how much expensive or difficult is going to be.

Sorry for changing a bit the topic, but I'm having an issue and I would like to request your advice, as I'm not sure if I'm doing something wrong.

I have two precisionPiezo boards, one is version 1.21 and the other is version 1.22. I'm currently using the 1.22 board, as I don't know why I had much better results with it (I think I've found the point and I'm now getting stability in my measures), I used to have really good results with the 1.21 board (I've posted them in the duet forum), but the I had some issues with the repeatability that I'm not having with the 1.22 board.

Anyway, I wasn't worried about as I was using just one, and I thought I just didn't find the point as I did with the 1.22, but as I'm now repairing the printer the second board is destined to, I tried to tune the 1.21 board, and I'm not even able to make it detect the touch, so I'm not sure if I'm doing something wrong.

I've set the resistance between VR1 and P3- so it shows ~550 in my tester (quite similar to the value I'm getting in the 1.22), and I'm setting the VR2 quite near the point when the blue light goes on, I've installed it in the same replacing the one that is working (so I'm sure the polarity is OK, the duet is OK and the piezo is working), and I'm not able to detect touch. I've reversed piezo's polarity and no luck either.

Am I doing something wrong? can I try something else? I can record a video if I didn't explain myself correctly

Thanks!

Edited 1 time(s). Last edit at 11/15/2017 03:48PM by okercho.

Regarding suggestions, I think I read before that you were thinking about replacing the pots with some kind of digital version, so it will be easier to just "program" it instead of playing around with the pots... I think that would be a really amazing improvement... although I'm not sure how much expensive or difficult is going to be.

Sorry for changing a bit the topic, but I'm having an issue and I would like to request your advice, as I'm not sure if I'm doing something wrong.

I have two precisionPiezo boards, one is version 1.21 and the other is version 1.22. I'm currently using the 1.22 board, as I don't know why I had much better results with it (I think I've found the point and I'm now getting stability in my measures), I used to have really good results with the 1.21 board (I've posted them in the duet forum), but the I had some issues with the repeatability that I'm not having with the 1.22 board.

Anyway, I wasn't worried about as I was using just one, and I thought I just didn't find the point as I did with the 1.22, but as I'm now repairing the printer the second board is destined to, I tried to tune the 1.21 board, and I'm not even able to make it detect the touch, so I'm not sure if I'm doing something wrong.

I've set the resistance between VR1 and P3- so it shows ~550 in my tester (quite similar to the value I'm getting in the 1.22), and I'm setting the VR2 quite near the point when the blue light goes on, I've installed it in the same replacing the one that is working (so I'm sure the polarity is OK, the duet is OK and the piezo is working), and I'm not able to detect touch. I've reversed piezo's polarity and no luck either.

Am I doing something wrong? can I try something else? I can record a video if I didn't explain myself correctly

Thanks!

Edited 1 time(s). Last edit at 11/15/2017 03:48PM by okercho.

|

Re: Precision Piezo Z-probe Now available. November 15, 2017 04:10PM |

Registered: 8 years ago Posts: 487 |

We are working on a version that does not require manual tuning but it's not a small task.

I'm sorry the board isn't working as it should, can you just confirm that it's the v1.21 board that doesn't work?

My first suggestion would be to check that the wires are soldered onto the piezo properly and that the piezo has no cracks in it.

Are you testing by tapping the piezo directly or is it in a mount/printer?

If you have a spare piezo try that.

Try tuning VR2 as close as possible to the point where the led turns on.

Try turning VR1 gently left and right a little before putting it back in the middle.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

I'm sorry the board isn't working as it should, can you just confirm that it's the v1.21 board that doesn't work?

My first suggestion would be to check that the wires are soldered onto the piezo properly and that the piezo has no cracks in it.

Are you testing by tapping the piezo directly or is it in a mount/printer?

If you have a spare piezo try that.

Try tuning VR2 as close as possible to the point where the led turns on.

Try turning VR1 gently left and right a little before putting it back in the middle.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. November 15, 2017 04:29PM |

Registered: 6 years ago Posts: 17 |

I have a wanhao i3, and (once I get my new printer working properly) I'm planning on experimenting with a mount that sits between the X rails and the z carriage. On mine (which might be unique or typical, really not sure) there is enough compliance in that joint to trigger a piezo.Quote

CaptainHero

Took off the motor and the filament guide part and this is how it looks. I guess technically i may be able to put the sensor somewhere at the black backplate that holds the extruder setup to the x carriage but its quite sturdy setup so i am not sure what good that would do since i don't think the motor would press against the sensor at all when the nozzle touches the plate. I could be mistaken tough but that is my initial reaction looking at this.

Edited 1 time(s). Last edit at 11/15/2017 04:29PM by jebk.

|

Re: Precision Piezo Z-probe Now available. November 15, 2017 04:54PM |

Registered: 6 years ago Posts: 19 |

Quote

jebk

On mine (which might be unique or typical, really not sure) there is enough compliance in that joint to trigger a piezo.

Will be experimenting with mine too around that area but let me know how your tests go and if successfull where exactly you placed the sensor with what kind of adapter if any.

|

Re: Precision Piezo Z-probe Now available. November 15, 2017 05:02PM |

Registered: 6 years ago Posts: 21 |

Quote

Moriquendi

We are working on a version that does not require manual tuning but it's not a small task.

I'm sorry the board isn't working as it should, can you just confirm that it's the v1.21 board that doesn't work?

My first suggestion would be to check that the wires are soldered onto the piezo properly and that the piezo has no cracks in it.

Are you testing by tapping the piezo directly or is it in a mount/printer?

If you have a spare piezo try that.

Try tuning VR2 as close as possible to the point where the led turns on.

Try turning VR1 gently left and right a little before putting it back in the middle.

Idris

Yes, the 1.21 is the one that is not working, and I'm sure the piezo is fine, as I put again the 1.22 board and works perfectly fine

.

.I will try that tomorrow (I'm printing now) and will record a video.

Thanks!

|

Re: Precision Piezo Z-probe Now available. November 16, 2017 05:11PM |

Registered: 7 years ago Posts: 10 |

hello, is it possible to mount it in an effector like this one?

I would like to mount it on a delta printer with bowden.

Thanks!!

Edited 1 time(s). Last edit at 11/16/2017 05:12PM by ESTIMULO.

I would like to mount it on a delta printer with bowden.

Thanks!!

Edited 1 time(s). Last edit at 11/16/2017 05:12PM by ESTIMULO.

|

Re: Precision Piezo Z-probe Now available. November 16, 2017 05:44PM |

Registered: 8 years ago Posts: 3,525 |

You using the groovemount Piezo20 Module and the horseshoe plate that comes with that effector is one way to do it.

If the hole centres on the 6 holes around the filament hole in the centre, are 25mm apart then the screwmount piezo20 will work, and be more stable.

Genuine e3d with micro bowden coupler inside the hotend grooremount will work. Clone e3d with bowden, you'll need to remove the bowden coupler, put ptfe tube between the piezo20 and the hotend, and attach a bowden coupler above it somewhere.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

If the hole centres on the 6 holes around the filament hole in the centre, are 25mm apart then the screwmount piezo20 will work, and be more stable.

Genuine e3d with micro bowden coupler inside the hotend grooremount will work. Clone e3d with bowden, you'll need to remove the bowden coupler, put ptfe tube between the piezo20 and the hotend, and attach a bowden coupler above it somewhere.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 17, 2017 06:45PM |

Registered: 8 years ago Posts: 3,525 |

HI all. Quick question, what are the best bowden tube pneumatic push fit connectors? What do you use, whats the most reliable i.e. does not disconnect etc...?

Thinking about some ideas around making a mk2 Piezo20 module, and would like to have a bowden pushfit as an option above the module with a filament guide below, so that you can connect your bowden tube directly to the module.

Thanks in advance for your advice.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Thinking about some ideas around making a mk2 Piezo20 module, and would like to have a bowden pushfit as an option above the module with a filament guide below, so that you can connect your bowden tube directly to the module.

Thanks in advance for your advice.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. November 18, 2017 08:31AM |

Registered: 10 years ago Posts: 24 |

|

Re: Precision Piezo Z-probe Now available. November 18, 2017 08:35AM |

Registered: 8 years ago Posts: 3,525 |

Thanks we were thinking about using these, how well do we feel they would work inserted into a printed groovemount, rather than the metal of the original hotend? I suppose I can always print one and try it.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.