Precision Piezo Z-probe Now available.

Posted by DjDemonD

|

Re: Precision Piezo Z-probe Now available. January 25, 2018 06:07AM |

Registered: 8 years ago Posts: 487 |

***** Beta Test*****

I need to ask for your help again, we have a number of products and updates in development and I'd like to get some samples into users hands to get some feedback. A few weeks ago we asked for beta testers and that will be going ahead however it has been delayed by Simons unavoidable absence. This beta is for a different prospective product and the requirements are different, nothing to stop someone being involved in both betas.

Ideally I'd like to hear from five people who:

Live in the UK (to keep postage costs down)

Currently use a PP20 module on their printer.

Are able to provide accuracy information like the information that's been posted in this thread previously.

There may be some back and forth with different boards hence wanting to keep postage costs down (postage will be paid by me) but you will end up with a board to keep. You may need to use a different cable to connect to the new board (supplied). I'd like to see it tested on as many different printers as possible, if you use multiple PP20 modules and would be willing to test on different printers that would be ideal.

If you're interested please drop me a PM.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

I need to ask for your help again, we have a number of products and updates in development and I'd like to get some samples into users hands to get some feedback. A few weeks ago we asked for beta testers and that will be going ahead however it has been delayed by Simons unavoidable absence. This beta is for a different prospective product and the requirements are different, nothing to stop someone being involved in both betas.

Ideally I'd like to hear from five people who:

Live in the UK (to keep postage costs down)

Currently use a PP20 module on their printer.

Are able to provide accuracy information like the information that's been posted in this thread previously.

There may be some back and forth with different boards hence wanting to keep postage costs down (postage will be paid by me) but you will end up with a board to keep. You may need to use a different cable to connect to the new board (supplied). I'd like to see it tested on as many different printers as possible, if you use multiple PP20 modules and would be willing to test on different printers that would be ideal.

If you're interested please drop me a PM.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. January 25, 2018 10:55AM |

Registered: 8 years ago Posts: 3,525 |

Yes little update on the first beta test, we will be getting that underway in the next few weeks. This is a separate product from the second beta test that Idris has posted above.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. January 25, 2018 01:31PM |

Registered: 8 years ago Posts: 3,525 |

We are now in a peer reviewed journal

[www.mdpi.com]

Huge congratulations to Mike (leadinglights) who did almost all of the work.

The reason for doing this was primarily to ensure that this idea cannot be patented later by commercial interests as this is prior art under the current copyright legislation.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

[www.mdpi.com]

Huge congratulations to Mike (leadinglights) who did almost all of the work.

The reason for doing this was primarily to ensure that this idea cannot be patented later by commercial interests as this is prior art under the current copyright legislation.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. January 27, 2018 04:45PM |

Registered: 8 years ago Posts: 34 |

I used this when I tuned the amplifier [www.instructables.com]

|

Re: Precision Piezo Z-probe Now available. January 27, 2018 08:24PM |

Registered: 6 years ago Posts: 2 |

Do any of you have a mounting suggestion (or even a finished model) for the E3D chimera? I've been trying on and off to come up with a proper piezo mount of this for quite some time now but apart from some overcomplicated lever mechanisms I'm not really getting anywhere.

|

Re: Precision Piezo Z-probe Now available. January 28, 2018 04:56AM |

Registered: 8 years ago Posts: 487 |

Quote

ulope

Do any of you have a mounting suggestion (or even a finished model) for the E3D chimera? I've been trying on and off to come up with a proper piezo mount of this for quite some time now but apart from some overcomplicated lever mechanisms I'm not really getting anywhere.

What kind of printer are you trying to mount it on?

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. January 28, 2018 02:29PM |

Registered: 6 years ago Posts: 2 |

|

Re: Precision Piezo Z-probe Now available. January 28, 2018 03:33PM |

Registered: 8 years ago Posts: 34 |

When I do a M48 and the hotend fan is on I get descent(good) results like

Finished!

Mean: 0.017850 Min: 0.011 Max: 0.021 Range: 0.010

Standard Deviation: 0.004587

but when the fan is of i get terrific results

Finished!

Mean: 0.010843 Min: 0.011 Max: 0.011 Range: 0.000

Standard Deviation: 0.000000

I have this activated

#define PROBING_HEATERS_OFF // Turn heaters off when probing

#define PROBING_FANS_OFF // Turn fans off when probing

#define DELAY_BEFORE_PROBING 600 // (ms) To prevent vibrations from triggering piezo sensors

Is the fan generating electricity or is it that it is unbalanced ?

Finished!

Mean: 0.017850 Min: 0.011 Max: 0.021 Range: 0.010

Standard Deviation: 0.004587

but when the fan is of i get terrific results

Finished!

Mean: 0.010843 Min: 0.011 Max: 0.011 Range: 0.000

Standard Deviation: 0.000000

I have this activated

#define PROBING_HEATERS_OFF // Turn heaters off when probing

#define PROBING_FANS_OFF // Turn fans off when probing

#define DELAY_BEFORE_PROBING 600 // (ms) To prevent vibrations from triggering piezo sensors

Is the fan generating electricity or is it that it is unbalanced ?

|

Re: Precision Piezo Z-probe Now available. January 28, 2018 05:06PM |

Registered: 8 years ago Posts: 487 |

Quote

ulope

It's an i3 clone / frankenstein.

Currently I have Chimera mounted via the three holes on the top of the cooler block.

If you do a search for Precision Piezo on thingiverse you'll find lots of different brackets for different printers and hotends which should give your some ideas of things that have been tried and proven, even if they're not for your printer. One advantage of piezo sensing being so sensitive is that the amount of movement required is very small, so small that you can frequently replace separate hinges and levers with single piece mounts provided you engineer flex in the right locations, take a look at my titan mount to see what I'm talking about.

Quote

Nitram

Is the fan generating electricity or is it that it is unbalanced ?

It is plausible that vibration is causing the poorer results when the fan is on, other possibilities are electromagnetic interference if the piezo disk or its wires are very close to the fan motor or noise in the power supply caused by the fan.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. January 29, 2018 04:55AM |

Registered: 6 years ago Posts: 9 |

|

Re: Precision Piezo Z-probe Now available. January 29, 2018 08:14AM |

Registered: 6 years ago Posts: 22 |

Quote

Moriquendi

Best of luck but I think you'll have difficulty drilling four holes in the ceramic of a 27mm piezo. If you can't get it to work you might try using smaller, undrilled, piezos glued to a sheet of some kind with holes drilled in the sheet. I've had success with 10.5 and 12mm piezos glued or soldered to pcbs.

Idris

So I was able to drill the 4 holes trought 27mm piezo...

But I have another problem with m558 P8 or P5 or P1 (all of them, so I think the problem is from my implementation.)

If I touch the hot end with my finger, it triggers, but if I touch the with a spatula, I can tap, or simply push, it won't trigger.

My piezo disk is fixed between my effector and the heatsink.

Should the Piezo disk be isolated form the heatsink (with Kapton?)?

In the piezo20 parts, The piezo is bent when the hotend triggers, is that necessary? I assumed it was to increase the sensitivity of the piezo...

|

Re: Precision Piezo Z-probe Now available. January 29, 2018 08:22AM |

Registered: 8 years ago Posts: 487 |

I would definitely suggest insulating the piezo from the heatsink. Most likely the reason it will trigger with your finger but not the spatula is that the capacitance of your finger/body is triggering the circuit, not the piezo. If you are finding it takes too much force to cause a trigger it's always worth reversing the polarity of the piezo to see whether that helps.

In the PP20 the piezo is bent because it is supported around the rim and pressed only in the center, this causes the piezo to bend and this type of piezo produces a much larger signal in response to bending than to direct pressure.

Idris

Edited 1 time(s). Last edit at 01/29/2018 08:24AM by Moriquendi.

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

In the PP20 the piezo is bent because it is supported around the rim and pressed only in the center, this causes the piezo to bend and this type of piezo produces a much larger signal in response to bending than to direct pressure.

Idris

Edited 1 time(s). Last edit at 01/29/2018 08:24AM by Moriquendi.

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. January 30, 2018 03:08AM |

Registered: 6 years ago Posts: 22 |

I listened to your advice...

I put some kapton tape around the piezo.

I drilled it (the kapton allows you to reduce the destruction of the PZT)

If you're trying to drill something fragile, put some tape on it. It's a common tip from fiberglass polyester industry.

I slide the disk between the heatsink and the effector, and Voilà

It worked nicely !

Thank you for this simple and easy way to make a Zprobe. I used a switch, a IR probe and finally, the precision-piezo probe. It's a very nice project. I can't go back, the piezo probe is just the right tool for me.

Is there any limitation for the length of the piezo wires?(I've got a Universal kit and I would like to reduce the number of components on the hotend...)

I understand that with the longer cable there is more risks of noise. Is there some reduced sensitivity too?

Edited 1 time(s). Last edit at 01/30/2018 05:24AM by tech-raton.

I put some kapton tape around the piezo.

I drilled it (the kapton allows you to reduce the destruction of the PZT)

If you're trying to drill something fragile, put some tape on it. It's a common tip from fiberglass polyester industry.

I slide the disk between the heatsink and the effector, and Voilà

It worked nicely !

Thank you for this simple and easy way to make a Zprobe. I used a switch, a IR probe and finally, the precision-piezo probe. It's a very nice project. I can't go back, the piezo probe is just the right tool for me.

Is there any limitation for the length of the piezo wires?(I've got a Universal kit and I would like to reduce the number of components on the hotend...)

I understand that with the longer cable there is more risks of noise. Is there some reduced sensitivity too?

Edited 1 time(s). Last edit at 01/30/2018 05:24AM by tech-raton.

|

Re: Precision Piezo Z-probe Now available. January 30, 2018 05:12AM |

Registered: 8 years ago Posts: 487 |

That's useful to know, I might try that.Quote

tech-raton

I put some kapton tape around the piezo.

I drilled it (the kapton allows you to reduce the destruction of the PZT)

I'm very glad you're pleased with itQuote

tech-raton

It worked nicely !

Thank you for this simple and easy way to make a Zprobe. I used a switch, a IR probe and finally, the precision-piezo probe. It's a very nice project. I can't go back, the piezo probe is just the right tool for me.

This is a bit of an unknown, shorter is always better but how long you can make the wires before you have problems I don't know, and it's probably different for every machine. I'd suggest trying a longer cable and testing it, one of our customers used shielded wires with the shield grounded, I think he found it helped.Quote

tech-raton

Is there any limitation for the length of the piezo wires?(I've got a Universal kit and I would like to reduce the number of components on the hotend...)

I understand that with the longer cable there is more risks of noise. Is there some reduced sensitivity too?

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. January 30, 2018 01:04PM |

Registered: 6 years ago Posts: 54 |

|

Re: Precision Piezo Z-probe Now available. January 31, 2018 01:56AM |

Registered: 6 years ago Posts: 22 |

I tried with a long cable (2m) and I worked.

I'll be using a shorter cable (1m so it should be ok.)

My cable to the effector contains 8 wires Now

4 for the heater

2 for the thermistor

2 for the piezo disk. It should be ok, then.

Before, it contained 11 wires

2 for the heater

2 for the thermistor

2 for the heatsink fan

2 for the parts fan

3 for the IR probe.

Thank you for your time, it's very cool to have a product with nice support.

I like this way of thinking.

Opensource and nice support are the best way. in my opinion.

Oh, and the dragon with shiny parts on the universal piezo 2 is a very nice touch !

I'll be using a shorter cable (1m so it should be ok.)

My cable to the effector contains 8 wires Now

4 for the heater

2 for the thermistor

2 for the piezo disk. It should be ok, then.

Before, it contained 11 wires

2 for the heater

2 for the thermistor

2 for the heatsink fan

2 for the parts fan

3 for the IR probe.

Thank you for your time, it's very cool to have a product with nice support.

I like this way of thinking.

Opensource and nice support are the best way. in my opinion.

Oh, and the dragon with shiny parts on the universal piezo 2 is a very nice touch !

|

Re: Precision Piezo Z-probe Now available. January 31, 2018 04:19AM |

Registered: 8 years ago Posts: 487 |

If it works for you that's great but with a cable that long, if you have problems with random triggers in the future that's where I'd look first.

We do our best with the trouble shooting and support, it's nice to know it's appreciated.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

We do our best with the trouble shooting and support, it's nice to know it's appreciated.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. February 03, 2018 12:55PM |

Registered: 6 years ago Posts: 22 |

I had some trigger problems...

so, based on your experience, I put back the PCB on the effector.

And I changed my piezo mount...

Now there are 3 piezo15 between the hotend and the effector...

And it works nicely...

Edited 1 time(s). Last edit at 02/03/2018 12:56PM by tech-raton.

so, based on your experience, I put back the PCB on the effector.

And I changed my piezo mount...

Now there are 3 piezo15 between the hotend and the effector...

And it works nicely...

Edited 1 time(s). Last edit at 02/03/2018 12:56PM by tech-raton.

|

Re: Precision Piezo Z-probe Now available. February 03, 2018 01:07PM |

Registered: 8 years ago Posts: 487 |

Looks good, what kind of repeatability are you getting?

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. February 03, 2018 03:07PM |

Registered: 6 years ago Posts: 22 |

I can't really mesure the repeatability...

mechanically, my printer isn't optimum.

But, if you wan't, I can give you the files to test it...

I reduced the quality to be able to send it via the forum.

tech-raton

Edited 1 time(s). Last edit at 02/03/2018 03:13PM by tech-raton.

mechanically, my printer isn't optimum.

But, if you wan't, I can give you the files to test it...

I reduced the quality to be able to send it via the forum.

tech-raton

Edited 1 time(s). Last edit at 02/03/2018 03:13PM by tech-raton.

|

Re: Precision Piezo Z-probe Now available. February 04, 2018 09:13AM |

Registered: 8 years ago Posts: 487 |

We test repeatability by calling G30 from a couple of millimetres off the bed and recording the reading, we take ~20 readings and calculate the range and standard deviation

Unfortunately my printer doesn't allow me to easily test groovemount systems but thanks for sharing the files. I'm using a completely integrated piezo effector to reclaim the lost Z-height that comes from mounting the heatsink below the effector.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Unfortunately my printer doesn't allow me to easily test groovemount systems but thanks for sharing the files. I'm using a completely integrated piezo effector to reclaim the lost Z-height that comes from mounting the heatsink below the effector.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. February 04, 2018 11:01AM |

Registered: 6 years ago Posts: 22 |

ok,

So I create a Macro with:

g30 S-1

G1 Z3

G30 S-1

G1 Z3

I think it's repeatable, no?

Or maybe there's something wrong with my macro...

So I create a Macro with:

g30 S-1

G1 Z3

G30 S-1

G1 Z3

I think it's repeatable, no?

Or maybe there's something wrong with my macro...

Quote

16:57:40

Stopped at height -0.035 mm

16:57:38

Stopped at height -0.035 mm

16:57:37

Stopped at height -0.035 mm

16:57:36

Stopped at height -0.035 mm

16:57:35

Stopped at height -0.035 mm

16:57:34

Stopped at height -0.035 mm

16:57:33

Stopped at height -0.035 mm

16:57:32

Stopped at height -0.035 mm

16:57:31

Stopped at height -0.035 mm

16:57:30

Stopped at height -0.035 mm

16:57:28

Stopped at height -0.035 mm

16:57:27

Stopped at height -0.035 mm

16:57:26

Stopped at height -0.035 mm

16:57:25

Stopped at height -0.035 mm

16:57:24

Stopped at height -0.035 mm

16:57:23

Stopped at height -0.035 mm

16:57:22

Stopped at height -0.035 mm

16:57:21

Stopped at height -0.035 mm

16:57:19

Stopped at height -0.035 mm

16:57:18

Stopped at height -0.035 mm

16:57:17

Stopped at height -0.035 mm

16:57:16

Stopped at height -0.035 mm

16:57:15

Stopped at height -0.035 mm

16:57:14

Stopped at height -0.035 mm

16:57:13

Stopped at height -0.035 mm

16:57:12

Stopped at height -0.035 mm

16:57:11

M98 P0:/macros/macor

Stopped at height -0.035 mm

|

Re: Precision Piezo Z-probe Now available. February 04, 2018 12:41PM |

Registered: 8 years ago Posts: 487 |

That seems to be working perfectly, you've got 26 probes that triggered at exactly the same place so your range and standard deviation are 0. In reality there probably is some variation but the firmware is probably reporting in 5 micron increments. Still, better than 5 micron repeatability is outstanding.

Have you printed with it yet?

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Have you printed with it yet?

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. February 04, 2018 02:53PM |

Registered: 6 years ago Posts: 22 |

|

Re: Precision Piezo Z-probe Now available. February 06, 2018 09:53AM |

Registered: 11 years ago Posts: 528 |

|

Re: Precision Piezo Z-probe Now available. February 06, 2018 10:13AM |

Registered: 8 years ago Posts: 3,525 |

Sweet! I hadn't seen this  I love a bit of mechanical stress.

I love a bit of mechanical stress.

Edited 1 time(s). Last edit at 02/06/2018 10:13AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I love a bit of mechanical stress.

I love a bit of mechanical stress.Edited 1 time(s). Last edit at 02/06/2018 10:13AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. February 12, 2018 04:27PM |

Registered: 8 years ago Posts: 3,525 |

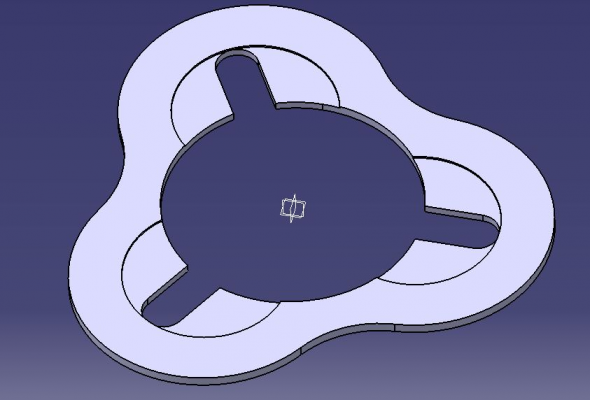

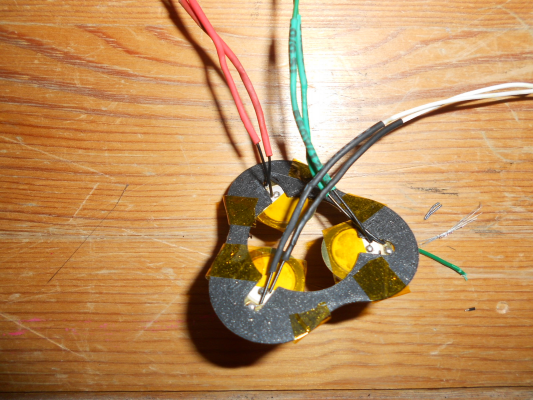

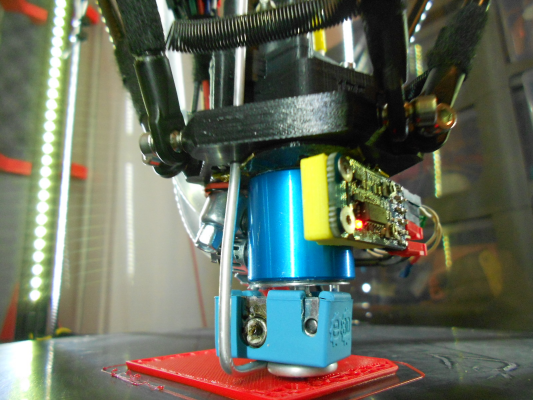

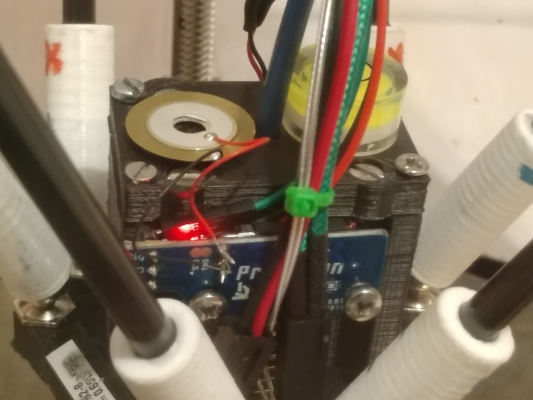

Okay so over in the delta forum section I have been building a delta in a cylinder with screw driven tower axes [forums.reprap.org]. It's a bit of a noisy machine mechanically, so when I tried to do some probing using the Piezo20 unit I integrated into this new effector [www.thingiverse.com] I was getting a lot of false triggers even when trying to lower the sensitivity as much as possible. So Olampe suggested, quite brilliantly, why not add another piezo to cancel noise?

So I did.

What I've done here is to get another drilled 20mm piezo disc, as I figured I'd want about the same amount of piezo ceramic in the noise cancelling piezo as in the sensor (which is a piezo20 below inside the effector). It would need to be either reversed in orientation, which is it, the piezo in the piezo20 unit faces the other way ceramic side down (you could just reverse the polarity of the leads), then I've connected it in parallel to the piezo20 PCB shown. I soldered it on here to the header pins, as it was easier than removing the 2 pin plug and recrimping it. If you keep the disc orientated the same way connect it in parallel but black to red, red to black instead. Bonded the second piezo onto the top of the effector, its important that this is is in the same orientation/plane as the "sensor" piezo below. It is important to bond it securely as you need every little vibration to transmit through it, don't stick it on with blutak!

Then I've been probing away at normal speed. I was using 300mm/min - 5mm/s probing speed with temporary z acceleration at just 5mm/s, now I'm using 500mm/min (8.5mms) probing speed and z acceleration set to 100mm/s. With perfect, and repeatable results.

In theory, whats happening is that the second noise-cancelling piezo generates voltage (noise) as the effector moves i.e. the mechanical noise, the sensor piezo generates the inverse voltage (noise) when the mechanical noise causes it, these cancel each other out, as the noise-cancelling piezo is facing the other direction from the sensor-piezo, the result is that when the sensor piezo is deformed by the nozzle hitting the bed, all that is left is just the genuine signal as the sensor piezo is deformed but the noise cancelling piezo is not.

I reorientated the noise-cancelling piezo (at Idris' request, to validate the idea) to 90 degrees to the effector and the performance was just as bad as before it was attached. So it seems to be a real effect. Also, XY movements will not allow this cancellation to occur and they still trigger the sensor (not that it matters as it's not probing during XY moves).

So for the experimental amongst you who have noisy machines and have been struggling this approach might help. You need an equal surface area of piezo ceramic for your noise cancelling piezos, so if you have 1 drilled, you need 1 more drilled, 3 undrilled needs 3 undrilled. Bond them to your carriage, or effector to which your piezo sensor is attached, ensuring they are lying in the same orientation as the sensor piezo/s, the easiest arrangement is with the noise cancelling piezo facing the other way to your sensor piezos. Now attach all the leads red to red and black to black in parallel and attach them to your piezo PCB. No retuning is required. We would love to hear if it works for you. Its a very exciting new way to use this tech.

I think we should call it the Olampe Balanced Piezo concept, unless the man himself would like to suggest a different name

Edited 9 time(s). Last edit at 02/13/2018 08:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So I did.

What I've done here is to get another drilled 20mm piezo disc, as I figured I'd want about the same amount of piezo ceramic in the noise cancelling piezo as in the sensor (which is a piezo20 below inside the effector). It would need to be either reversed in orientation, which is it, the piezo in the piezo20 unit faces the other way ceramic side down (you could just reverse the polarity of the leads), then I've connected it in parallel to the piezo20 PCB shown. I soldered it on here to the header pins, as it was easier than removing the 2 pin plug and recrimping it. If you keep the disc orientated the same way connect it in parallel but black to red, red to black instead. Bonded the second piezo onto the top of the effector, its important that this is is in the same orientation/plane as the "sensor" piezo below. It is important to bond it securely as you need every little vibration to transmit through it, don't stick it on with blutak!

Then I've been probing away at normal speed. I was using 300mm/min - 5mm/s probing speed with temporary z acceleration at just 5mm/s, now I'm using 500mm/min (8.5mms) probing speed and z acceleration set to 100mm/s. With perfect, and repeatable results.

In theory, whats happening is that the second noise-cancelling piezo generates voltage (noise) as the effector moves i.e. the mechanical noise, the sensor piezo generates the inverse voltage (noise) when the mechanical noise causes it, these cancel each other out, as the noise-cancelling piezo is facing the other direction from the sensor-piezo, the result is that when the sensor piezo is deformed by the nozzle hitting the bed, all that is left is just the genuine signal as the sensor piezo is deformed but the noise cancelling piezo is not.

I reorientated the noise-cancelling piezo (at Idris' request, to validate the idea) to 90 degrees to the effector and the performance was just as bad as before it was attached. So it seems to be a real effect. Also, XY movements will not allow this cancellation to occur and they still trigger the sensor (not that it matters as it's not probing during XY moves).

So for the experimental amongst you who have noisy machines and have been struggling this approach might help. You need an equal surface area of piezo ceramic for your noise cancelling piezos, so if you have 1 drilled, you need 1 more drilled, 3 undrilled needs 3 undrilled. Bond them to your carriage, or effector to which your piezo sensor is attached, ensuring they are lying in the same orientation as the sensor piezo/s, the easiest arrangement is with the noise cancelling piezo facing the other way to your sensor piezos. Now attach all the leads red to red and black to black in parallel and attach them to your piezo PCB. No retuning is required. We would love to hear if it works for you. Its a very exciting new way to use this tech.

I think we should call it the Olampe Balanced Piezo concept, unless the man himself would like to suggest a different name

Edited 9 time(s). Last edit at 02/13/2018 08:55AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Precision Piezo Z-probe Now available. February 13, 2018 02:36AM |

Registered: 6 years ago Posts: 60 |

|

Re: Precision Piezo Z-probe Now available. February 13, 2018 02:51AM |

Registered: 8 years ago Posts: 5,232 |

Quote

I think we should call it the Olampe Balanced Piezo concept, unless the man himself would like to suggest a different name

The inverted noise reduction is not my idea. AFAIK, it is common practice for active noise dampers. Audi even tried to build exhausts with this technic, IIRC.

I'm surprised it was so easy to implement without any OpAmp, although I'm wondering why you didn't put the piezos in series? But then again, IDK the Piezo circuit.

|

Re: Precision Piezo Z-probe Now available. February 13, 2018 03:42AM |

Registered: 8 years ago Posts: 3,525 |

I can certainly try it in series, I'm going to attempt further validation of this technique on my corexy, where a setup with underbed piezos just did not work despite much effort at the time. What do you see as the benefit of doing so?

It was easy to implement as there is only one direction in which the noise needs to be eliminated (vertically since it is irrelevant laterally) and the noise must be present within the unit in which the piezo sensor sits. So bonding the piezo onto the effector transmits the noise to it equally compared to the sensor-piezo and they cancel out as the PZT ceramic is polarised in this direction.

Edited 1 time(s). Last edit at 02/13/2018 03:42AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

It was easy to implement as there is only one direction in which the noise needs to be eliminated (vertically since it is irrelevant laterally) and the noise must be present within the unit in which the piezo sensor sits. So bonding the piezo onto the effector transmits the noise to it equally compared to the sensor-piezo and they cancel out as the PZT ceramic is polarised in this direction.

Edited 1 time(s). Last edit at 02/13/2018 03:42AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.