|

Re: Precision Piezo Z-probe Now available. November 11, 2019 06:31AM |

Registered: 12 years ago Posts: 1,450 |

Quote

MKSA

Quote

whosrdaddy

Underbed sensing is really only suitable for stationary beds (think Delta's). You can always put a piezo between the carriage and hotend assembly.

Works flawlessly on my P3 steel :

Suitable ? How ?.

For Delta, DC42 has a neat solution, a Wheastone bridge of strain gauges integrated in the effector.

DC42s Smart Effector is indeed a good solution - I see that SeMeCNCs Rostock printers now use an almost identical method with strain gauge traces etched into the PCB.

Having said that, most of the Z sensors have strengths and weaknesses - even the BL Touch has the advantage of being something which is quick to attach and accurate - with the downside of offsets in X, Y and Z. The only sensor technology that I have investigated and completely discounted is the use of accelerometers - even though this was the prefered method on some Rostock printers.

The only significant problem with underbed piezo sensors is that each user is re-inventing the wheel in the mounting of the sensors. There are many good ways of mounting the sensors, but very many more bad ways doing it.

Mike

|

Re: Precision Piezo Z-probe Now available. November 12, 2019 12:51PM |

Registered: 8 years ago Posts: 487 |

The Andromeda is best suited to stationary beds but it can be made to work with beds that move. What you will find is that, if your bed moves in Z, you will need to reduce the jerk to 0, and keep acceleration very low to avoid the inertia of the bed triggering the sensor when the bed begins to move. This becomes more pronounced as the mass of the bed increases.

It's difficult to produce a generic under bed solution that will work for lots of printers because, unlike hotend mounting, there's no standard way of mounting a heat bed. The Andromeda is my attempt to make it easier.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

It's difficult to produce a generic under bed solution that will work for lots of printers because, unlike hotend mounting, there's no standard way of mounting a heat bed. The Andromeda is my attempt to make it easier.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. November 12, 2019 03:08PM |

Registered: 6 years ago Posts: 60 |

Quote

MKSA

Quote

whosrdaddy

Underbed sensing is really only suitable for stationary beds (think Delta's). You can always put a piezo between the carriage and hotend assembly.

Works flawlessly on my P3 steel :

Suitable ? How ?.

For Delta, DC42 has a neat solution, a Wheastone bridge of strain gauges integrated in the effector.

Hi MKSA,

I don't understand your comment?

I was only saying that underbed piezo sensing is very difficult on a moving bed. (And it seems leadinglights might have a solution for that

)

)I know the smart effector but that was not my point...

|

Re: Precision Piezo Z-probe Now available. November 13, 2019 02:41AM |

Registered: 6 years ago Posts: 1,007 |

Quote

whosrdaddy

Hi MKSA,

I don't understand your comment?

I was only saying that underbed piezo sensing is very difficult on a moving bed. (And it seems leadinglights might have a solution for that)

I know the smart effector but that was not my point...

Explain how and why you find this system (when it works) suitable for a 3D printer ? Simpler, better, proven solutions exist.

Of course, for a Cartesian, the simple way to go is to build it properly. Better eliminate a problem than solve it isn't ?.

A sensor mounted in the carriage will make the Z0 limit switch and adjustment unnecessary. Just a plus, not a necessity.

Edited 1 time(s). Last edit at 11/13/2019 02:43AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Precision Piezo Z-probe Now available. November 13, 2019 11:26AM |

Registered: 6 years ago Posts: 60 |

|

Re: Precision Piezo Z-probe Now available. November 16, 2019 07:05AM |

Registered: 4 years ago Posts: 4 |

|

Re: Precision Piezo Z-probe Now available. November 16, 2019 01:47PM |

Admin Registered: 11 years ago Posts: 3,096 |

I really, really love the idea of being able to use the piezo since it essentially uses the nozzle tip as a probe. This technique seems to be praised as being the 'best' solution so far on many different blogs. There is one thing I'm mainly interested in, and that is: are there good effectors for Delta printers available that make use of this piezo technique? I am interested in the latest Orion module but I'm having difficulty with the implementation of the part.

Honestly, I think a custom effector carriage would be better than designing a carriage that would allow to fit the Orion probe being sold 'as is'. Are there any files available from which I can pull the sizes for such a carriage so I can design my own and is the warranty void when I put the piezo module into my custom designed effector?

http://www.marinusdebeer.nl/

Honestly, I think a custom effector carriage would be better than designing a carriage that would allow to fit the Orion probe being sold 'as is'. Are there any files available from which I can pull the sizes for such a carriage so I can design my own and is the warranty void when I put the piezo module into my custom designed effector?

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. November 16, 2019 02:13PM |

Registered: 6 years ago Posts: 1,007 |

Quote

Ohmarinus

I really, really love the idea of being able to use the piezo since it essentially uses the nozzle tip as a probe. This technique seems to be praised as being the 'best' solution so far on many different blogs. There is one thing I'm mainly interested in, and that is: are there good effectors for Delta printers available that make use of this piezo technique? I am interested in the latest Orion module but I'm having difficulty with the implementation of the part.

Honestly, I think a custom effector carriage would be better than designing a carriage that would allow to fit the Orion probe being sold 'as is'. Are there any files available from which I can pull the sizes for such a carriage so I can design my own and is the warranty void when I put the piezo module into my custom designed effector?

For a Delta I consider DC42 effector using a bridge of strain gauges to be the best solution.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Precision Piezo Z-probe Now available. November 16, 2019 03:17PM |

Registered: 12 years ago Posts: 1,450 |

Quote

Ohmarinus

I really, really love the idea of being able to use the piezo since it essentially uses the nozzle tip as a probe. This technique seems to be praised as being the 'best' solution so far on many different blogs. There is one thing I'm mainly interested in, and that is: are there good effectors for Delta printers available that make use of this piezo technique? I am interested in the latest Orion module but I'm having difficulty with the implementation of the part.

Honestly, I think a custom effector carriage would be better than designing a carriage that would allow to fit the Orion probe being sold 'as is'. Are there any files available from which I can pull the sizes for such a carriage so I can design my own and is the warranty void when I put the piezo module into my custom designed effector?

If the problem is that DC42s smart effector has a different size to what you need, you could try something like this [reprap.org]

It should work well with a Precision Piezo conditioner board.

Mike

|

Re: Precision Piezo Z-probe Now available. November 18, 2019 12:25PM |

Registered: 8 years ago Posts: 487 |

@Chris54,

Yes, I have a product nearing release that does this, I've been using it for months now with great success.

@Ohmarinus,

Many people have used the Orion on delta machines, go to thingiverse and search for "piezo Orion" you should find plenty. You'll find models of the standard Orion parts on thingiverse here. Alternatively, I can see ways to use the Andromeda sensors to produce a custom effector that wouldn't waste so much Z-height. Or you can use underbed sensors, either bare disks or Andromeda sensors.

@MKSA,

Have you used any of my products on a delta machine?

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Yes, I have a product nearing release that does this, I've been using it for months now with great success.

@Ohmarinus,

Many people have used the Orion on delta machines, go to thingiverse and search for "piezo Orion" you should find plenty. You'll find models of the standard Orion parts on thingiverse here. Alternatively, I can see ways to use the Andromeda sensors to produce a custom effector that wouldn't waste so much Z-height. Or you can use underbed sensors, either bare disks or Andromeda sensors.

@MKSA,

Have you used any of my products on a delta machine?

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. November 20, 2019 05:54AM |

Registered: 7 years ago Posts: 154 |

I have two deltas with Piezos as under bed sensors. Work perfectly since more than two years

[reprap.org]

[reprap.org]

|

Re: Precision Piezo Z-probe Now available. November 20, 2019 06:09PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Dancer

I have two deltas with Piezos as under bed sensors. Work perfectly since more than two years

[reprap.org]

Looks interesting, however, with my current setup I am hitting sub 0.02 deviation every time. Usually in the 0.012 ~ 0.016 range. So I don't really feel I would need anything better right now that I realize how good my current setup is already working.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. November 27, 2019 01:47AM |

Registered: 5 years ago Posts: 60 |

Stepping up on a soap box to vent my frustrations:

I am about to toss my Orion Piezo setup. I just can't deal with the random errors any more.

A bit of background - I am running a CR10-S5 printer with a E3D Chimera dual extruder running volcano hot ends and I have been tweaking this setup for close to a year now. I have tried different mounts, different pizo versions, differently tweaked mounting screw tension til I was blue in my face but I have not been able to achieve consistency.

The sensor is EXTREMELY sensitive which is great but possibly due to the large mass of the hot end and the solid brass volcano heater blocks, I have to do all my calibration moves at a painfully slow speed lest I get a false trigger.

Despite trying to decouple the bowden tubes from the printhead, if I so much as look at the bowden tube I get a trigger event. The bowden tube is supposed to go into the Chimera heat sink and seat against the bottom of the heatsink against the heat break. I have a gap to prevent the bowden tube pushing on the hot end and this gap causes loading of filament to be extremely frustrating. Even though the fitting that captures the bowden tube rides on the fixed end of the mount and not the part that moves when a touch event happens, still it triggers.

Despite the obvious high sensitivity, some areas of the large 500*500 print bed end up being pushed down enough during probing that I can see it happening. Other areas just barely touch.

I did a lot of tweaking today and thought I had achieved nirvana . I set up the printer to repeatedly measure a certain point on the build plate (10 measurements without moving x or y) and got to the point where the nozzle would barely touch the build surface and trigger very reliably with height values all being within +- 0.003mm. I was ecstatic ... until I tried to run a 4 point bed leveling (at the corners). One corner might measure well, another might require enough pressure to move the bed and yet another triggered before the nozzle touched the bed.

Even if I got all the compromised just right, there were occasional hiccups and I ended up having to do multiple probes on the same point in order to weed out bad data.

I have been close to tossing the piezo for a BlTouch before but the convenience of measuring through the nozzle and not having to calibrate probe height offset for virtually any operation was enough of a carrot for me to keep trying. Alas, it is driving me insane and I can't deal with it any longer.

If you are still with me, I thank you for listening to my rant.

I am about to toss my Orion Piezo setup. I just can't deal with the random errors any more.

A bit of background - I am running a CR10-S5 printer with a E3D Chimera dual extruder running volcano hot ends and I have been tweaking this setup for close to a year now. I have tried different mounts, different pizo versions, differently tweaked mounting screw tension til I was blue in my face but I have not been able to achieve consistency.

The sensor is EXTREMELY sensitive which is great but possibly due to the large mass of the hot end and the solid brass volcano heater blocks, I have to do all my calibration moves at a painfully slow speed lest I get a false trigger.

Despite trying to decouple the bowden tubes from the printhead, if I so much as look at the bowden tube I get a trigger event. The bowden tube is supposed to go into the Chimera heat sink and seat against the bottom of the heatsink against the heat break. I have a gap to prevent the bowden tube pushing on the hot end and this gap causes loading of filament to be extremely frustrating. Even though the fitting that captures the bowden tube rides on the fixed end of the mount and not the part that moves when a touch event happens, still it triggers.

Despite the obvious high sensitivity, some areas of the large 500*500 print bed end up being pushed down enough during probing that I can see it happening. Other areas just barely touch.

I did a lot of tweaking today and thought I had achieved nirvana . I set up the printer to repeatedly measure a certain point on the build plate (10 measurements without moving x or y) and got to the point where the nozzle would barely touch the build surface and trigger very reliably with height values all being within +- 0.003mm. I was ecstatic ... until I tried to run a 4 point bed leveling (at the corners). One corner might measure well, another might require enough pressure to move the bed and yet another triggered before the nozzle touched the bed.

Even if I got all the compromised just right, there were occasional hiccups and I ended up having to do multiple probes on the same point in order to weed out bad data.

I have been close to tossing the piezo for a BlTouch before but the convenience of measuring through the nozzle and not having to calibrate probe height offset for virtually any operation was enough of a carrot for me to keep trying. Alas, it is driving me insane and I can't deal with it any longer.

If you are still with me, I thank you for listening to my rant.

|

Re: Precision Piezo Z-probe Now available. November 27, 2019 03:03AM |

Admin Registered: 11 years ago Posts: 3,096 |

Since you're not using a Delta I'd say a BLtouch would work fine. And you only have to configure the z-offset once. Depending on where you live, I'd happily buy the 2nd hand piezo probe from you since I'm running a Delta printer and I don't feel like buying anything new anymore. This machine has cost me too much.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. November 27, 2019 03:16AM |

Registered: 5 years ago Posts: 60 |

I am not sure how you figure that the z offset only needs setting up once. You need to enter the height difference between the probe trigger point relative to the nozzle tip. This figure changes every time you pull the nozzle to clean it. It changes if you adjust the nozzle height which is independently adjustable for the two nozzles on a Chimera setup.

I am in Canada but I think that for now I will hang on to the piezo units (I have two older version Orions and two newer versions) until I can confirm that the BlTouch setup is more reliable. I have heard many stories about lower accuracy.

I am in Canada but I think that for now I will hang on to the piezo units (I have two older version Orions and two newer versions) until I can confirm that the BlTouch setup is more reliable. I have heard many stories about lower accuracy.

|

Re: Precision Piezo Z-probe Now available. December 03, 2019 01:17PM |

Registered: 4 years ago Posts: 1 |

Hi guys, I'm using the Piezo Orion on a E3D V6 setup with a bowden extruder and it works really well.

Now I ordered an E3D Hemera and I want to use the Orion with that. Is there any chance to make it work? Maybe use the Orion vertically between the Hemera and it's mounting plate to detect the touch on the build plate?

Any pointers on what I can do are welcomed.

Now I ordered an E3D Hemera and I want to use the Orion with that. Is there any chance to make it work? Maybe use the Orion vertically between the Hemera and it's mounting plate to detect the touch on the build plate?

Any pointers on what I can do are welcomed.

|

Re: Precision Piezo Z-probe Now available. December 04, 2019 11:50PM |

Registered: 4 years ago Posts: 6 |

PrecisionPiezo v2 PCB not triggering z endstop on my RAMBO board when running g28 command. The hotend will proceed until it digs into the bed.

Running Marlin 1.1.9.34 firmware.

Piezo board plugged into z min endstop pins and powered on. These are the same pins that work to trigger a z min on the RAMBO board / Marlin firmware when a mechanical endstop is plugged into them.

M119 shows all end stops open when piezo board connected just like it does when mechanical endstop plugged in.

Red light turns blue on piezo board when I manually tap the nozzle, but hotend does not stop moving down when blue light triggered during g28 or g30 commands.

When I connect John's fsr board to same z min endstop pins and manually push on fsr the z min endstop is triggered during g28 and g30 commands, but piezo board does not trigger z min endstop when it is connected and I compress the piezo.

Any suggestions to get the piezo system running correctly are appreciated.

Edited 1 time(s). Last edit at 12/05/2019 07:37AM by inventabuild.

Running Marlin 1.1.9.34 firmware.

Piezo board plugged into z min endstop pins and powered on. These are the same pins that work to trigger a z min on the RAMBO board / Marlin firmware when a mechanical endstop is plugged into them.

M119 shows all end stops open when piezo board connected just like it does when mechanical endstop plugged in.

Red light turns blue on piezo board when I manually tap the nozzle, but hotend does not stop moving down when blue light triggered during g28 or g30 commands.

When I connect John's fsr board to same z min endstop pins and manually push on fsr the z min endstop is triggered during g28 and g30 commands, but piezo board does not trigger z min endstop when it is connected and I compress the piezo.

Any suggestions to get the piezo system running correctly are appreciated.

Edited 1 time(s). Last edit at 12/05/2019 07:37AM by inventabuild.

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 12:46AM |

Registered: 5 years ago Posts: 5 |

Quote

jens53

Quote

ryan99alero

There were area's that would spike up and move around with multiple probe attempts. I have been tweaking and getting those reduced. I finally finished designing new fan guides that will also hold the BL Touch so I can compare probing system's map results.

I too see odd bumps and stuff. Not only that but there are odd patterns to the bumps. In any case, please be sure to post your results of the BlTouch comparison. I am very much looking forward to those comparisons.

I have attached a screen shot of my height map.

Sorry for it taking so long to get back about results. WIth work, vacations and my OEM Duet2 board going south. It took me some time to get everything up and going again. I'm happy yet disappointed to say the BLTouch is way better compared to the Piezo setup I had in my configuration. I don't have all the fluctuations between readings like I did with the under bed Piezo setup. I really wanted to go the Piezo route as I think it offers up a better way to get consistency for actual clearance between bed and the print head. Especially if you change print heads. Only thing I could think of is if I maybe installed 4 more Piezo's or once I get my Slice heads and new rail system installed I can build a solution that puts the piezo under the head mount vs on the bed. Then maybe it'd be consistent. But from my tests the underbed Piezo system with 4 sensors setup on a 300mm square bed just don't work.

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 01:18AM |

Registered: 5 years ago Posts: 60 |

Interesting that you should be posting your results now (thanks btw) .... I have just switched over from an Orion piezo setup to a BLTouch setup and am running tests.

I too would have preferred the piezo setup but for whatever reasons, I could not get the probing force required to be consistent and as a result the measurements were not consistent.

I was hoping to get away from the slow probing speed and the multiple probing requirement with the BLTouch but have found that I needed the exact same setup with slow probing, multiple probes per location and settling time between probes.

I have also found that the probing accuracy of the BLTouch is not as good as the piezo probe. This is mainly visible when one point is probed multiple times. It is completely hidden once you start moving the head as all kinds of other errors drown the errors of multiple probings.

My take-away of the switch is that neither probing procedure is satisfactory but they both are as good as it gets. I suspect that other issues (printer build quality) get in the way of things.

I am happier having my print nozzle rigid rather than it flopping (compliant is more appropriate I guess) about. That is the one most disappointing thing about the piezo system ... that things need to be able to move. The example mounts that suggest being able to fully tighten the screws between the two sides that hold the piezo sensor is misleading. When you think about it, it makes sense that things need to be able to move but when I first looked into piezo sensors, the implications of that movement were not clear to me.

I too would have preferred the piezo setup but for whatever reasons, I could not get the probing force required to be consistent and as a result the measurements were not consistent.

I was hoping to get away from the slow probing speed and the multiple probing requirement with the BLTouch but have found that I needed the exact same setup with slow probing, multiple probes per location and settling time between probes.

I have also found that the probing accuracy of the BLTouch is not as good as the piezo probe. This is mainly visible when one point is probed multiple times. It is completely hidden once you start moving the head as all kinds of other errors drown the errors of multiple probings.

My take-away of the switch is that neither probing procedure is satisfactory but they both are as good as it gets. I suspect that other issues (printer build quality) get in the way of things.

I am happier having my print nozzle rigid rather than it flopping (compliant is more appropriate I guess) about. That is the one most disappointing thing about the piezo system ... that things need to be able to move. The example mounts that suggest being able to fully tighten the screws between the two sides that hold the piezo sensor is misleading. When you think about it, it makes sense that things need to be able to move but when I first looked into piezo sensors, the implications of that movement were not clear to me.

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 02:44AM |

Admin Registered: 11 years ago Posts: 3,096 |

I see so many solutions. Right now I have ordered a piezoelectric disc that you can mount temporarily under the tip of the hotend. My idea is to do a really good bed leveling program and then save the mesh because the delta shouldn't really change much in between prints. When it's done I can take off the disc and just print without it. I'll probably have to level it every once in a while but for me this feels like the best solution.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 02:54AM |

Registered: 5 years ago Posts: 60 |

Quote

Ohmarinus

I see so many solutions. Right now I have ordered a piezoelectric disc that you can mount temporarily under the tip of the hotend. My idea is to do a really good bed leveling program and then save the mesh because the delta shouldn't really change much in between prints. When it's done I can take off the disc and just print without it. I'll probably have to level it every once in a while but for me this feels like the best solution.

Can you elaborate how this mount would look like ?

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 04:02AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

jens53

Quote

Ohmarinus

I see so many solutions. Right now I have ordered a piezoelectric disc that you can mount temporarily under the tip of the hotend. My idea is to do a really good bed leveling program and then save the mesh because the delta shouldn't really change much in between prints. When it's done I can take off the disc and just print without it. I'll probably have to level it every once in a while but for me this feels like the best solution.

Can you elaborate how this mount would look like ?

It's this one:

[youtu.be]

Edited 1 time(s). Last edit at 12/05/2019 04:02AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 04:19AM |

Registered: 5 years ago Posts: 60 |

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 07:52AM |

Registered: 8 years ago Posts: 487 |

@Ohmarinus,

That's not actually a piezo sensor at all, it's an FSR, a force sensitive resistor, they are much more delicate than piezo disks and not as accurate.

I hear what you guys are saying about underbed piezos, from my experience it can be harder to get consistent, good, probing. This has only got harder as people start mounting heavier and larger beds on their printers. My Andromeda product was an attempt to improve the situation.

Another point that I think is worth mentioning is that piezo probing is perhaps more dependent on the rigidity of the printer than other technologies, eg BLtouch as you're probing through more mass, whether that's the hotend assembly or the bed.

@Jens53,

The amount of movement of the nozzle should be very very small, less than one microstep. If your nozzle has more movement than than then something is wrong.

Any mechanical nozzle probe technology is going to require dome degree of movement of the nozzle, the Orion PCB and mounting parts are designed to minimise this, I have not seen any system that uses the nozzle as the probe that has less movement than piezos.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

That's not actually a piezo sensor at all, it's an FSR, a force sensitive resistor, they are much more delicate than piezo disks and not as accurate.

I hear what you guys are saying about underbed piezos, from my experience it can be harder to get consistent, good, probing. This has only got harder as people start mounting heavier and larger beds on their printers. My Andromeda product was an attempt to improve the situation.

Another point that I think is worth mentioning is that piezo probing is perhaps more dependent on the rigidity of the printer than other technologies, eg BLtouch as you're probing through more mass, whether that's the hotend assembly or the bed.

@Jens53,

The amount of movement of the nozzle should be very very small, less than one microstep. If your nozzle has more movement than than then something is wrong.

Any mechanical nozzle probe technology is going to require dome degree of movement of the nozzle, the Orion PCB and mounting parts are designed to minimise this, I have not seen any system that uses the nozzle as the probe that has less movement than piezos.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 08:14AM |

Registered: 5 years ago Posts: 60 |

Quote

Moriquendi

The amount of movement of the nozzle should be very very small, less than one microstep. If your nozzle has more movement than than then something is wrong.

Any mechanical nozzle probe technology is going to require dome degree of movement of the nozzle, the Orion PCB and mounting parts are designed to minimise this, I have not seen any system that uses the nozzle as the probe that has less movement than piezos.

Idris

I had MUCH more play there and I tweaked the mounting screws until I was ready to do some serious harm to the world in general

I also tried different mounts. The up/down play may not have been visible but the sideways play was easily 0.5 to 1 mm. Mounting screws were around 3/4 to a full turn loosened after they were lightly tightened up.

I have not given up on the piezo setup but needed a break from it. My setup, a CR10-S5, has a lot of mass compared to the mechanical members used and I was using a Chimera arrangement with dual copper volcano hot ends so there was a fair bit of mass. As mentioned, the biggest issue was the probing force required (hence going to the BLTouch). I could tweak things for a few grams on one spot but then get visually obvious bed and gantry deflection from much higher probing forces at a different spot.

Oh, I could easily get a trigger out of the system by looking at it sideways ... extremely sensitive .... but that didn't translate into less probing force for reasons that were beyond me.

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 08:37AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Moriquendi

@Ohmarinus,

That's not actually a piezo sensor at all, it's an FSR, a force sensitive resistor, they are much more delicate than piezo disks and not as accurate.

Idris

Okay, even though it is not a piezo, I wouldn't dismiss this design because it has been proven to be accurate enough.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 10:11AM |

Registered: 12 years ago Posts: 1,450 |

I think I may be able to offer some possible reasons why your piezos may be playing up. These are only speculations and it may be something entirely different: Like the little girl in the nursery rhyme, when piezos are good they are very very good; but when they are bad they are horrid.

Warning, this may be Too Long Did Not Read, it was damn near Too Long Did Not Write.

I have used piezos on all of my printers and they have been remarkably consistent, but I have come across the occasional anomaly. The most recent problem is instructive. This was on an underbed setup using three piezos built into the bed leveling jacks and the problem was found during trials of a new conditioning circuit.

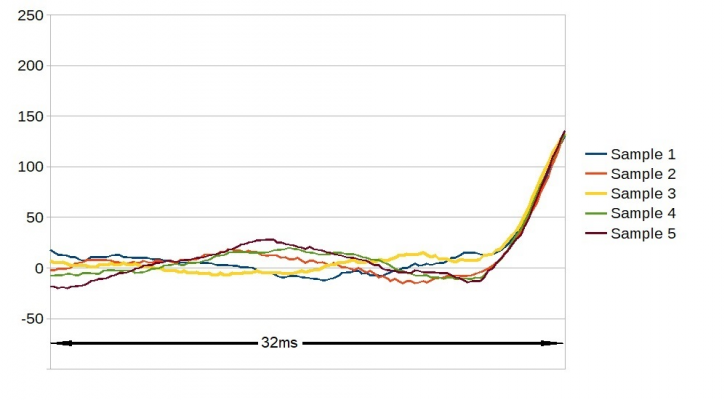

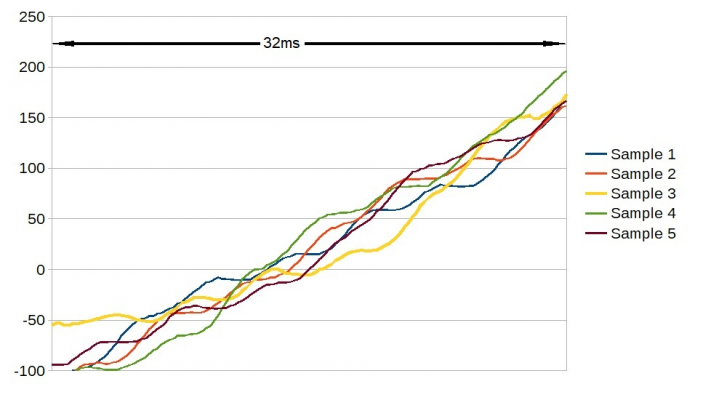

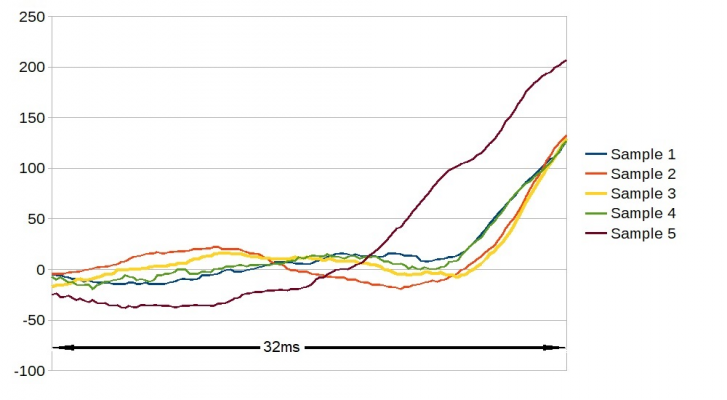

The plots below were taken directly from the buffer memory of the conditioning microcontroller. The first set of five plots show the contact of the nozzle with the bed at 3mm per second in the middle of the bed. A good contact occurs if the line between the Y value of 48 and 128 is clean and has no significant bend - in this case, the conditioner gives a green light. The problem occurred on only one corner of the bed at 2mm per second where I consistently did not get a green light. The plots from the microcontroller buffer were also very strange, as seen in the second plot.

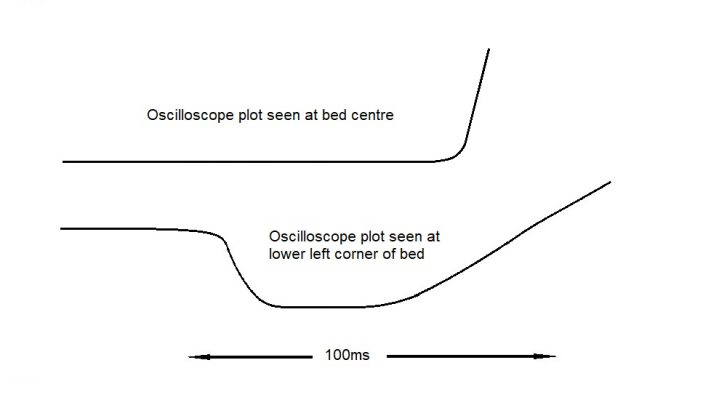

Viewing the output from the piezo discs on an oscilloscope I got the same plot for each of the three sensors. I tried tapping with a fingernail, tapping with a fingertip, pushing down with a finger and dropping an 8mm steel ball from 10mm. In each case, the plot was sensibly as expected for all three sensors. With the nozzle making contact with the middle of the bed at 2mm per second the oscilloscope showed what was expected, a baseline with a sharply upward rise at the moment of contact. The first clue came when looking at an oscilloscope trace at the corner: Initially, the plot went down before rising - at very much the sort of rate shown in the earlier plot. The drawings below are from memory as I hadn't set up the scope to record.

When I took the piezo sensor assembly apart I found that I had assembled the pressure pad quite off-centre of the piezo disk. My excuse is that the pad and disk are not visible when being assembled and something slipped without me noticing it.

As to why the off-centre pressure pad gave such a peculiar output I can only speculate. I do know that it is possible for the output from a piezo disk put under pressure to be the opposite to what it is when bent - obvious when you think about it. Possibly the disk was being driven into the Kapton film that was under it so bent slightly before giving a pressure output - the thickness of a Kapton film with the adhesive is about 60 µm which is a lot in the world of piezo disks.

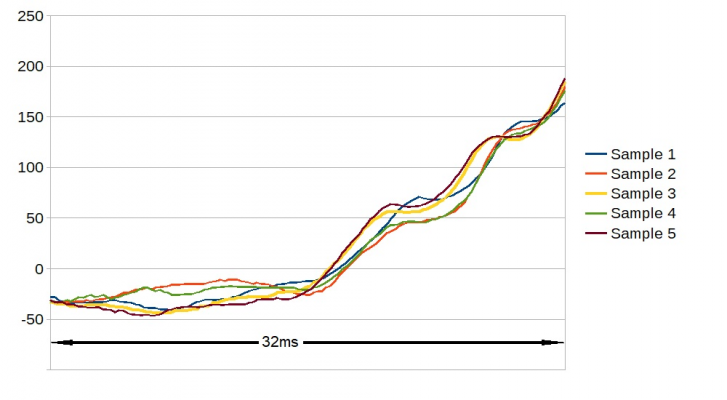

On the last point, I have attached two pictures, the first showing the nozzle bouncing on the bare metal bed at 2mm per second while the second shows that a Kapton film was enough to almost totally dampen the bounce with 4 out of 5 good contacts recorded - 60 µm is indeed a long distance in piezoland. Also notable is that the bounce gives rise to the possibility of the trigger point being found on different bounces each time.

Mike

Edited 2 time(s). Last edit at 12/05/2019 10:13AM by leadinglights.

Warning, this may be Too Long Did Not Read, it was damn near Too Long Did Not Write.

I have used piezos on all of my printers and they have been remarkably consistent, but I have come across the occasional anomaly. The most recent problem is instructive. This was on an underbed setup using three piezos built into the bed leveling jacks and the problem was found during trials of a new conditioning circuit.

The plots below were taken directly from the buffer memory of the conditioning microcontroller. The first set of five plots show the contact of the nozzle with the bed at 3mm per second in the middle of the bed. A good contact occurs if the line between the Y value of 48 and 128 is clean and has no significant bend - in this case, the conditioner gives a green light. The problem occurred on only one corner of the bed at 2mm per second where I consistently did not get a green light. The plots from the microcontroller buffer were also very strange, as seen in the second plot.

Viewing the output from the piezo discs on an oscilloscope I got the same plot for each of the three sensors. I tried tapping with a fingernail, tapping with a fingertip, pushing down with a finger and dropping an 8mm steel ball from 10mm. In each case, the plot was sensibly as expected for all three sensors. With the nozzle making contact with the middle of the bed at 2mm per second the oscilloscope showed what was expected, a baseline with a sharply upward rise at the moment of contact. The first clue came when looking at an oscilloscope trace at the corner: Initially, the plot went down before rising - at very much the sort of rate shown in the earlier plot. The drawings below are from memory as I hadn't set up the scope to record.

When I took the piezo sensor assembly apart I found that I had assembled the pressure pad quite off-centre of the piezo disk. My excuse is that the pad and disk are not visible when being assembled and something slipped without me noticing it.

As to why the off-centre pressure pad gave such a peculiar output I can only speculate. I do know that it is possible for the output from a piezo disk put under pressure to be the opposite to what it is when bent - obvious when you think about it. Possibly the disk was being driven into the Kapton film that was under it so bent slightly before giving a pressure output - the thickness of a Kapton film with the adhesive is about 60 µm which is a lot in the world of piezo disks.

On the last point, I have attached two pictures, the first showing the nozzle bouncing on the bare metal bed at 2mm per second while the second shows that a Kapton film was enough to almost totally dampen the bounce with 4 out of 5 good contacts recorded - 60 µm is indeed a long distance in piezoland. Also notable is that the bounce gives rise to the possibility of the trigger point being found on different bounces each time.

Mike

Edited 2 time(s). Last edit at 12/05/2019 10:13AM by leadinglights.

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 10:53AM |

Registered: 5 years ago Posts: 60 |

Interesting .... the very first plot is what I would expect to see. The second plot seems to represent what I suspect is going on.

I do not own anything that would enable me to grab data of this nature. It certainly would have been interesting to see what my data would have looked like. Alas, for now the BLTouch is it.

In my case, off center mounting of the disk was not possible and it was a nozzle sensor rather than a bed sensor.

I do not own anything that would enable me to grab data of this nature. It certainly would have been interesting to see what my data would have looked like. Alas, for now the BLTouch is it.

In my case, off center mounting of the disk was not possible and it was a nozzle sensor rather than a bed sensor.

|

Re: Precision Piezo Z-probe Now available. December 05, 2019 12:16PM |

Registered: 6 years ago Posts: 110 |

|

Re: Precision Piezo Z-probe Now available. December 06, 2019 11:27AM |

Registered: 6 years ago Posts: 22 |

Sorry, only registered users may post in this forum.