LokBuild, first impressions

Posted by o_lampe

|

LokBuild, first impressions May 18, 2017 12:56PM |

Registered: 8 years ago Posts: 5,232 |

I got a 12" sheet of the new(ish) LokBuild printbed surface.

It is pretty thin: 0.65mm measured with protection foil on the back. That's actually good news, because I can still use my 12mm inductive proximity sensor

It can be cut with standard scissors and it's easy to apply on the printbed.

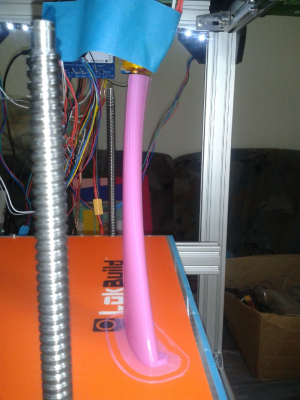

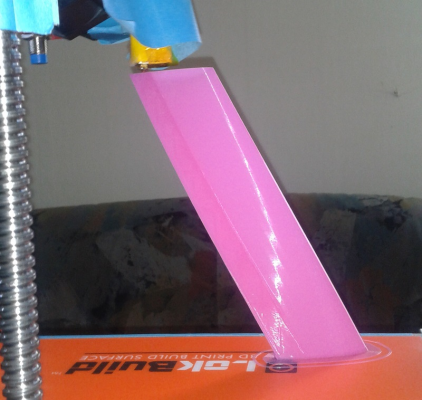

After some testprints to find the new nozzle height, I tried the ultimate test: a 220mm tall airfoil of a vertical windmill, which has a very small footprint.

PLA@205°C on a cold bed. Even the solid tip worked out pretty good. I expected the worst....

Sorry for the color, it looks a bit too "fleshy" for my liking...

I also made a short video, to demonstrate first layer adhesion.

I'm pretty happy with it. I'll make a warping test and also some ABS-parts later.

It is pretty thin: 0.65mm measured with protection foil on the back. That's actually good news, because I can still use my 12mm inductive proximity sensor

It can be cut with standard scissors and it's easy to apply on the printbed.

After some testprints to find the new nozzle height, I tried the ultimate test: a 220mm tall airfoil of a vertical windmill, which has a very small footprint.

PLA@205°C on a cold bed. Even the solid tip worked out pretty good. I expected the worst....

Sorry for the color, it looks a bit too "fleshy" for my liking...

I also made a short video, to demonstrate first layer adhesion.

I'm pretty happy with it. I'll make a warping test and also some ABS-parts later.

|

Re: LokBuild, first impressions May 18, 2017 02:20PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: LokBuild, first impressions May 18, 2017 04:51PM |

Registered: 9 years ago Posts: 59 |

|

Re: LokBuild, first impressions May 18, 2017 05:05PM |

Registered: 8 years ago Posts: 3,525 |

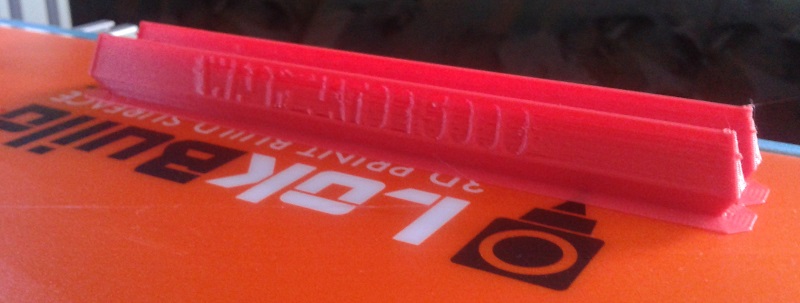

That's quite a good test part. Though I'd consider the ultimate to be the Warpinator 5000 in ABS. Printed one on Printbite no warping. Would be very keen to see if it can be printed on Lokbuild.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: LokBuild, first impressions May 18, 2017 07:47PM |

Registered: 8 years ago Posts: 601 |

Any comparisons to other bed materials like Printbite, PEI etc?

As a comparison I can print a part like that on printbite. I printed a 60mm tube, 2mm wall thickness angled at 45 degrees the other day that was at least 100mm in height.

Lokbuild certainly looks interesting, although its a shame about the colour and the massive logo. My printers isn't winning an award for prettiness any time soon but I'd rather it wasn't a billboard

Edited 1 time(s). Last edit at 05/18/2017 07:49PM by Origamib.

As a comparison I can print a part like that on printbite. I printed a 60mm tube, 2mm wall thickness angled at 45 degrees the other day that was at least 100mm in height.

Lokbuild certainly looks interesting, although its a shame about the colour and the massive logo. My printers isn't winning an award for prettiness any time soon but I'd rather it wasn't a billboard

Edited 1 time(s). Last edit at 05/18/2017 07:49PM by Origamib.

|

Re: LokBuild, first impressions May 19, 2017 05:41AM |

Registered: 8 years ago Posts: 5,232 |

The PLA part was printed at 24°C roomtemp.

The warpinator failed the 1st time, but with part-fan off and a 6mm brim it worked perfect. Only the high skirt had to be taped down.

Maybe I test it again with a smaller brim and without skirt. The main reason for the failure was the part-fan 50% on.

I can only compare it to blue tape and it's a huge leap forward. I have a 300x100 strip of LokBuild I can test on my Prusa-bed, which isn't as flat as the cast aluminum tooling plate.

I like the orange colour, since it's the official colour from my friends in The Netherlands.

Edited 1 time(s). Last edit at 05/19/2017 05:43AM by o_lampe.

The warpinator failed the 1st time, but with part-fan off and a 6mm brim it worked perfect. Only the high skirt had to be taped down.

Maybe I test it again with a smaller brim and without skirt. The main reason for the failure was the part-fan 50% on.

I can only compare it to blue tape and it's a huge leap forward. I have a 300x100 strip of LokBuild I can test on my Prusa-bed, which isn't as flat as the cast aluminum tooling plate.

I like the orange colour, since it's the official colour from my friends in The Netherlands.

Edited 1 time(s). Last edit at 05/19/2017 05:43AM by o_lampe.

|

Re: LokBuild, first impressions May 19, 2017 06:06AM |

Registered: 8 years ago Posts: 3,525 |

Yeah the warpinator is tricky, it needs to be printed without a brim to be considered technically successful. But fair play for having a go.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: LokBuild, first impressions May 20, 2017 01:48PM |

Registered: 8 years ago Posts: 5,232 |

A few more details about PLA:

1st layer temp should be high (~210°C) and it helps when the bed is ~30°C for the first layer. I was able to speed up 1st layer from 25mm/s to 50mm/s.

Vase mode or single wall parts are more difficult to remove. We can still use blue tape, when top-adhesion is not important.

Edited 1 time(s). Last edit at 05/20/2017 01:53PM by o_lampe.

1st layer temp should be high (~210°C) and it helps when the bed is ~30°C for the first layer. I was able to speed up 1st layer from 25mm/s to 50mm/s.

Vase mode or single wall parts are more difficult to remove. We can still use blue tape, when top-adhesion is not important.

Edited 1 time(s). Last edit at 05/20/2017 01:53PM by o_lampe.

|

Re: LokBuild, first impressions May 22, 2017 07:18AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: LokBuild, first impressions May 22, 2017 07:31AM |

Registered: 8 years ago Posts: 3,525 |

Yeah I find a good 200mm purge when changing filaments is definitely a good idea, with a "warm" pull beforehand, to clear any debris. So LokBuild seems to be shaping up then? How well do parts release? At what temperatures?

I recently tried a sample of 3mm PEI and I printed some ABS onto it with my usual settings 250 first layer bed at 115 and it bonded to it so well I had to cut it off, ruined the PEI sheet. So that stuff works but IMO far too well. Might definitely keep a thin (cheap) sheet for when you absolutely, positively have to get a part to stick no matter what but doesn't seem as convenient for me as Printbite which with a thin ABS wash every now and again holds parts really well and importantly releases them predictably and at a sensible temperature so as not to slow the workflow down too much.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I recently tried a sample of 3mm PEI and I printed some ABS onto it with my usual settings 250 first layer bed at 115 and it bonded to it so well I had to cut it off, ruined the PEI sheet. So that stuff works but IMO far too well. Might definitely keep a thin (cheap) sheet for when you absolutely, positively have to get a part to stick no matter what but doesn't seem as convenient for me as Printbite which with a thin ABS wash every now and again holds parts really well and importantly releases them predictably and at a sensible temperature so as not to slow the workflow down too much.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: LokBuild, first impressions May 22, 2017 11:19PM |

Registered: 7 years ago Posts: 16 |

|

Re: LokBuild, first impressions May 23, 2017 02:03AM |

Registered: 8 years ago Posts: 5,232 |

PLA and PETG can be removed immediately after the print. I ripped off the bottom of a single wall vase, though better be careful.

ABS needs to cool down and removes easier, after you reheat it to 50-60°C.

If I had to build the print bed again, I'd mill a small maze into the tooling plate to be able to pump some coolant right underneath the surface to shorten cooling time. ( liquidcooled hotbed so to speak )

ABS needs to cool down and removes easier, after you reheat it to 50-60°C.

If I had to build the print bed again, I'd mill a small maze into the tooling plate to be able to pump some coolant right underneath the surface to shorten cooling time. ( liquidcooled hotbed so to speak )

|

Re: LokBuild, first impressions May 23, 2017 03:51AM |

Registered: 8 years ago Posts: 3,525 |

Quote

Traveler0612

I have found that PEI lets go of ABS easily if you let it drop to 60 degrees Celsius first. On a rare occasion, I might need to gently slide a razor blade under the edge. PEI is the best surface I have used to date.

Well this stuff I was trying must have been something different then, even completely cold the part was welded to it. I literally had to saw it off the plate.

Love the idea of a liquid cooled build plate, but I think having two removable beds, one can be put in the freezer while you print on the other one, makes a lot of sense.

Edited 1 time(s). Last edit at 05/23/2017 03:52AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: LokBuild, first impressions May 23, 2017 10:27PM |

Registered: 7 years ago Posts: 16 |

|

Re: LokBuild, first impressions May 25, 2017 12:42PM |

Registered: 8 years ago Posts: 3,525 |

I think that whilst lokbuild and printbite are discreet products Pei comes from a wide range of sources and I'm willing to bet is quite variable.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: LokBuild, first impressions May 25, 2017 04:47PM |

Registered: 8 years ago Posts: 601 |

Quote

DjDemonD

I think that whilst lokbuild and printbite are discreet products Pei comes from a wide range of sources and I'm willing to bet is quite variable.

Sounds about right... It's also known as Ultem (its product name) and they make hundreds of variations for specific applications

|

Re: LokBuild, first impressions May 25, 2017 09:49PM |

Registered: 7 years ago Posts: 619 |

This sounds great. Consistent "stick" is definitely the holy grail.

But nothing lasts forever, damage is a given, especially if you end up using a razor, etc to pry something off the bed. How easy is it to get LokBuild off of the bed?

I have a heated aluminum plate, which has hot spots that cause me issues on occasion - I have been planning on putting a glass plate on top to smooth out the temperature gradients. I wonder if you can put this on glass and still get it off again...

Thanks for the report out!

DLC

But nothing lasts forever, damage is a given, especially if you end up using a razor, etc to pry something off the bed. How easy is it to get LokBuild off of the bed?

I have a heated aluminum plate, which has hot spots that cause me issues on occasion - I have been planning on putting a glass plate on top to smooth out the temperature gradients. I wonder if you can put this on glass and still get it off again...

Thanks for the report out!

DLC

|

Re: LokBuild, first impressions May 26, 2017 02:20AM |

Registered: 8 years ago Posts: 5,232 |

You could put in on glass too and it is only 0.65mm thick, so chances are you can remove it from a thick glass plate. But a glass plate wouldn't even out the temp gradients very well.

The tape on the back of LokBuild isn't marked or branded and also the homepage doesn't specify it. So removing it will lead to a problem: finding the right tape. We know that PEI sticks to almost nothing. Let's hope LokBuild works with the already proven 3M-tapes.

Edited 1 time(s). Last edit at 05/26/2017 02:21AM by o_lampe.

The tape on the back of LokBuild isn't marked or branded and also the homepage doesn't specify it. So removing it will lead to a problem: finding the right tape. We know that PEI sticks to almost nothing. Let's hope LokBuild works with the already proven 3M-tapes.

Edited 1 time(s). Last edit at 05/26/2017 02:21AM by o_lampe.

|

Re: LokBuild, first impressions May 26, 2017 09:39AM |

Registered: 8 years ago Posts: 916 |

Quote

DjDemonD

I recently tried a sample of 3mm PEI and I printed some ABS onto it with my usual settings 250 first layer bed at 115 and it bonded to it so well I had to cut it off, ruined the PEI sheet. So that stuff works but IMO far too well. Might definitely keep a thin (cheap) sheet for when you absolutely, positively have to get a part to stick no matter what but doesn't seem as convenient for me as Printbite which with a thin ABS wash every now and again holds parts really well and importantly releases them predictably and at a sensible temperature so as not to slow the workflow down too much.

The nice thing about PEI is that the adhesion can be tuned by using bed temperature. I find 105/100 or so to work quite well for ABS. You're way too high at 115, and at that temperature you'll get lower wall cave-in, which is why I prefer PEI to PrintBite, at least for printing ABS.

I recently took possession of a Robox Dual, which has a "PEI" build plate. I say it in inverted quotes, because it looks for all the world like fibreglass. Perhaps it's a thin layer of PEI on a fibreglass substrate.

Prints stick well at temperature, but then literally fall off when it gets down to 50 degrees. My other printers with PEI have the parts stuck to them even at room temperature. Perhaps this PEI is shinier or something.

|

Re: LokBuild, first impressions August 04, 2017 02:05AM |

Registered: 11 years ago Posts: 1,592 |

Quote: The nice thing about PEI is that the adhesion can be tuned by using bed temperature. I find 105/100 or so to work quite well for ABS. You're way too high at 115, and at that temperature you'll get lower wall cave-in, which is why I prefer PEI to PrintBite, at least for printing ABS. Unquote

I can attest to this having recently purchased some PEI sheet myself. I found that after setting the bed temp to 105C and hotend to 230C - (my normal settings for ABS), I had extreme difficulty removing the printed part ( a 55mm diameter vac hose adaptor).

My next test (a ~3" lathe gear) was printed at the same hotend temp but bed dropped to 95C. Part was still stuck well but was a bit easier to remove. Seems to prove Nebbians experience of the bed temp being the important variable. I have not harmed the print surface as yet - which is very "glassy".

I'm well satisfied with the parts I've printed thus far but I shall continue with some tweaks to see what the best settings are. I may "sand" the other sheet with some 1500 or 2000 grit wet n dry to see how that performs. Incidentally, the PEI sheet I purchased is 0.8mm thick plus whatever the supplied sticky backed sheet is and was around US$26 for 2 sheets. I stuck the first sheet to my glass build plate.

_______________________________________

Waitaki 3D Printer

I can attest to this having recently purchased some PEI sheet myself. I found that after setting the bed temp to 105C and hotend to 230C - (my normal settings for ABS), I had extreme difficulty removing the printed part ( a 55mm diameter vac hose adaptor).

My next test (a ~3" lathe gear) was printed at the same hotend temp but bed dropped to 95C. Part was still stuck well but was a bit easier to remove. Seems to prove Nebbians experience of the bed temp being the important variable. I have not harmed the print surface as yet - which is very "glassy".

I'm well satisfied with the parts I've printed thus far but I shall continue with some tweaks to see what the best settings are. I may "sand" the other sheet with some 1500 or 2000 grit wet n dry to see how that performs. Incidentally, the PEI sheet I purchased is 0.8mm thick plus whatever the supplied sticky backed sheet is and was around US$26 for 2 sheets. I stuck the first sheet to my glass build plate.

_______________________________________

Waitaki 3D Printer

|

Re: LokBuild, first impressions August 04, 2017 11:41PM |

Registered: 9 years ago Posts: 425 |

Different things work for different people, different products/settings/environments. One of the largest variances (aside from infill, perimeters etc) is the composition of the plastics, and is rarely mentioned or considered in comments about print surfaces.

PEI functions on the basis of a slight mechanical fusing of deposited plastic onto the PEI surface, the combined thermoplastics will momentarily go above the Tg point as hot nozzle deposits molten material onto the PEI surface that is already heated someway toward the Tg of the bed material. This is evident by the need to mechanically persuade the finished part to detach from the PEI surface irrespective of the material printed.

PrintBite works in a different way without that mechanical fusing, evident in the way parts will self release during cooldown.

ABS of one brand/colour, can perform far differently to that from another manufacturer. A good example of this is ABS-X which will adhere solidly to PrintBite at 90/95c bed temp whereas another ABS may require 110/115. The extent of other phenomena is also dependant on more than just bed temperatures.

To add further, there are numerous additives available for ABS to alter its behaviour in different ways, from changing its odour, mechanical hardness, shrinkage, to changing its resistance to scratching or altering its flow properties (critical for filament production), additives to even influencing how well a pigment will mix with the plastic. Often these additives include other thermoplastics in themselves such as PE PP etc, and so ABS is rarely "pure" ABS

It is horses for courses and the range of choice out there gives people the opportunity to select what works best for them or most suits their personal preference, given the variables that are often beyond the scope of general consideration relating to print surfaces.

Choice is good.

Just food for thought.

Edited 1 time(s). Last edit at 08/05/2017 12:20AM by Mutley3D.

Flex3Drive.com

PEI functions on the basis of a slight mechanical fusing of deposited plastic onto the PEI surface, the combined thermoplastics will momentarily go above the Tg point as hot nozzle deposits molten material onto the PEI surface that is already heated someway toward the Tg of the bed material. This is evident by the need to mechanically persuade the finished part to detach from the PEI surface irrespective of the material printed.

PrintBite works in a different way without that mechanical fusing, evident in the way parts will self release during cooldown.

ABS of one brand/colour, can perform far differently to that from another manufacturer. A good example of this is ABS-X which will adhere solidly to PrintBite at 90/95c bed temp whereas another ABS may require 110/115. The extent of other phenomena is also dependant on more than just bed temperatures.

To add further, there are numerous additives available for ABS to alter its behaviour in different ways, from changing its odour, mechanical hardness, shrinkage, to changing its resistance to scratching or altering its flow properties (critical for filament production), additives to even influencing how well a pigment will mix with the plastic. Often these additives include other thermoplastics in themselves such as PE PP etc, and so ABS is rarely "pure" ABS

It is horses for courses and the range of choice out there gives people the opportunity to select what works best for them or most suits their personal preference, given the variables that are often beyond the scope of general consideration relating to print surfaces.

Choice is good.

Just food for thought.

Edited 1 time(s). Last edit at 08/05/2017 12:20AM by Mutley3D.

Flex3Drive.com

|

Re: LokBuild, first impressions August 05, 2017 11:04PM |

Registered: 11 years ago Posts: 1,592 |

Sorry, only registered users may post in this forum.