Enclosure Air Filtration system

Posted by simspeed

|

Enclosure Air Filtration system May 18, 2017 08:34PM |

Registered: 10 years ago Posts: 169 |

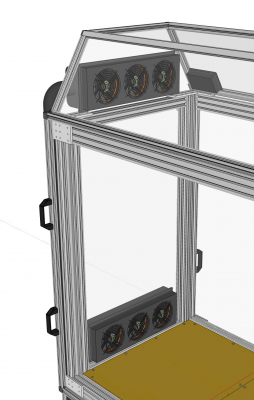

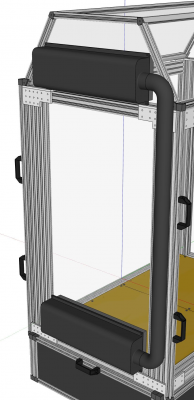

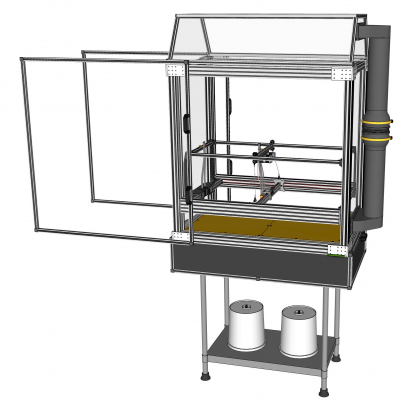

I am considering adding an air filtration system to my heated printer enclosure based on the attached design and fan components I found on EBay. The air boxes outside the closure would contain carbon filters to keep the air scrubbed. These fans have a programmable speed controller with air temp sensor, timer, and digital display. The controller is DC with converter and USB connections for the fans. The enclosure is made from Lexan panels fitted to Open Beam C-beam extrusions and Misumi 120° corner extrusion. What are your thoughts or experiences with circulation and filtering of heated air enclosures? Thanks in advance....

|

Re: Enclosure Air Filtration system May 19, 2017 03:03AM |

Registered: 8 years ago Posts: 601 |

|

Re: Enclosure Air Filtration system May 19, 2017 04:05AM |

Registered: 10 years ago Posts: 169 |

Don't know about Db of the fans but they would be semi-enclosed since the sliding doors would be shut and the shroud covers the back side. I'll be using an air pump to feed cool air to the radiator of the hot end, and the XY motors (and the print at the nozzle). Don't know about the life of the carbon filters before cleaning them but I should be able to find that base on the CFM flow...maybe. All the interior parts that won't be actively cooled are aluminum, Delrin, Alumide and Lexan. The silicone heater beneath the aluminum plate bed is rated to 3000 watts but I doubt I'll ever have the need to try and run it anywhere near that. I'm thinking a max of 100 C for the environment if I try to print PEEK. Otherwise probably max 60° C for the inside and 100-110 C for the heat bed...?? What I wondering is how much the air flow will affect the prints if the temperature inside remains stabilized. Shouldn't matter should it? Thanks....

Edited 1 time(s). Last edit at 05/19/2017 04:08AM by simspeed.

Edited 1 time(s). Last edit at 05/19/2017 04:08AM by simspeed.

|

Re: Enclosure Air Filtration system May 19, 2017 04:20AM |

Registered: 8 years ago Posts: 3,525 |

Recirculating the air from the top of the enclosure to the bottom is a very good idea, however you probably don't need so much airflow, given that you are continuously "polishing" the air inside. Indeed you don't want the air return at the bottom of the enclosure to be directed at the print at all, it might return best through a large "diffuser" inlet spread over a wide area.

Don't forget to include some HEPA or equivalent filtration in your airflow, its not just volatiles but ultra fine particles that need to be scrubbed, as these are also hazardous (although quite how much you can expect, and how hazardous is yet to be scientifically determined).

You might find the airflow down the diameter pipe shown in your diagram is a bit disappointing, I think very few of us are impressed with how well axial fans can duct air, most of the air flow just comes back out past the fan blades.

Why not simplify it to one decent sized blower/turbine/c-pap machine fan drawing the air away at the top of the enclosure and a large

perhaps increasing diameter tube to carry the air down through the filter and return it to the bottom of the machine at quite low pressure at the return which will potentially disrupt your print the least.

Just a few thoughts having tried something similar a while back.

Edited 1 time(s). Last edit at 05/19/2017 04:20AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Don't forget to include some HEPA or equivalent filtration in your airflow, its not just volatiles but ultra fine particles that need to be scrubbed, as these are also hazardous (although quite how much you can expect, and how hazardous is yet to be scientifically determined).

You might find the airflow down the diameter pipe shown in your diagram is a bit disappointing, I think very few of us are impressed with how well axial fans can duct air, most of the air flow just comes back out past the fan blades.

Why not simplify it to one decent sized blower/turbine/c-pap machine fan drawing the air away at the top of the enclosure and a large

perhaps increasing diameter tube to carry the air down through the filter and return it to the bottom of the machine at quite low pressure at the return which will potentially disrupt your print the least.

Just a few thoughts having tried something similar a while back.

Edited 1 time(s). Last edit at 05/19/2017 04:20AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Enclosure Air Filtration system May 19, 2017 04:51AM |

Registered: 8 years ago Posts: 601 |

|

Re: Enclosure Air Filtration system May 19, 2017 05:05AM |

Registered: 10 years ago Posts: 169 |

Good points DjDemonD....I hadn't considered backpressure on the fains I just ran across this fan, sensor, controller combo and it seemed like a good fit for my machine. How about using an inline axial fan in the pipe itself with just intake and exhaust ports in the lexan panel facings? I'll see if I can find one of those near the correct size and redo the drawing for fit. I'd like to use an external sensor/controller for fan speed and timing instead of tying it to the Duet print controller. This one just seemed to have what I was looking for....too bad about the back pressure issue. I do intend to use HEPA filters rather than carbon as I stated....just couldn't think of the name. Thanks for the tips from you and Origamib both...

|

Re: Enclosure Air Filtration system May 19, 2017 05:40AM |

Registered: 8 years ago Posts: 3,525 |

You're welcome. I think previous experiments with this type of system lead to the conclusion you need enough pressure to get the air through the filters and both Hepa and Carbon used together are most effective. It does work, but I wanted a solution that was controlled by the printer so that I didn't have external units to switch off, especially on an overnight print.

In the end I just bought a large room air filtration unit, with charcoal/hepa filters and I run this whilst printing and for 6 hours afterwards, same effect but its the whole room being scrubbed not just the inside of the printer.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

In the end I just bought a large room air filtration unit, with charcoal/hepa filters and I run this whilst printing and for 6 hours afterwards, same effect but its the whole room being scrubbed not just the inside of the printer.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Enclosure Air Filtration system May 19, 2017 07:08AM |

Registered: 8 years ago Posts: 601 |

|

Re: Enclosure Air Filtration system May 25, 2017 01:08AM |

Registered: 10 years ago Posts: 169 |

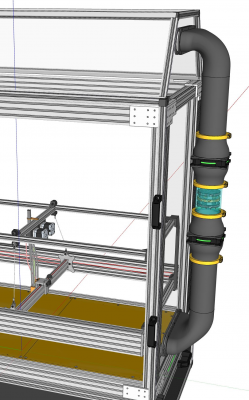

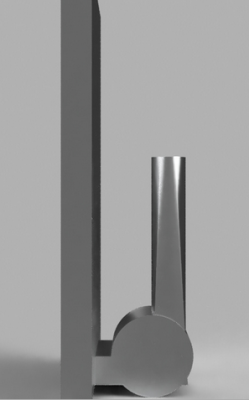

Here is a redesign using 3" ABS pipe with two 120 mm inline case fans. The center section is clear PVC with both Hepa and Charcoal filters sitting on thin stainless rods. The center section would use quick release ring clamps to allow the disc filters to be serviced or replaced. I don't see this needing to be program controlled; just a on/off/speed manual switch should do the job don't you think? Thanks...

|

Re: Enclosure Air Filtration system May 25, 2017 01:40AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Enclosure Air Filtration system May 25, 2017 03:55AM |

Registered: 8 years ago Posts: 3,525 |

Its a better design for sure, more likely to work, the fans should be quiet and should move enough air. I like o_lamps suggestion of putting the charcoal filter at the outlet. It is worth putting a pre-filter / dust filter somewhere to remove "macro" particles of house dust, it will prolong the life of your hepa filter.

As for service interval, the dust filter (which can just be refreshed with a vacuum cleaner periodically) might need regular cleaning, but the amount of actual UFP's and volatiles produced, IMO is far less than you might expect, so try it, you can always retrofit a wider filter in-line later.

When I tried this (I was also using a hairdryer to move the air and heat the chamber) I used a vacuum cleaner hepa filter which is a cone type (K&N car air filter style), which I filled with activated charcoal beads, both very cheap.

Edited 1 time(s). Last edit at 05/25/2017 03:56AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

As for service interval, the dust filter (which can just be refreshed with a vacuum cleaner periodically) might need regular cleaning, but the amount of actual UFP's and volatiles produced, IMO is far less than you might expect, so try it, you can always retrofit a wider filter in-line later.

When I tried this (I was also using a hairdryer to move the air and heat the chamber) I used a vacuum cleaner hepa filter which is a cone type (K&N car air filter style), which I filled with activated charcoal beads, both very cheap.

Edited 1 time(s). Last edit at 05/25/2017 03:56AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Enclosure Air Filtration system May 25, 2017 04:17PM |

Registered: 8 years ago Posts: 601 |

Quote

simspeed

[attachment 94536 Recirculatingfilteredairassembly.JPG]

Here is a redesign using 3" ABS pipe with two 120 mm inline case fans. The center section is clear PVC with both Hepa and Charcoal filters sitting on thin stainless rods. The center section would use quick release ring clamps to allow the disc filters to be serviced or replaced. I don't see this needing to be program controlled; just a on/off/speed manual switch should do the job don't you think? Thanks...

Would be nice to have it thermostatically controlled. It could then be used to control chamber heat more efficiently, or at least turn off if chamber heat is too low. Would be handy to turn it off if a fire starts (thermal runaway controls) as otherwise it may just oxygenate any fire that starts.

|

Re: Enclosure Air Filtration system May 26, 2017 02:39AM |

Registered: 10 years ago Posts: 169 |

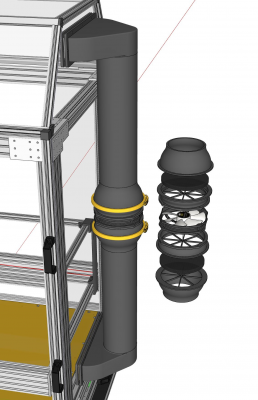

Good points fellas....thanks for pitching new ideas. I think this redesign is likely what I will go with. I'm using a larger 140mm fan and up-sizing the pipe to 4" ABS. This allows me to build reducer adapters that hold two 1/2" x 5.5" activated charcoal coffee filters above and below the fan as shown. I want to keep the quick change clamps to change these filters when needed. This also allows me to add a Hepa filter at the upper inlet to catch particulates before they get to the charcoal filters. Like DjDemonD says I can vacuum that off the screen without having to unbolt anything from inside the chamber. The inlet housings I can also build from ABS sheet rather than trying to print the more stylish but complex design from the previous drawing. Printing the reducer adapters should be pretty straight forward. The middle two will bolt directly to the fan housing and the outer two will solvent weld to the ABS pipe.

|

Re: Enclosure Air Filtration system May 26, 2017 07:03AM |

Registered: 8 years ago Posts: 413 |

|

Re: Enclosure Air Filtration system May 26, 2017 03:18PM |

Registered: 10 years ago Posts: 169 |

Quote

MCcarman

Now all you need to do is attach both ends to the same piece of the door or frame. Currently you have one end on the fixed top and the other on the sliding door.

Actually the sliding doors of the enclosure are on either side along the Y axis. The end panels are fixed, so the air recirculating assembly is hard mounted to the top and lower side panels at the end shown. The center section where the fan and filters are is removable using the quick release lever clamps. I will probably add support brackets to the pipe sections above and below the center section so everything remains rigid when the center section is removed for maintenance.

|

Re: Enclosure Air Filtration system May 26, 2017 04:20PM |

Registered: 7 years ago Posts: 270 |

Quote

simspeed

[attachment 94570 Recirculatingfilteredairassembly-2.JPG]

Good points fellas....thanks for pitching new ideas. I think this redesign is likely what I will go with. I'm using a larger 140mm fan and up-sizing the pipe to 4" ABS. This allows me to build reducer adapters that hold two 1/2" x 5.5" activated charcoal coffee filters above and below the fan as shown. I want to keep the quick change clamps to change these filters when needed. This also allows me to add a Hepa filter at the upper inlet to catch particulates before they get to the charcoal filters. Like DjDemonD says I can vacuum that off the screen without having to unbolt anything from inside the chamber. The inlet housings I can also build from ABS sheet rather than trying to print the more stylish but complex design from the previous drawing. Printing the reducer adapters should be pretty straight forward. The middle two will bolt directly to the fan housing and the outer two will solvent weld to the ABS pipe.

Why not use fireplace blower at the bottom as exhaust and filters atop.

It's already made to withstand high temperatures and squirrel cage fan is better for high pressure compared to axial fans. They usually move 70cfm and are 9in wide.

Edited 1 time(s). Last edit at 05/26/2017 04:20PM by newbob.

|

Re: Enclosure Air Filtration system May 27, 2017 01:57AM |

Registered: 10 years ago Posts: 169 |

Hi Newbob...I'm sure that would be more efficient but there are a couple of problems with it for my printer. First, my hot bed fills the complete area between the bottom rails. The bed is 1/4" milled aluminum with 3mm PEI fitted to the top and a silicone heater glued to the bottom side. There's no room between the hot bed and the stainless table top to duct anything. If the cage blower mounted to the end panel where the exhaust duct I'm showing is mounted, there's no way I can see to recirculate the air back down from the top inlet position. I don't want to feed unheated air into the chamber while printing, I just want to recirculate the existing hot air through a filter to clean smells, particulates, and all the nasty plastic fumes that makes me cough. I really think the amount of air the 140mm fan can pull and push through the Hepa and charcoal filters will be sufficient for my needs. Thanks for your example.

|

Re: Enclosure Air Filtration system May 27, 2017 07:55AM |

Registered: 7 years ago Posts: 270 |

Hi Simspeed

Just to clarify (not to convince) how I imagined it would go together:

Hookup and conduits would be the same as per your drawing only larger. Of course it could be mounted at the bottom or the top. What software are you using, btw?

Edited 1 time(s). Last edit at 05/27/2017 08:01AM by newbob.

Just to clarify (not to convince) how I imagined it would go together:

Hookup and conduits would be the same as per your drawing only larger. Of course it could be mounted at the bottom or the top. What software are you using, btw?

Edited 1 time(s). Last edit at 05/27/2017 08:01AM by newbob.

|

Re: Enclosure Air Filtration system May 27, 2017 07:25PM |

Registered: 10 years ago Posts: 169 |

Sorry, only registered users may post in this forum.